Dedicated electric tailoring cutter for fur

A technology of electric cutting and scissors, which is applied in the field of cutting, which can solve the problems that the cutting section is not easy to keep neat and consistent, the cutting is difficult to ensure straightness, and the leather cannot be operated, so as to achieve safe and reliable work efficiency, fast cutting speed, and neat and consistent cutting surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

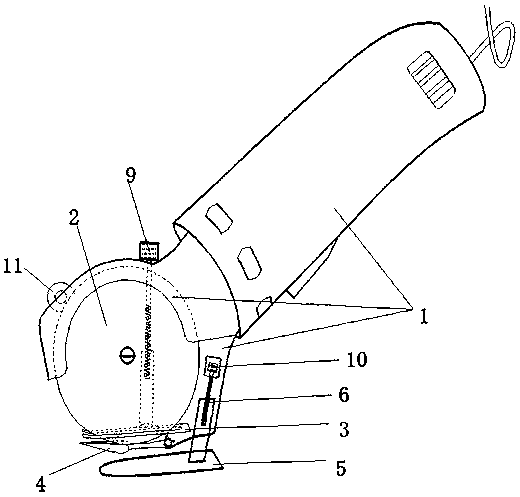

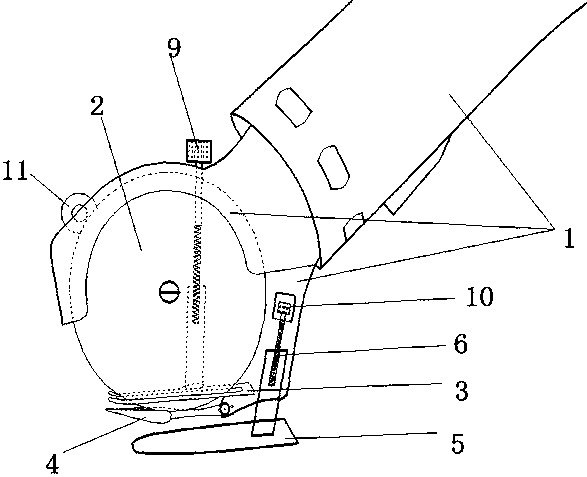

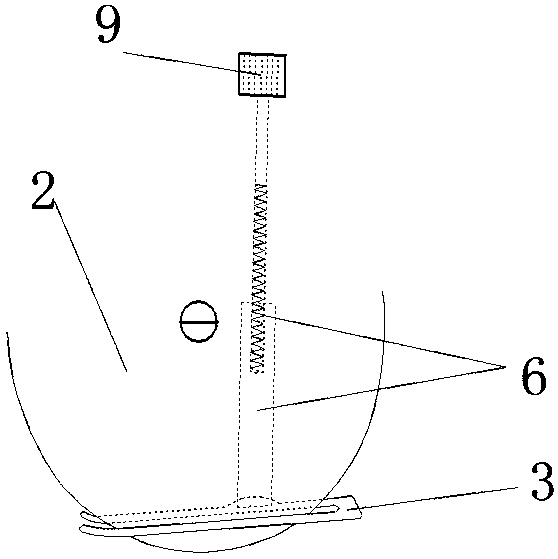

[0021] Such as figure 1 , 2 As shown in , 3 and 4, a special electric cutting knife for furs, including a body 1, a rotary cutting blade 2 installed at the head end, a height-adjustable upper stopper presser foot 3 fixed on the head, fixed at the lower end of the head The lower hair removal fork 4, the hair removal fork and the head connection point are provided with the hair removal fork rebound device 7, which is connected to the height-adjustable sticker sliding base 5 of the head.

[0022] The body 1 includes a power supply, a power switch, an electric motor, a casing, a machine head, a safety cover, a sharpening device, the size and position of each part, and the power, which can be set according to the ease of use and aesthetics.

[0023] The rotary cutting blade 2 is driven by an electric motor to rotate at a high speed through the machine head to realize fabric cutting, and the blade can be circular or equilateral polygonal.

[0024] The upper stopper presser foot 3 ...

Embodiment 2

[0029] The difference from Embodiment 1 is that the connection adjustment method of the upper stop presser foot 3 and the sliding base 5 with the machine head does not necessarily have to adopt the adjustment method of nuts and bolts; the connection point can also use a certain pressure and can be used The movable riveting method uses the principle of leverage to adjust its height. In the present embodiment 1 and 2, two ways of adjusting the height of bolts and nuts for adjusting 3 and 5 are given, but it is not a restriction on the way of adjusting the height. Other methods can be used. way, as long as the principles given in this implementation example are realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com