Cutting method for LED lamp tube pins

A technology of LED lamp tubes and pins, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of LED lamp tube movement, inaccurate cutting of LED lamp pins, and damage of LED lamp tubes, etc., to achieve The pin cutting place is flat, improving the quality of pin cutting and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

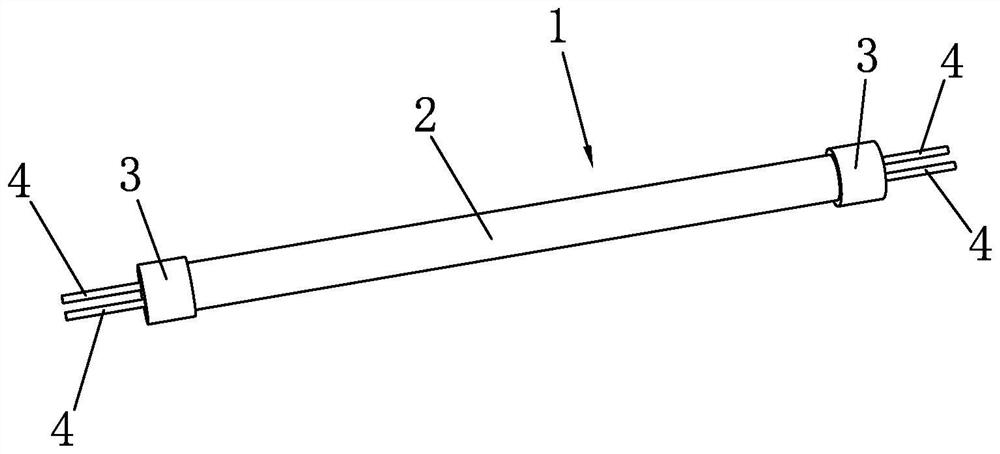

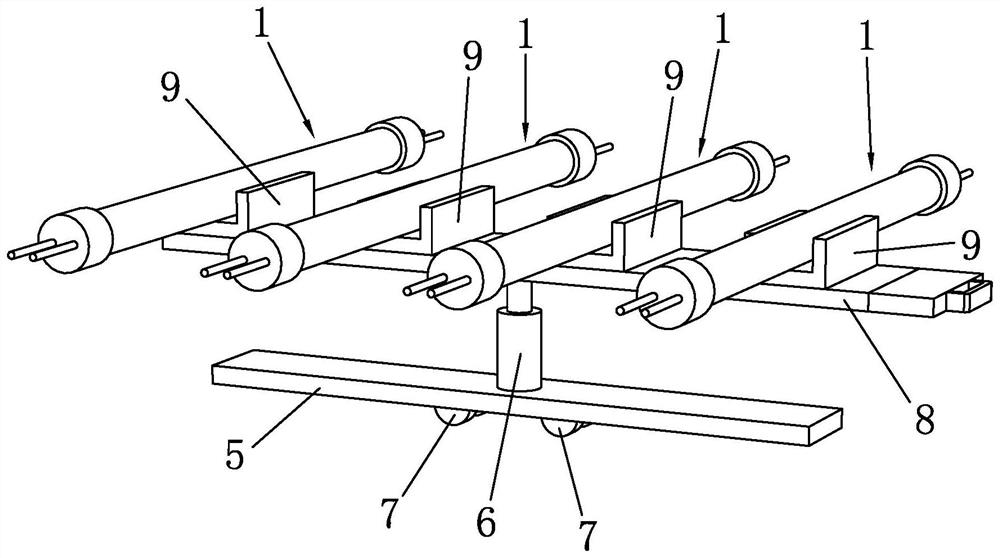

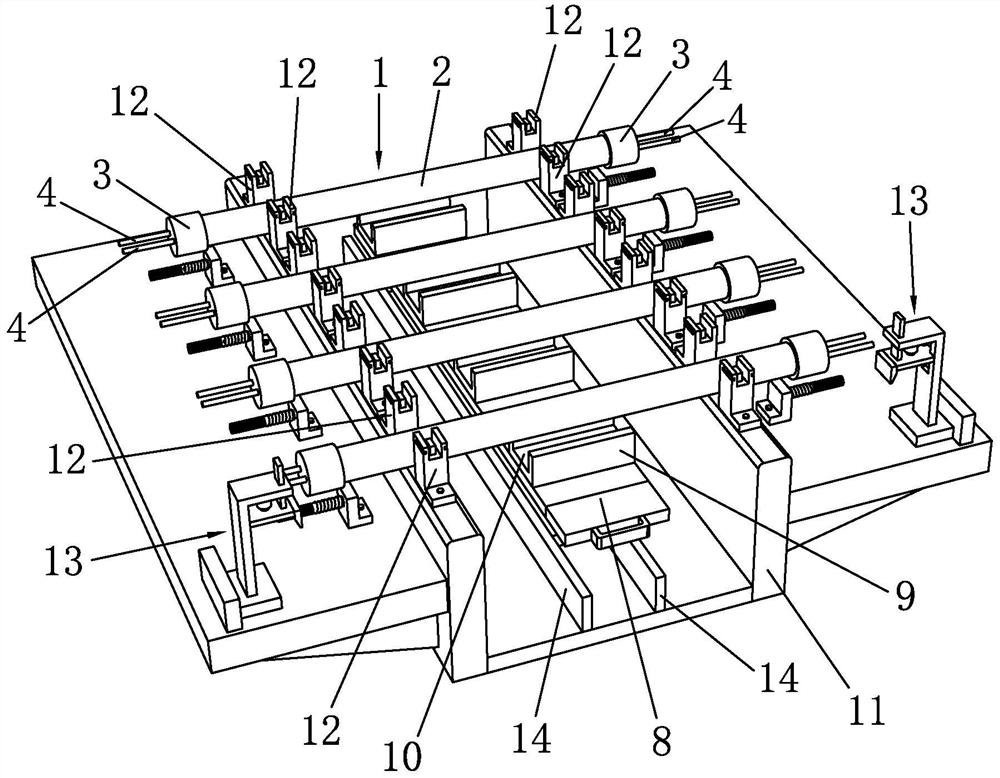

[0048] Such as Figure 1 to Figure 17 Shown, be the cutting method of a kind of LED lamp tube pin of the present invention, comprise the steps:

[0049] a. According to the design drawings, fix the mounting seat 28 on the thread cutting table 11 with screws, and the mounting seat 28 is L-shaped. The mounting seat 28 is welded with a threaded column 26 which is arranged in a horizontal direction, and the threaded column 26 is sleeved with a first spring 27 .

[0050] b. A plurality of LED light tube limiting units are installed on the thread cutting table 11. The present invention provides four LED light tube limiting units, and two symmetrically arranged limiting bases 12 are used as the LED light tube limiting units, and Control the distance between the two limit bases 12 in the LED light tube limit unit, form a placement slot between the two limit bases 12, and then fix the limit base 12 to the thread trimmer 11 by screws.

[0051] c. Send the uncut LED light tube into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com