Coke oven crude gas sensible heat recycling system

A sensible heat recovery and raw gas technology, applied in the heating of coke ovens, coke ovens, liquid degassing, etc., can solve the problems of wasting water resources and electricity, wasting sensible heat of raw gas, increasing sewage discharge, etc., and achieves convenient maintenance , Sensible heat recovery effect is good, stable and efficient recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

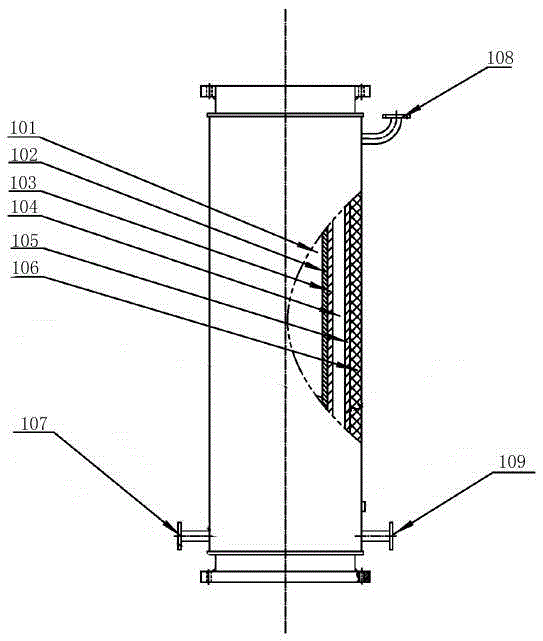

[0034] Such as figure 2 As shown in the present invention, the figure 2 The riser heat exchanger shown in 1.

[0035] Specifically, the riser heat exchanger 1 includes an inner tube 103 and an outer tube 105 sleeved on the inner tube 103, the inner tube 103 is hollow, forming a raw gas channel 101 for the circulation of raw gas; the inner tube 103 and the outer tube A cavity 104 is formed between 105, and the cavity 104 is the water supply channel. The lower end of the cavity 104 is provided with a water inlet 107, and the upper end is provided with a steam outlet 108. The feed water enters the cavity 104 through the water inlet 107, and heat exchange through the inner tube 103 absorbs the sensible heat of the raw gas to raise the temperature. Become a steam-water mixture, and discharge from the steam outlet 108; Wherein, the water inlet 107 is also provided with a flow guide element that makes the water entering by the water inlet 107 diffuse to the circumference of the c...

Embodiment 2

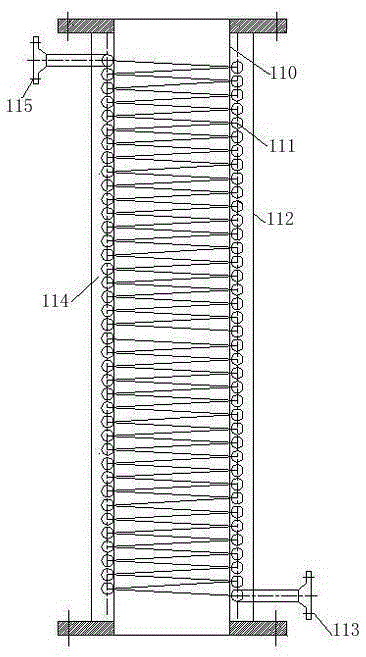

[0041] Such as image 3 As shown in the present invention can also be used image 3 The riser heat exchanger 1 shown in , the riser heat exchanger 1 in this embodiment is a deformation of the riser heat exchanger in the first embodiment.

[0042] In this embodiment, the riser heat exchanger 1 includes an inner tube 110 and an outer tube 112 sleeved on the inner tube 110, a cavity 114 is formed between the inner tube 110 and the outer tube 112; the inner tube 110 and the outer tube The specific structure can refer to what is shown in the first embodiment, which is not limited here.

[0043] In this embodiment, the cavity 114 can be provided with a coil 111 spirally wound on the outer wall of the inner tube 110; the lower end of the cavity 114 is provided with a water inlet 113 communicating with the coil 111, and the upper end is provided with a The steam outlet 11 communicated with the other end of the coil pipe 111. The coiled tube 111 is wound tightly and without gaps on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com