Once-shaped forming die of air chamber rubber diaphragm and forming process

A technology of rubber diaphragm and forming mold, applied in the production field of rubber parts, can solve the problems of sintering, inconvenient fitting of ferrule and lower film cavity, complicated steps, etc., so as to improve production efficiency, save energy and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The best implementation mode of the present invention will be described in detail below in conjunction with the accompanying drawings, but not limited thereto.

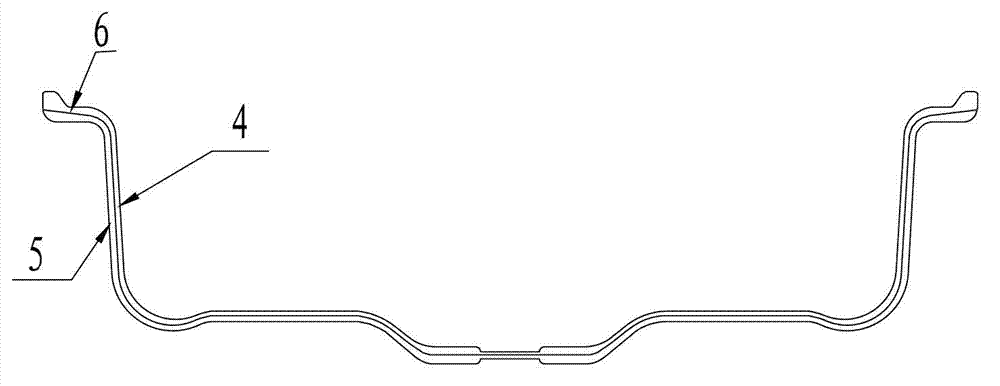

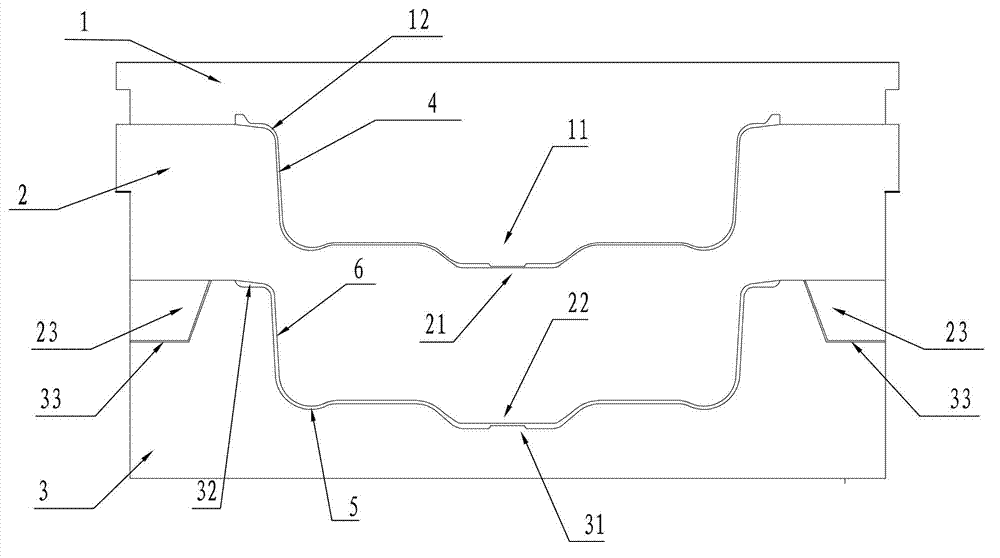

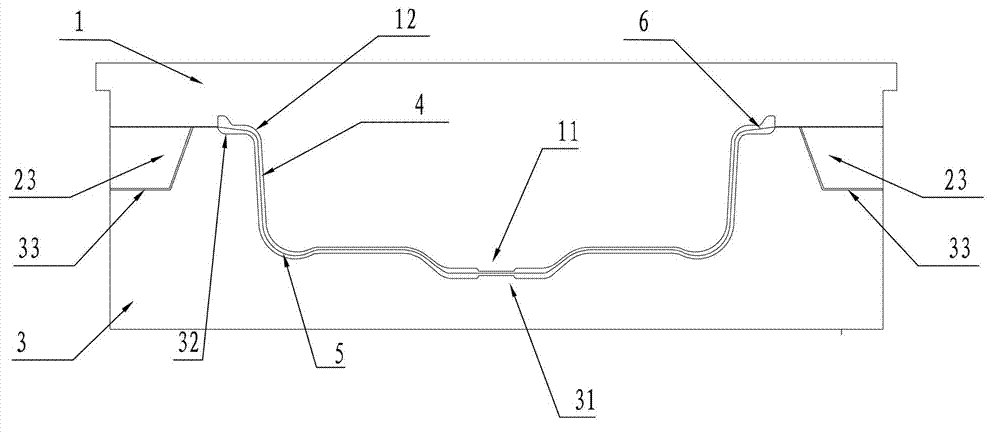

[0034] like Figure 2-3 As shown, the present invention provides a one-time shaping mold for the air chamber rubber diaphragm, which is a mold core group applied to the vulcanization molding process of the air chamber rubber diaphragm, which includes: an upper mold 1, a middle mold 2 and a lower mold 3; 1 The lower side is formed with an upper flange 11 corresponding to the shape of the air chamber rubber diaphragm, and the surface of the upper flange 11 is indented inward to form an upper cavity 12 capable of forming the upper half 4 of the air chamber rubber diaphragm, so as to form the upper half 4 , and the surface roughness of the cavity 12 of the upper mold 1 is larger than the surface roughness of the core of the mold 2 in the mold. Make the preformed air chamber rubber diaphragm upper half 4 adhere to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com