Method and equipment for recycling crude gas waste heat in ascending pipes of coke oven

A waste heat recovery and waste gas technology, applied in lighting and heating equipment, indirect heat exchangers, etc., can solve the problems of poor thermal stress, inability to run stably for a long period, overheating and coking of heat transfer oil, etc., and achieve large thermal expansion deformation and Effects of thermal stress, smooth and reliable steam-water circulation, and easy operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

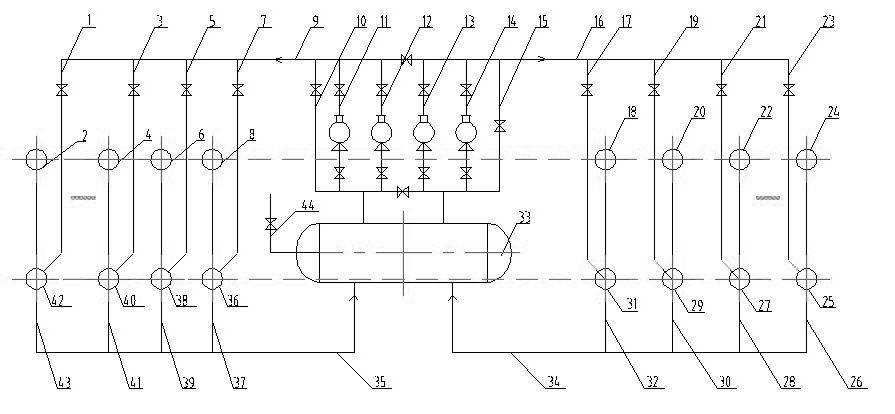

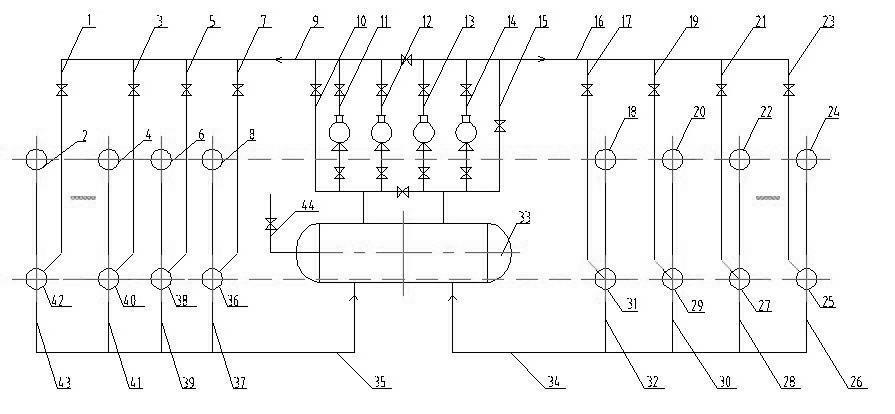

[0014] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

[0015] In this embodiment, a concentrated steam drum 33 is provided at the middle gap of the coke oven roof, and circulating water pumps 11, 12, 13, 14 pump water out from the water outlet of the concentrated steam drum and pump it to the water supply main pipe 9 on the left side. In the main water supply pipe 16 on the right side, it is distributed to all heat exchangers on the left and right sides through the water supply pipes 1, 3, 5...7 of the left heat exchanger and the water supply pipes 17, 19, 21...23 of the right heat exchanger In 31, 29, 27...25 and 36, 38, 40...42, the heat-absorbing part in the heat exchanger is vaporized, and the steam-water mixture is connected to the outlets of the heat exchangers on the left and right sides 37, 39, 41...43 and 32 . And through 34,35, flow into the concentrated steam drum 33 and carry out steam-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com