Connecting adjustment device of double-hearth lime kiln burning calcium carbide furnace tail gas

A technology of calcium carbide furnace tail gas and double-chamber lime kiln is applied in the field of calcined lime, which can solve the problem of high cost performance, achieve the effects of reducing investment, comprehensive utilization of energy saving and environmental protection, and avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

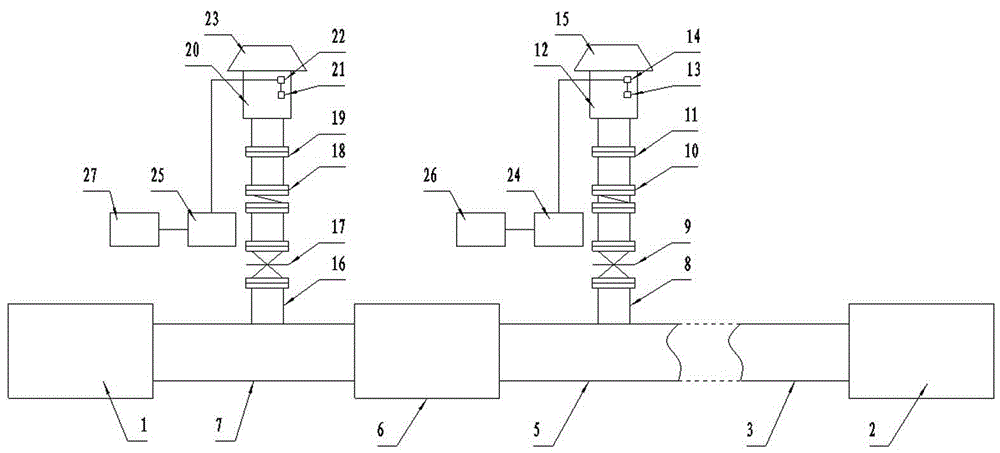

[0014] The connection adjustment device for calcium carbide furnace tail gas used in gas-fired double-chamber lime kiln, including calcium carbide furnace tail gas pipeline 3 connected to the gas outlet of calcium carbide furnace 2, gas pressurizer 6 connected to double-chamber lime kiln 1 through high-pressure main pipe 7, Connected to the low-pressure main pipe 5 of the air inlet of the gas pressurizer 6, the low-pressure main pipe 5 communicates with the tail gas pipeline 3 of the calcium carbide furnace, and the connection regulating device also includes a first group of regulating devices and a second group of regulating devices, the first The group regulating device includes the first discharge pipe 8 connected to the low-pressure main pipe 5, the pneumatic regulating valve 10 installed on the first discharge pipe 8 from bottom to top, and the first flashback preventer 11 installed at the end of the first discharge pipe 8 The first flame combustion chamber 12 in the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com