Steel wire shearing machine

A shearing machine and steel wire technology, applied in the field of mechanical processing, can solve the problems of time-consuming and laborious steel wire, unsmooth steel wire port, low efficiency, etc., and achieve the effects of convenient operation, simple structure and high cutting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

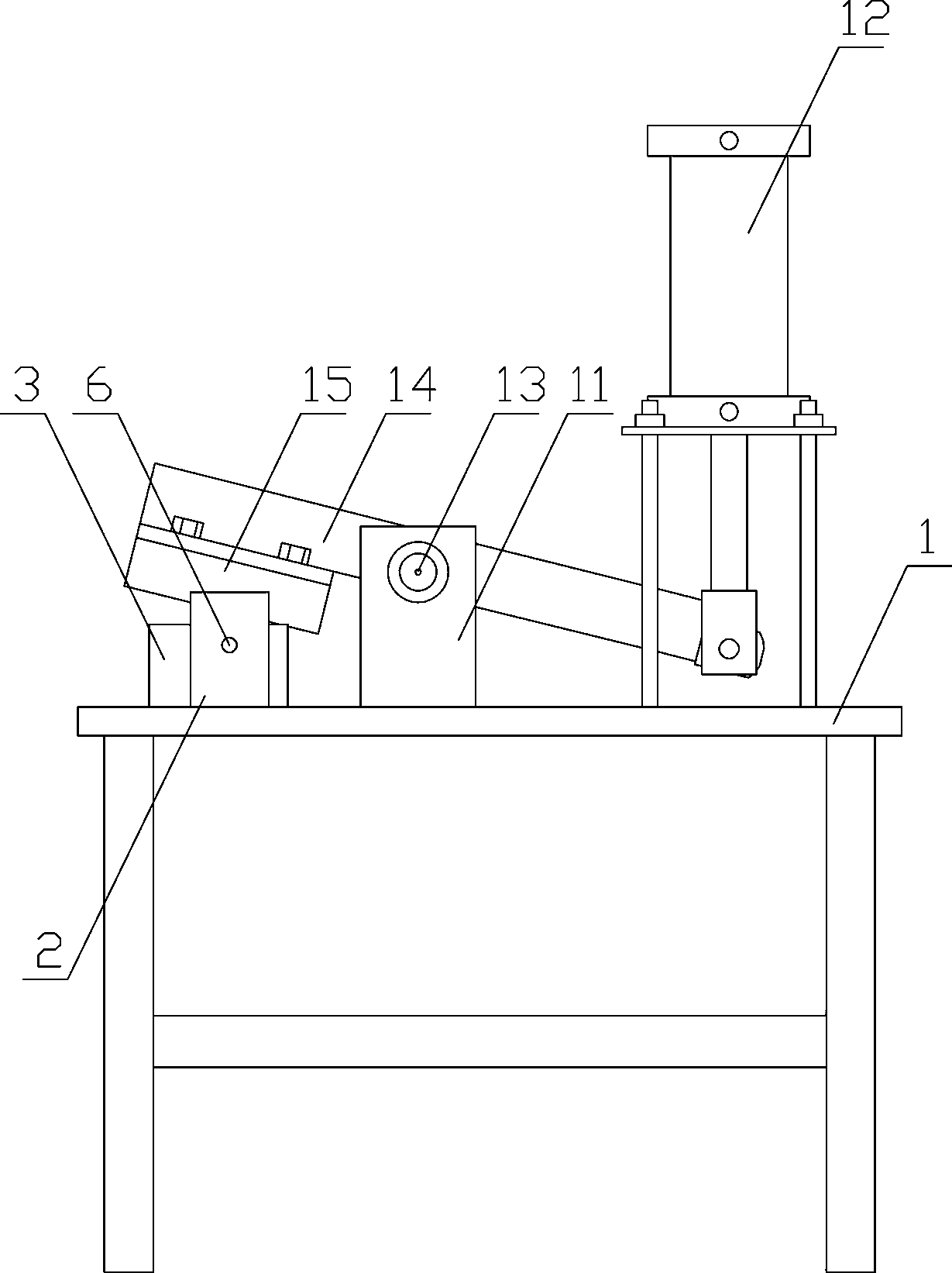

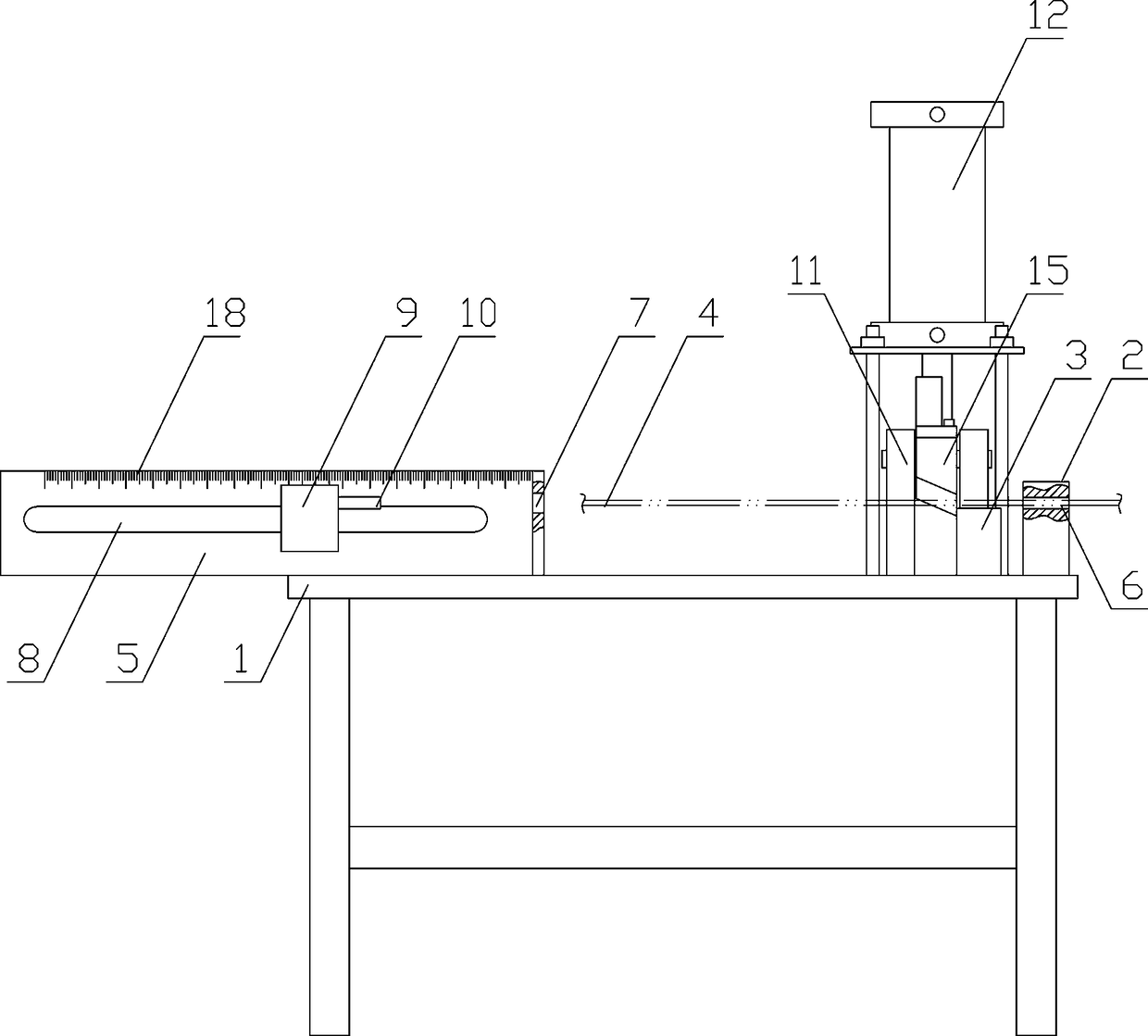

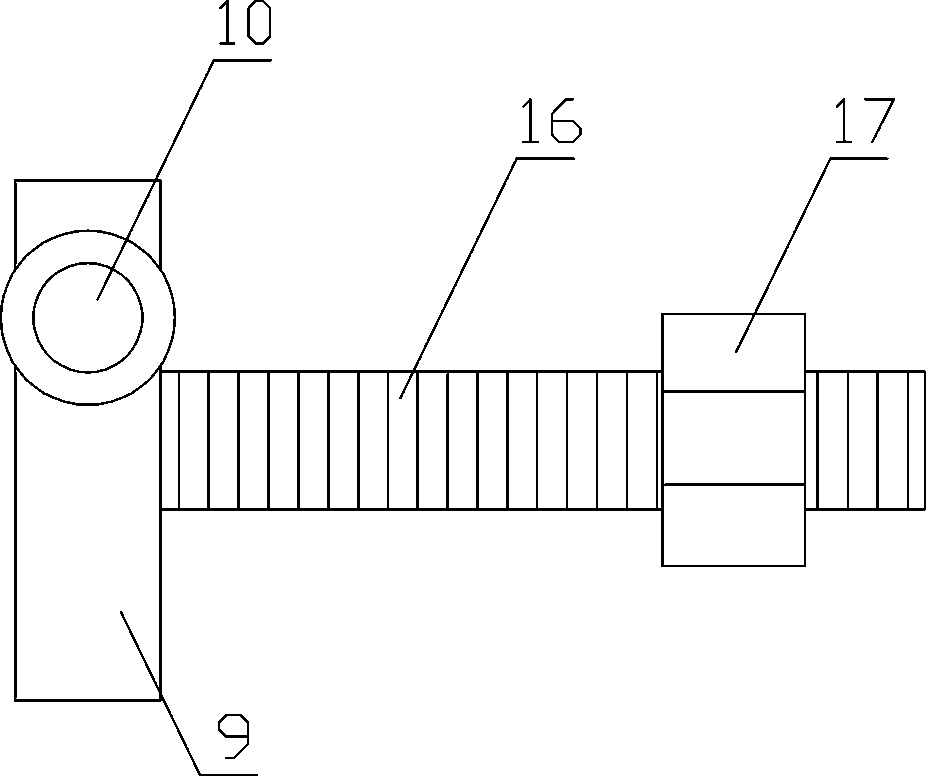

[0012] see Figure 1-2 , a steel wire shearing machine, has a working platform 1, on which a guide block 2, a cam 3 and a length adjustment device are arranged in sequence along the transverse direction, wherein the guide block 2 is provided with a head-end input for the steel wire 4 The input hole 6, the length adjusting device has an "L"-shaped bracket 5, the short side of the "L"-shaped bracket 5 is arranged against the former 3, and an output hole coaxially arranged with the input hole 6 is provided on its short side 7. On the long side of the "L"-shaped bracket 5, there is an adjustment hole 8 along the horizontal direction. The adjustment hole 8 is equipped with a contact 9 that can be adjusted horizontally, and a proximity switch that is directly opposite to the output hole 7 is installed on the contact 9. 10. On the working platform 1, a support block 11 and a vertically downwardly arranged cylinder 12 are sequentially fixed along one of the longitudinal sides of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com