Patents

Literature

32results about How to "No impact on production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-energy-consumption device and method capable of producing oxygen-enriched gas and high-purity nitrogen simultaneously

PendingCN106989567AReduce output pressureMeet heat transfer requirementsSolidificationLiquefactionAir compressionMolecular sieve

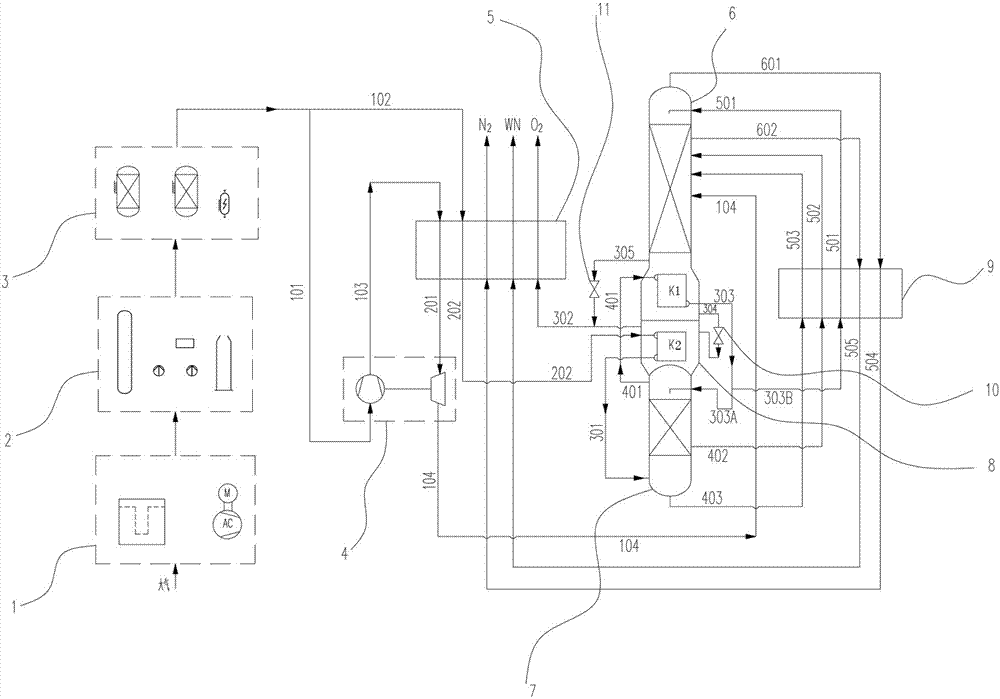

The invention provides a device capable of producing oxygen-enriched gas and high-purity nitrogen simultaneously. The device comprises an air compression system, an air precooling system, a molecular sieve purification system, a booster expansion turbine, a main heat exchanger, a rectifying column and a supercooler. All the devices communicate with one another through corresponding pipelines. The invention further provides a method capable of producing the oxygen-enriched gas and the high-purity nitrogen simultaneously. In specific, air in the atmosphere is divided into two paths after being filtered, compressed and purified; one path of the air enters the booster expansion turbine and then enters an upper column body for rectification separation after passing through the main heat exchanger; and the other path of the air directly enters the main heat exchanger to be cooled and then enters a lower-layer main condensing evaporator and a lower column body in sequence, primary rectification separation is carried out in the lower column body, and then the air enters the upper column body to conduct final rectification separation. By the adoption of the device and method, the oxygen-enriched gas of different purities can be produced while the high-purity nitrogen is produced, the oxygen-enriched gas can be directly used by follow-on production, repeated construction and investment of equipment are reduced, and the production cost is also reduced.

Owner:HENAN KAIYUAN AIR SEPARATION GRP CO LTD

Cultivation method of chromosomal-translocation triploid seedless watermelons

InactiveCN103168678AOvercoming Breeding DifficultiesExpand the scope of plantingPlant genotype modificationColchicineTemperature difference

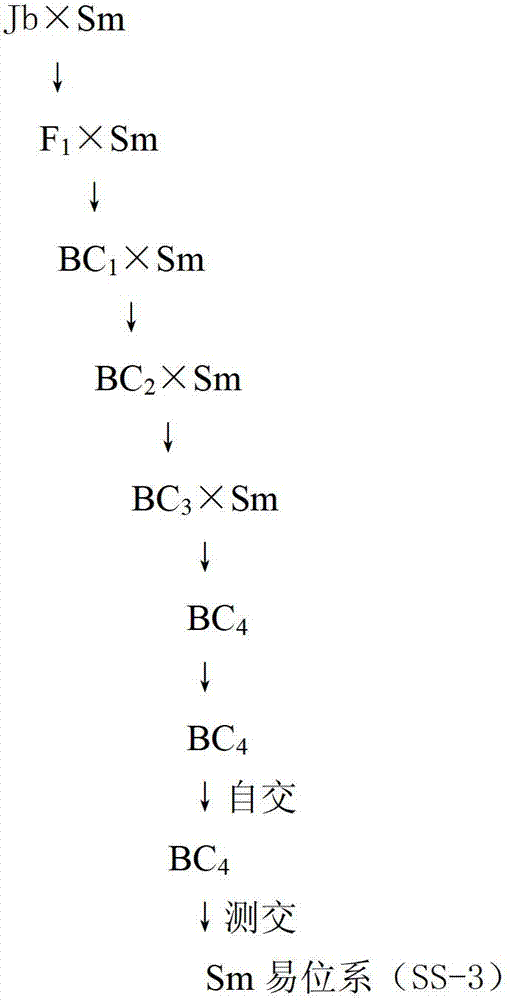

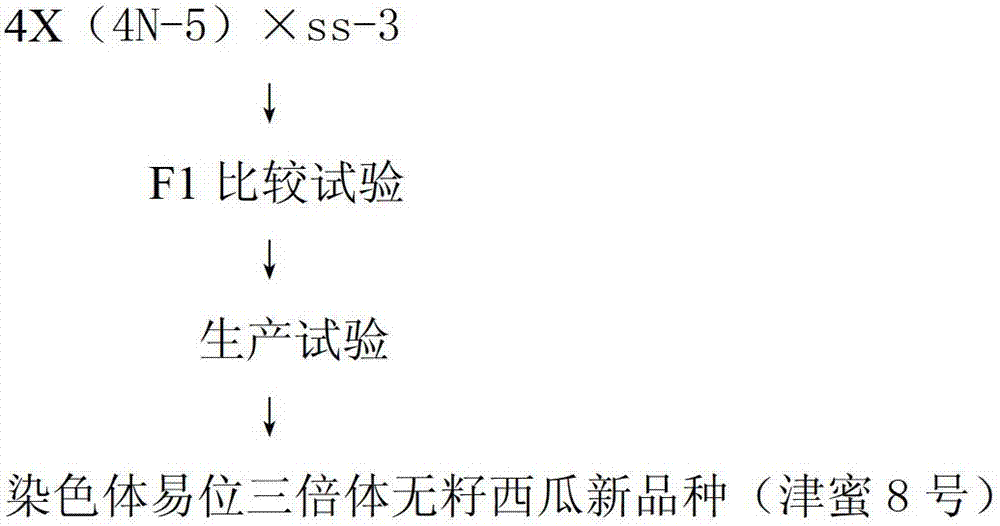

The invention discloses a cultivation method of chromosomal-translocation triploid seedless watermelons. The cultivation method comprises the following steps of: (a) breeding of a male parent, namely crossing a chromosomal-translocation diploid watermelon breeding material with a diploid material suitable for serving as a seedless watermelon male parent, thus obtaining the male parent in a breeding method for four-generation continuous backcross, one-generation self cross and one-generation test cross; (b) breeding of a female parent, wherein mutating a diploid watermelon breeding material suitable for being mutated into tetraploid watermelons into tetraploid watermelons by a colchicine solution with the mass concentration of 0.2%, thus obtaining the female parent by self-crossing fertile restoration for 3-4 generations; and (c) performing cross matching on the female parent and the male parent to obtain the chromosomal-translocation triploid seedless watermelon variety through variety tests. The cultivation method disclosed by the invention has the advantages that chromosomal translocation and 3X double abortion are superposed, so that the breeding difficulty of more colored and abortive grains of 3X seedless watermelons is effectively overcome; and when the chromosomal-translocation triploid seedless watermelons are planted in protected areas and areas with large temperature difference at day and night, the colored and abortive grains do not occur, so that the planting range is expanded.

Owner:TIANJIN KERNEL VEGETABLE RES INST

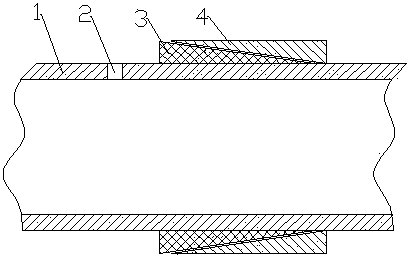

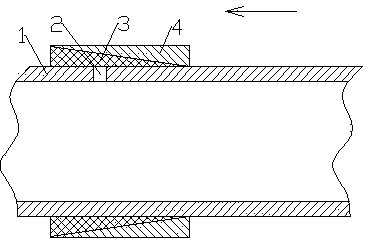

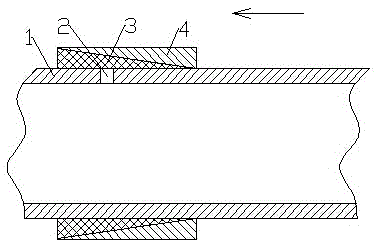

Special pipeline leaking stoppage recovery method for petrochemical industry

The invention relates to a pipeline leaking stoppage recovery method, in particular to a special pipeline leaking stoppage recovery method for the petrochemical industry. The method comprises the following steps: using a disposable leak stopper to plug up a pipeline leaking point, wherein the disposable leak stopper is composed of an oil-proof, acid-proof and high-pressure resistant wedge-shaped sealing silicone ring, and a stainless steel wedge-shaped strapping ring with an opposite shape; cleaning oil stains and sundries on the pipeline around the disposable leak stopper, grinding the pipeline with a brush so as to show a matte surface on the surface of the pipeline, and then tightening the disposable leak stopper and the surrounding pipeline with a high-strength compression plugging adhesive tape; fixing a reinforced fixing socket, which is internally coated with a special high-strength compression plugging adhesive, outside the high-strength compression plugging adhesive tape to form a permanent plugging structure. The special pipeline leaking stoppage recovery method for the petrochemical industry can be implemented under pressure without production halt, has no influence on production, needs no evacuation and nitrogen replacement, needs no hot work, prevents fire and security risk, and is suitable for compression cold treatment plugging and physical plugging technologies of the petrochemical industry.

Owner:唐山迪华石油钻采设备有限公司

Cleaning agent for organic sediments inside oil tank and preparation method of cleaning agent

InactiveCN104263533ANo solubilityNo emulsificationAnionic surface-active compoundsDetergent compounding agentsSludgeCleansing Agents

The invention relates to a cleaning agent for organic sediments inside an oil tank and a preparation method of the cleaning agent. The cleaning agent comprises the following components in percentage by mass: 30%-60% of tetramethoxy-propane, 20%-40% of dimethoxy-ethane, 5%-15% of diethylene glycol octyl ether, 2%-10% of sodium polyphosphate, 1%-1.5% of sodium alkyl benzene sulfonate and 2%-3.5% of lauryl sodium sulfate. The cleaning agent disclosed by the invention can be cleaned on line and also be cleaned off line, generates no influence on production because of no need of shutdown when used for cleaning on line, so that cost and time are saved; the cleaning agent is harmless to an operator because an operator unnecessarily enters the oil tank, is pollution-free on the environment, can be used for recovering 90% hydrocarbon by recycling sludge and has the advantages of outstanding economic benefit, simple preparation method, short cleaning operation time, high cleaning quality, ecological and environmental friendliness, no three wastes discharge, no need of anti-rust treatment on a container after cleaning, good social benefit and economic benefit, harmlessness on human bodies, no corrosion on equipment and no secondary pollution.

Owner:JINAN RUIDONG IND

Low-cost slag washing method

ActiveCN108018402ANo crusting on the bottom of the bagNo sintering on the bottom of the bagProcess efficiency improvementSlagSulfur

The invention belongs to the technical field of iron and steel metallurgy and in particular relates to a low-cost slag washing method. The low-cost slag washing method comprises the following steps: producing synthetic slag for slag washing in a steel ladle, obtained by casting molten steel, by utilizing refining slag and a deoxidant; then utilizing the produced solid-state synthetic slag with relatively high temperature for slag washing operation of a steel tapping process of the next heat. The method provided by the invention has a simple technology and is low in cost; the consumption of slag production materials is less and the heat of the refining slag is recycled; smooth production is not influenced; compared with cyclic utilization of heat-state refining slag, the low-cost slag washing method has remarkable advantages. Sulfur is effectively removed.

Owner:SHANDONG IRON & STEEL CO LTD

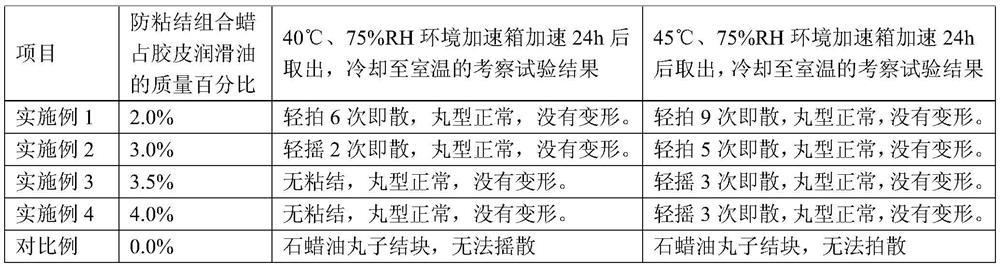

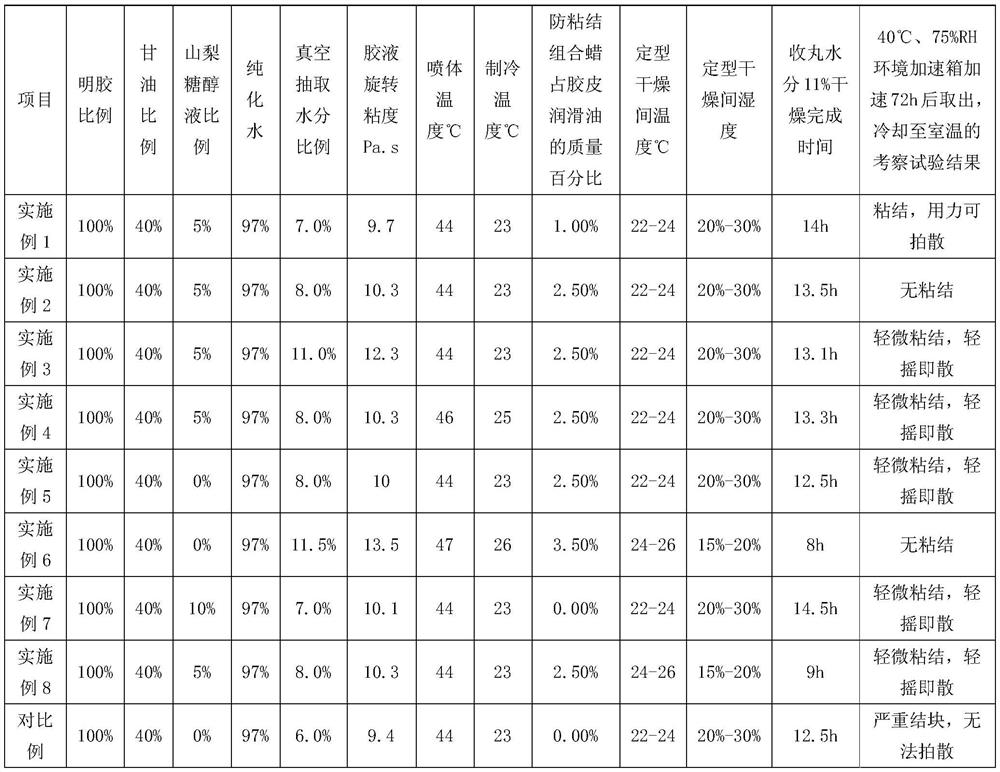

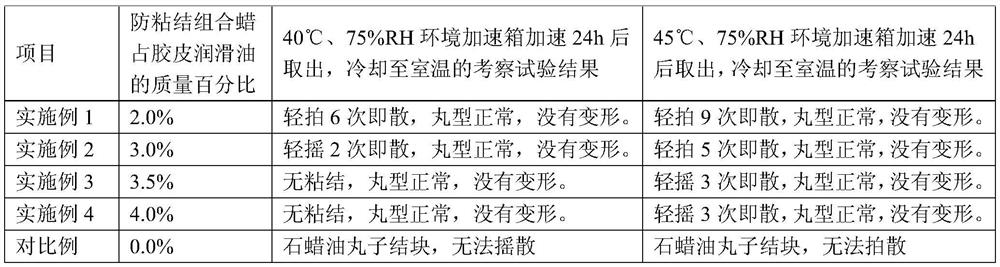

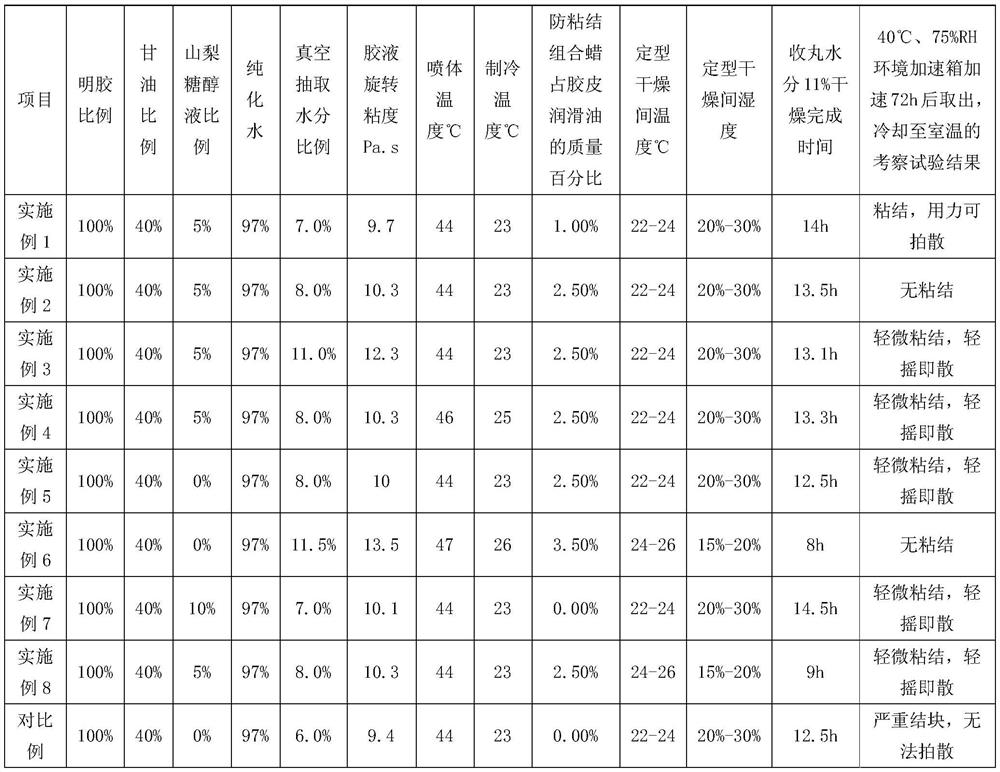

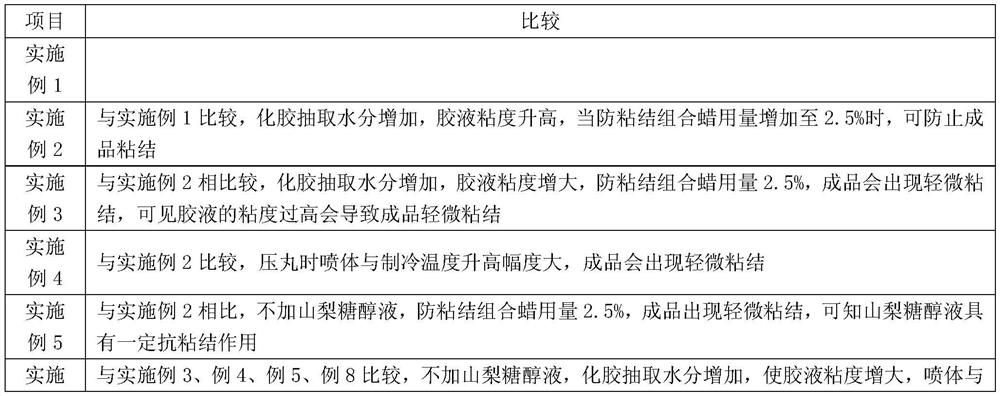

Production process for anti-bonding soft capsule and anti-bonding combined solution for same

ActiveCN111956626AImprove protectionNo impact on productionOrganic non-active ingredientsCapsule deliverySoftgelMedicine

The invention provides a production process for an anti-bonding soft capsule. The anti-bonding soft capsule comprises a gelatin solution used for making a capsule and an anti-bonding combined solutionused for performing anti-bonding treatment on the capsule, wherein the gelatin solution comprises the following components in terms of the weight ratio of gelatin: 100% of the gelatin, 40-50% of glycerin, 5-15% of a sorbitol solution and 95-100% of purified water. The process comprises the following steps: step 1, melting of the gelatin: a step of dissolving the gelatin, the glycerin, the sorbitol solution, the purified water and the like according to a certain ratio so as to prepare the gelatin solution used for pelleting; step 2, batching: a step of preparing contents according to a formulaproportion, paying attention to the fineness, solid content, viscosity and fluidity of materials when the materials are prepared for a suspension soft capsule, and carrying out grinding through a bead mill if necessary; step 3, pelleting and shaping: a step of pressing soft capsules through a soft capsule pelleting machine, and performing primary shaping and drying in a shaping rotary cage; step4, drying and spraying of the anti-bonding combined solution: a step of wrapping the outer surface of the rubber of the soft capsule with the anti-bonding combined solution; and step 5, pellet picking. The production process provided by the invention can effectively solve the production technical problem that the soft capsules are easy to bond.

Owner:浙江新维士生物科技有限公司

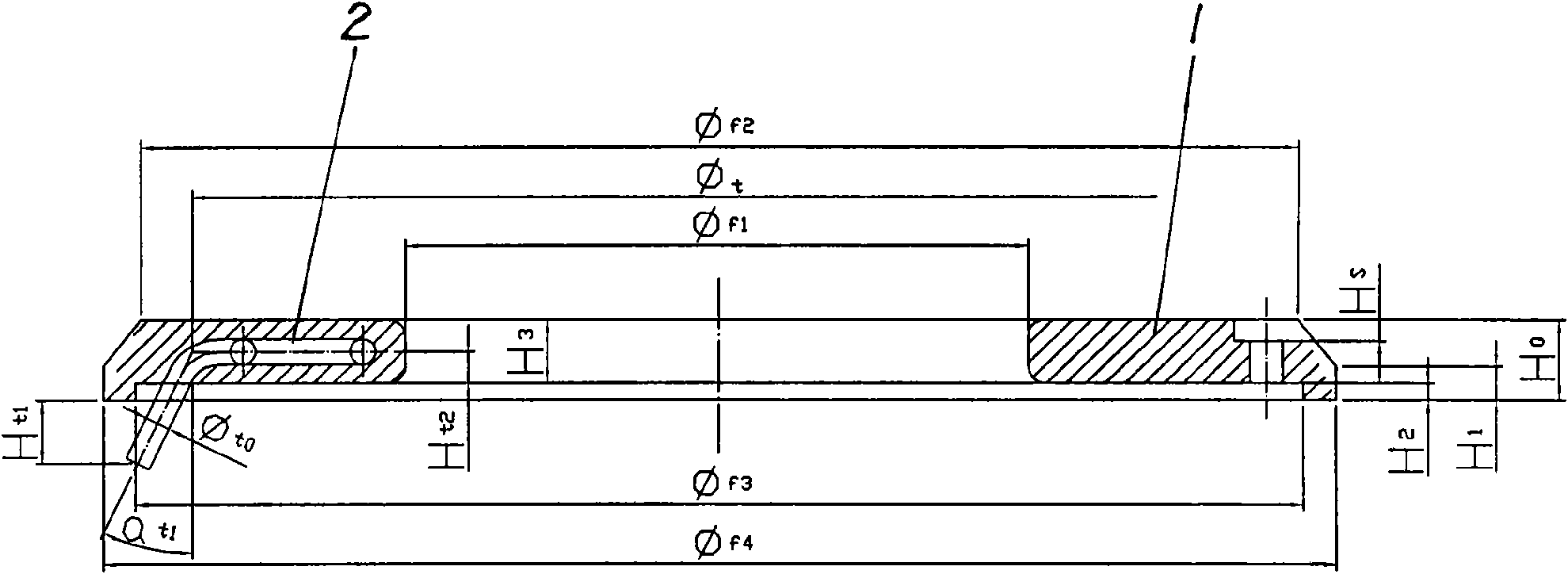

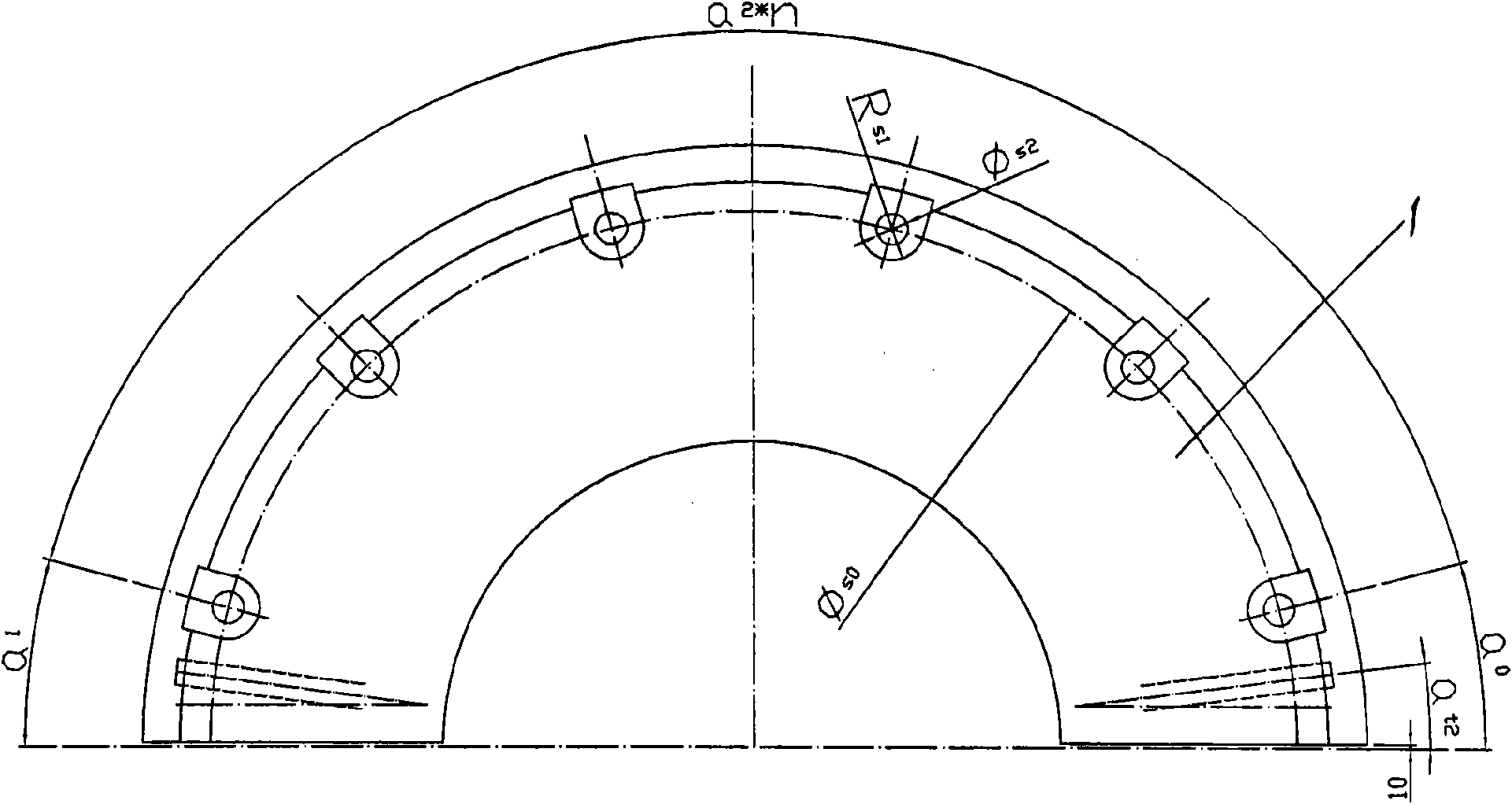

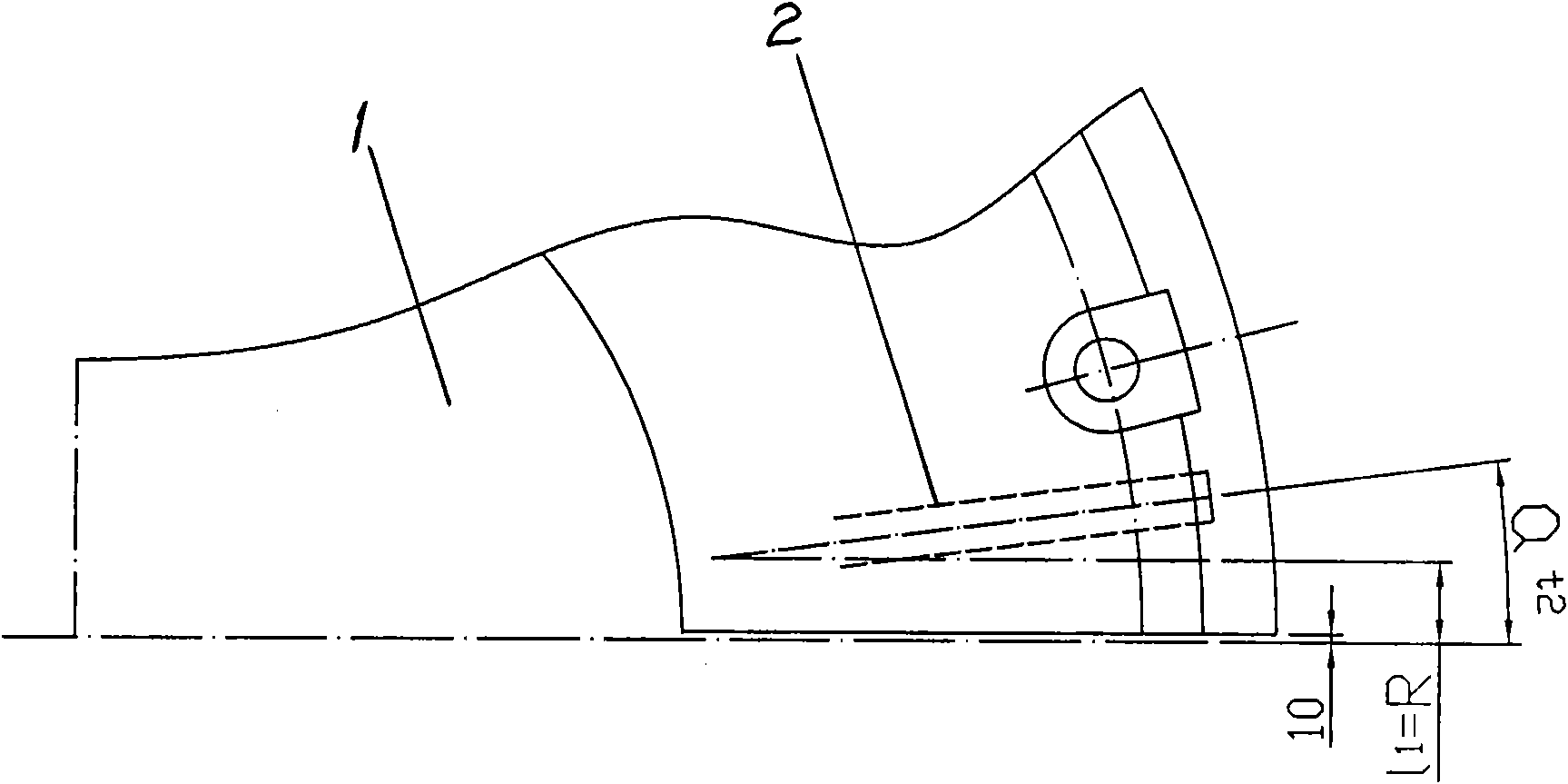

Design method of converter cast iron water-cooling mouth

The invention relates to a design method of a converter cast iron water-cooling mouth, comprising the steps of: 1. designing shape size; 2. designing install size; 3. designing a converter cooling system; and 4. designing the main body material of the converter mouth. The converter cast iron water-cooling mouth has the following advantages and benefits: 1. water tight: a cast mode which is pre-cast with a cooling water pipe is adopted, the water pipe is shaped by means of cold bend, and the surface of the water pipe has a good protection layer, therefore, the cast iron water-cooling mouth is watertight; 2. no mending: the mouth is watertight, therefore, the mouth can be out of maintenance; 3. long service life: under the normal using condition, the cast iron converter mouth can use one converter campaign without needing to change the converter mouth to prevent from affecting the manufacture; 4. hard deformation; and 5. hard sludge adhering and easy sludge removing. Because the materialis different, the cast iron converter mouth is hard to be adheree with the sludge and easy to remove less quantity of the sludge.

Owner:SHANGHAI BAOSTEEL CASTING

Detection method for checking air leakage of non-oxidation heat treatment furnace radiant tube

InactiveCN110926713ALess restrictiveNo impact on productionDetection of fluid at leakage pointHeat treatment process controlThermodynamicsProcess engineering

The invention relates to a detection method for checking air leakage of a radiant tube of a non-oxidation heat treatment furnace, and belongs to the field of equipment troubleshooting methods. The method comprises the steps of when a heat treatment furnace is in an ignition state, closing burners in all areas in the heat treatment furnace; reducing the residual oxygen amount in the heat treatmentfurnace to a specified numerical value, and igniting each burner zone by zone; detecting the residual oxygen amount in the heat treatment furnace after the single-area burner is ignited, and judging whether the residual oxygen amount is higher than a specified residual oxygen amount value; and closing the burner gas inlet pipeline of the heat treatment furnace higher than the specified value of the residual oxygen amount to finish detection and overhaul. According to the detection method for checking the air leakage of the radiant tube of the non-oxidation heat treatment furnace, the checkinglimit conditions are few, and almost no influence is caused to production. During production, after air leakage of the radiant tube is found, the furnace does not need to be shut down, cooled or inspected in the furnace, and the heat treatment furnace can be checked in an ignition state and is not influenced by the temperature of the furnace.

Owner:ZHANGJIAGANG HONGCHANG STEEL PLATE CO LTD +1

A kind of anti-adhesion soft capsule production process and anti-adhesion combination liquid

ActiveCN111956626BImprove protectionNo impact on productionOrganic non-active ingredientsCapsule deliveryMedicineGlycerol

Owner:浙江新维士生物科技有限公司

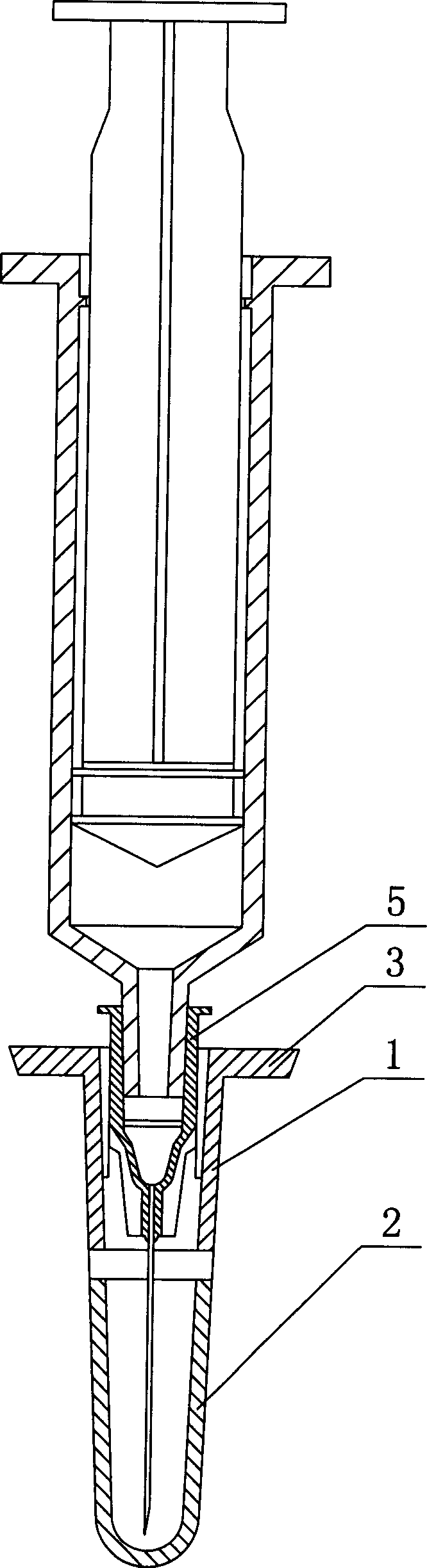

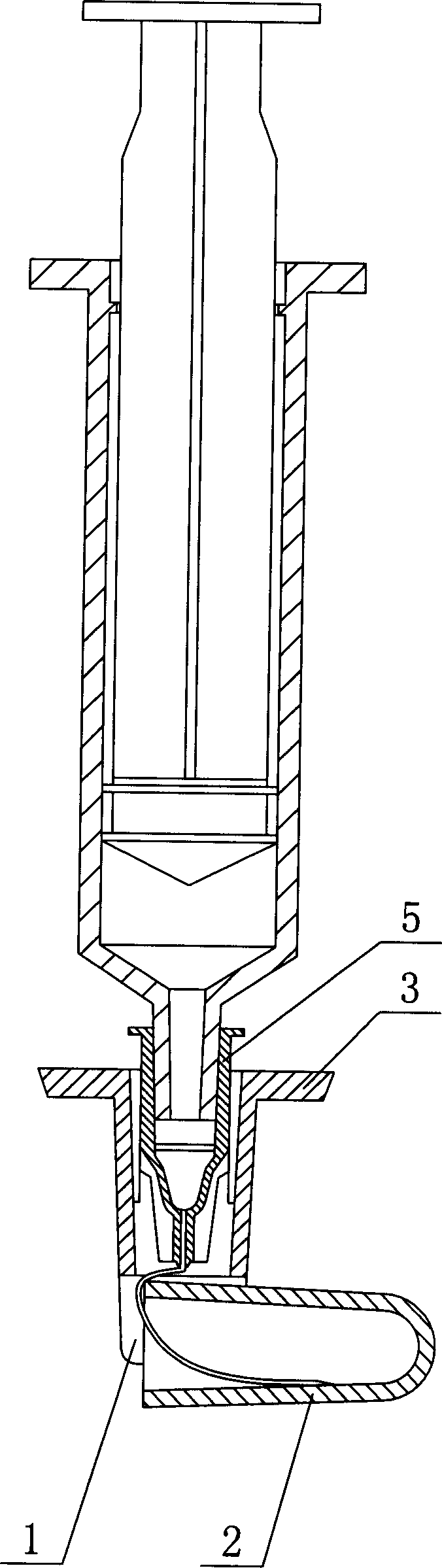

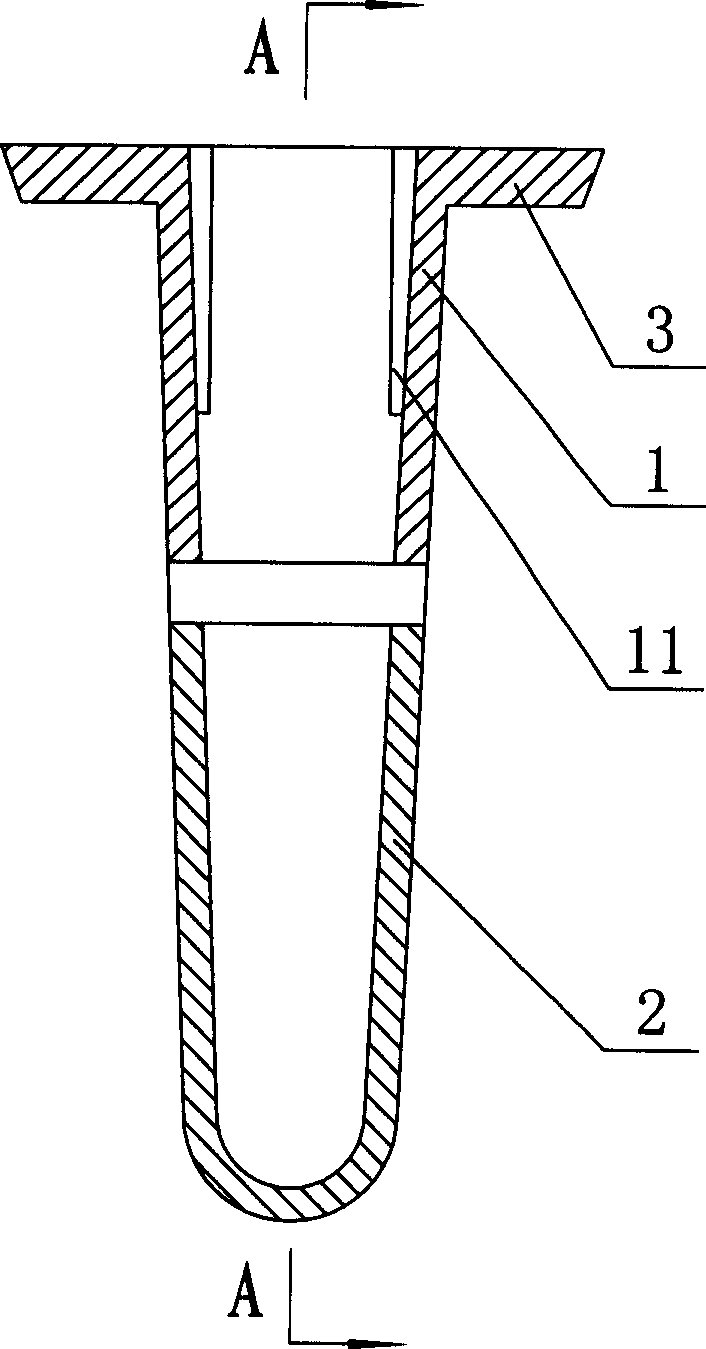

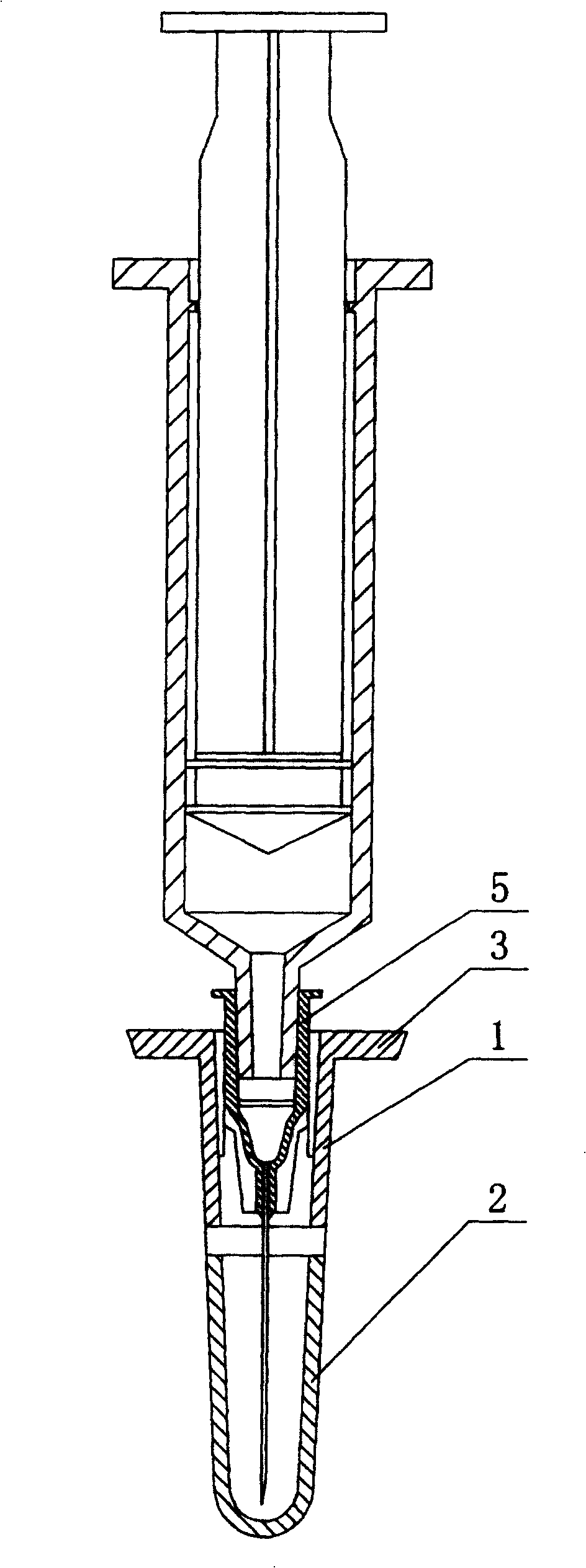

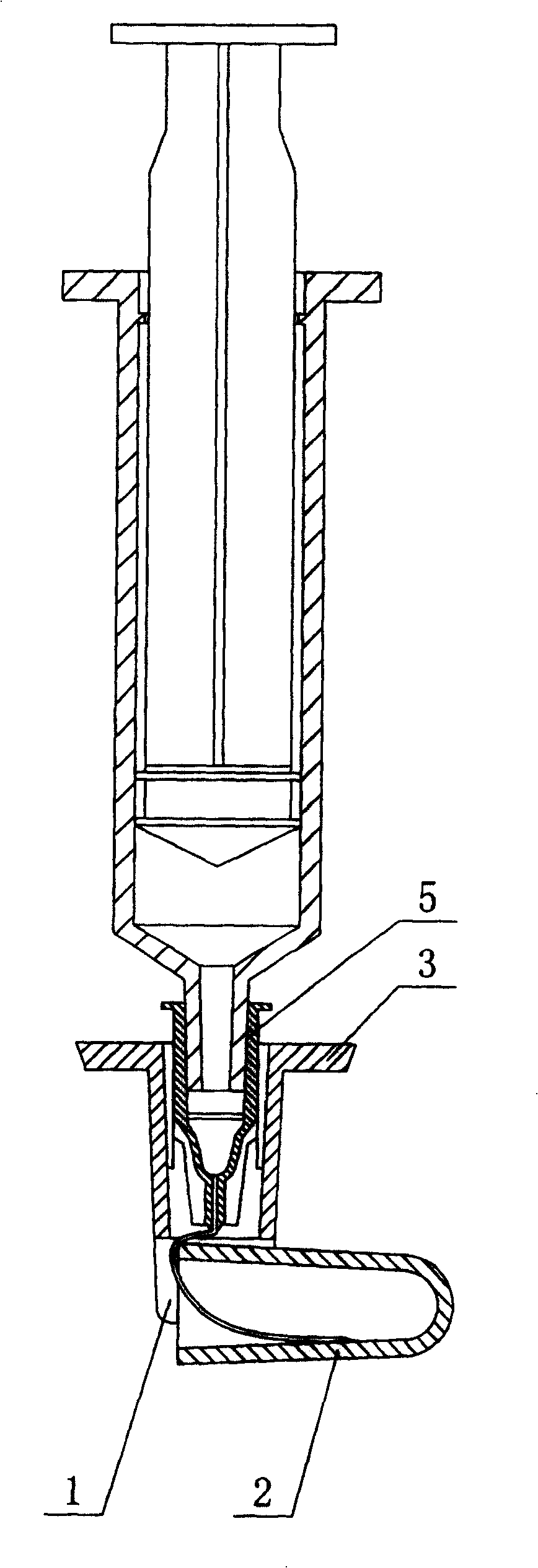

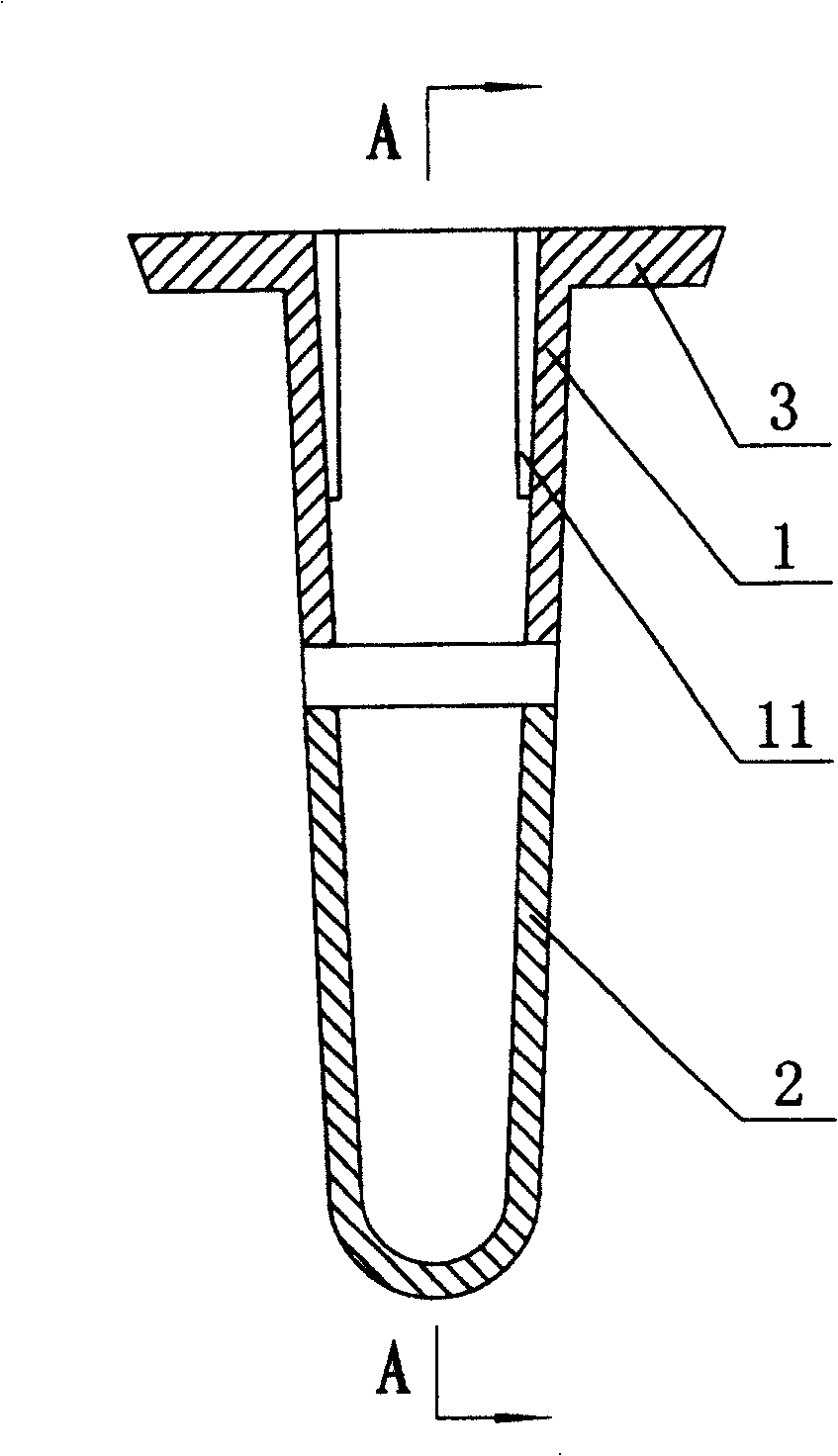

Safty injector with destroyable needle

InactiveCN1792392AFew partsEasy to assembleInfusion syringesInfusion needlesSyringe needleNeedle holder

A high-safety needle destroying unit for injector has an upper part which is a hollow cylindrical body with a central through hole and sleeve-jointed with needle holder, and a low part which is a hollow cylindrical body with open top end and closed bottom end, and connected with said upper part in rotary mode.

Owner:虞家珍

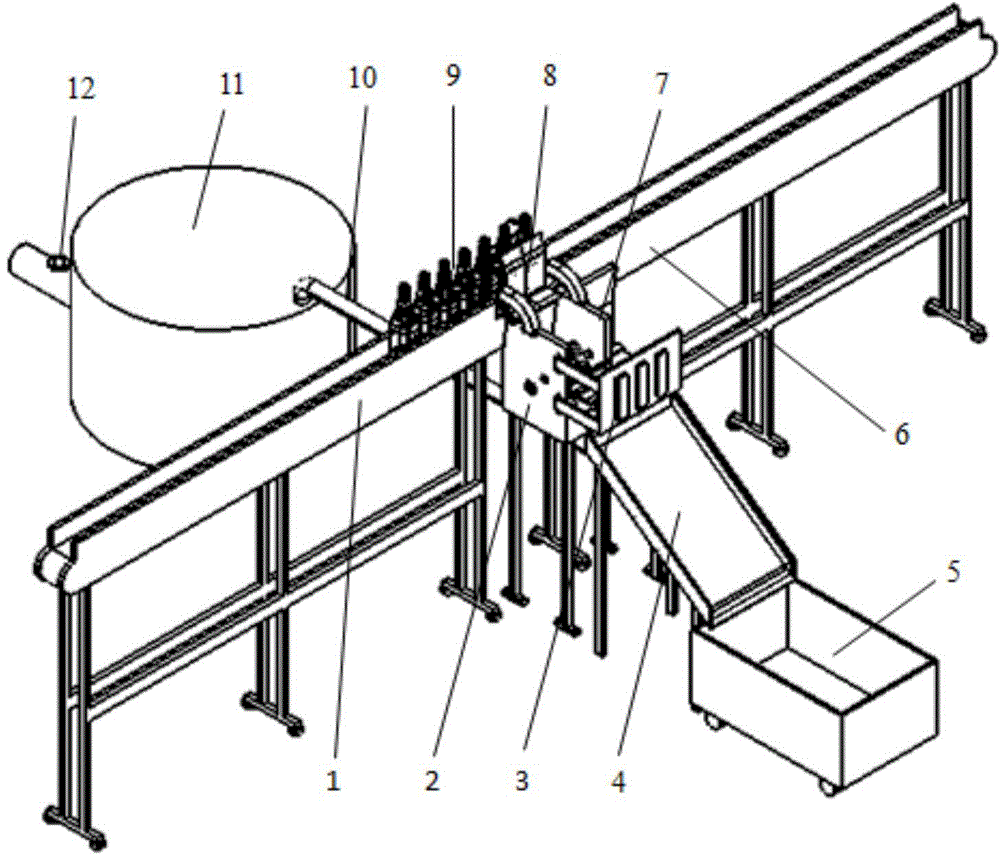

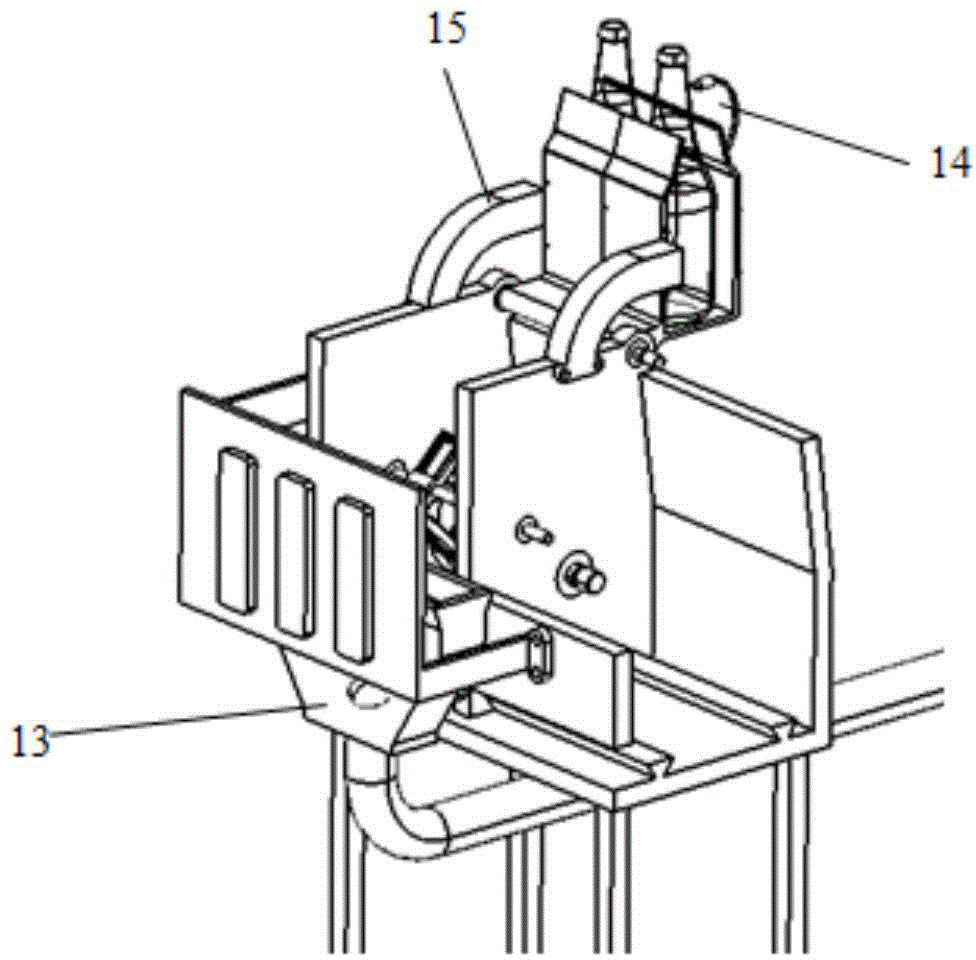

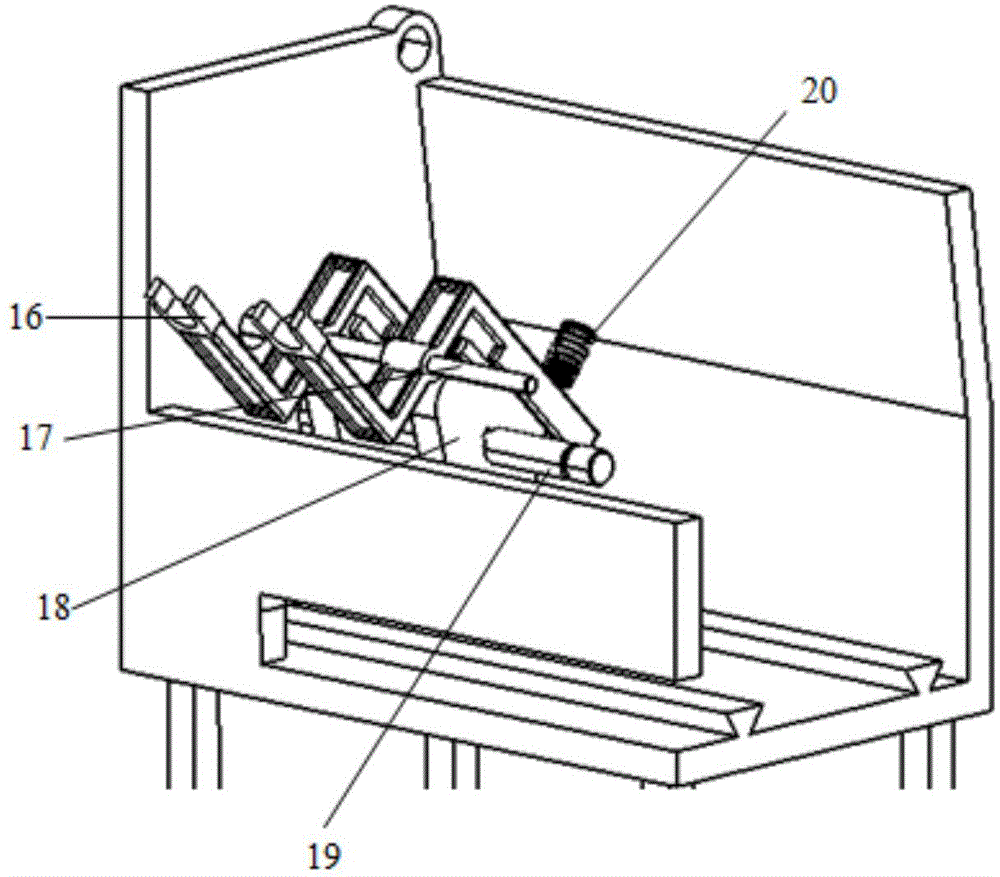

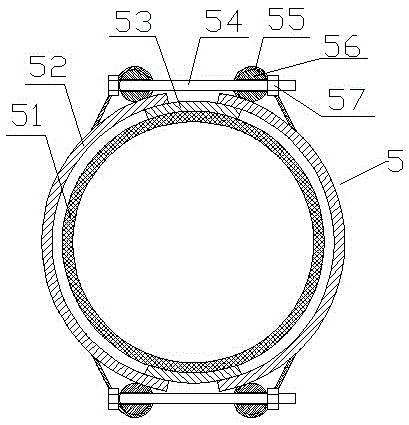

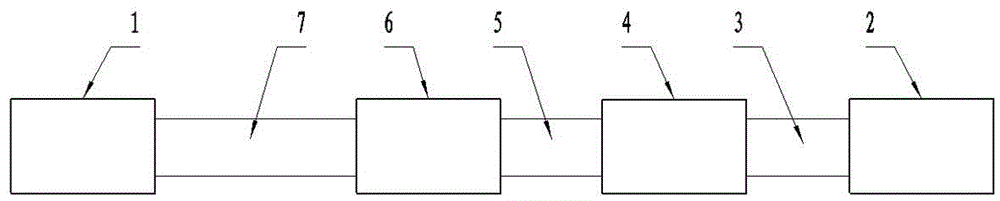

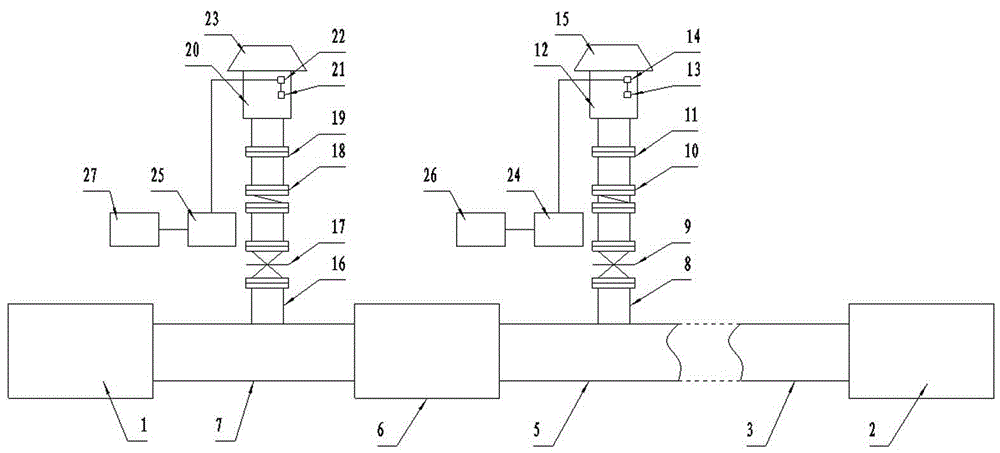

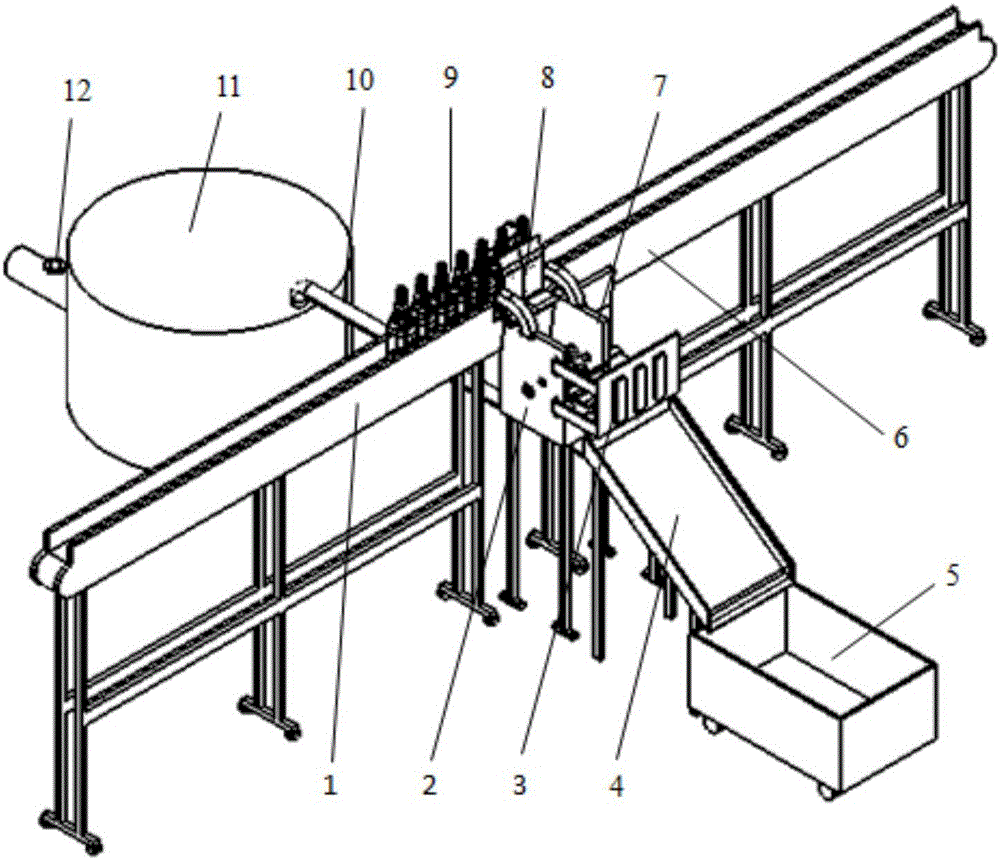

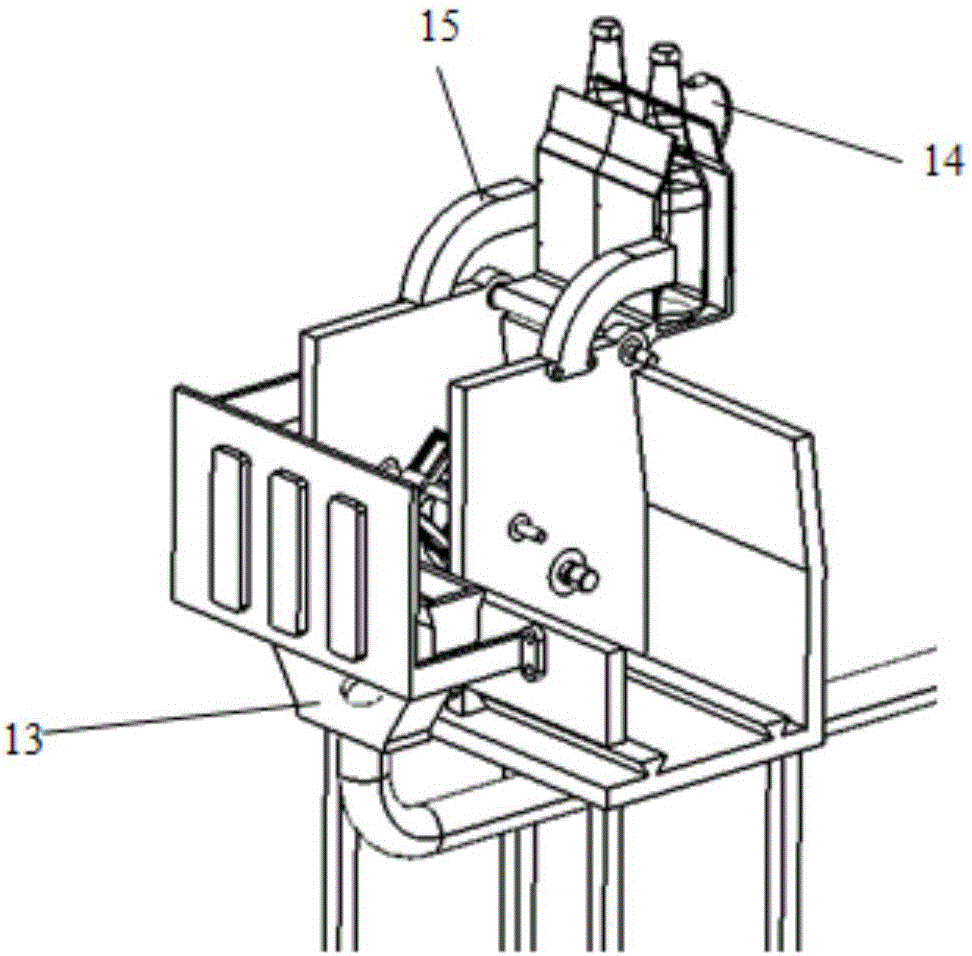

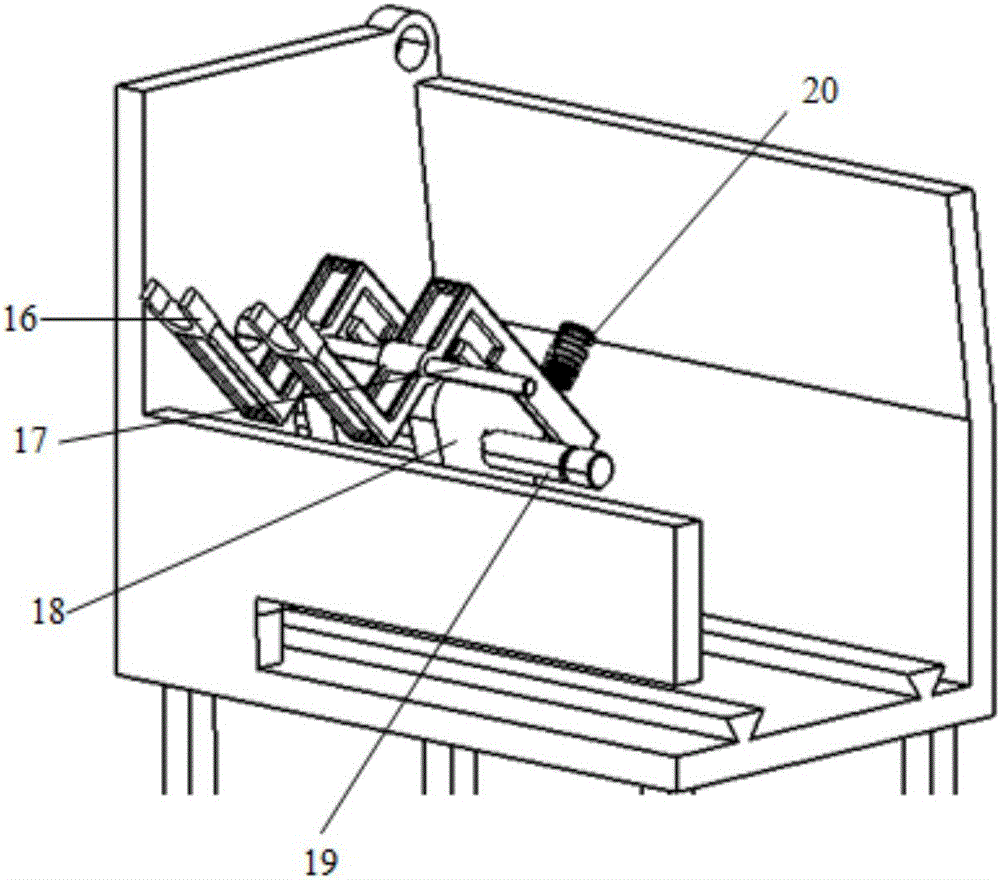

Recycling device of unqualified bottled beer

InactiveCN103910316ARealize rational utilizationAvoid handlingFlanged caps removalBottle emptyingProduction lineProduct inspection

The invention provides a recycling device of unqualified bottled beer. The recycling device of unqualified bottled beer comprises an unqualified bottled beer feeding system, a bottle uncapping and beer pouring system, and a storage and discharge system. The unqualified bottled beer feeding system is disposed at the front end of the bottle uncapping and beer pouring system; the storage and discharge system is disposed at the rear end of the bottle uncapping and beer pouring system. The recycling device of unqualified bottled beer can be connected to a 'finished product inspection' link of a beer production line; inferior-quality products on the production line are fed into th device; separated glass bottles and beer are discharged; the glass bottles and beer are subjected to certain treatment and can be fed into an original beer production system, a closed-loop system is formed, and resources are reasonably utilized. The recycling device of unqualified bottled beer has the advantages that the storage and discharge system is provided, the inferior-quality products occurring in the production process are directly treated in the corresponding recycling device, unnecessary carrying of the inferior-quality products is avoided, and risk of bottle bodies being damaged is lowered.

Owner:SHANGHAI JIAO TONG UNIV

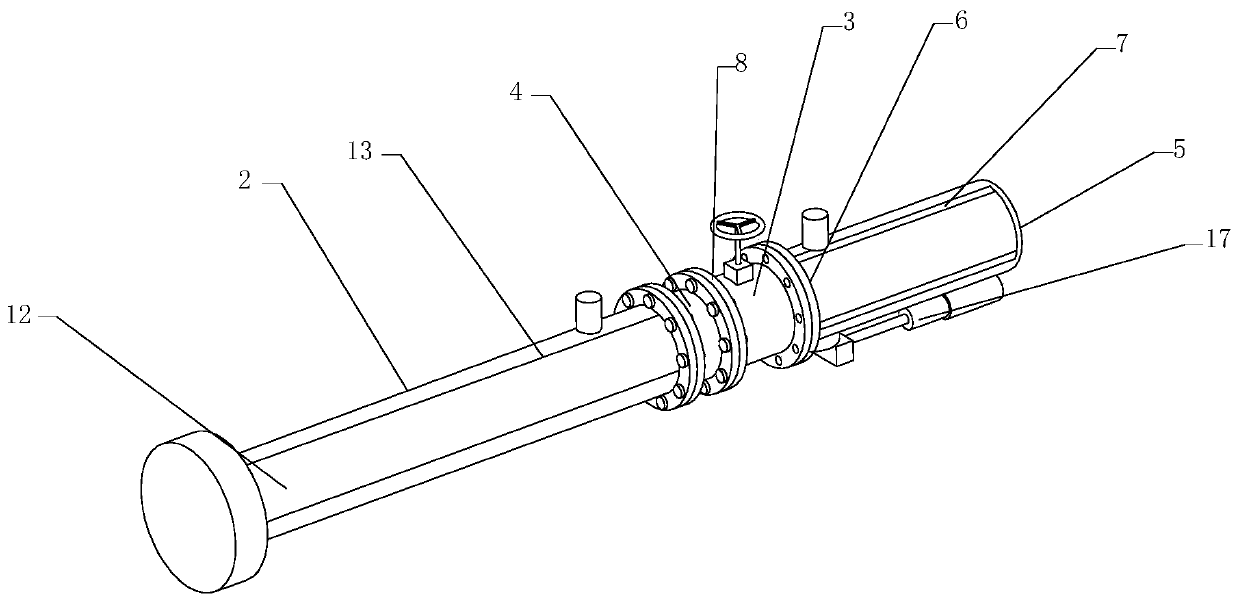

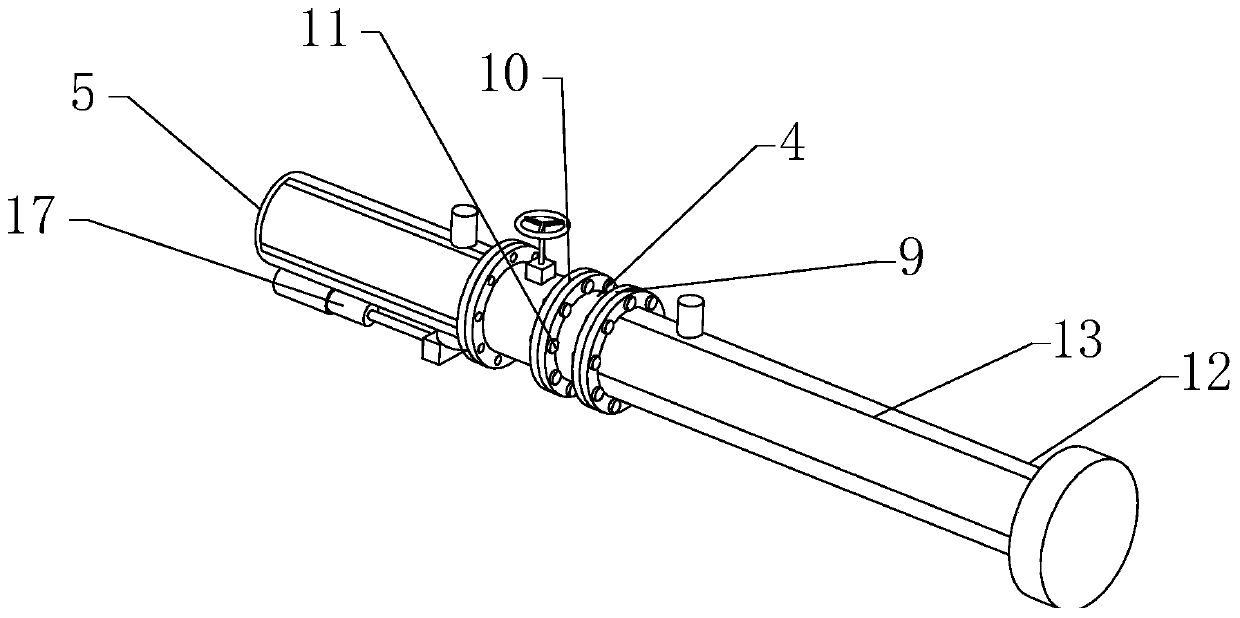

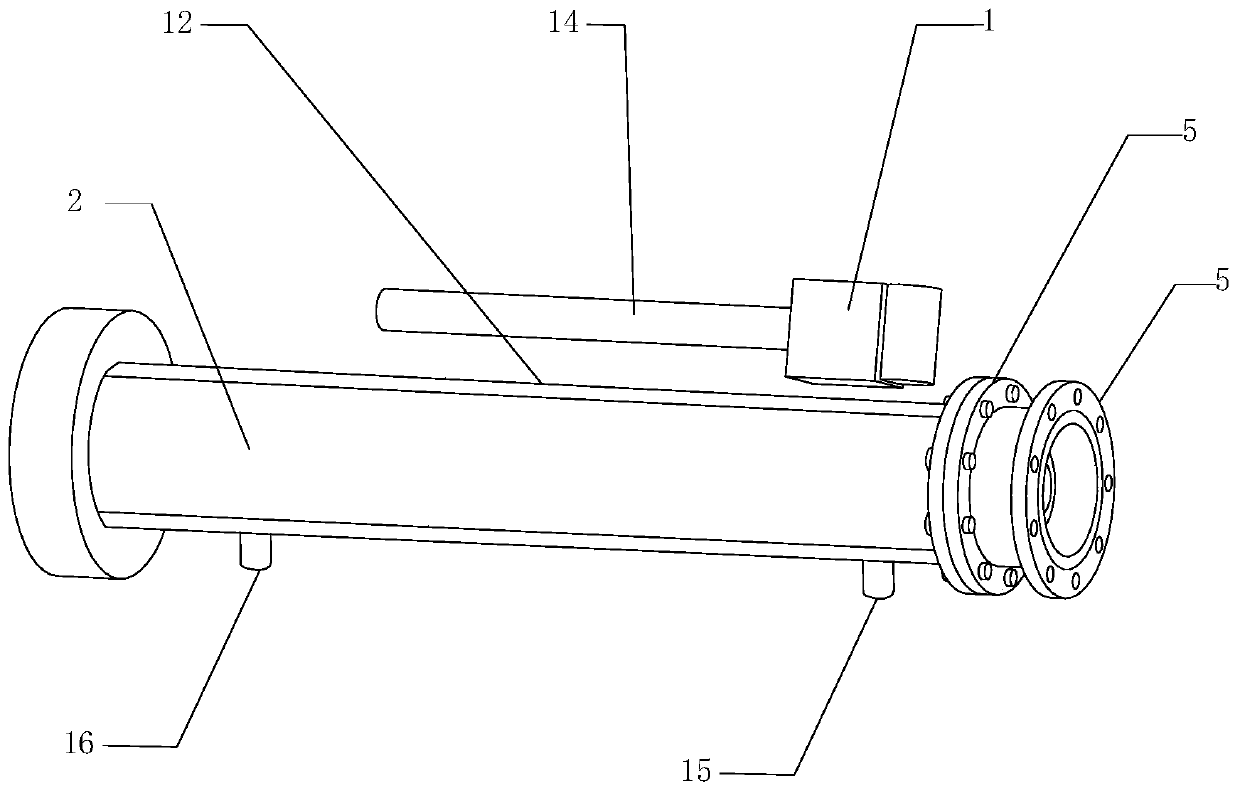

Pneumatic advancing-retreating belt sweeping and protection device with short and exquisite structure

The invention relates to the field of blooming furnace observation devices, in particular to a pneumatic advancing-retreating belt sweeping and protection device with a short and exquisite structure.The device comprises a thermal imager, a closed air cylinder, a ball valve, a transition sleeve, a base guide pipe and a water jacket fixedly mounted on the base guide pipe. A first flange and a second flange are fixedly arranged at the left end and the right end of the ball valve correspondingly. A third flange and a fourth flange are arranged at the left end and the right end of the transition sleeve correspondingly. The other end of the water jacket is fixedly mounted on the first flange. The fourth flange at the right end of the transition sleeve is fixedly connected with the first flangethrough bolts. The closed air cylinder comprises a cylinder barrel and a cylinder rod. A containing groove is formed in the cylinder rod. The thermal imager is fixedly mounted in the containing groovethrough a support. A front end cap is further arranged at the front end of the containing groove. A preformed hole is formed in the front end cap. The end of the cylinder rod of the closed air cylinder is fixedly connected with the third flange. The overall product structure of the device is short and exquisite, subsequent equipment maintenance is convenient, and the thermal imager can be protected.

Owner:天津市德力达电子科技有限公司

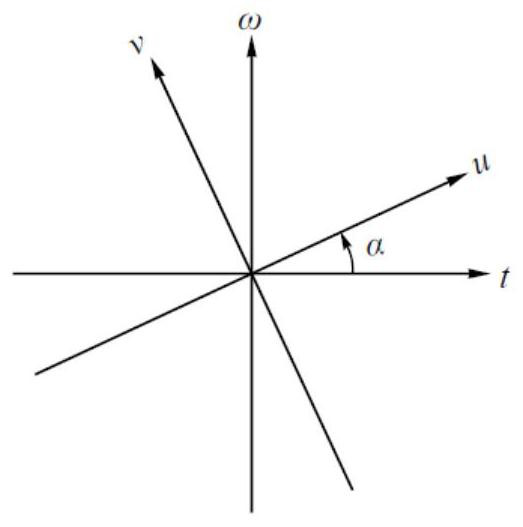

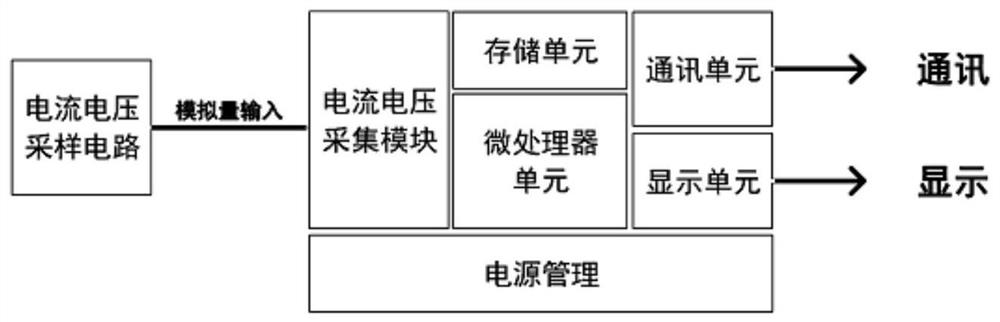

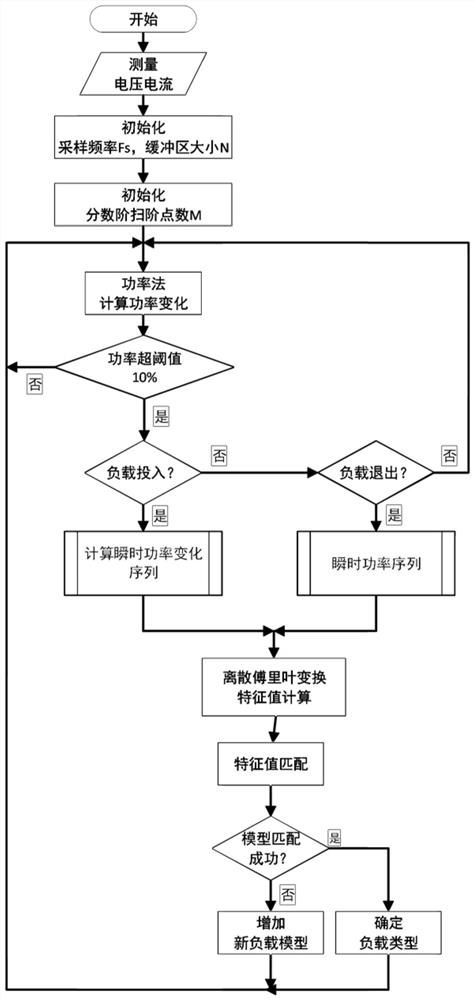

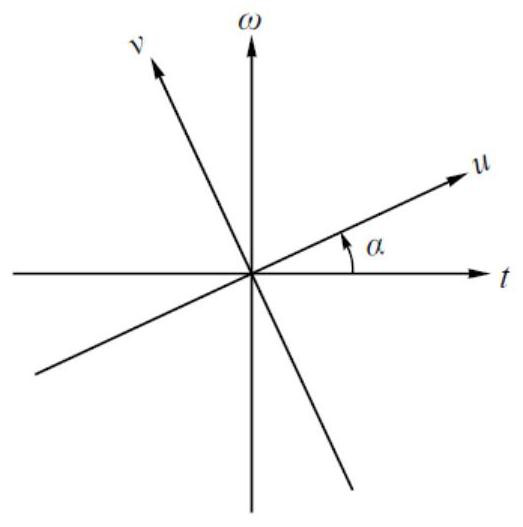

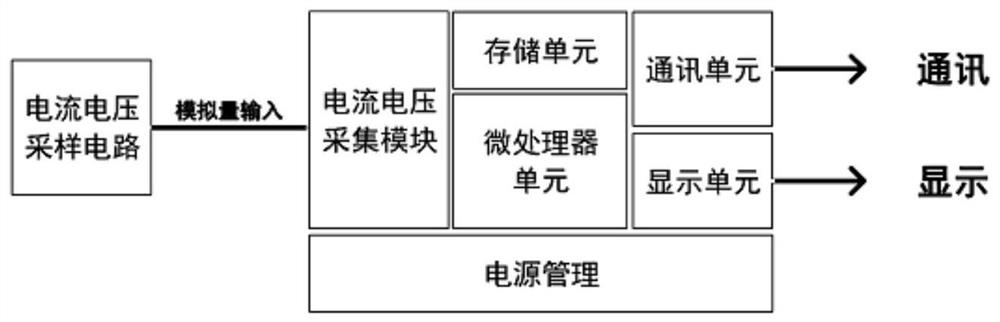

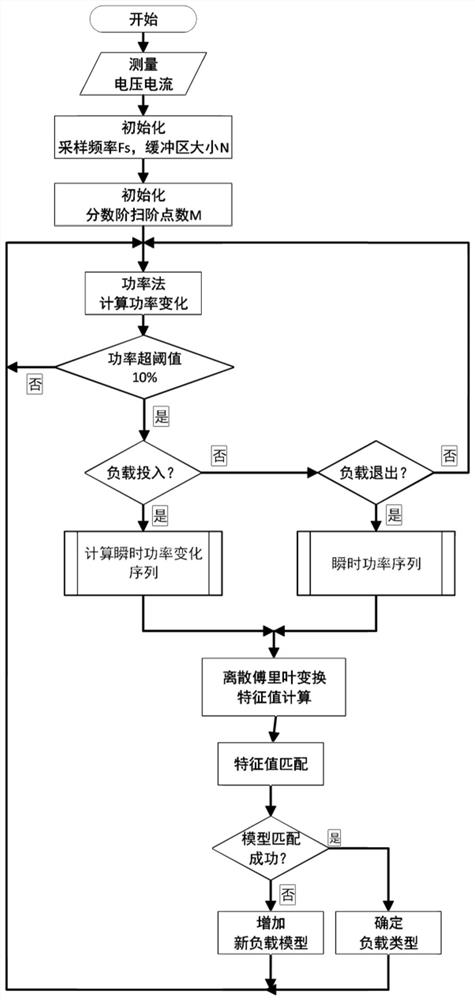

Non-intrusive load identification device and method based on Fourier transform

ActiveCN112924790ASafe and stable operationNo impact on productionSpectral/fourier analysisElectrical testingFeature vectorAlgorithm

The invention discloses a non-intrusive load identification device and method based on Fourier transform, and the method comprises the steps: judging the change of instantaneous power, analyzing the input and removal of a load, calculating the feature quantity extraction of the load when the load is input through the variable quantity of the load, and calculating the feature quantity extraction of the load after the load is removed through the instantaneous power after the load is removed. According to the method, a discrete fractional order Fourier transform algorithm is adopted to extract a load feature vector, key parameters required by transform are defined, the load feature vector and feature values of a feature library are subjected to amplitude and phase angle matching, and when an error is smaller than a tolerance range, matching is fed back; when the feature library is not matched, the feature vector is stored as a new load feature, and a notification is sent out; and compared with a traditional non-intrusive load recognition algorithm, the algorithm has the advantages of being high in precision and small in error.

Owner:上海逐鲨智能科技有限公司 +2

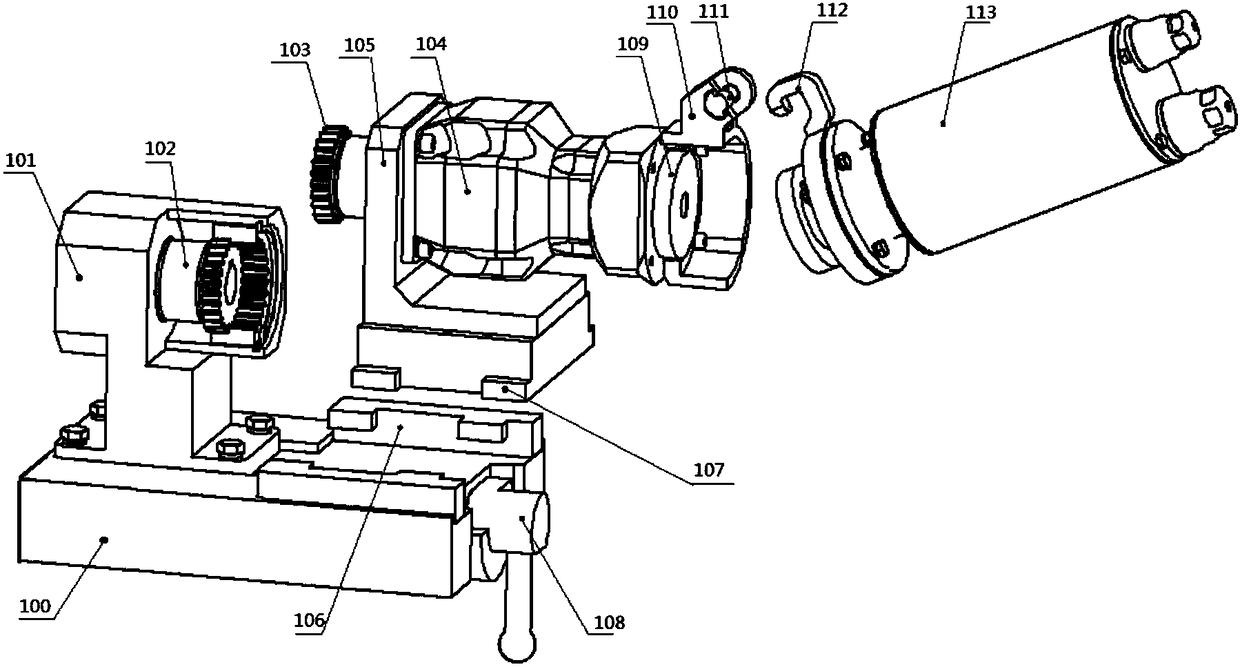

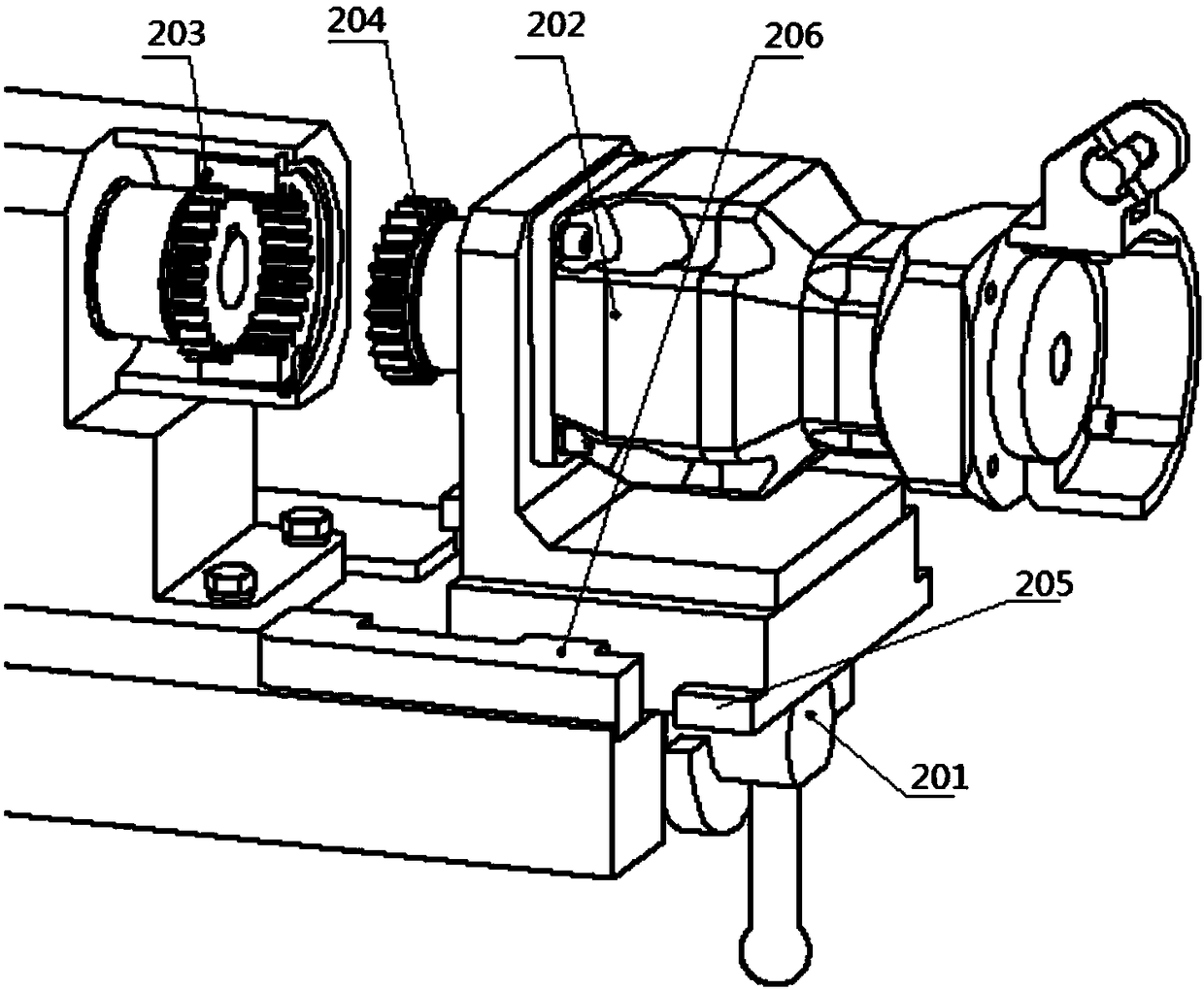

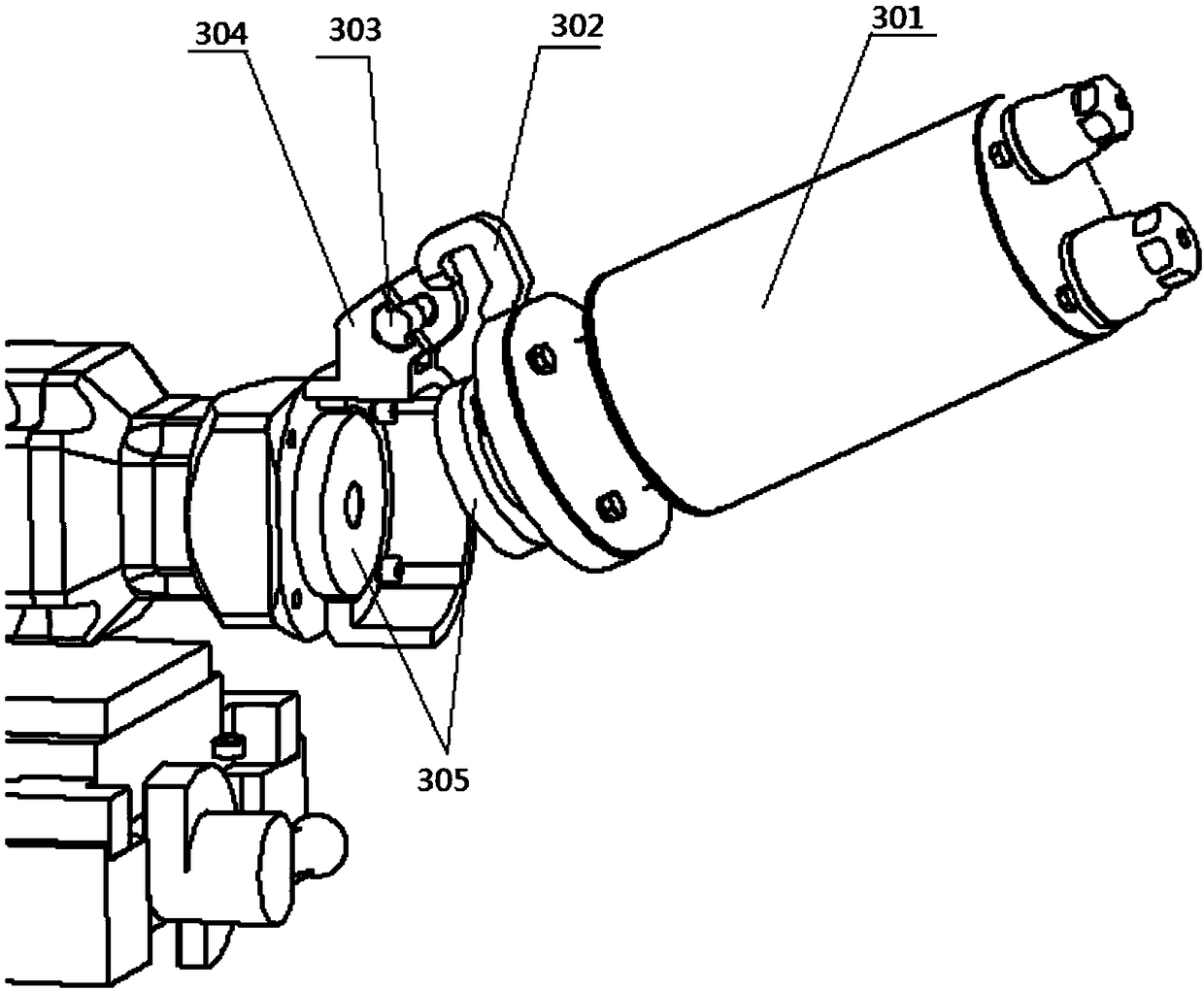

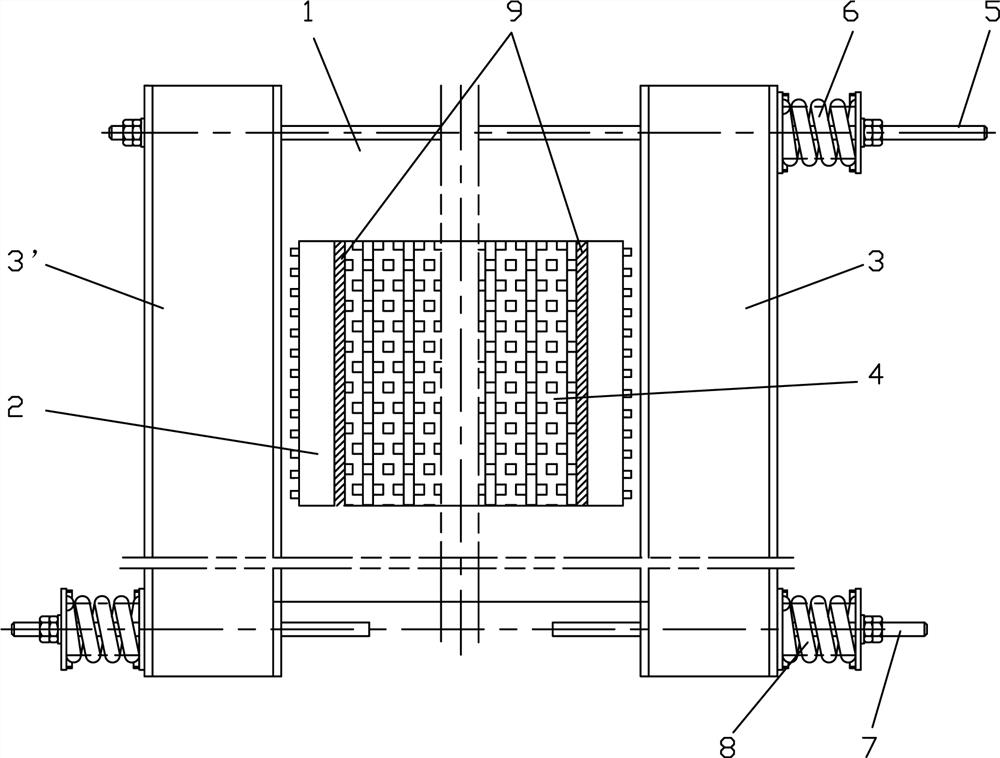

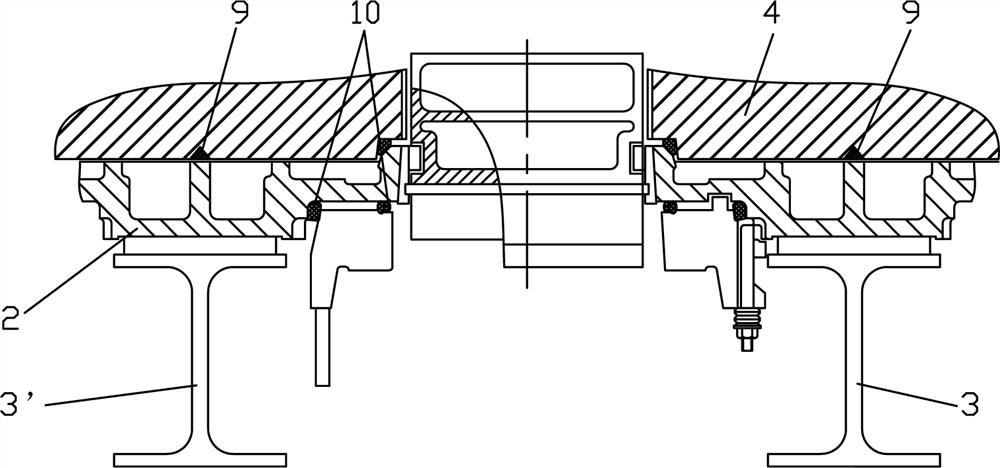

Power transmission device and disassembly method

PendingCN108591290ASolve replacement maintenance problemsFor quick replacementYielding couplingElectric machineCoupling

The invention discloses a power transmission device. The power transmission device comprises a base, a gear coupling, a speed reducer and a motor; the gear coupling comprises a first gear module and asecond gear module coaxially engaged through a connecting inner gear ring; the first gear module is fixed on one side of the top surface of the base; the second gear module is fixed at one end of thespeed reducer; a clamping groove is formed in the other side of the base; the speed reducer comprises a speed reducer body and a stand; a convex block cooperating with the clamping groove is arrangedat the bottom of the stand; and the end, far from the gear coupling, of the speed reducer is fixedly connected with the motor. The invention further provides a disassembly method of the power transmission device. The power transmission device can simply and conveniently replace the motor and the speed reducer without needing staff to enter a heat chamber, greatly reduces the personal safety risk,guarantees the personal safety, is short in replacement and maintenance time, and improves the production efficiency.

Owner:BEIJING XUANYU INTELLIGENT TECH CO LTD

Leakage Plugging and Emergency Rescue Method for Petrochemical Special Pipeline

The invention relates to a pipeline leaking stoppage recovery method, in particular to a special pipeline leaking stoppage recovery method for the petrochemical industry. The method comprises the following steps: using a disposable leak stopper to plug up a pipeline leaking point, wherein the disposable leak stopper is composed of an oil-proof, acid-proof and high-pressure resistant wedge-shaped sealing silicone ring, and a stainless steel wedge-shaped strapping ring with an opposite shape; cleaning oil stains and sundries on the pipeline around the disposable leak stopper, grinding the pipeline with a brush so as to show a matte surface on the surface of the pipeline, and then tightening the disposable leak stopper and the surrounding pipeline with a high-strength compression plugging adhesive tape; fixing a reinforced fixing socket, which is internally coated with a special high-strength compression plugging adhesive, outside the high-strength compression plugging adhesive tape to form a permanent plugging structure. The special pipeline leaking stoppage recovery method for the petrochemical industry can be implemented under pressure without production halt, has no influence on production, needs no evacuation and nitrogen replacement, needs no hot work, prevents fire and security risk, and is suitable for compression cold treatment plugging and physical plugging technologies of the petrochemical industry.

Owner:唐山迪华石油钻采设备有限公司

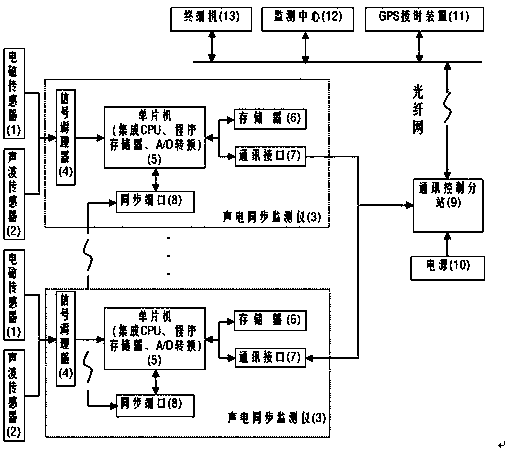

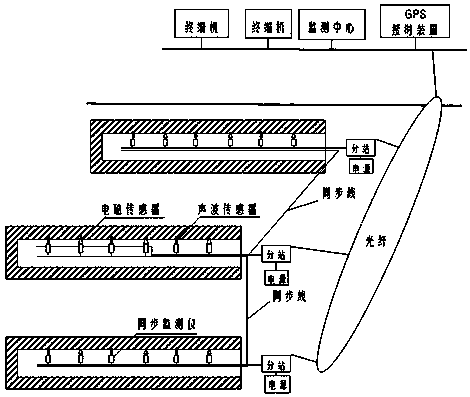

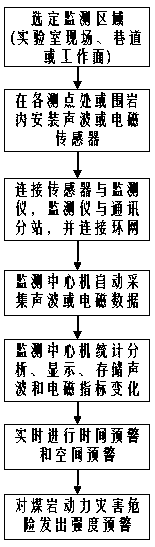

Distributed coal-rock dynamic disaster sound and electricity synchronous monitoring system and method

The invention discloses a distributed coal and rock dynamic disaster sound and electricity synchronous monitoring system and method, belonging to the synchronous monitoring system and method of sound and electricity. The electro-acoustic synchronous monitors of the monitoring system are connected by synchronous lines, the sound sensor or the electromagnetic sensor are connected with the input end of the electro-acoustic synchronous monitors, the output ends of the electro-acoustic synchronous monitors are connected with the communication control substation, and the power supply supplies power to the communication control substation and the electro-acoustic synchronous monitors. The electro-acoustic synchronous monitors are connected with a GPS timing device, a monitoring center and a monitoring terminal through the communication control substation and the optical fiber network, the system can simultaneously trigger the monitoring of sound waves and electromagnetic radiation signal. Via real-time multipoint monitoring and collecting waveforms of the acoustic signal and electromagnetic radiation signals generated by the coal-bearing rock, coal and rock dynamic disaster evolution process is reflected to send early warning according to signal changes; the position of the sound wave source and the electromagnetic anomaly area are located in real time, and the danger area can be determined according to their distribution. The distributed coal and rock dynamic disaster sound and electricity synchronous monitoring system is convenient to mount and move, and high in automation in monitoring, analysis and early warning.

Owner:CHINA UNIV OF MINING & TECH

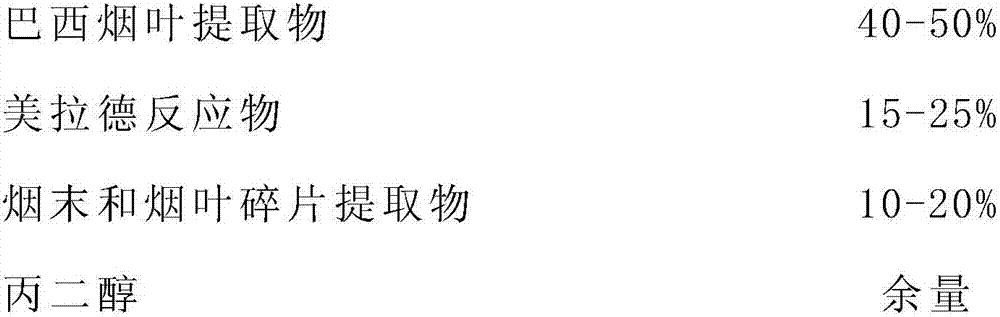

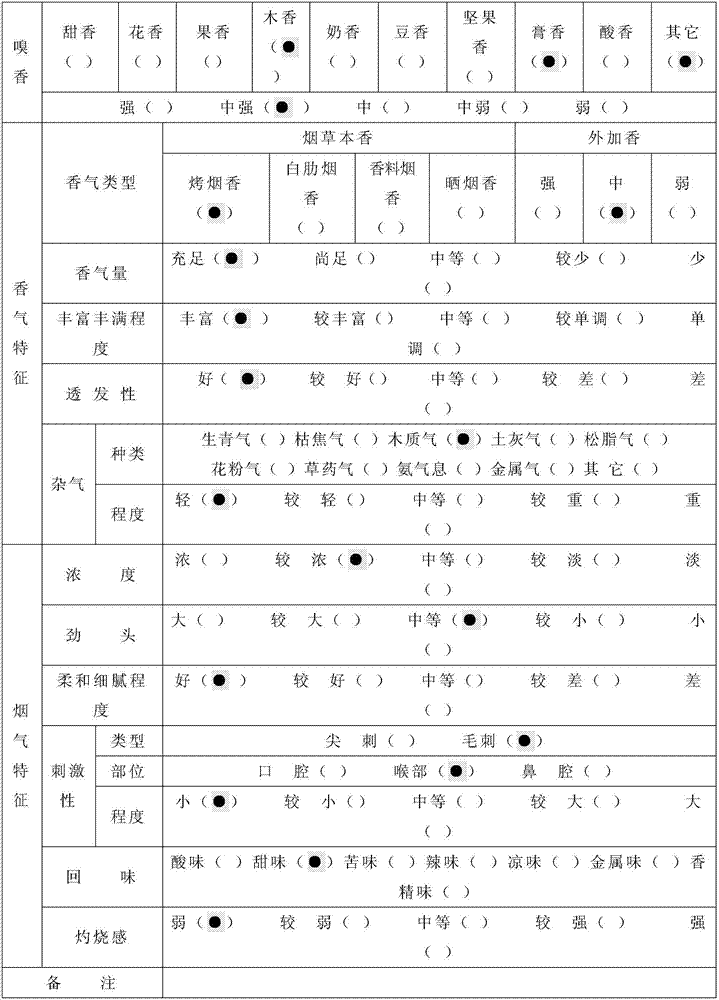

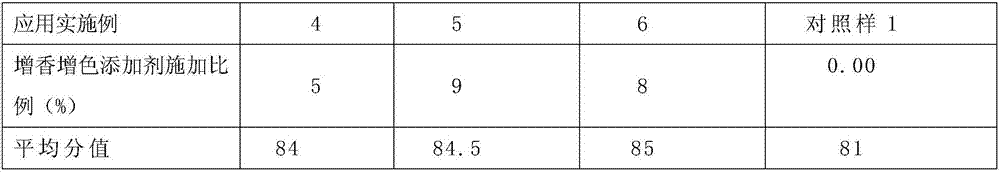

Flavoring additive for tobacco sheet and its preparation method and application

The invention provides an aroma-increasing additive used for a tobacco sheet as well as a preparation method and application thereof. The aroma-increasing additive used for the tobacco sheet is obtained by mixing Brazil tobacco leaf extract, Maillard reactant, tobacco powder and tobacco leaf fragment extract and propylene glycol, stirring and standing, wherein the Mailard reactant is obtained by carrying out reaction on purified water, glucose, praline, ammonia water with the concentration of 26% and caramel colour at specific temperature and under the regulation and has relative density of 1.1826 + / - 0.0080 (20 DEG C); and the tobacco powder and tobacco leaf fragment extract is obtained by extracting tobacco powder and tobacco leaf fragment with 50% ethanol, filtering, concentrating to the relative density of 1.3186 + / - 0.0080 (20 DEG C)and filtering again. When the aroma-increasing additive is added into coating liquid of the tobacco sheet, the problems that the tobacco sheet is dim in colour, aroma is missing and miscellaneous qi is strong can be effectively solved, aroma amount of tobacco in a suction process is increased, aroma texture is improved, and the miscellaneous qi is alleviated.

Owner:HUBEI CHINA TOBACCO IND

Safty injector with destroyable needle

InactiveCN100420492CFew partsEasy to assembleInfusion syringesInfusion needlesSyringe needleNeedle holder

A high-safety needle destroying unit for injector has an upper part which is a hollow cylindrical body with a central through hole and sleeve-jointed with needle holder, and a low part which is a hollow cylindrical body with open top end and closed bottom end, and connected with said upper part in rotary mode.

Owner:虞家珍

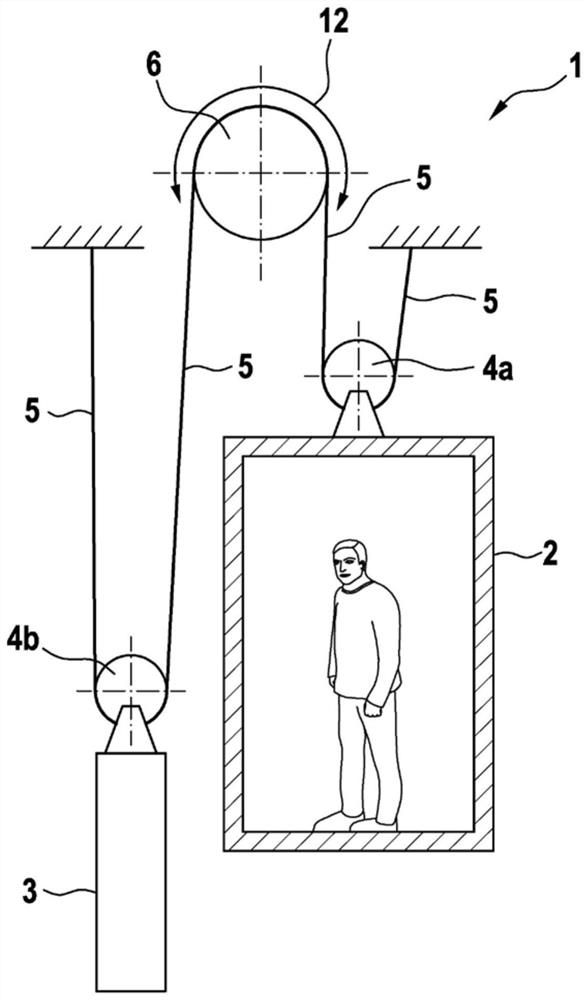

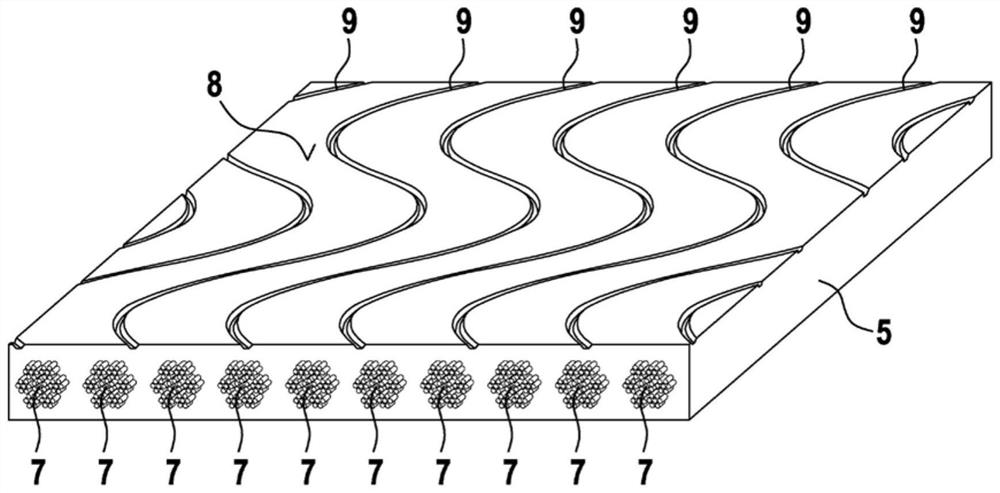

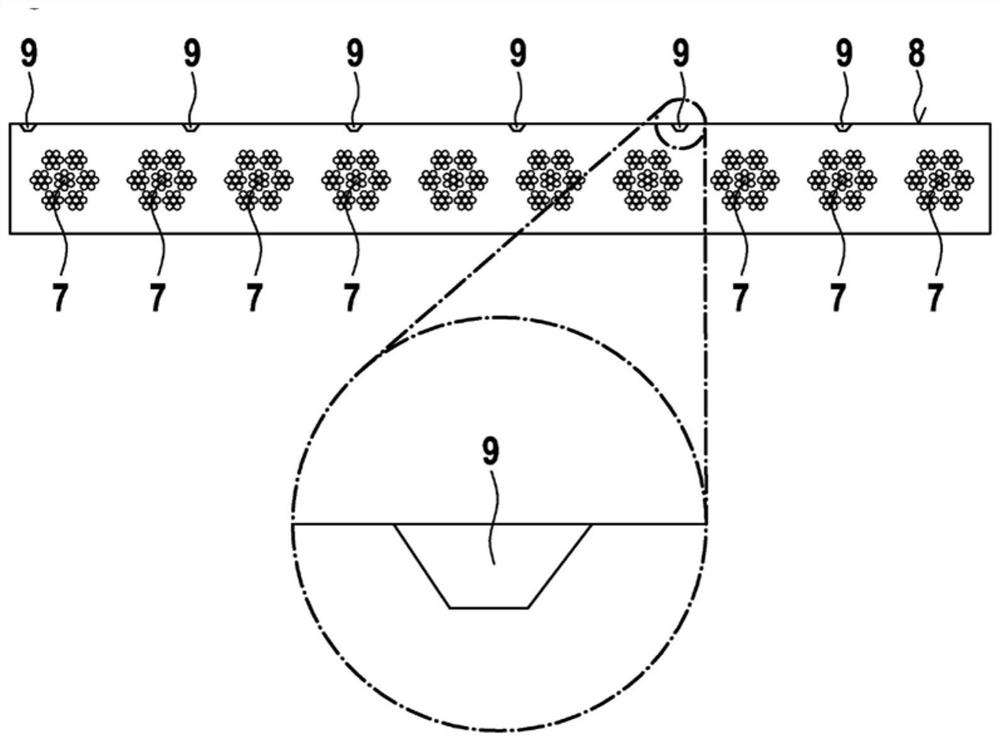

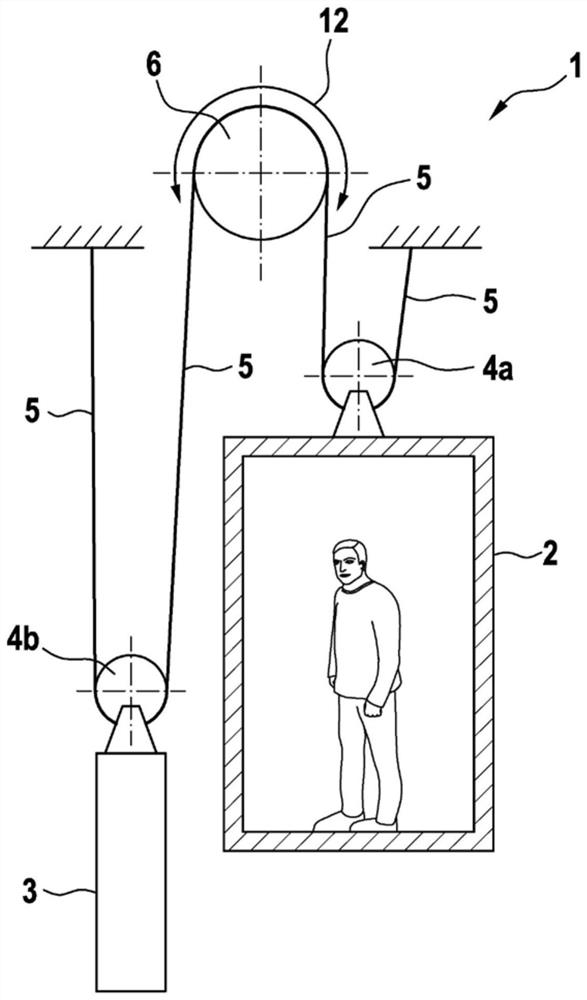

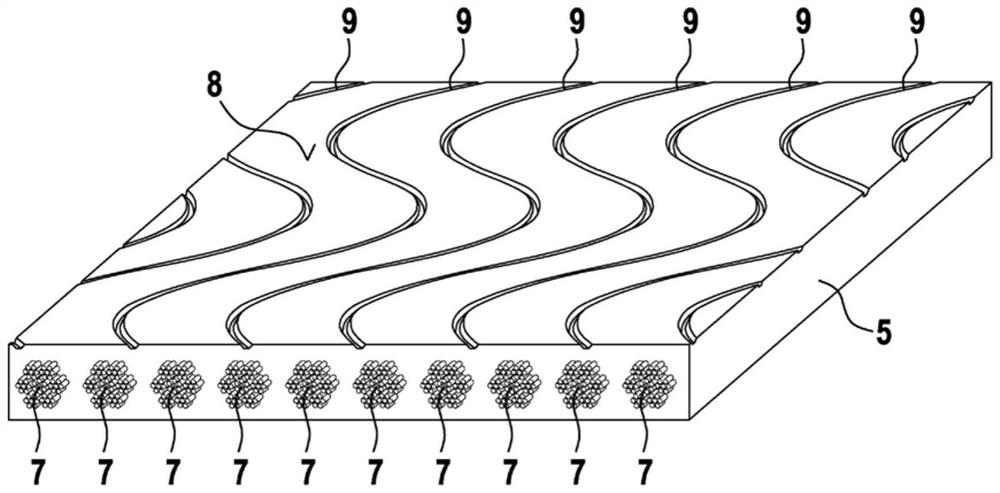

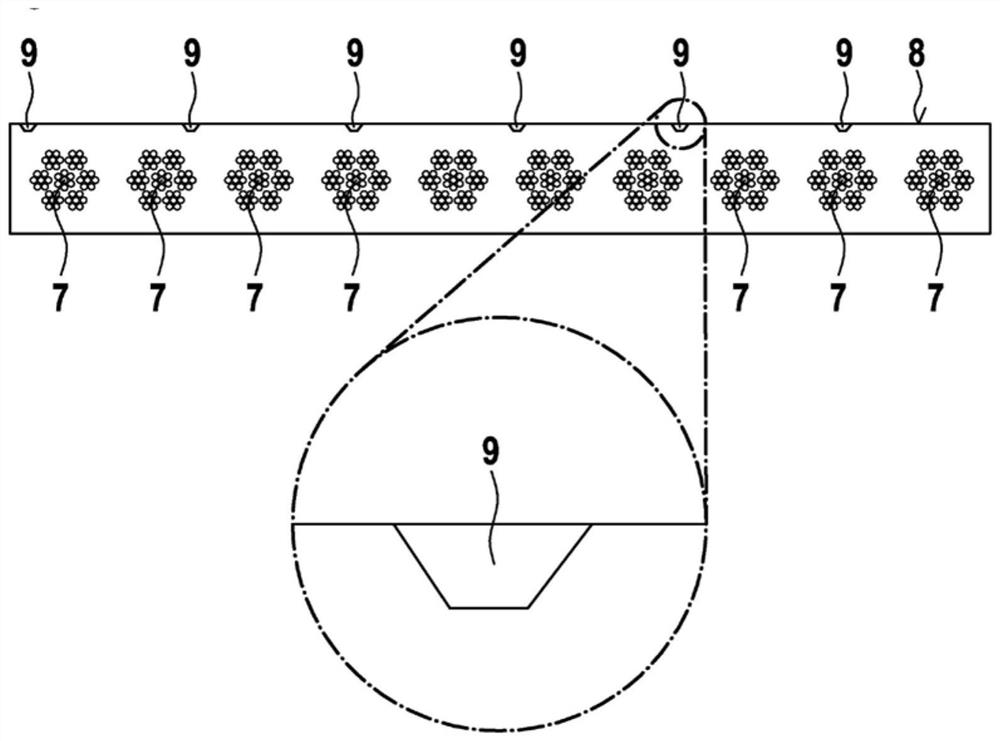

Tension belt or harness

Tension belt or harness made of elastic material with an essentially flat drive side, in particular an elevator belt, in which tension carriers or cords running parallel in its longitudinal direction are embedded in the elastic material of the tension belt or harness , and the tension belt or harness swivels around the pulleys and / or deflection rollers of the belt drive, thereby driving, turning or guiding the tension belt or harness, wherein the flat drive side of the tension belt or harness is provided with a or A plurality of grooves, wherein portions of the grooves extend with varying inclinations relative to the longitudinal direction of the belt and have a periodicity in the longitudinal direction of the belt, wherein, within one period, the orientation of the individual groove portions relative to the longitudinal direction or The inclination is formed such that the lateral force components induced by the orientation or inclination of the grooves and acting on the latter during the rotation of the belt are balanced.

Owner:CONTITECH ANTRIEBSSYST GMBH

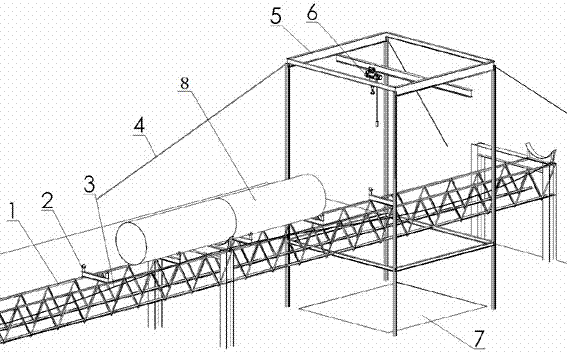

Installation tooling and installation method for large-span and large-diameter pipes on a roof

ActiveCN106121234BSolve the problem of maintenance and installationEasy to holdPipe laying and repairBuilding material handlingStructure of the EarthEngineering

The invention relates to a roof large-span large-diameter pipe installing tool and installing method. The installing tool comprises a truss, guide carrier rollers, a portal frame and an electric block. The portal frame is a rectangular frame structure formed from I-beams; the portal frame is arranged on a roof; the electric block is arranged at the top end of the portal frame; the truss is arranged on the roof after penetrating the portal frame. Each guide carrier roller comprises a pedestal and two roller wheels used for carrying and conveying pipes; the pedestal is fixedly arranged on the truss and the two roller wheels are arranged at the two ends of the pedestal; the distance between the two roller wheels is less than the diameter of the pipes. The truss penetrates pipe supports on the roof; the two roller wheels of each guide carrier roller are higher than the pipe supports on the roof; the roof is provided with a lifting opening at the portal frame. The problem in maintenance and installation of pipes on roofs that a hoist cannot be used at a large-span factory and the periphery thereof for hoisting is solved; the installing tool and the installing method have no influence on production in the factory.

Owner:GUANGXI METALLURGICAL CONSTR

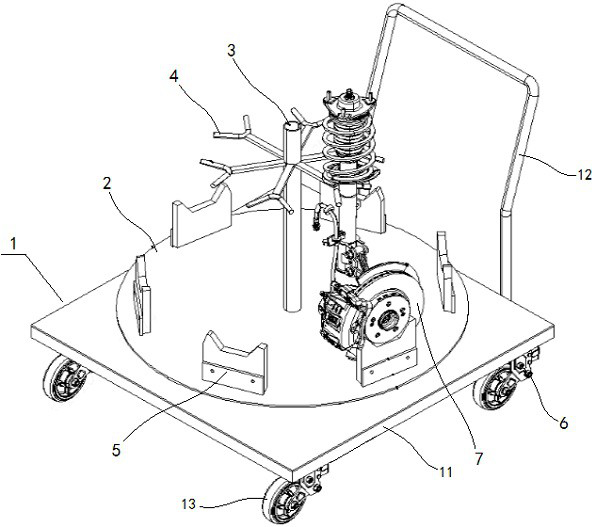

Storing, taking and transferring device and method for automobile sliding column brake assembly

InactiveCN112278027ASave man hoursImprove work efficiencySupporting partsHand carts with multiple axesRotational axisBrake

The invention relates to a storing, taking and transferring device and method for an automobile sliding column brake assembly, and is characterized in that the storing, taking and transferring devicecomprises a transferring trolley and a rotating platform, the rotating platform is rotatably arranged on the transferring trolley through a rotating shaft, and the rotating platform is fixedly connected with the rotating shaft; a plurality of brake disc fixing bases are evenly distributed on the rotating platform in the circumferential direction, a plurality of sliding column fixing frames are evenly distributed on the rotating shaft in the circumferential direction, and the brake disc fixing bases and the sliding column fixing frames are matched to work in a one-to-one correspondence mode. According to the device, the function of transferring the sliding column brake assembly is achieved, meanwhile, the problems that parts are inconvenient to store and take by operators and the efficiencyis low are solved, and the high efficiency of assembly is effectively guaranteed.

Owner:CHERY AUTOMOBILE CO LTD

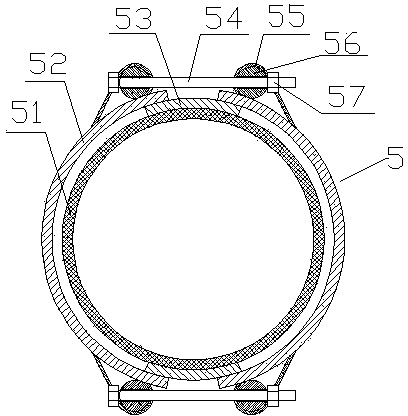

Connecting adjustment device of double-hearth lime kiln burning calcium carbide furnace tail gas

ActiveCN103708745BRealize comprehensive utilizationNo impact on productionWaste heat treatmentTorchHigh pressure

The invention relates to the field of application of calcium carbide furnace tail gas in lime burning, and particularly relates to a connecting adjustment device of a double-hearth lime kiln burning the calcium carbide furnace tail gas. The connecting adjustment device comprises a calcium carbide furnace tail gas pipeline, a coal gas pressing machine and a low-pressure main pipe, wherein the calcium carbide furnace tail gas pipeline is connected to a gas outlet of a calcium carbide furnace, the coal gas pressing machine is connected to the double-hearth lime kiln through a high-pressure main pipe, and the low-pressure main pipe is connected to a gas inlet of the coal gas pressing machine and is communicated with the calcium carbide furnace tail gas pipeline; and the connecting adjustment device also comprises a first set of adjustment device and a second set of adjustment devices, wherein the first set of adjustment device comprises a first diffusion pipeline, a pneumatic control valve, a first tempering prevention device and a first flame combustor, the first diffusion pipeline is communicated with the low-pressure main pipe, the pneumatic control valve and the first tempering prevention device are arranged on the first diffusion pipeline from bottom to top, the first flame combustor is arranged at the end part of the first diffusion pipeline, and a first electronic burning torch and a first flame detectors are arranged in the first flame combustor.

Owner:北京嘉永会通能源科技有限公司

A low-cost slag washing method

The invention belongs to the technical field of iron and steel metallurgy and in particular relates to a low-cost slag washing method. The low-cost slag washing method comprises the following steps: producing synthetic slag for slag washing in a steel ladle, obtained by casting molten steel, by utilizing refining slag and a deoxidant; then utilizing the produced solid-state synthetic slag with relatively high temperature for slag washing operation of a steel tapping process of the next heat. The method provided by the invention has a simple technology and is low in cost; the consumption of slag production materials is less and the heat of the refining slag is recycled; smooth production is not influenced; compared with cyclic utilization of heat-state refining slag, the low-cost slag washing method has remarkable advantages. Sulfur is effectively removed.

Owner:SHANDONG IRON & STEEL CO LTD

Non-intrusive load identification method based on Fourier transform using non-intrusive load identification device

ActiveCN112924790BSafe and stable operationNo impact on productionSpectral/fourier analysisElectrical testingFeature vectorAlgorithm

The invention discloses a non-intrusive load identification device and method based on Fourier transform. By judging the change of instantaneous power, analyzing the input and removal of load, and using the variation of load to calculate the feature quantity extraction when the load is input , use the instantaneous power after load removal to calculate the feature quantity extraction after load removal; the present invention uses discrete fractional Fourier transform algorithm to extract the load feature vector, and defines the key parameters required for the transformation, and combines the load feature vector with the feature library The eigenvalues are matched in terms of amplitude and phase angle. When the error is less than the tolerance range, the feedback is matched; when there is no match in the feature library, the eigenvector will be saved as a new load feature and a notification will be issued; Compared with the traditional non-intrusive load identification algorithm, this algorithm has the characteristics of high precision and small error.

Owner:上海逐鲨智能科技有限公司 +2

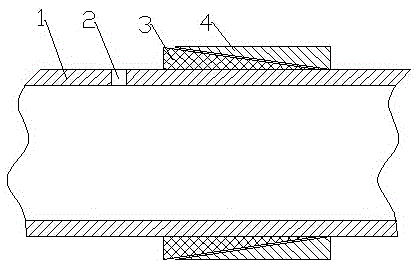

Repair method for external corrosion defect of submarine pipeline

InactiveCN113915454AEffective protectionChange natureThermal insulationCorrosion preventionAlkali freeLap joint

The invention discloses a maintenance method for an external corrosion defect of a submarine pipeline. The maintenance method comprises the following step (1) of polishing and cleaning the corrosion defect; the step (2) of filling corrosion pits cleaned in the step (1) with repair agents, pressing and trowelling the corrosion pits, and removing seawater; (3) the corrosion defect position of a pipe wall is wound in a lap joint mode through an alkali-free glass fiber belt coated with binders on the front side and the back side; and (4) the corrosion defect position of the pipe wall in the lap joint mode is wound through a reinforced winding belt, and therefore the yield strength of the corrosion defect position is recovered to the state before corrosion; the step (5) of installing a grouting mold at a repair area when the reinforced winding belt reaches the curing hardness, then pouring high-strength cement to remove seawater, till the grouting operation is completed after grout is returned from a grout return port; and forming a concrete balance weight insulation protection layer after the high-strength cement is solidified, and finishing maintenance. According to the repair method, the corrosion development can be effectively controlled; the pipeline property is not changed, the integrity of the pipeline can be kept, and magnetic flux leakage detection is facilitated; the construction is convenient; the requirement for construction resources is low; and the construction cost is low.

Owner:中海石油技术检测有限公司

Online production coke oven combustion chamber furnace end sealing method

ActiveCN113462403ASeal reachedEffective blockingCoke oven doors/closuresCombustion chamberCarbonization

An online production coke oven combustion chamber furnace end sealing method comprises the following steps: 1) drilling a combustion chamber furnace end; 2) performing air pressure sealing on the combustion chamber furnace end; and 3) grouting the combustion chamber furnace end to make the slurry extend into the bottom of a drilled hole in the combustion chamber furnace end through a slurry spraying pipe, and grouting for the second time till complete sealing is achieved; and then blocking the grouting hole by castable, knocking ceramic fiber ropes into a protection plate and the upper portion of the furnace end, and then building upper furnace end bricks. According to the method, sealing material injection, high-fluidity grouting material pouring and grouting material press-in are conducted between the combustion chamber furnace wall furnace end and the large protection plate, large and small gaps caused by long-time production between the carbonization chamber furnace end and the protection plate are effectively blocked, therefore, furnace end sealing is achieved, raw gas overflow is avoided, and the working environment is protected.

Owner:BAOSHAN IRON & STEEL CO LTD

Unqualified bottled beer recovery treatment device

InactiveCN103910316BRealize rational utilizationAvoid handlingFlanged caps removalBottle emptyingProduct inspectionEnvironmental engineering

The invention provides a recycling device of unqualified bottled beer. The recycling device of unqualified bottled beer comprises an unqualified bottled beer feeding system, a bottle uncapping and beer pouring system, and a storage and discharge system. The unqualified bottled beer feeding system is disposed at the front end of the bottle uncapping and beer pouring system; the storage and discharge system is disposed at the rear end of the bottle uncapping and beer pouring system. The recycling device of unqualified bottled beer can be connected to a 'finished product inspection' link of a beer production line; inferior-quality products on the production line are fed into th device; separated glass bottles and beer are discharged; the glass bottles and beer are subjected to certain treatment and can be fed into an original beer production system, a closed-loop system is formed, and resources are reasonably utilized. The recycling device of unqualified bottled beer has the advantages that the storage and discharge system is provided, the inferior-quality products occurring in the production process are directly treated in the corresponding recycling device, unnecessary carrying of the inferior-quality products is avoided, and risk of bottle bodies being damaged is lowered.

Owner:SHANGHAI JIAO TONG UNIV

Tension belt or hanging belt

A tension belt or a hanging belt is made of an elastic material, and has a substantially flat drive side, in particular an elevator belt, wherein tension carriers or cords extending in parallel in thelongitudinal direction of the tension belt or sling are embedded in the elastic material of the tension belt or sling. The tension belt or the lifting belt surrounds a belt wheel and / or a steering roller of the belt transmission device in a rotary manner; therefore, the tension belt or the lifting belt is driven, turned or guided; the flat driving side of the tension belt or the hanging belt is provided with one or more grooves; some parts of the groove extend at a variable inclination relative to the longitudinal direction of the belt and have periodicity in the longitudinal direction of thebelt; wherein, in one period, the orientation or inclination of each groove part relative to the longitudinal direction is formed in such a way that a transverse force component, which is caused by the orientation or inclination of the groove and acts on the latter during the rotation of the belt, is balanced.

Owner:CONTITECH ANTRIEBSSYST

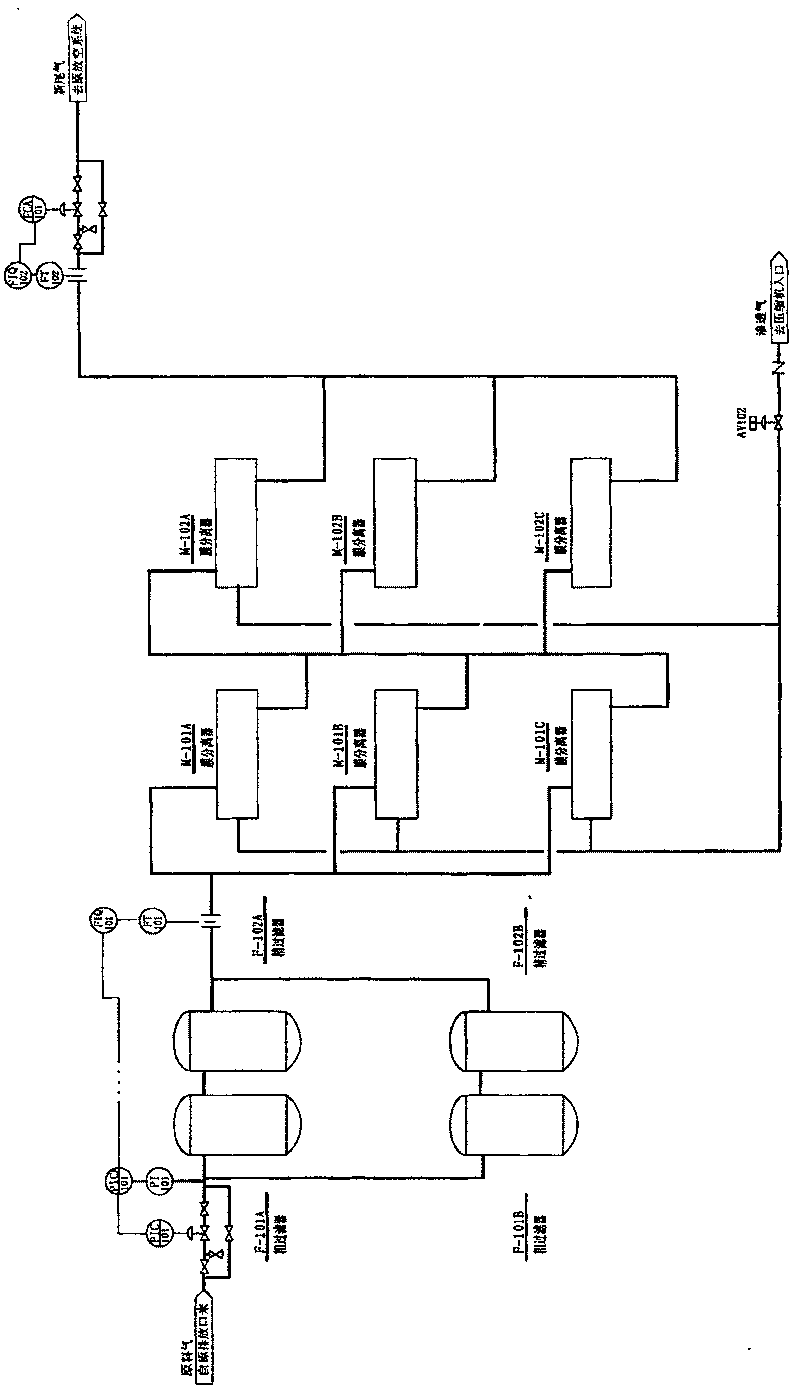

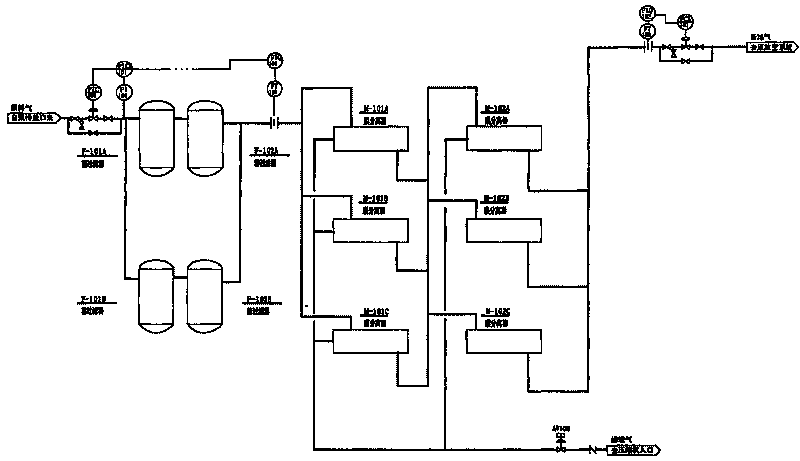

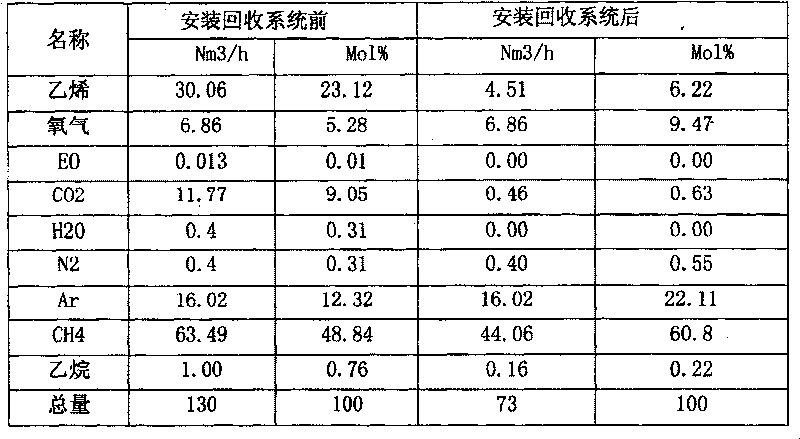

Process of recovering ethylene and methane from emptying end gas of glycol apparatus

ActiveCN101012144BReduce pollutionReduce consumptionMembrane purification/separationEthylene oxideSolid particle

The invention discloses a recycling technique of ethylene and methane in the organic compound manufacturing course, which comprises the following steps: transmitting tail gas of washing tower top intorough filter F-101; sieving through 40-order screen; transmitting into fine filter F-102; sieving through 60-order screen; removing solid particle; passing one-grade film separator M-101 and two-grade film separator M-102; obtaining permeatible gas with ethylene and methane; recycling; boosting through compressor; returning to decarburizing system of ethandiol device; obtaining new tail gas; transmitting into blow-down system; draining into atmosphere through torch.

Owner:中石油吉林化工工程有限公司

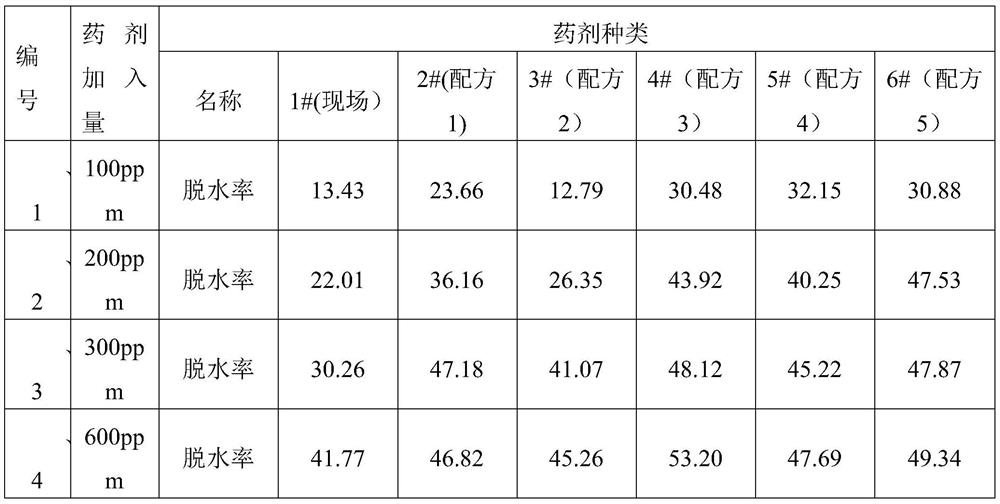

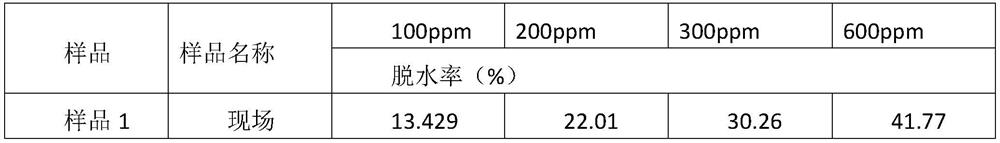

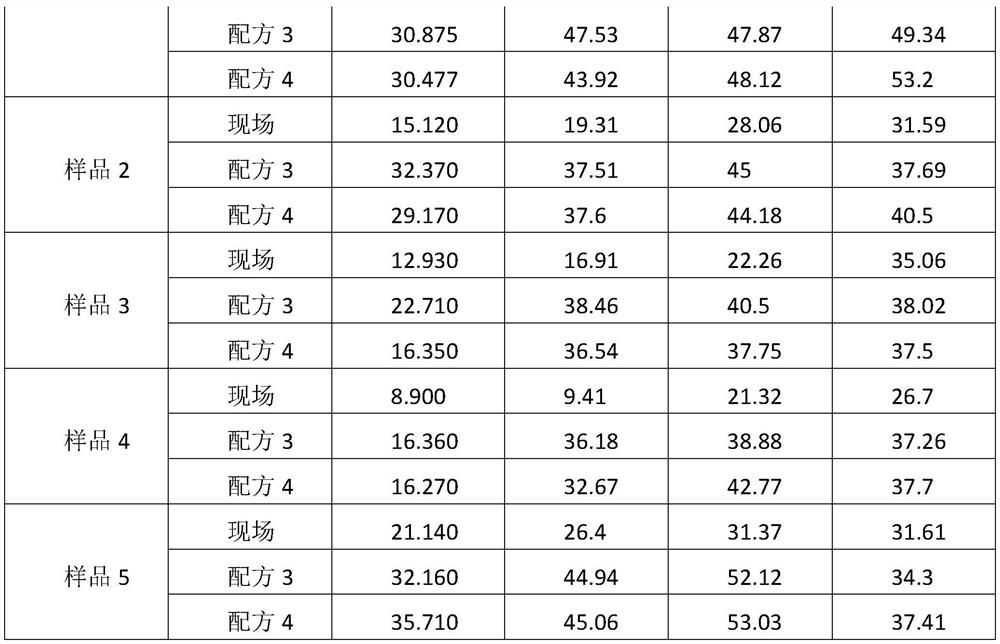

Dehydrating agent for aluminum hydroxide and preparation method thereof

PendingCN113499758AGood effectReduce unit consumptionAluminium compoundsOther chemical processesChemical compositionAluminium hydroxide

The invention discloses a dehydrating agent for filtration in an aluminum oxide production process and a preparation method thereof. The dehydrating agent comprises the following components in percentage by weight: 7-15% of a nonionic surfactant, 2-4% of a zwitterionic surfactant, 7-15% of an anionic surfactant, 1-2% of an auxiliary agent, 0.5-2% of an organic amine salt active agent and the balance of water. The dehydrating agent disclosed by the invention is strong in dehydrating effect, green, low in foam and low in cost. The dehydrating agent can change the physical property and chemical composition of the material surface, destroy the structure formed by aluminum hydroxide and water, and effectively reduce the surface tension of water, thereby improving the dehydration performance of aluminum hydroxide. Meanwhile, due to the addition of the auxiliary agent, the surface tension of the dehydrating agent during action is effectively reduced, and the foaming capacity of the surfactant in the dehydrating process is effectively inhibited, so that the dehydrating agent has low foam.

Owner:中铝中州铝业有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com