Converter steam dome high/low water level automatic feedwater unit

A technology for automatic water supply and steelmaking converters, which is applied in the manufacture of converters, etc., can solve the problems of unsuitability to safety production and modern management requirements, difficulty in ensuring automatic control accuracy, out-of-synchronization, etc. Good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

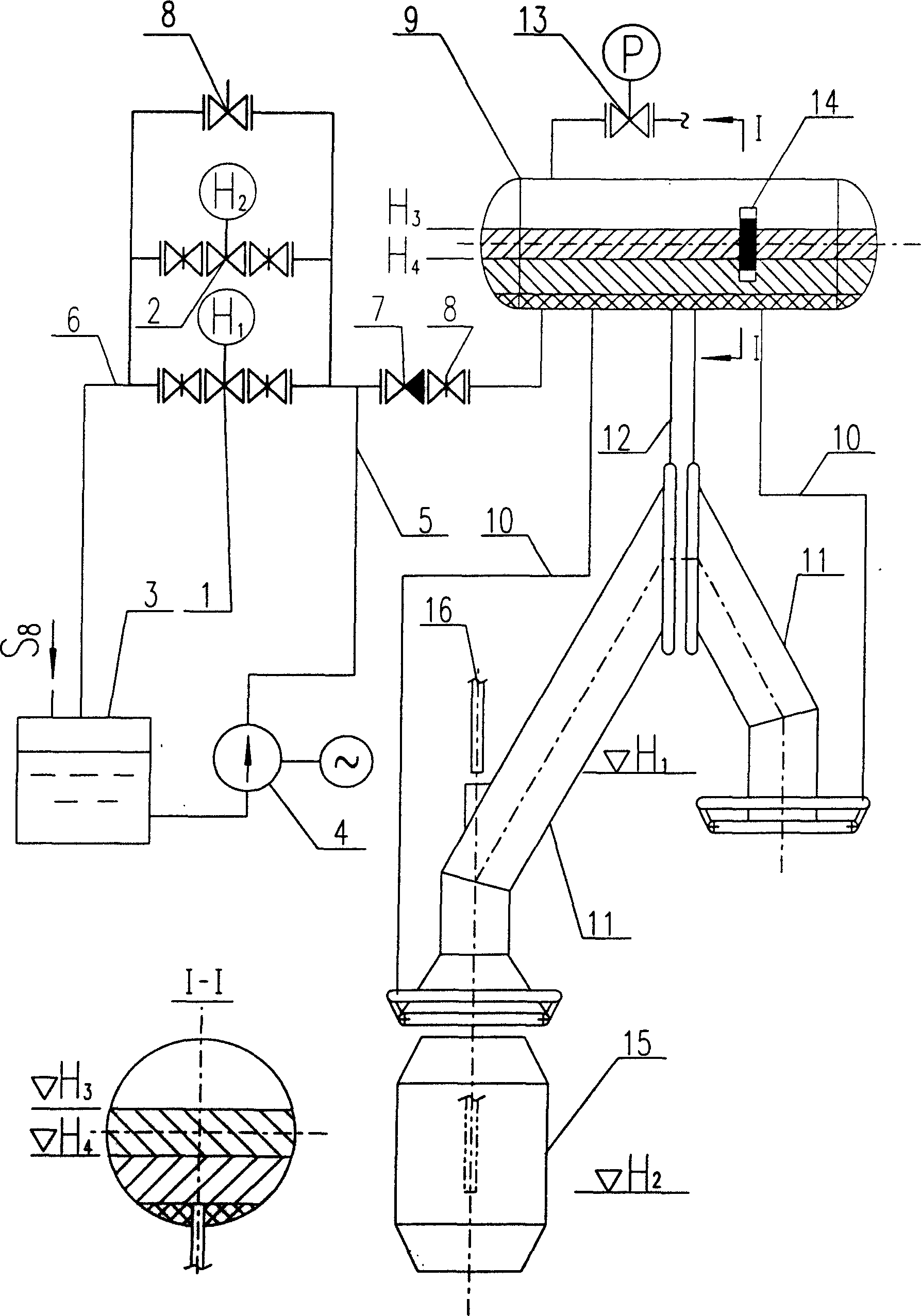

[0020] From attached figure 1 It can be seen that the automatic water supply device composed of low water level regulating valve 1, high water level regulating valve 2 and valve 8 is connected to the return pipe 6 in parallel, and the oxygen lance 16 is in the rising state before the blowing of the converter 15, at H1, and in the deoxygenated water tank 3 The soft water enters the steam drum through the water supply pump 4, the water supply pipe 5, the check valve 7 and the valve 8, and then is sent to the water inlet header below the converter flue 11 through the downcomer 10, and the converter flue 11 is blowing in the converter 15 The heated mixture returns to the steam drum 9 along the rising pipe 12. When the steam drum 9 reaches the working pressure, the pressure regulating valve 13 opens to send steam outward, and the electric contact water level gauge 14 continuously transmits the water level signal of the steam drum 9 to the Low water level regulating valve 1 and high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com