Control method for keeping waterway clean and steam oven

A control method and technology of a steam oven, applied to steam cooking utensils, roasters/barbecue grids, cooking utensils, etc., to achieve the effects of avoiding health problems, easy operation, and simple control methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

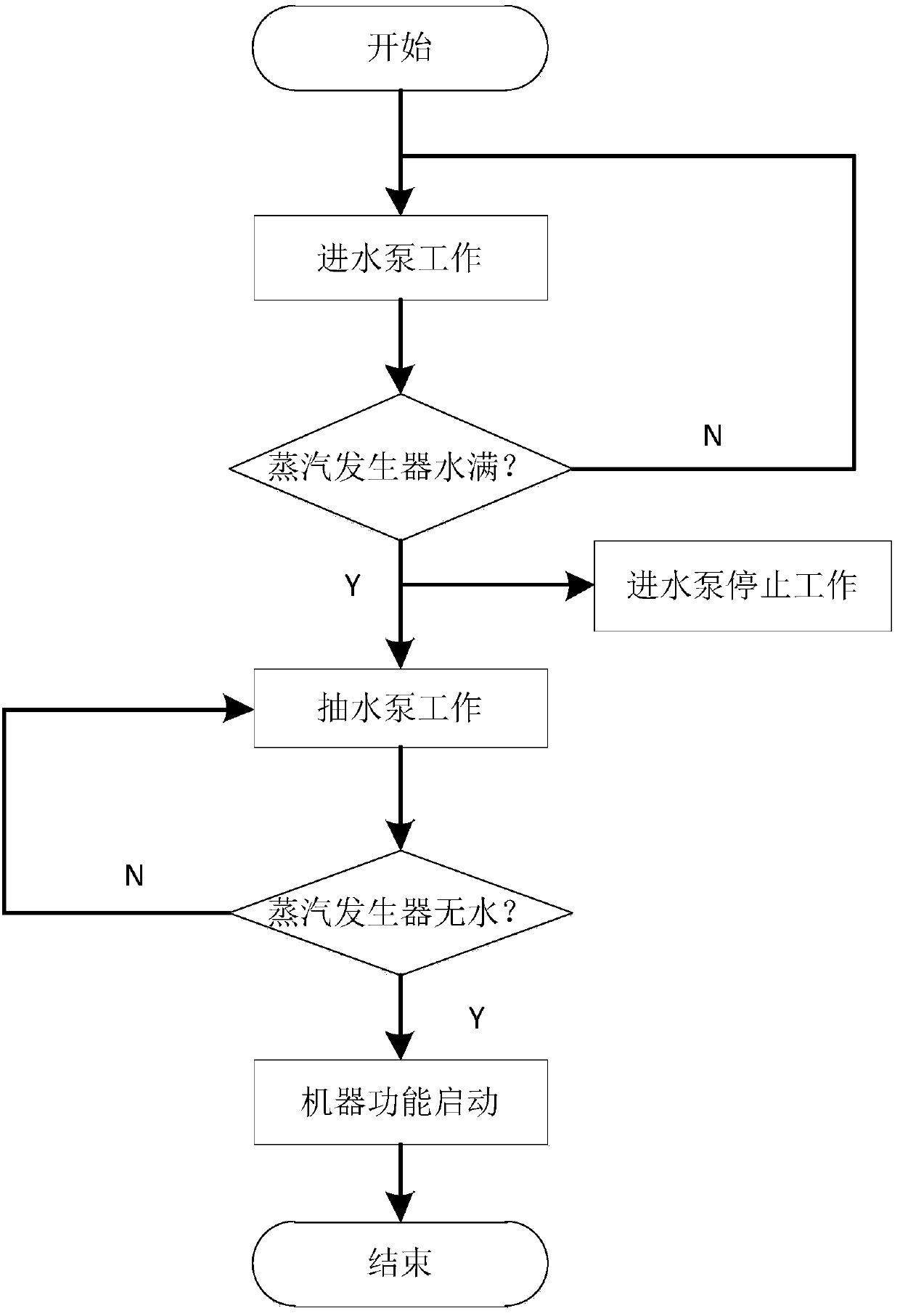

[0044] Such as figure 1 As shown, this embodiment introduces a control method for keeping the waterway clean. Before the steam oven executes the working procedure, the flushing procedure performed specifically includes the following steps:

[0045] S1. Start the water inlet pump, and the water inlet pump will transport the water to the steam generator through the water hose;

[0046] S2. The water level gauge in the steam generator monitors the water level in the steam generator and feeds it back to the control unit. If it is not full, proceed to step S1. If it is full and the water inlet pump stops, then proceed to step S3;

[0047] S3. The control unit controls the start of the water pump, and the water pump discharges the water from the steam generator;

[0048] S4. The water level gauge in the steam generator detects the water level in the steam generator and feeds it back to the control unit. If there is water, continue to perform step S3. If the water has been emptied, ...

Embodiment 2

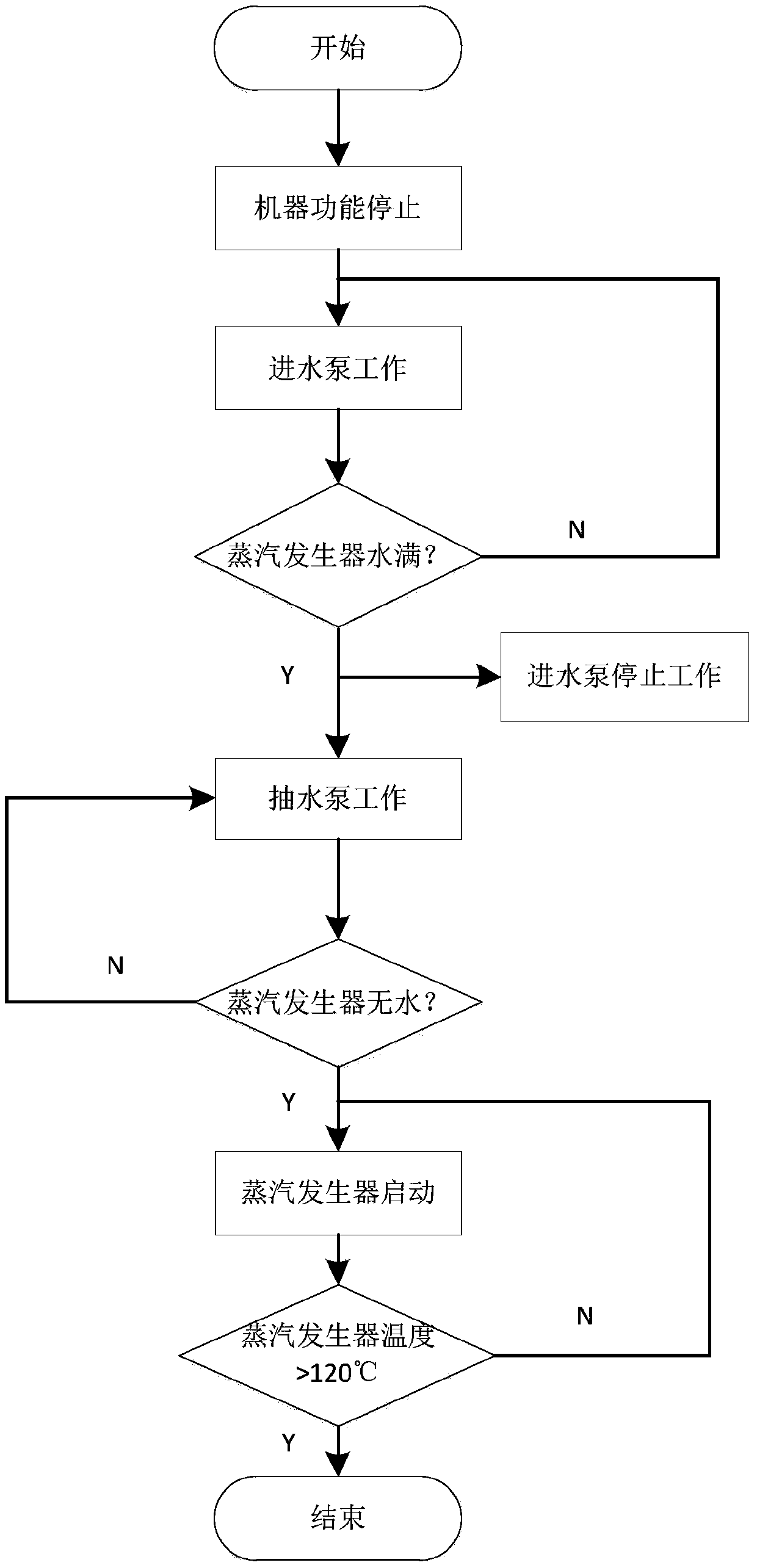

[0053] Such as figure 2 As shown, this embodiment introduces a control method for keeping the waterway clean. After the steam oven stops executing the working procedure, the flushing procedure executed specifically includes the following steps:

[0054] S21. The water inlet pump is started, and the water inlet pump transports the water to the steam generator through the water hose;

[0055] S22. The water level gauge in the steam generator monitors the water level in the steam generator and feeds it back to the control unit. If it is not full, continue to perform step S21. If it is full and the water inlet pump stops, then perform step S23;

[0056] S23. The water pump is started, and the water pump discharges the water from the steam generator;

[0057] S24. The water level gauge in the steam generator detects the water level in the steam generator and feeds it back to the control unit. If there is water, continue to perform step S23. If the water has been emptied and the wat...

Embodiment 3

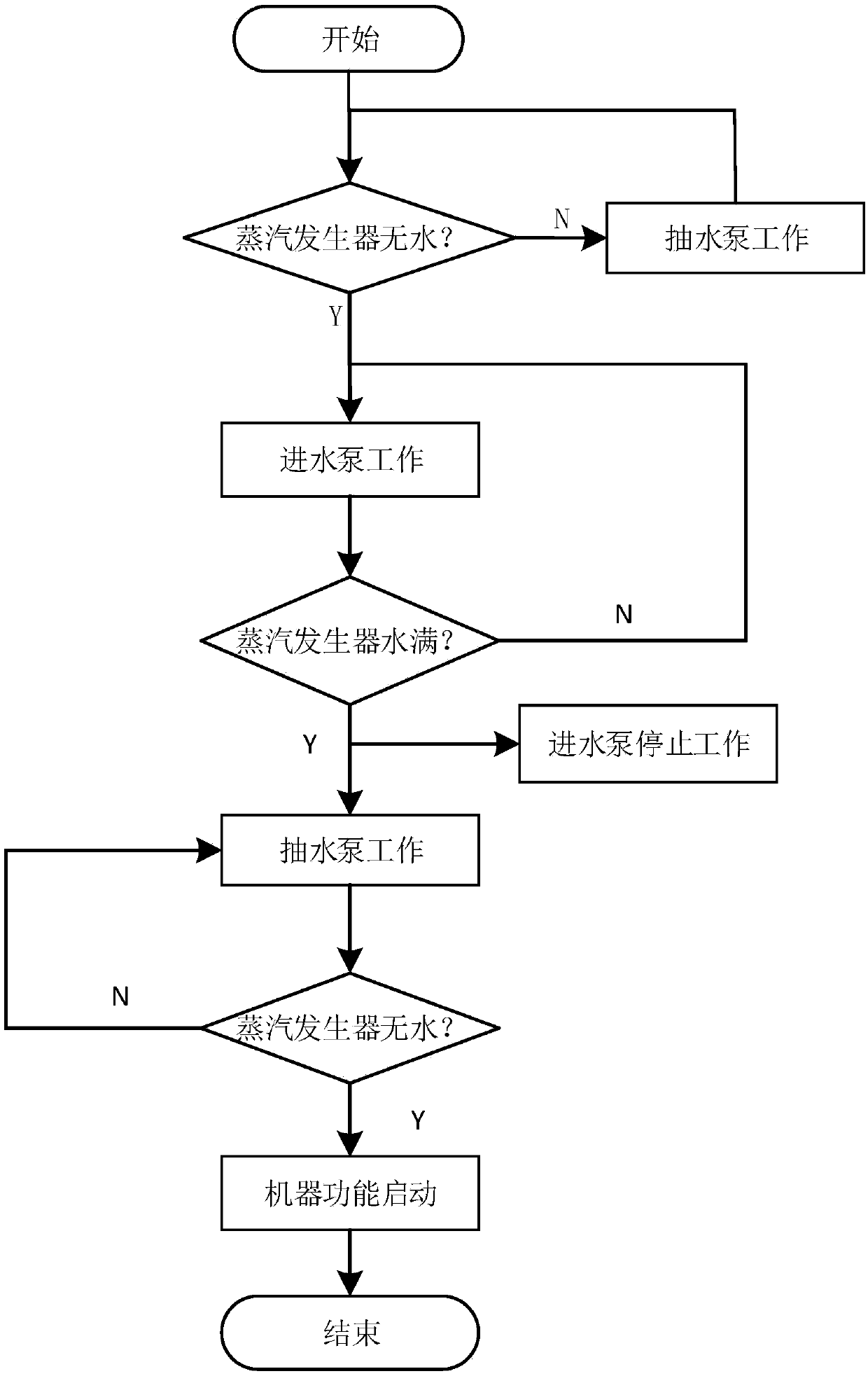

[0062] Such as image 3 As shown, the embodiment of the present invention introduces a control method to keep the waterway clean. Before executing the flushing procedure, the water pump works for a certain period of time, and then executes the flushing procedure after draining all the residual water in the steam generator. The cleaning procedure performed specifically includes the following steps:

[0063] S31. The steam generator water level gauge monitors the water level in the steam generator and feeds it back to the control unit. If there is water, execute step S32, and if there is no water, execute step S34;

[0064] S32. The water pump is started, and the water pump discharges the water from the steam generator;

[0065] S33. The steam generator water level gauge detects the water level in the steam generator and feeds it back to the control unit. If there is water, then continue to perform step S32. If the water has been emptied and the water pump stops, then perform s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com