Full-automatic mask production line

A fully automatic, production-line technology, applied in the directions of external support, transportation and packaging, winding strips, etc., can solve the problems of wasting time and labor costs, many steps in mask bagging, low efficiency, etc., achieving low cost and outstanding economic benefits. , the effect of meeting the functional requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

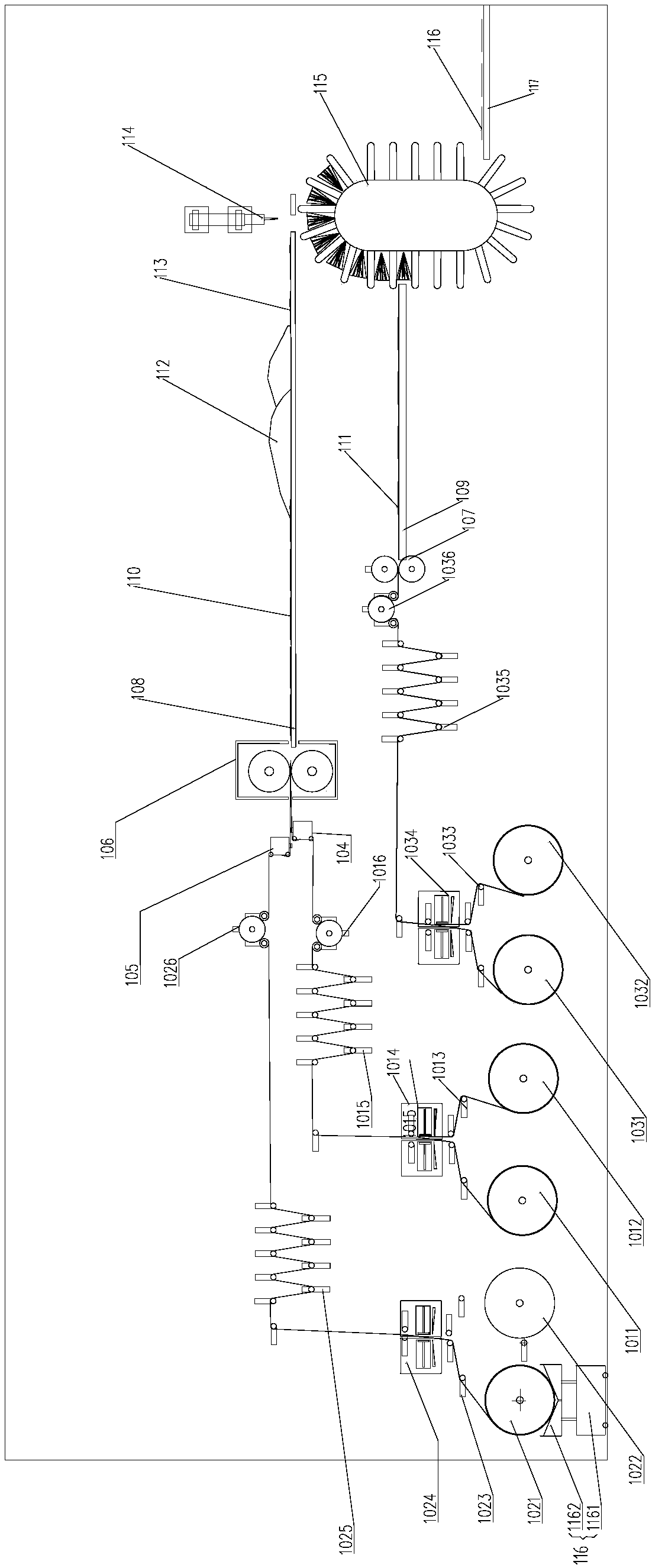

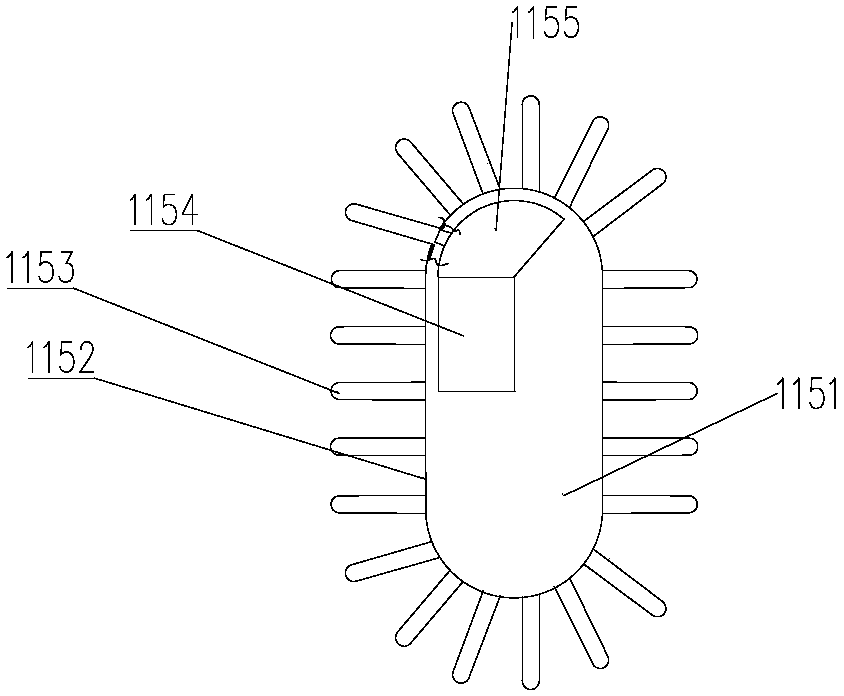

[0028] Such as figure 1 As shown, the present invention discloses a fully automatic facial mask production line, which includes a facial mask unwinding device, a facial mask film unwinding device, a facial mask packaging bag unwinding device, a first deviation correcting device 104, and a second deviation correcting device 105 , the first drum die-cutting machine 106, the second drum die-cutting machine 107, the first belt conveyor line 108, the second belt conveyor line 109, the bag opening device 115 and the cylinder telescopic arm 114; Device 104 is connected with the first roller die-cutting machine 106, and the first deviation correcting device 104 is used for the facial mask material that the deviation-correcting facial mask unwinding device emits, and the facial film coating unwinding dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com