Tension belt or hanging belt

A belt and tension technology, applied in belts/chains/gears, transmission belts, textile cables, etc., can solve problems such as target conflicts, difficulties, noise emission effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

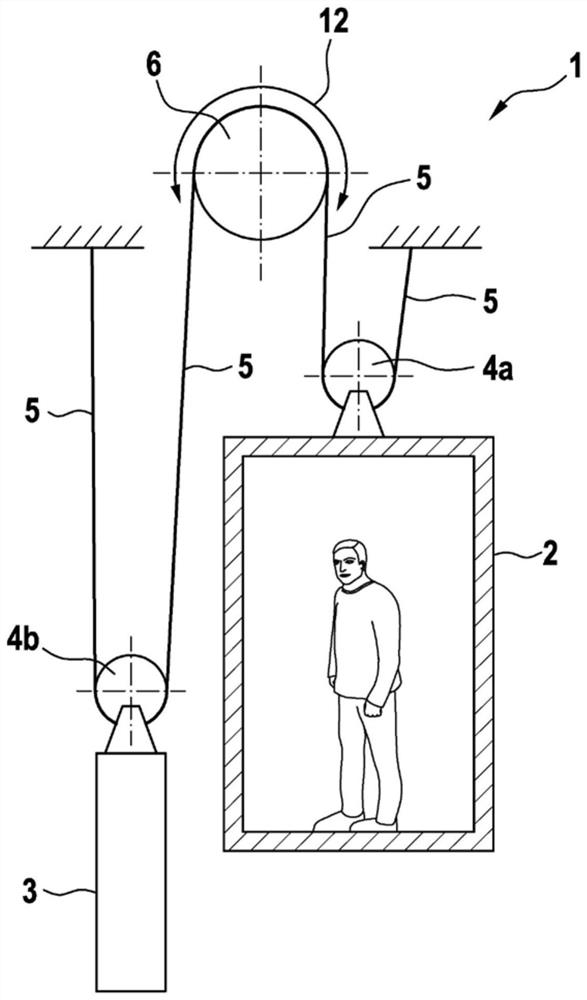

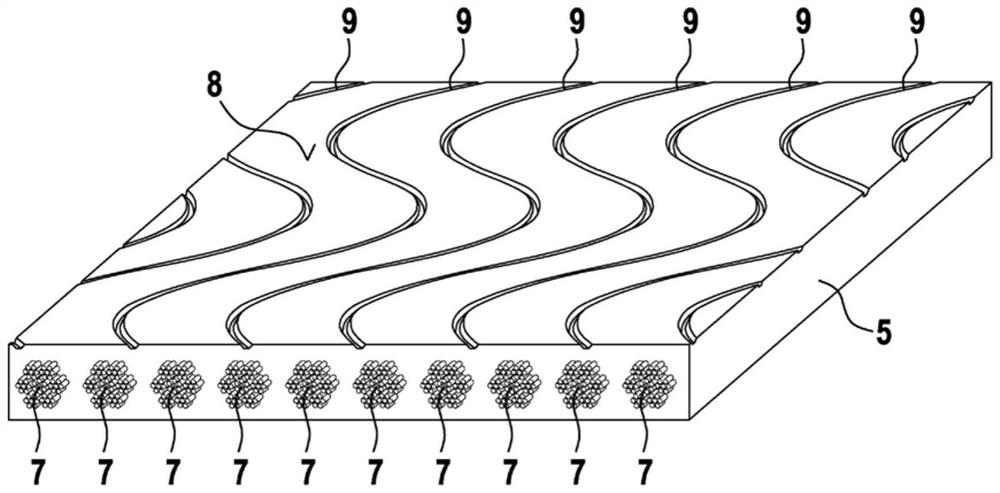

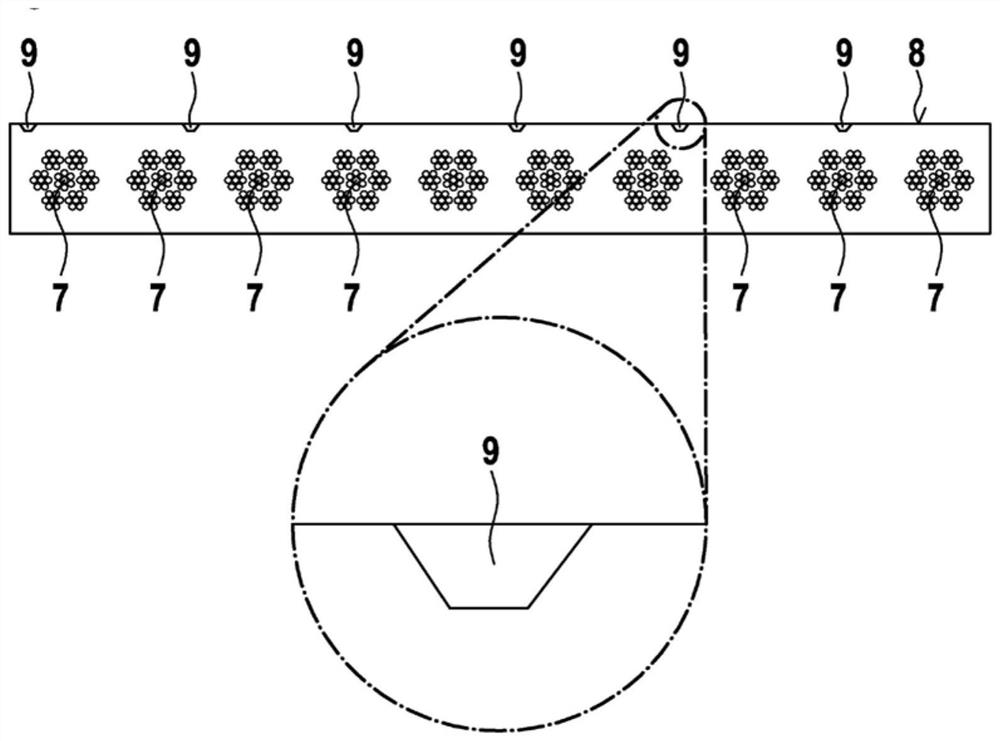

[0032] figure 1 The use of a flat belt according to the invention within an elevator system 1 is shown in schematic form. This is an elevator system / lifting device in the form of a 2:1 suspension in which the belt ends are fastened to the shaft head of the elevator shaft. The car 2 and the counterweight 3 are respectively suspended by means of deflection rollers 4a, 4b on straps formed as flat belts 5 .

[0033] The suspension belt made of elastomer material has a flat drive side 8 and is driven by a traction or drive pulley 6 driven by a motor, not further shown, which is arranged between the car and the counterweight in the upper region of the elevator shaft . From this a simple pulley block was created. As a result, the travel speed of the flat belt 5 is twice the travel speed of the car 2 . The pulling force is transmitted to the drive wheel 6 by surrounding friction. The deflection rollers 4 a and 4 b are also surrounded in a rotational manner by the flat belt 5 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com