Flavoring additive for tobacco sheet and its preparation method and application

A tobacco sheet and additive technology, which is applied in the directions of tobacco, application, and treatment of tobacco, can solve the problems of no special provision of tobacco sheet color, little research on tobacco sheet flavor and color, dull color of the sheet, etc., so as to improve the dull color and cost. Inexpensive, aroma and texture-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

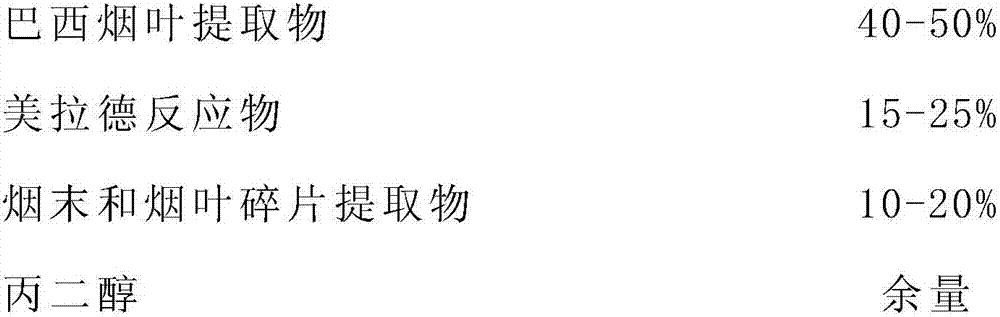

[0032] Embodiment 1, a kind of preparation method of flavoring additive for tobacco sheet, concrete steps are as follows:

[0033] (1) Prepare raw materials according to the following components by weight percentage: 42% of Brazilian tobacco leaf extract, 18% of Maillard reaction product, 12% of tobacco dust and tobacco leaf fragment extract, 28% of propylene glycol; Flavoring and coloring additives for tobacco sheets, the above-mentioned raw materials of Brazilian tobacco leaf extract and propylene glycol are commercially available products.

[0034] (2) After mixing the above raw materials, put them into a reaction kettle with a stirring device, stir, the stirring speed is 200r / min, and the stirring time is 2h. After stirring, let it stand for 1h, and then fill it to obtain the thin film. Flavor and color additive A, spare.

Embodiment 2

[0035] Embodiment 2, a kind of preparation method of flavoring additive for tobacco sheet, concrete steps are as follows:

[0036] (1) Prepare raw materials according to the following components by weight percentage: Brazilian tobacco leaf extract 48%, Maillard reaction product 22%, tobacco powder and tobacco leaf fragment extract 18%, propylene glycol 12%, in the above-mentioned raw materials, Brazilian tobacco leaf extract, Propylene glycol is a commercially available product;

[0037] (2) After mixing the above raw materials, put them into a reaction kettle with a stirring device, stir them, the stirring speed is 200r / min, and the stirring time is 2.5h. After stirring, let them stand for 1.5h, and then fill them to obtain the described Thin slices use flavoring and coloring additive B, set aside.

Embodiment 3

[0038] Embodiment 3, a kind of preparation method of flavoring additive for tobacco sheet, concrete steps are as follows:

[0039] (1) Prepare raw materials according to the following components by weight percentage: Brazilian tobacco leaf extract 45%, Maillard reaction product 20%, tobacco powder and tobacco leaf fragment extract 15%, propylene glycol 20%, in the above-mentioned raw materials, Brazilian tobacco leaf extract, Propylene glycol is a commercially available product;

[0040] (2) After mixing the above raw materials, put them into a reaction kettle with a stirring device, stir, the stirring speed is 150r / min, and the stirring time is 3h. After stirring, let it stand for 2h, and then fill it to obtain the thin film. Flavor and color additive C, spare.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com