Paper box automatic forming device used for automatic labelling and boxing assembly line

A technology of automatic forming and standard boxing, applied in packaging and other directions, can solve the problems of inability to collect waste, slow speed, single function, etc., and achieve the effect of improving forming efficiency, facilitating promotion and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

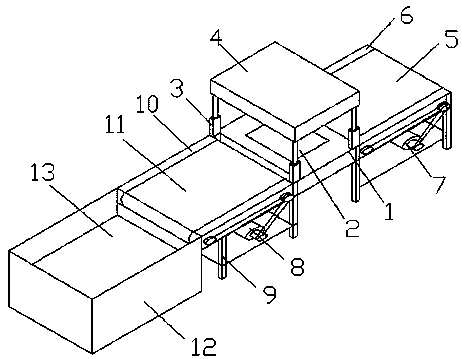

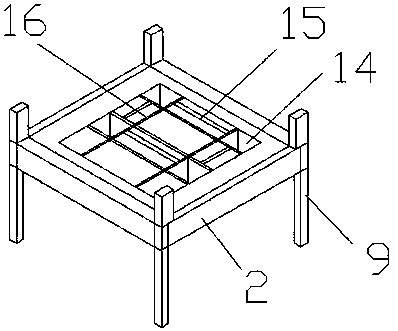

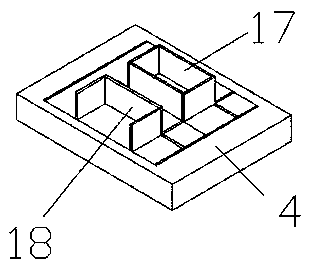

[0022] see Figure 1-5 , the present invention provides a technical solution: an automatic carton forming device for an automatic labeling and boxing line, including a device body 1, a cardboard storage box 12 is provided at one end of the device body 1, and a cardboard storage box 12 is provided inside the cardboard storage box 12. Placement plate 13, the bottom end of cardboard placement plate 13 is provided with second electric telescopic rod 21, the middle part of device body 1 is provided with workbench 2, and one side of workbench 2 is provided with discharge conveyor belt fixing frame 6, and discharge conveyor belt is fixed The frame 6 is provided with a discharge conveyor belt 5, the bottom end of the discharge conveyor belt 5 is provided with a discharge conveyor belt motor 7, the other side of the workbench 2 is provided with a feed conveyor belt fixed mount 10, and the feed conveyor belt fixed mount 10 is provided with a Feed conveyor belt 11, the bottom end of feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com