Safety control mechanism for powdered coal gasifier

A technology of safety control and gasification furnace, which is applied in the manufacture of combustible gas, steam generators, petroleum industry, etc. It can solve the problems of inaccuracy, lagging temperature of the gasification furnace reaction chamber, and inability to directly measure the temperature of the gasification furnace. Achieve rapid response and avoid further deterioration of operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

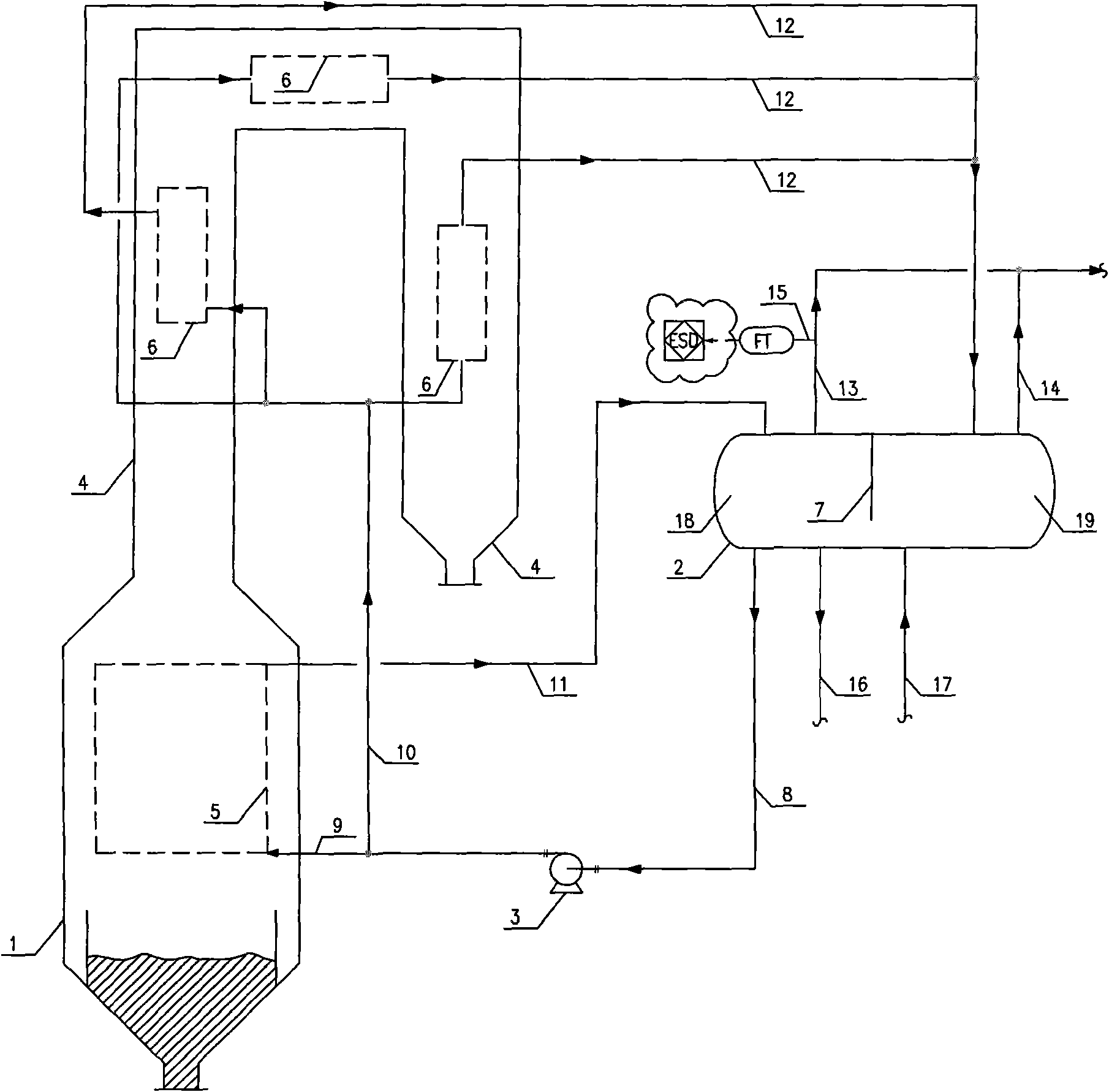

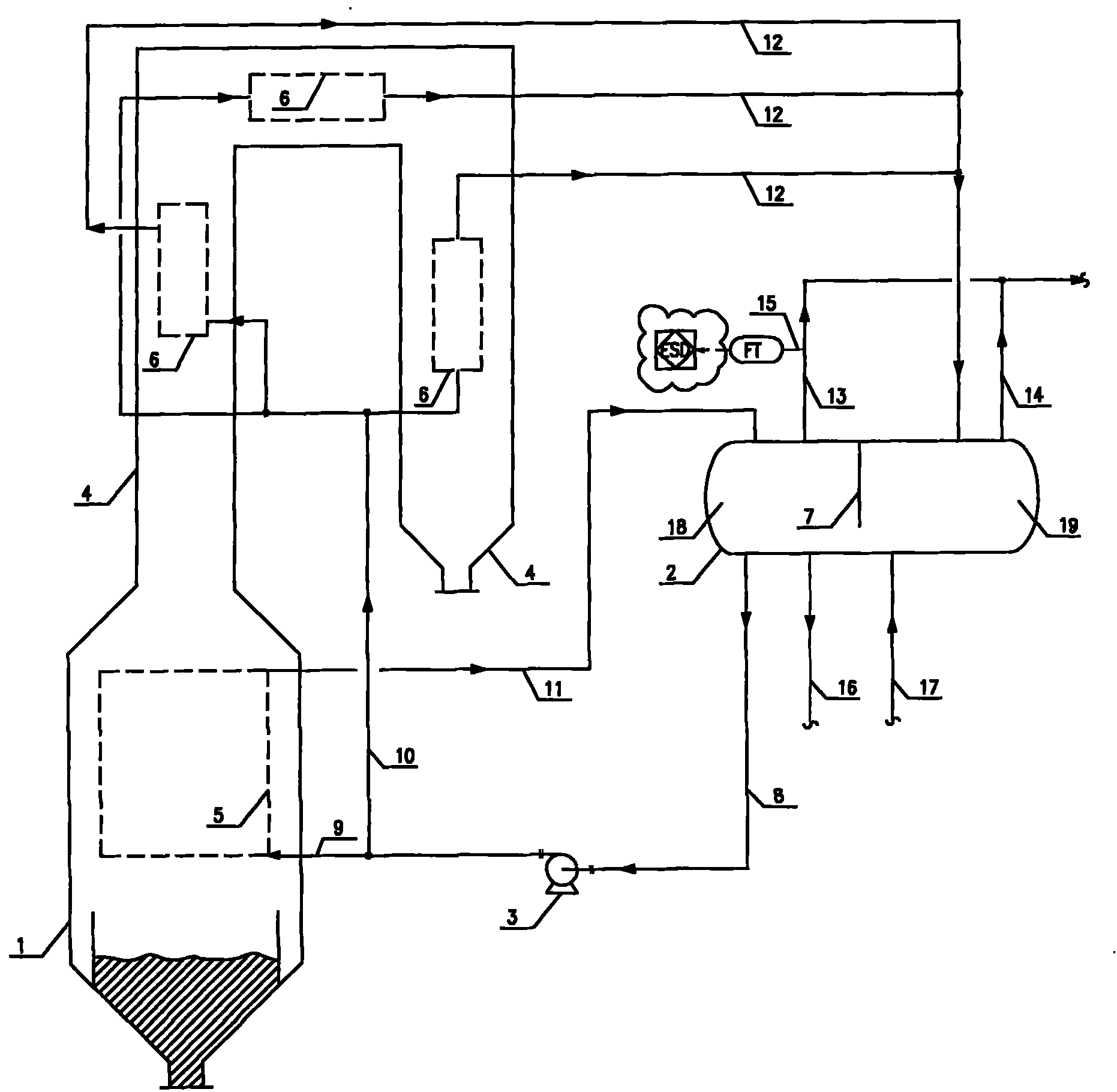

[0016] like figure 1 As shown, the safety control mechanism of the pulverized coal gasifier includes a gasifier shell 1, a synthesis gas cooler shell 4 and a steam drum 2. The gasifier water wall 5 is arranged in the gasifier shell 1, and the synthesis gas cools The steam generator 6 is arranged in the shell 4 of the syngas cooler, and the steam drum 2 is provided with a steam drum separator 7 to separate the steam drum 2 into two chambers, namely the steam separation chamber 18 of the steam drum gasifier. and the steam separation chamber 19 of the drum syngas cooler;

[0017] The external boiler water enters the steam drum 2 through the pipeline 17. After the heat exchange temperature rises to the water saturation temperature, it enters the boiler circulating water pump 3 through the pipeline 8 and enters the pipeline 9 and the pipeline 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com