Special pipeline leaking stoppage recovery method for petrochemical industry

A petrochemical and pipeline technology, applied in the direction of pipe components, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of large fire, explosion risk, reduction of overall compressive strength, and large impact on production and operation, to prevent fire , the effect of safeguarding risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

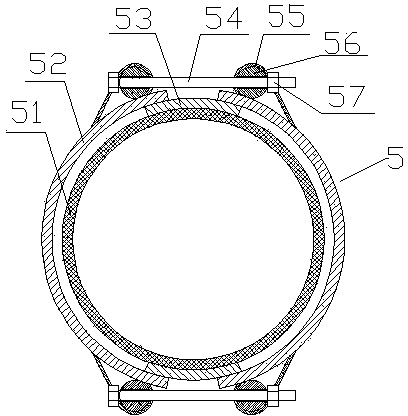

[0023] The present invention will be described in detail below through the accompanying drawings and examples. The examples given are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0024] The leak plugging and emergency rescue method for petrochemical special pipelines described in this embodiment is suitable for the petrochemical industry, with pressure and cold treatment plugging and physical leak plugging processes. The specific steps are as follows:

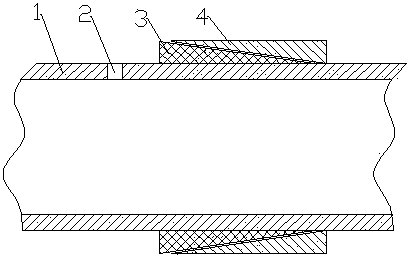

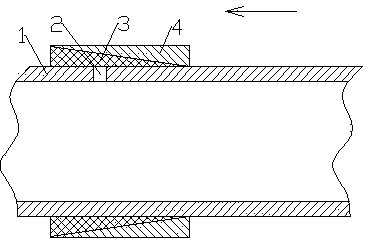

[0025] Step 1, use a leak stopper to plug leak point 2 on pipeline 1:

[0026] (1) Prepare a primary leak stopper. The primary leak stopper is composed of an oil-proof, acid-proof, high-pressure-resistant wedge-shaped sealing silicone ring 3 and a stainless steel wedge-shaped binding ring 4 with opposite shapes. Wrap the wedge-shaped sealing silicone ring 3 on the leak point 2 Near the pipeline, wrap the stainless steel we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com