Patents

Literature

33results about How to "Reliable exhaust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

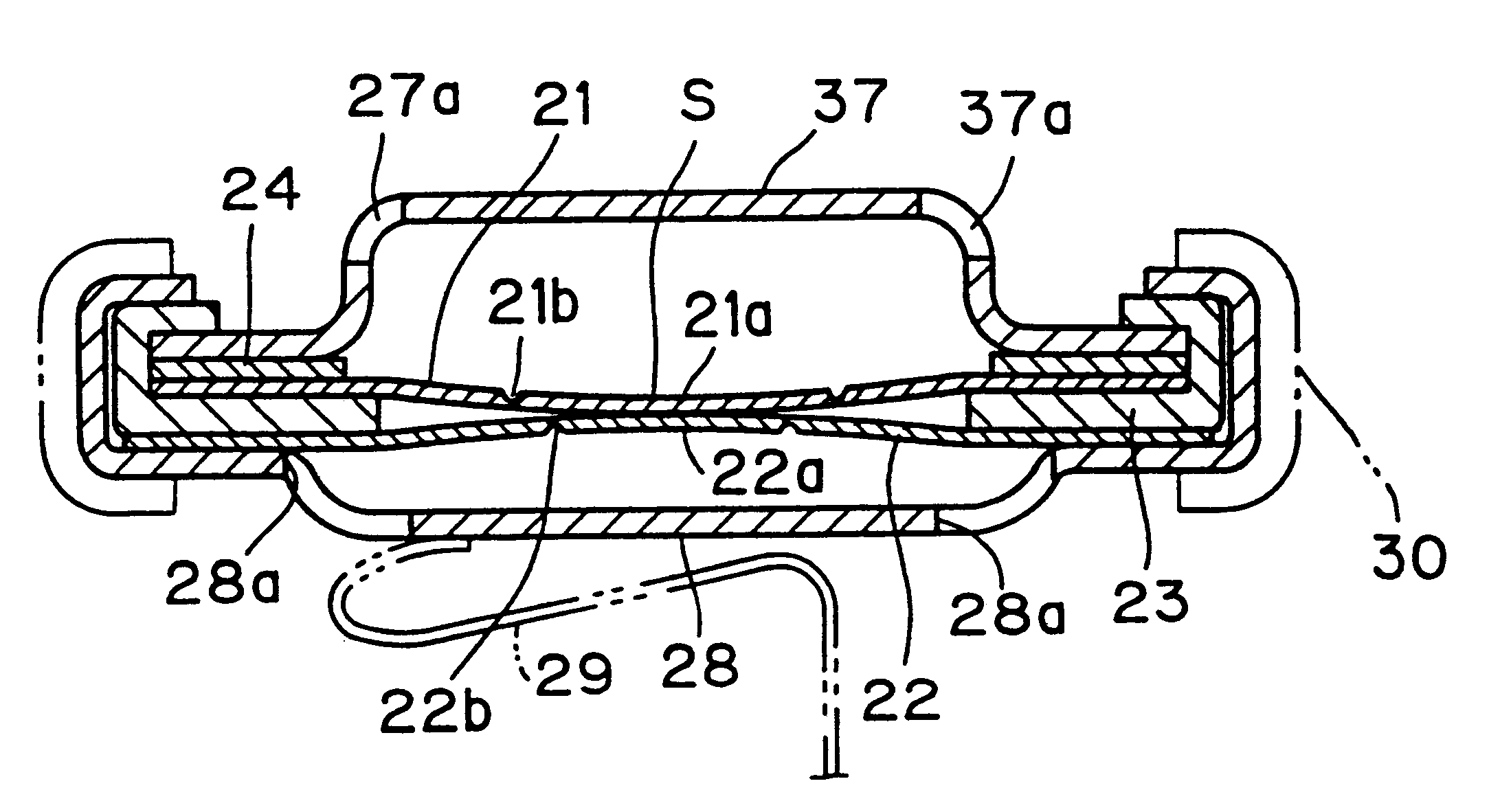

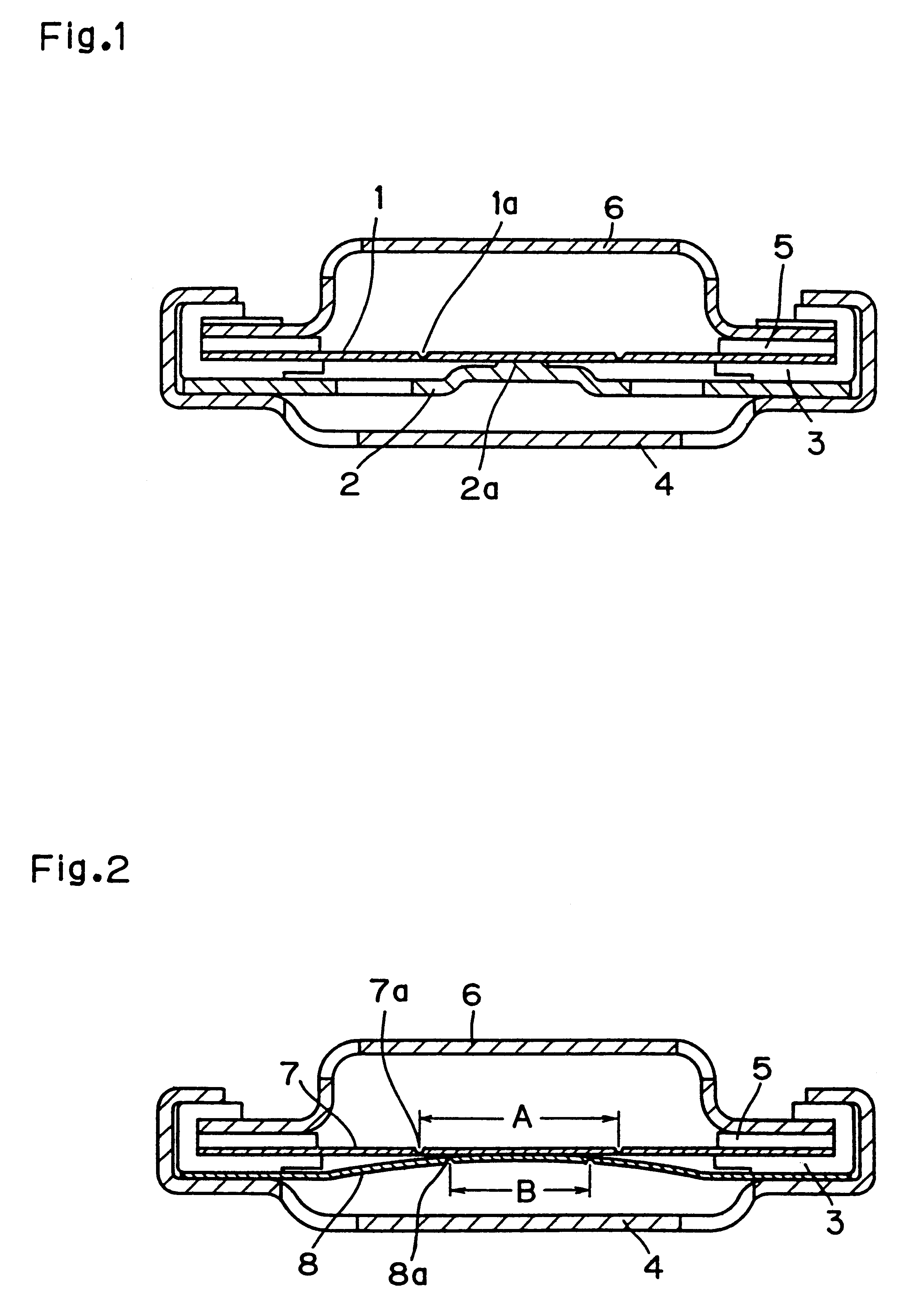

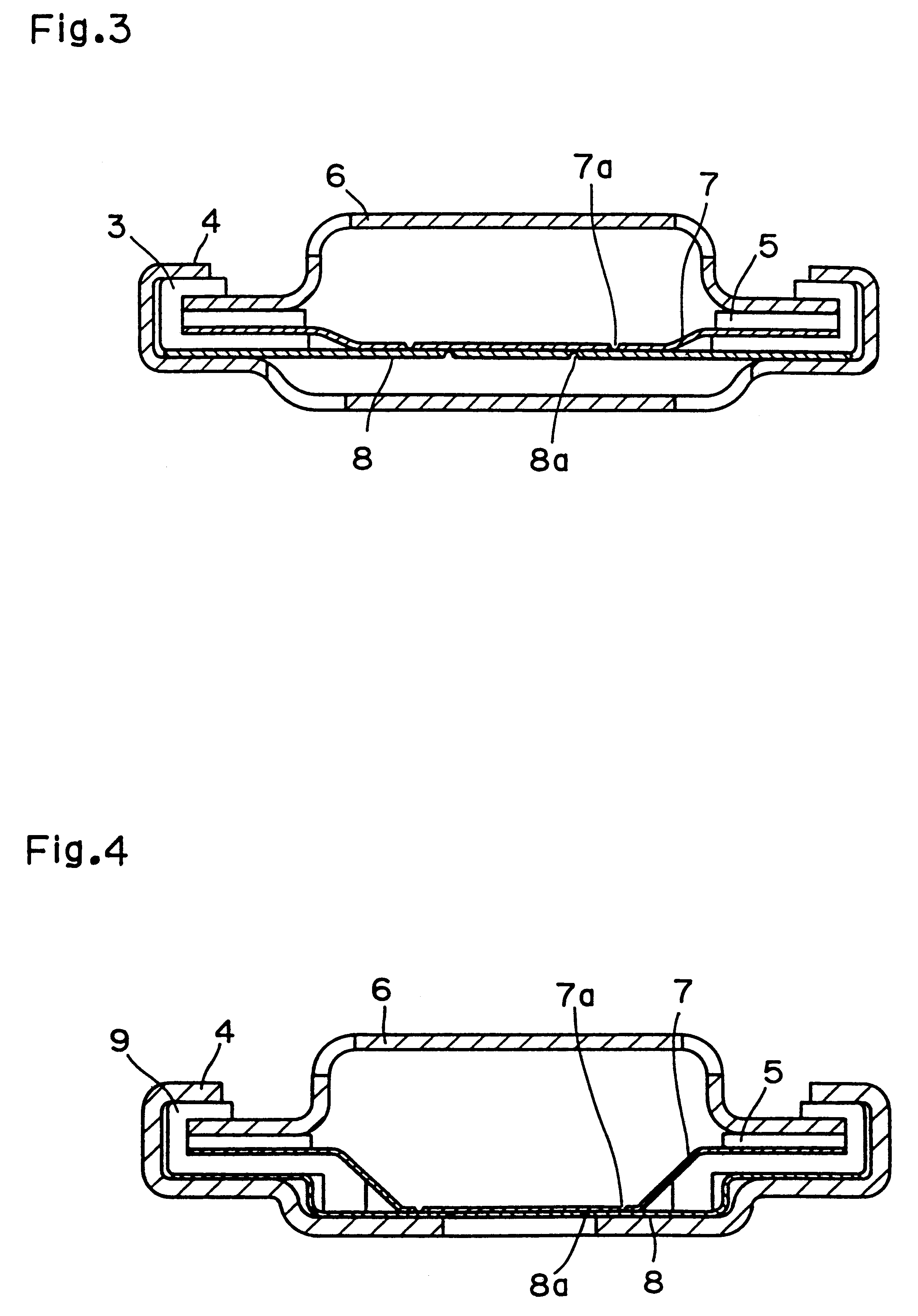

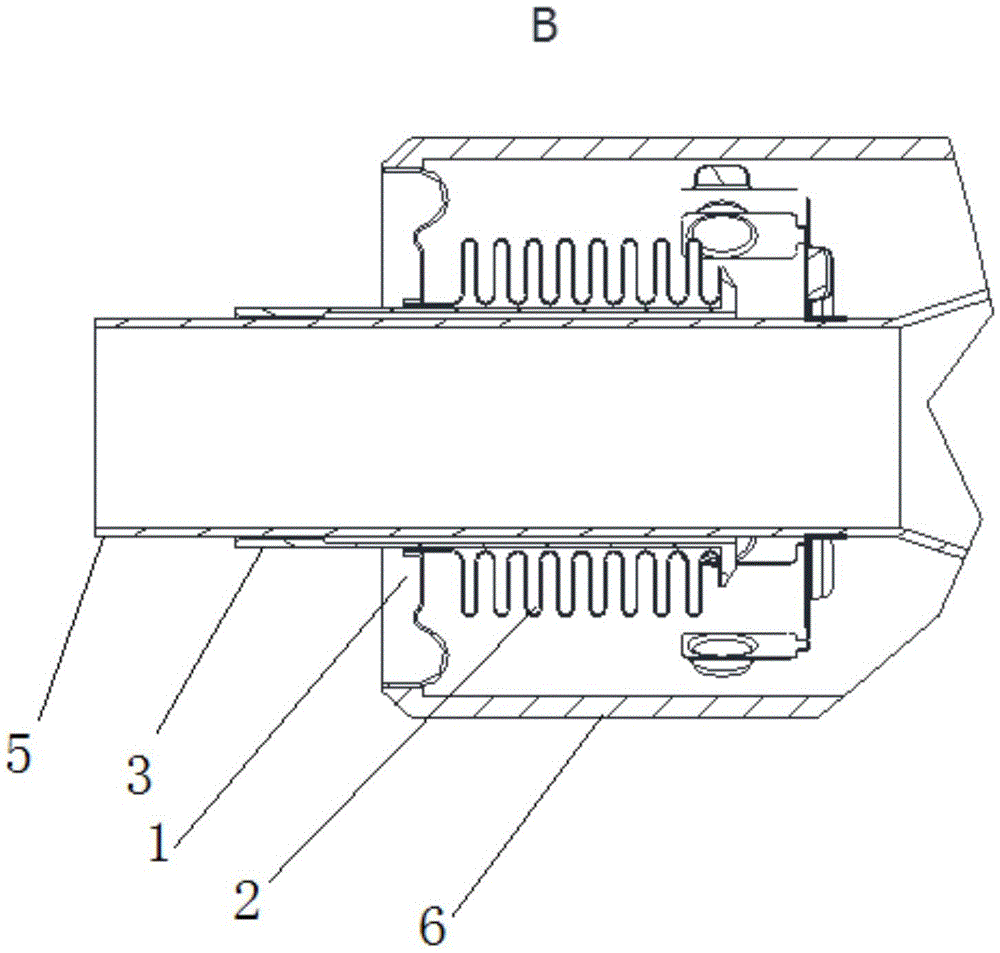

Explosion-proof seal plate for enclosed type cell and production method thereof

InactiveUS6242126B1Weld firmlyReliable exhaustCell component detailsElectrochemical responseMetallic foil

The present invention relates to an explosion-proof seal plate for a sealed cell and a production method thereof and aims at providing an explosion-proof seal plate and production method thereof, wherein problems of a risk of explosion of a cell due to an excessive pressure inside the cell caused by abnormal generation of a gas through a chemical reaction accompanying over charge or erroneous use of the cell or damaging of electronic equipment using the cell as the power source are solved, ignition and other accidents can be prevented with a high accuracy by reliably cutting off an electric current when the cell internal pressure increases, and the increase in the resistance due to permeation of an electrolyte can be limited. In order to accomplish this aim, the present invention provides a thin portion 7a having a breaking strength of 18-24 kg / cm2 in the central portion of an upper metallic foil 7 made of aluminum and a thin portion 8a having a breaking strength of 10-13 kg / cm2 in the central portion of a lower metallic foil 8 made of aluminum, wherein the diameter A of the thin portion 7a of the upper metallic foil and the diameter B of the thin portion 8a of the lower metallic foil 8 satisfy the relation AB. The two metallic foils are welded at the central portions with an insulating gasket interposed, and encased in a metallic case 4 made of aluminum having 4 vent holes, on top of which a temperature dependent resistor 5 and a metallic cap 6 having 4 vent holes are then placed. A seal plate is obtained by sealing the periphery of the metallic case 4, with which it is possible to prevent accidents such as ignition and explosion of a cell by reliably allowing internal gas to exhaust in the event of generation of a large volume of gas under an abnormal condition of a sealed cell.

Owner:PANASONIC CORP

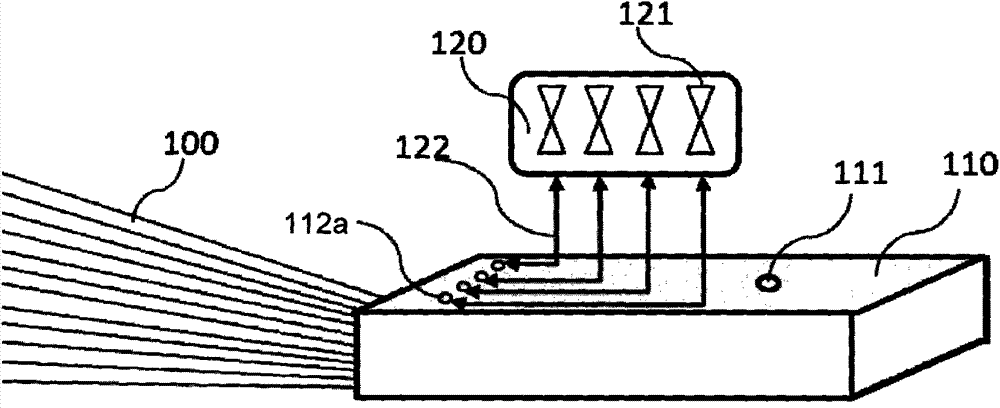

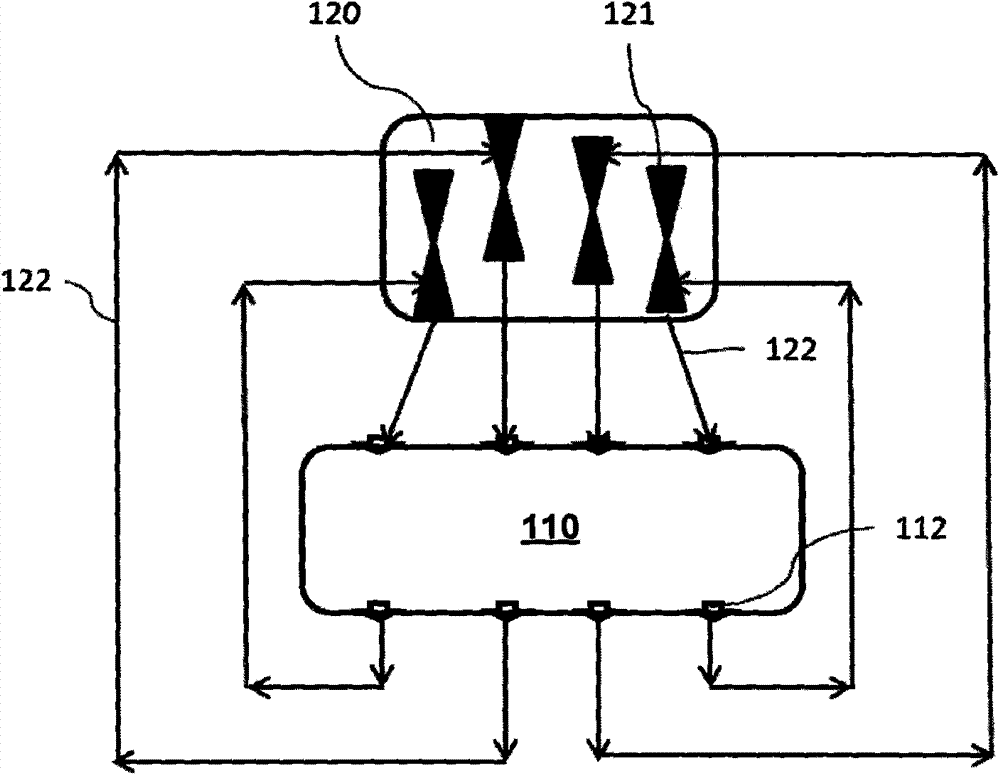

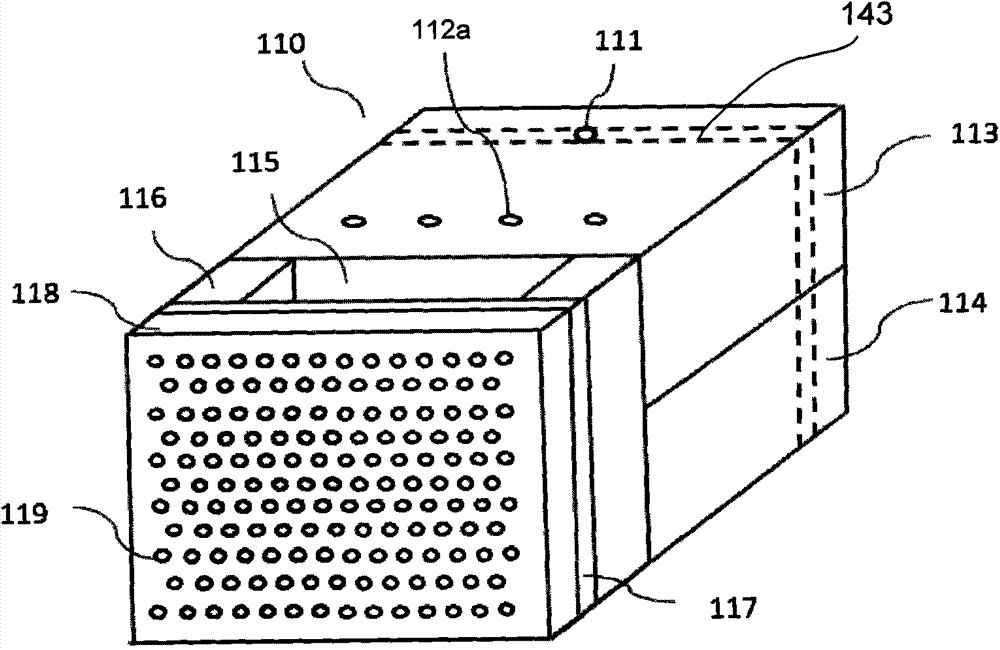

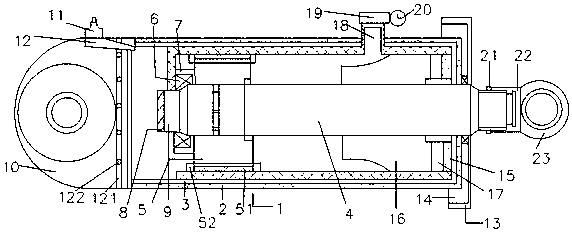

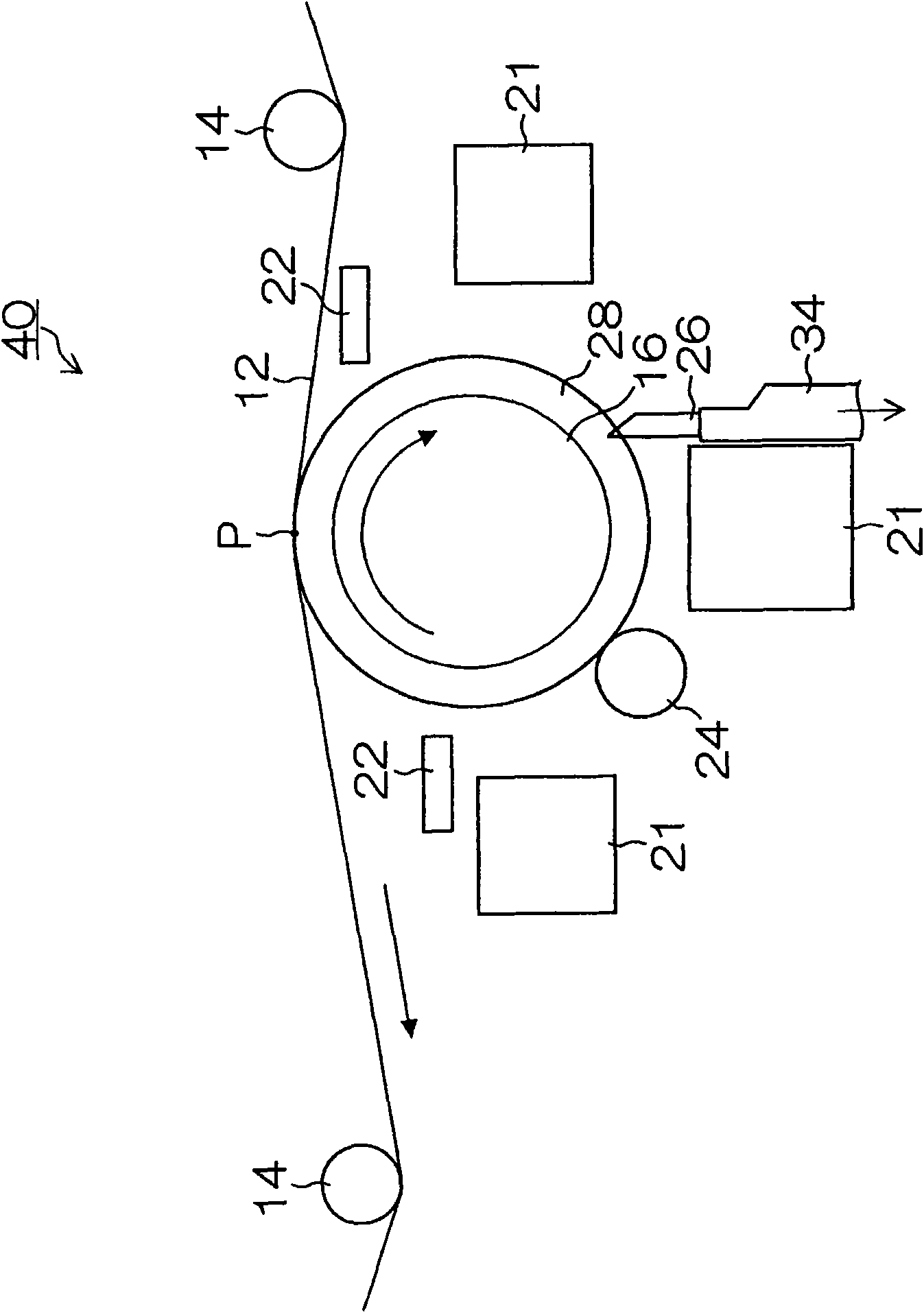

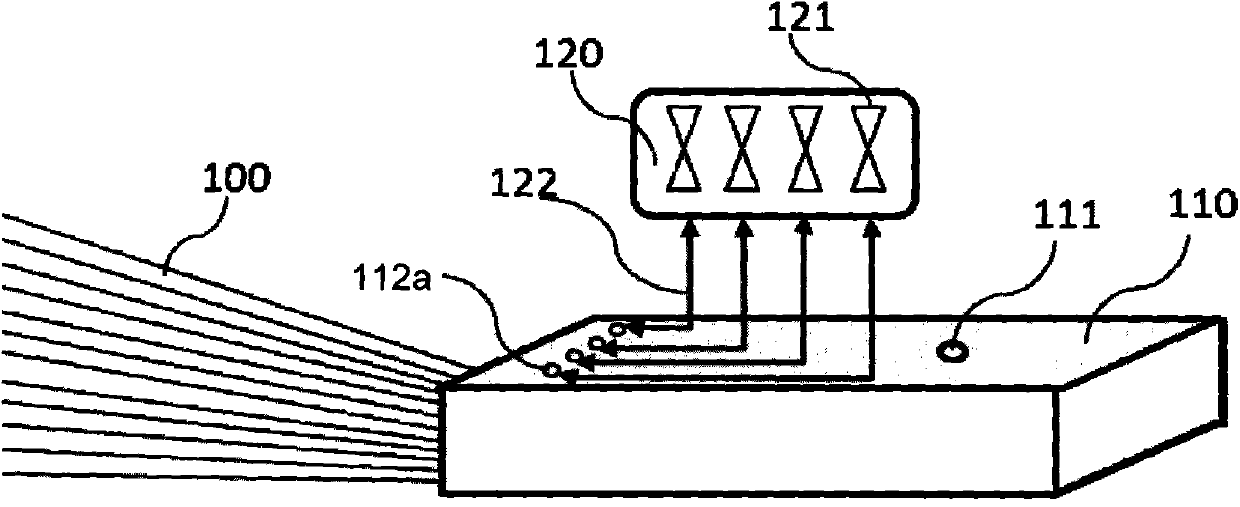

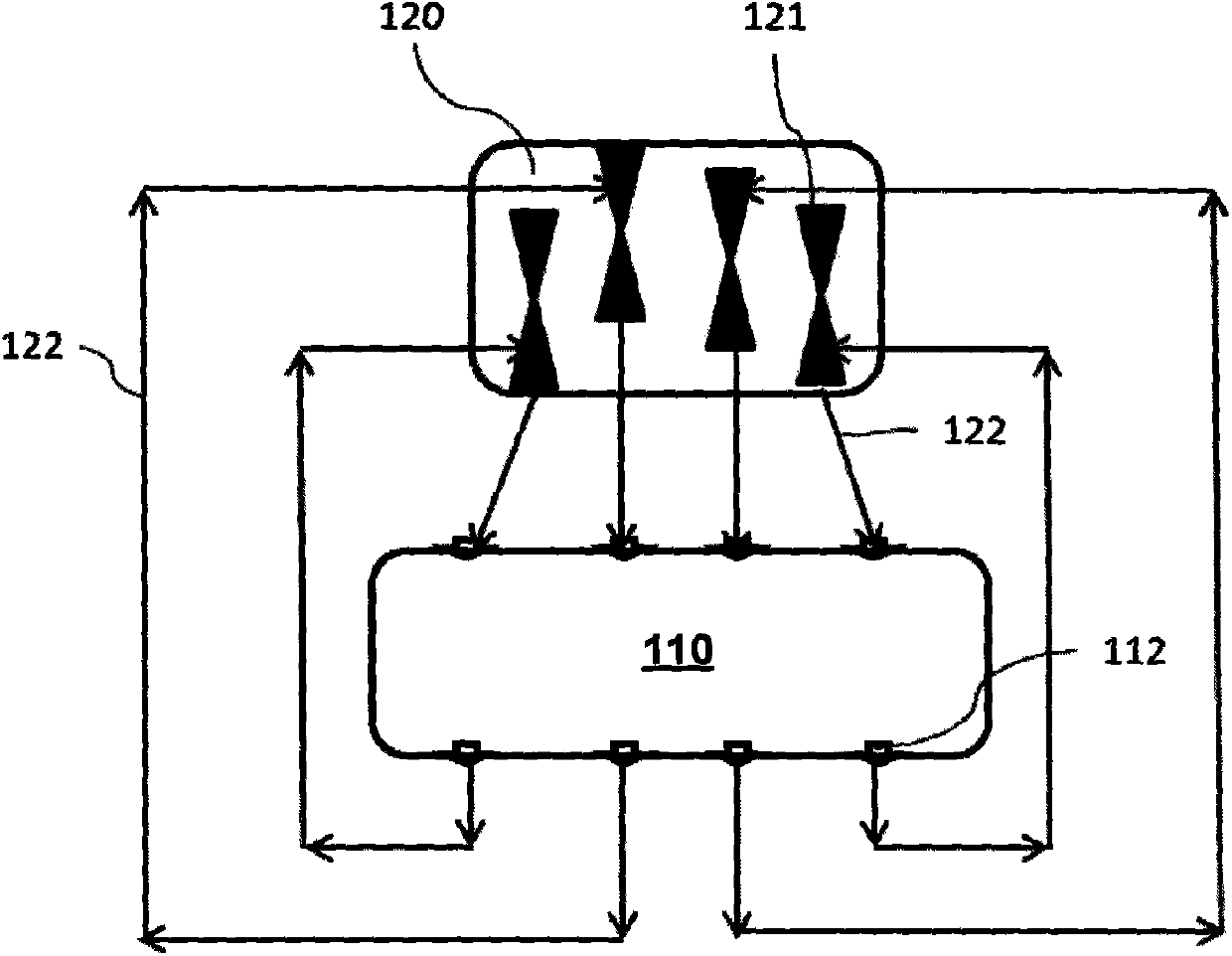

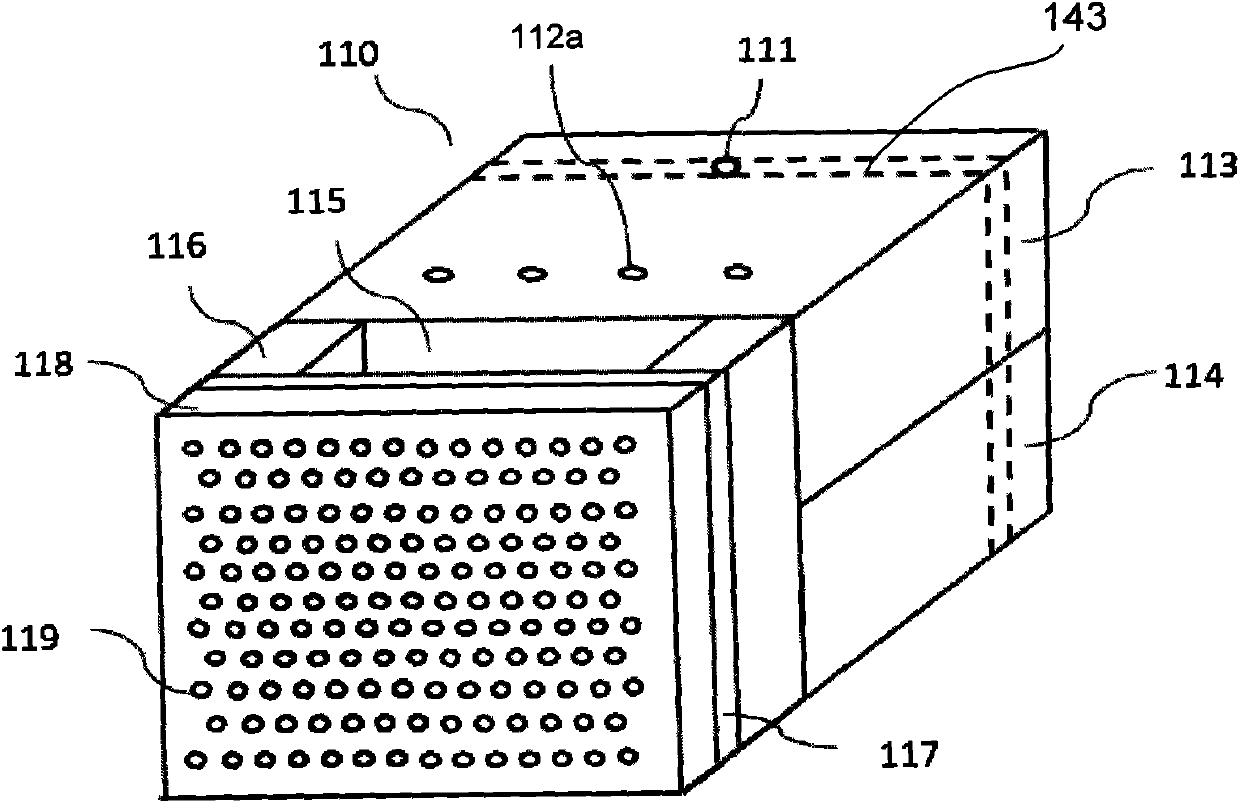

Multi-pipeline pump driving type fiber impregnation system

ActiveCN104742274AChange the unfavorable situationRaise the exhaustCoatingsPeristaltic pumpDiaphragm pump

The invention relates to a fiber impregnation system. The fiber impregnation system comprises a fiber impregnation box (110) and a driving pump (120) connected with the fiber impregnation box (110) by one or more refluxing hoses (122), wherein the refluxing hoses (122-1, 122-2 and 122-3) are used for recycling resin from the fiber impregnation box and refilling the fiber impregnation box with the resin under the driving action of the driving pump; and preferentially, the driving pump (120) is a peristaltic pump or a diaphragm pump. Besides, the invention also relates to equipment for performing pultrusion on fibers (100) to obtain a section material (200) by use of the fiber impregnation box. According to the fiber impregnation system, the fiber impregnation box and the peristaltic pump provided with at least one pump head are combined, and the quantity of pumps, pump heads and pipelines is increased as required by production and processing, thus, the fiber impregnation box is not required to be closely connected with a corresponding molding and solidifying device, and a yarn guiding plate can be arranged in the fiber impregnation box; and the fiber impregnation box and the corresponding molding and solidifying device can be separable and vacuumizing operation is carried out, and thus, the fiber exhaust efficiency is improved.

Owner:COVESTRO DEUTSCHLAND AG

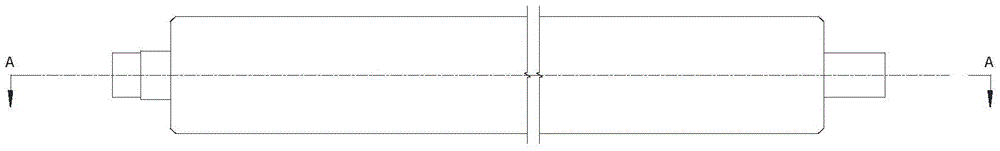

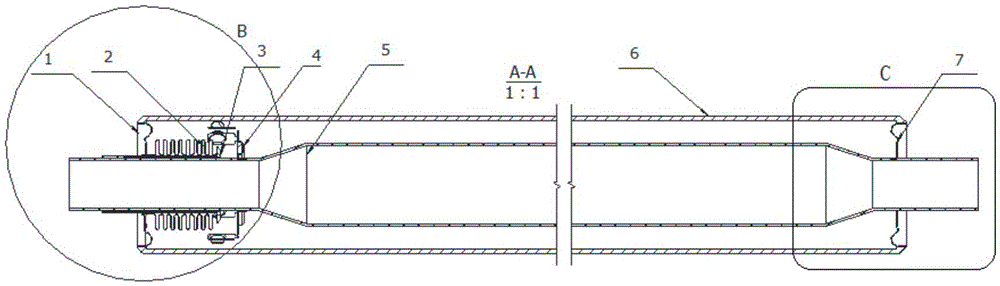

Solar thermal collecting pipe and processing method thereof

InactiveCN105588351AAchieve protectionEasy to assembleSolar heating energySolar heat devicesEngineeringCover glass

The invention discloses a solar thermal collecting pipe. A left end cap is formed by sequentially connecting an inner hole flange, a straight section, a circular-arc section, an outer circle and an outer circle flange from inside to outside. A connecting sleeve penetrates through a corrugated pipe and the right end of the connecting sleeve is welded to the right end of the corrugated pipe. The left end of the connecting sleeve is in seal connection with the inner circumferential face of the left end of the corrugated pipe. The outer circumferential face of the left end of the corrugated pipe is in seal connection with the inner hole flange of the left end cap. Transition glass is arranged on the circumference of the outer circle of the left end cap. The outer edge of the transition glass of the left end cap is connected with a cover glass pipe through fusion sealing. A right end cap and the left end cap are of the same structure. The right end cap is formed by sequentially connecting a right inner hole flange, a right straight section, a right circular-arc section, a right outer circle and a right outer circle flange from inside to outside. A right end diameter-changing section is in welded connection with the right inner hole flange. Right transition glass is arranged on the circumference of the right end cap. The outer edge of the right transition glass is connected with the cover glass pipe through fusion sealing. The invention further discloses a processing method of the solar thermal collecting pipe. The solar thermal collecting pipe is simple, reliable, convenient to produce and high in cost performance.

Owner:NANJING CHENGYUAN SOLAR HEATING

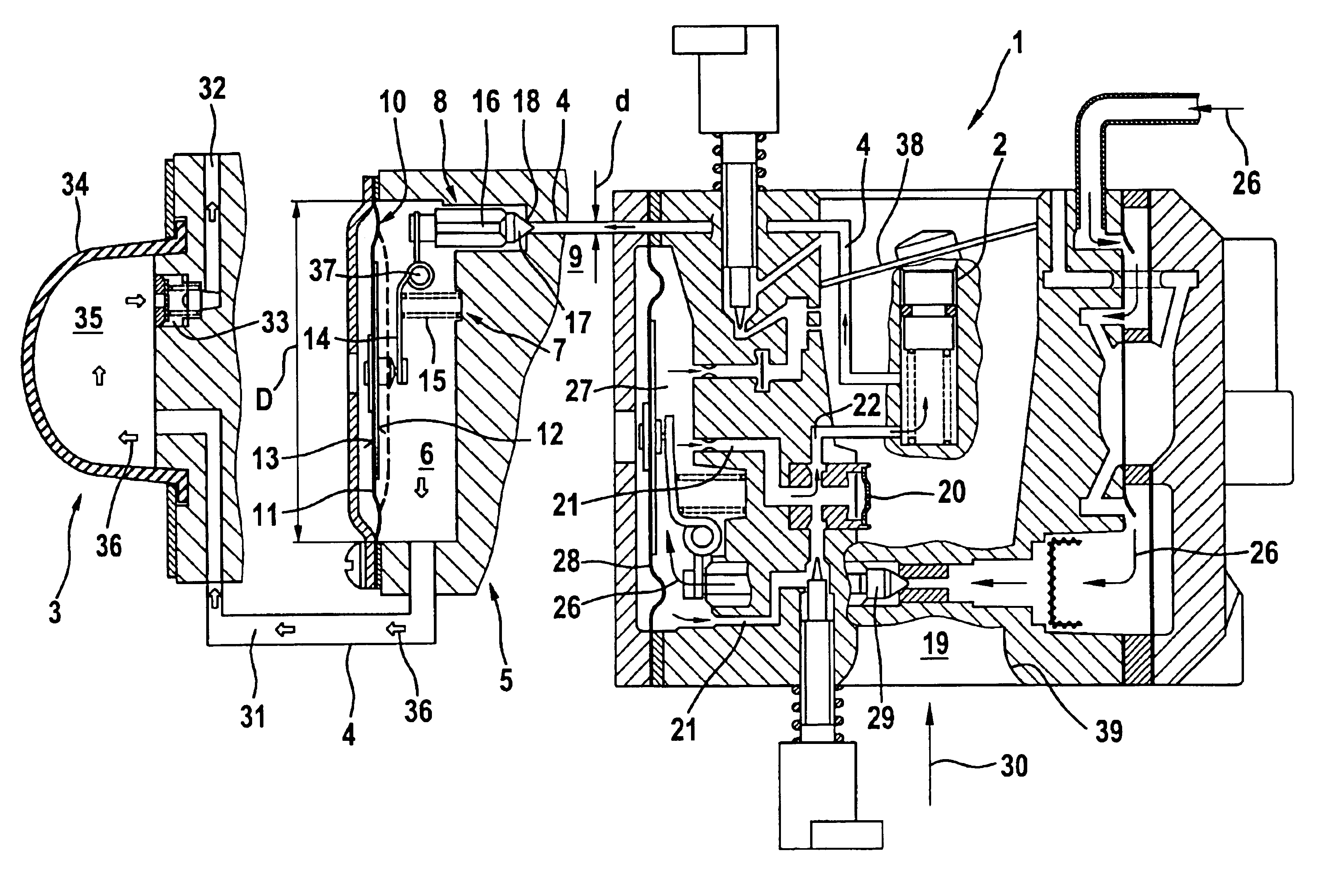

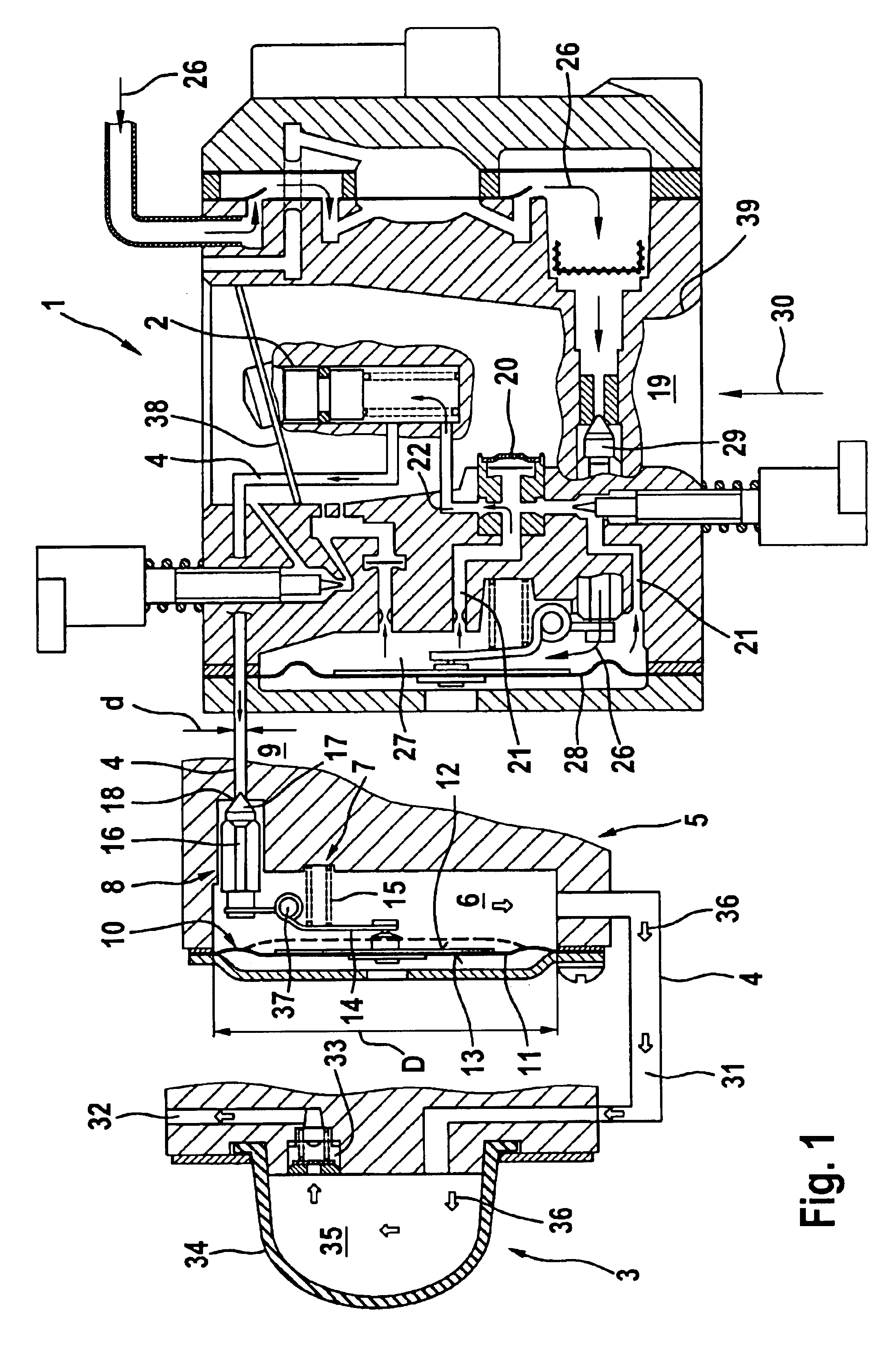

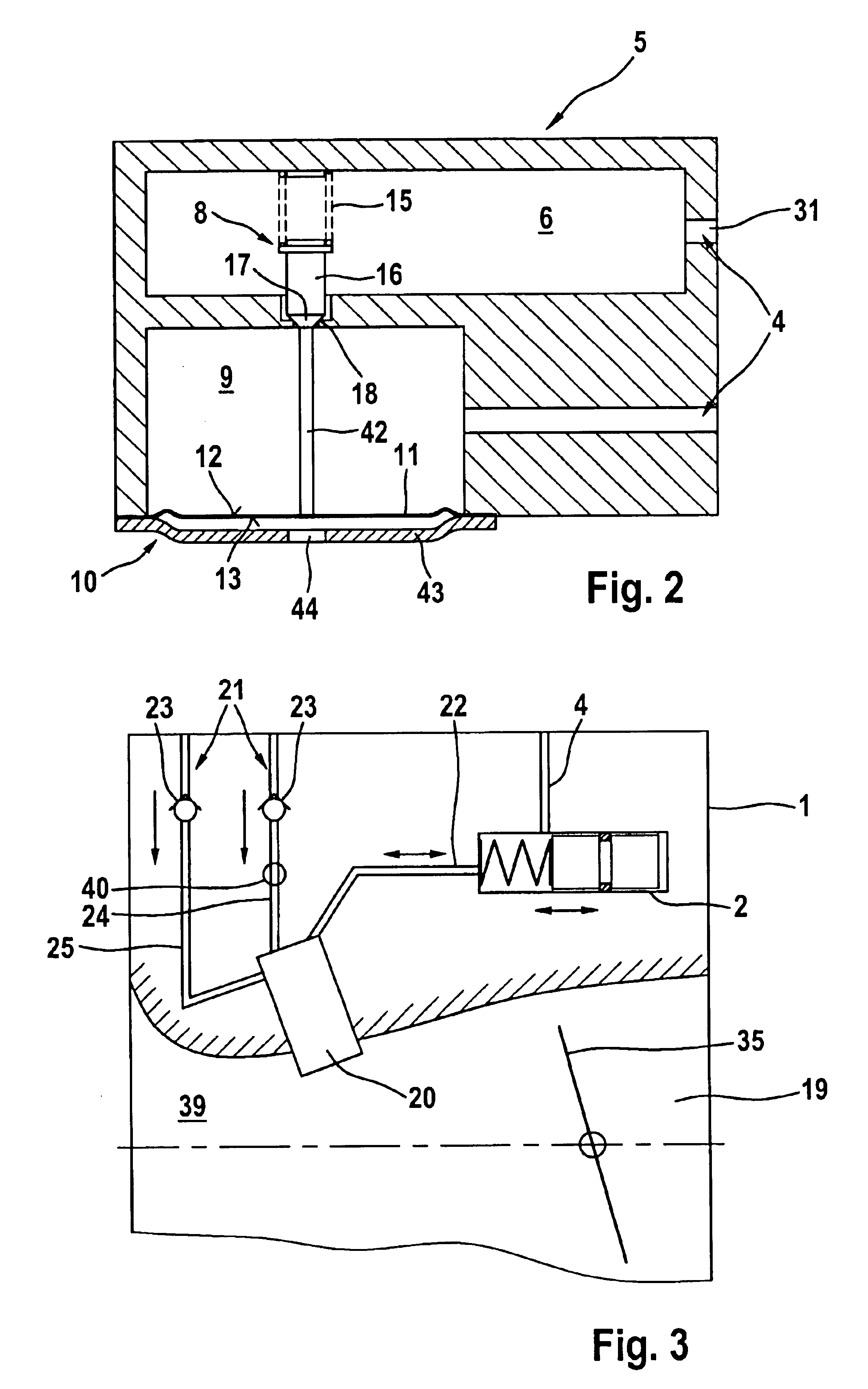

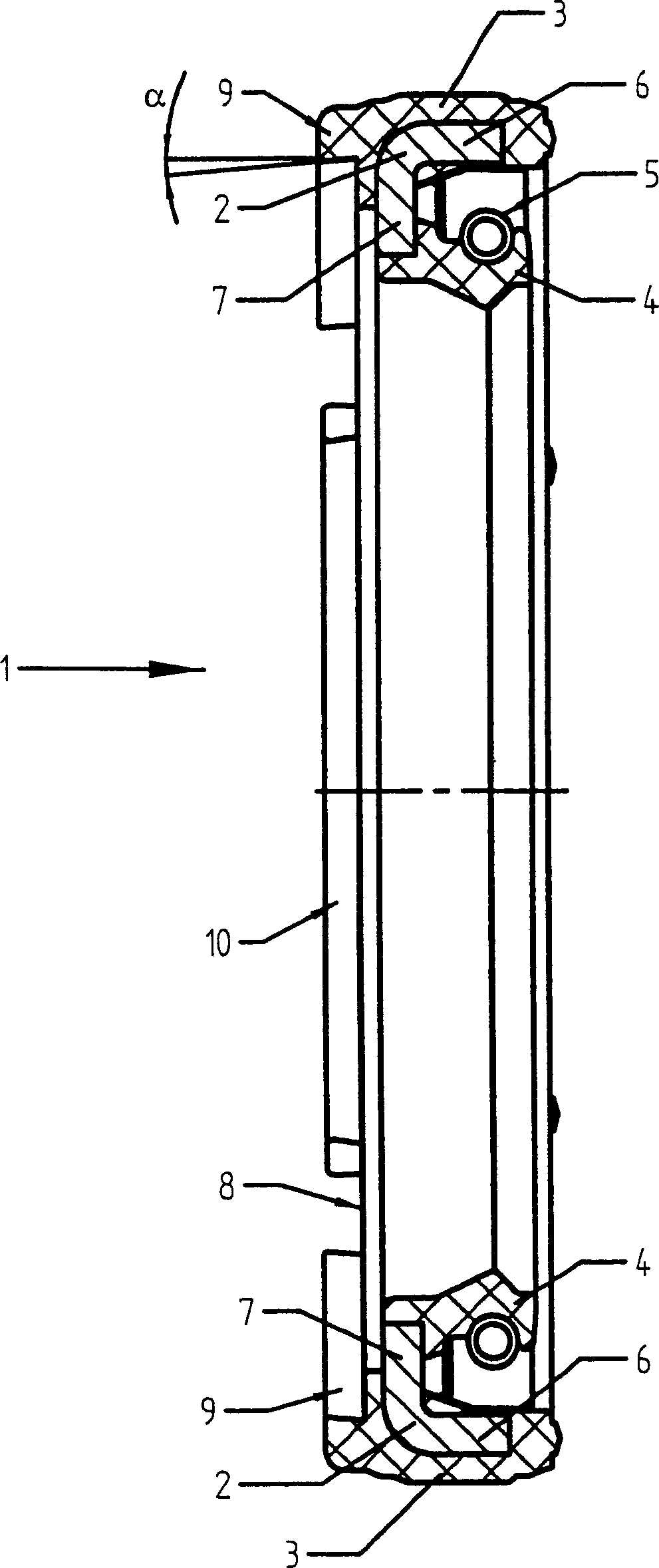

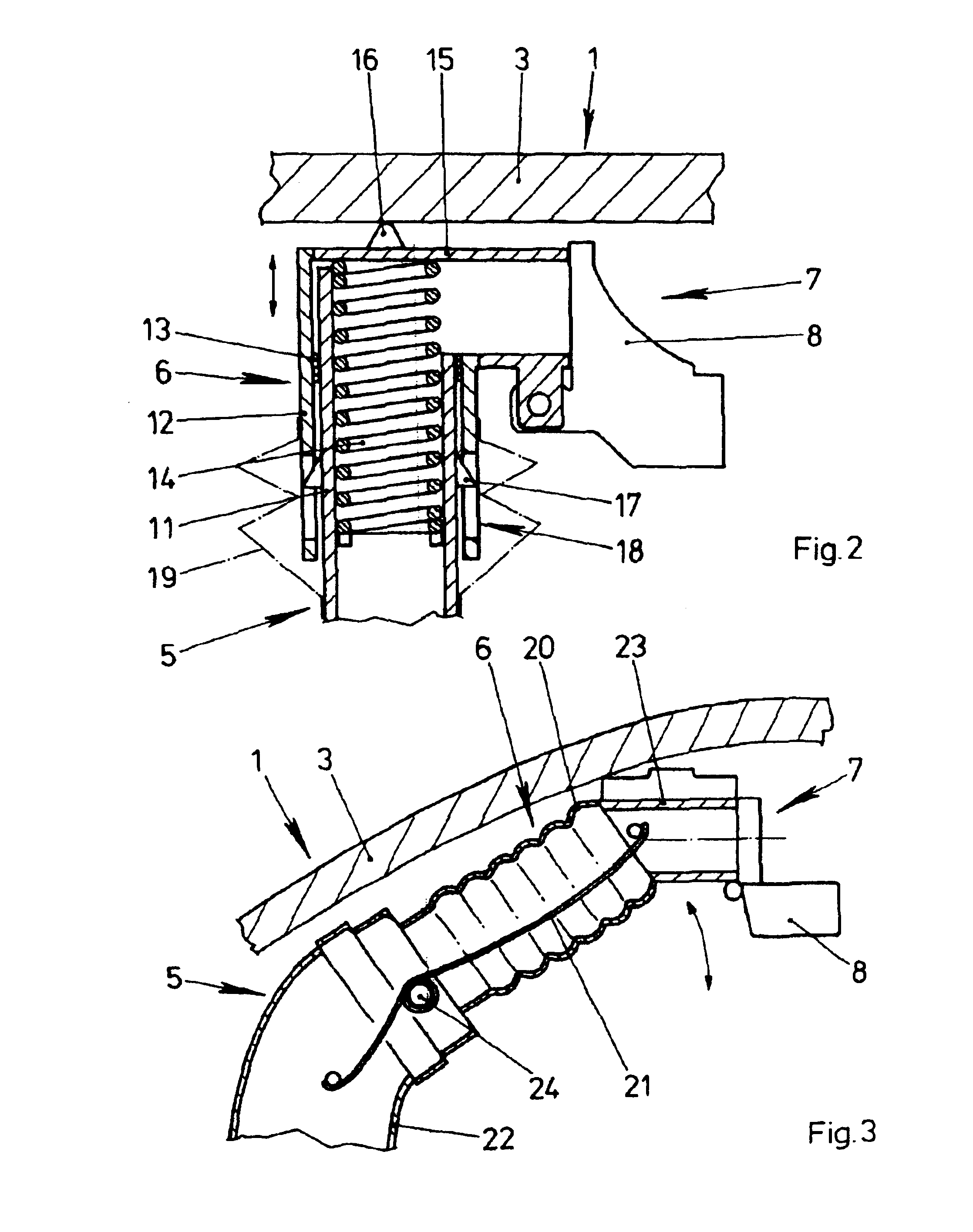

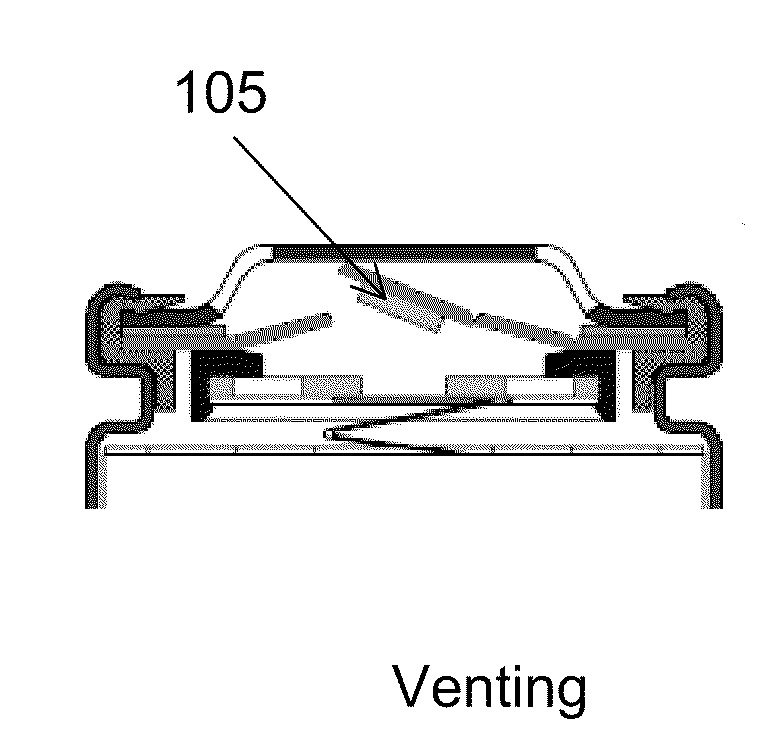

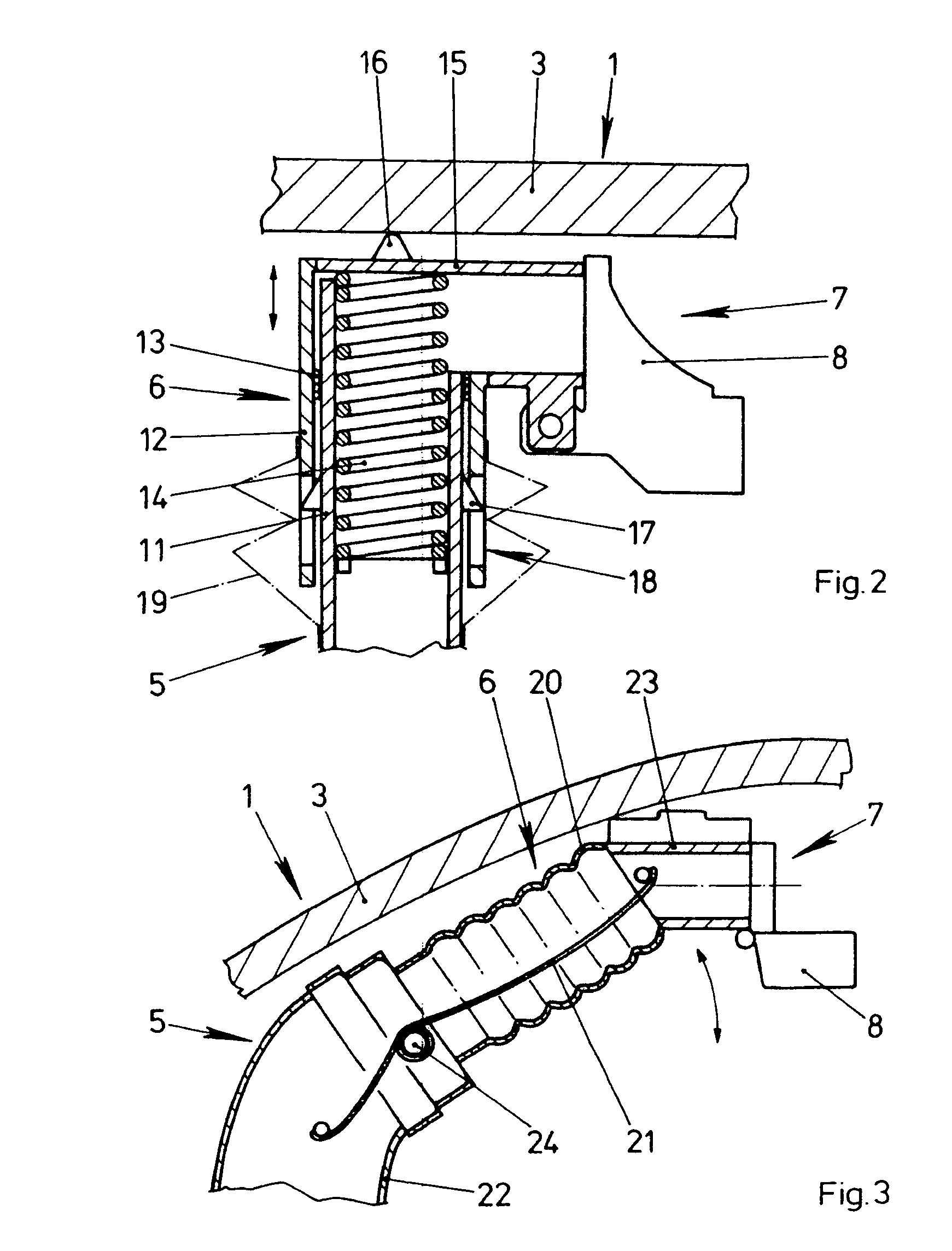

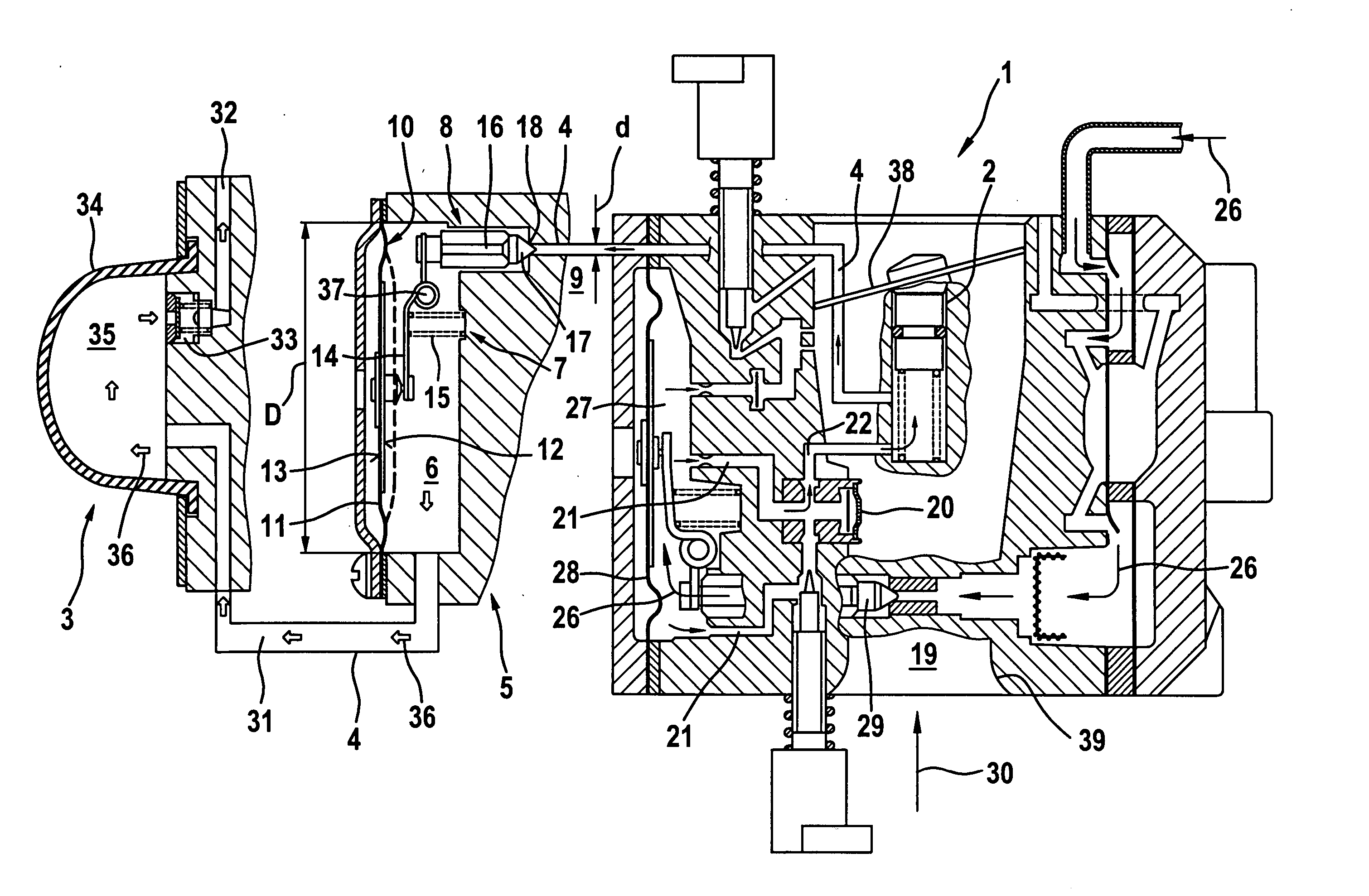

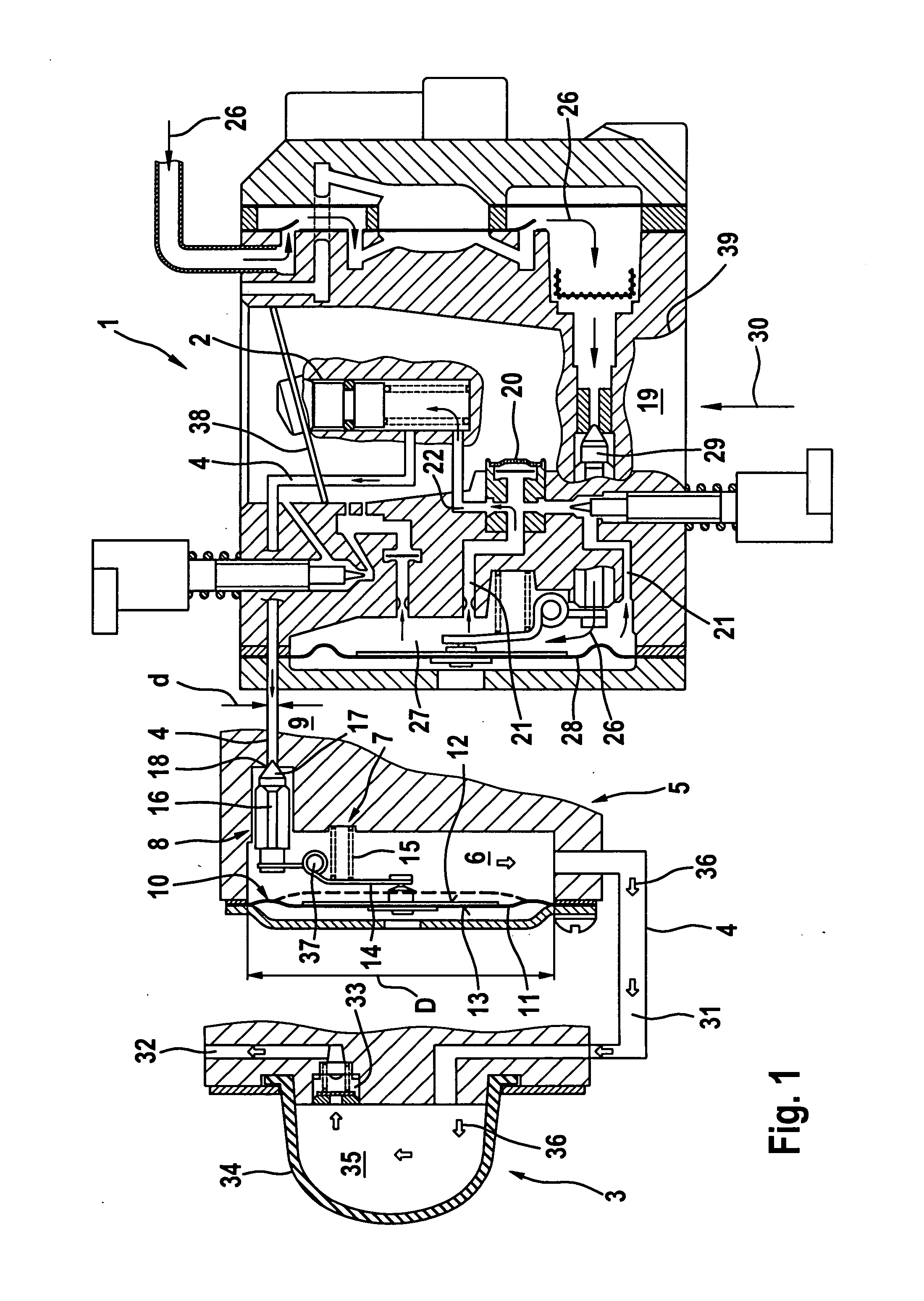

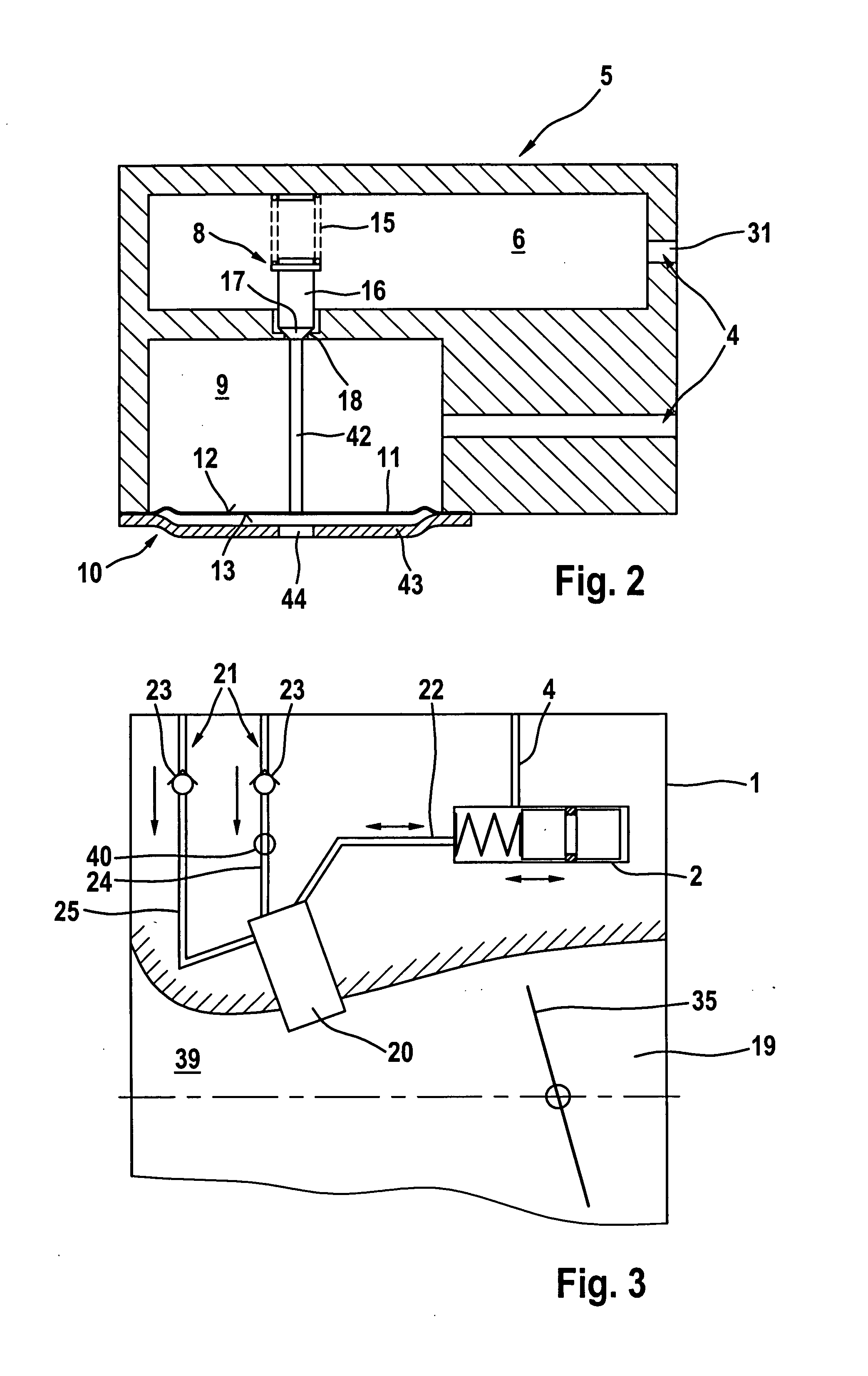

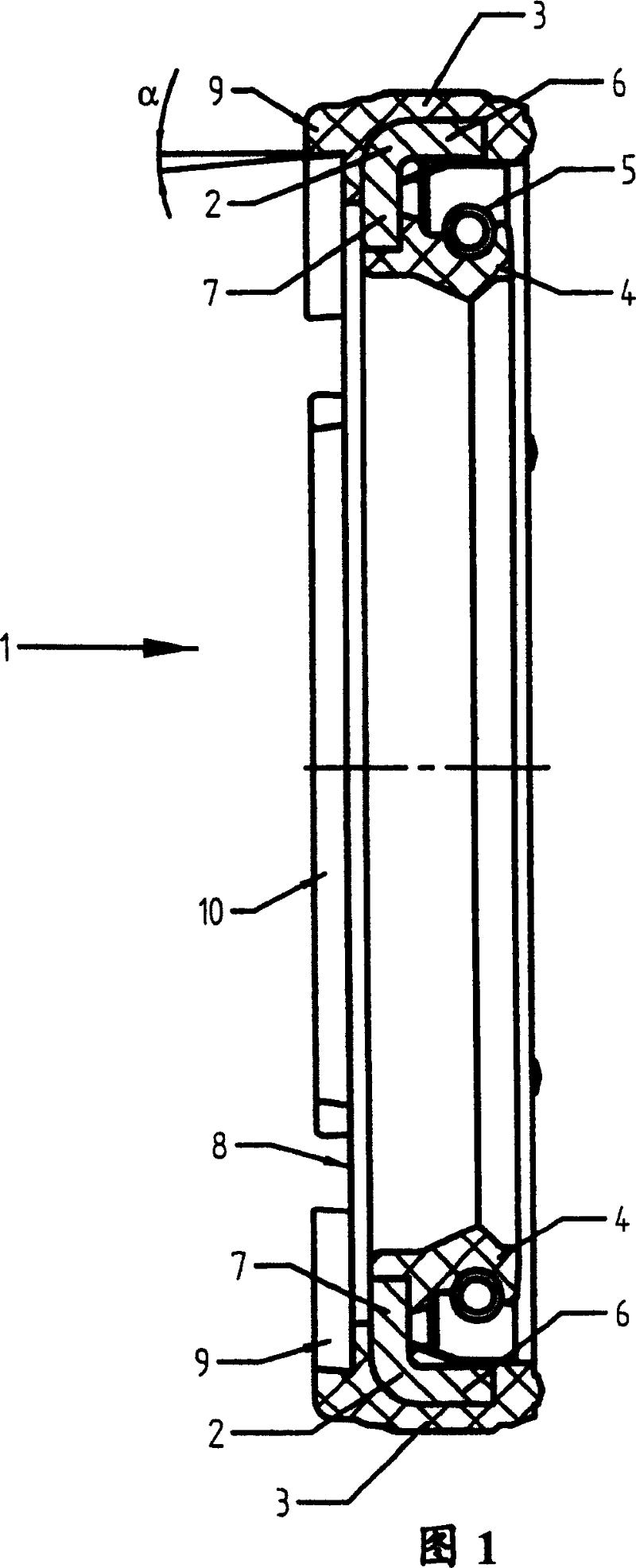

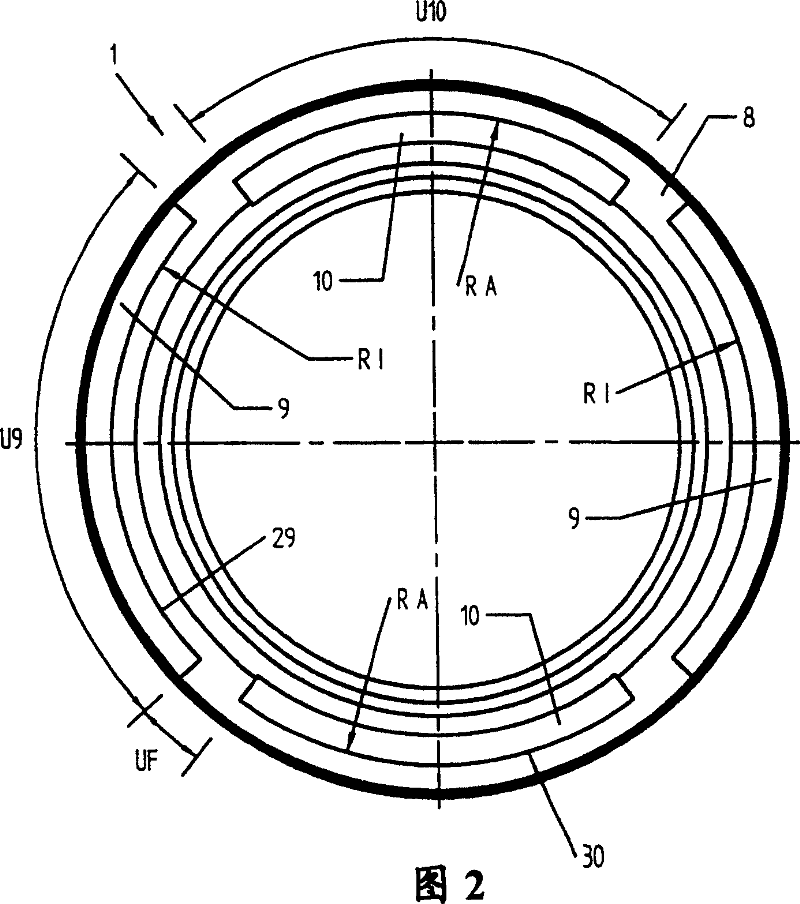

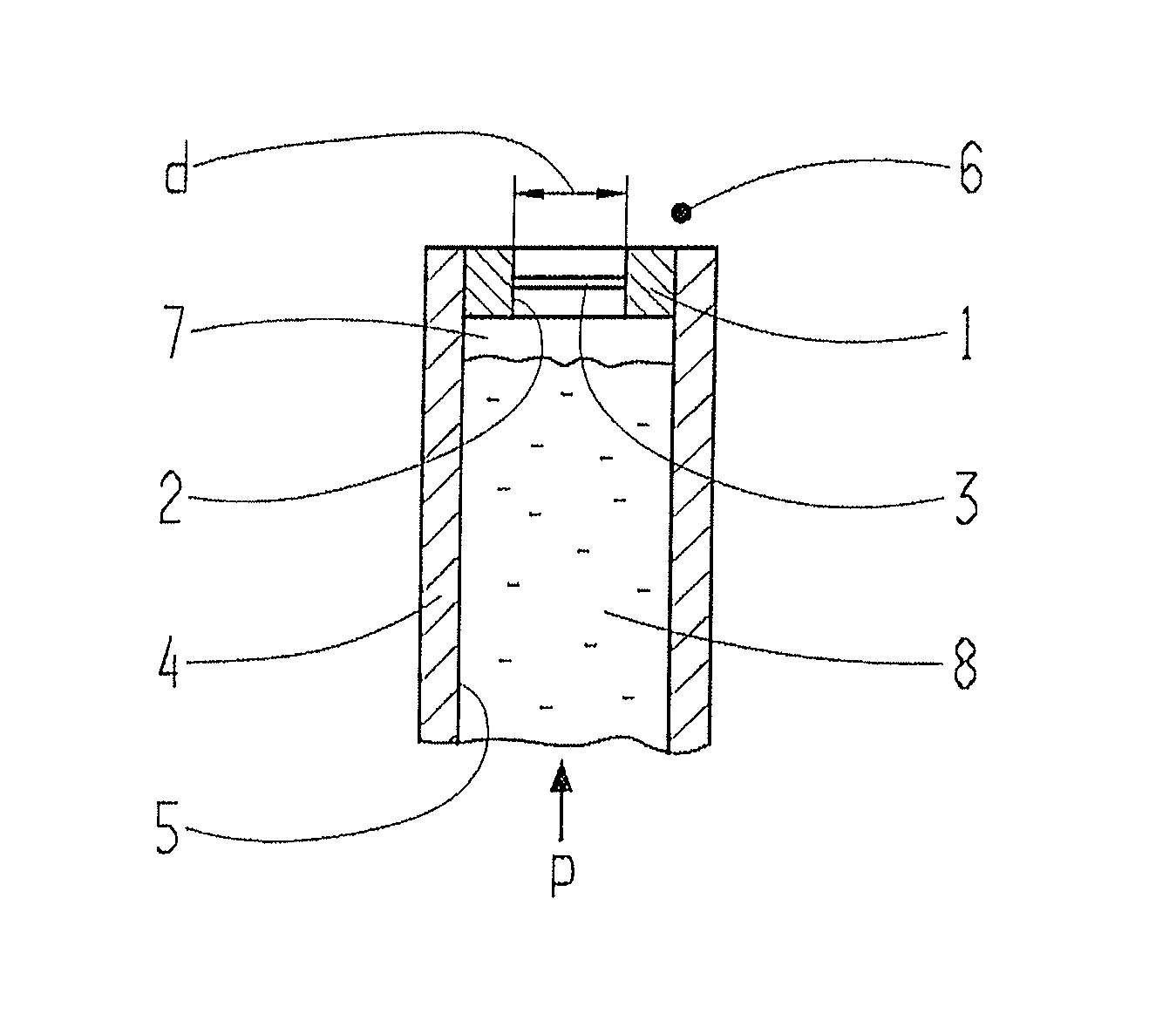

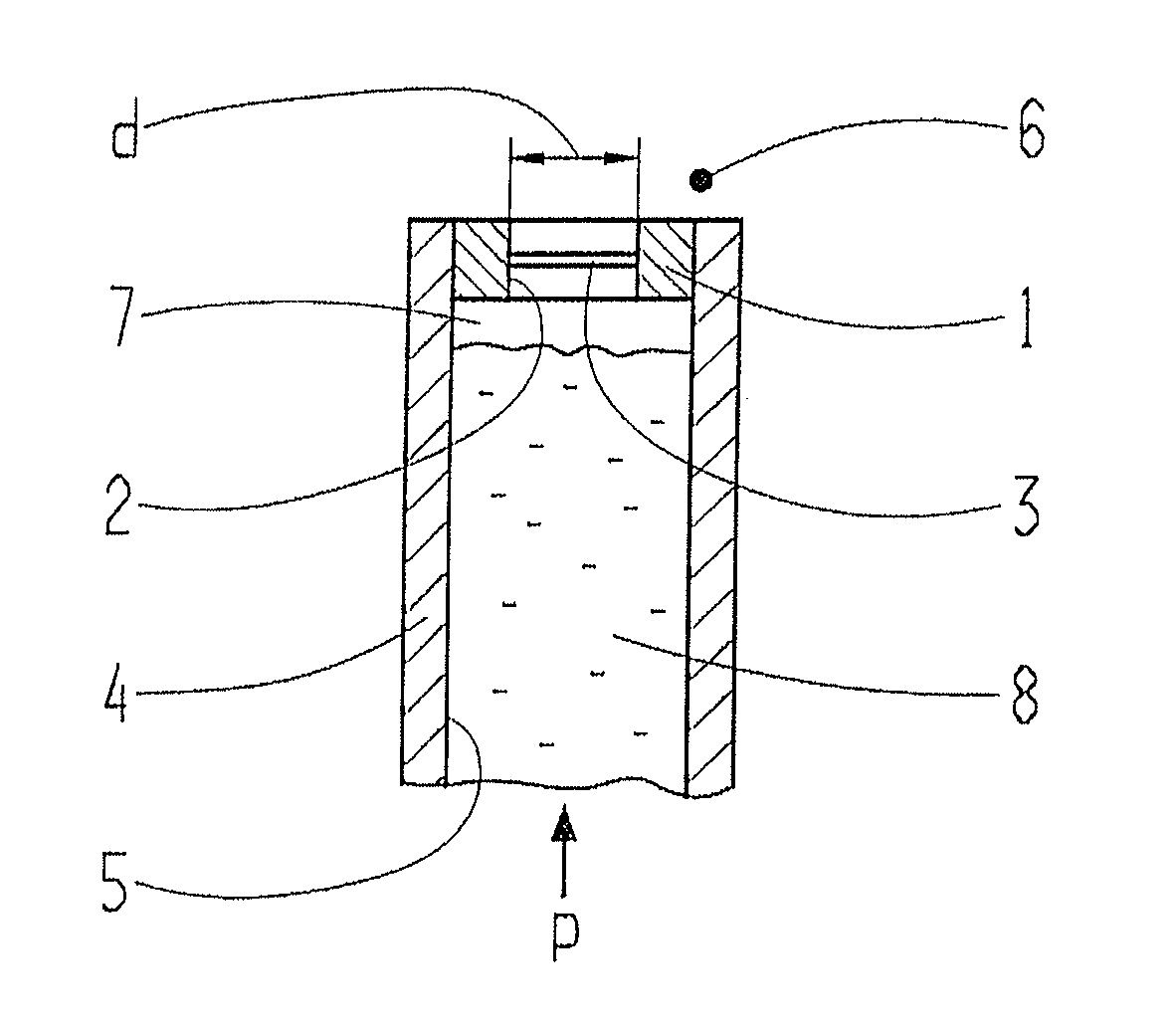

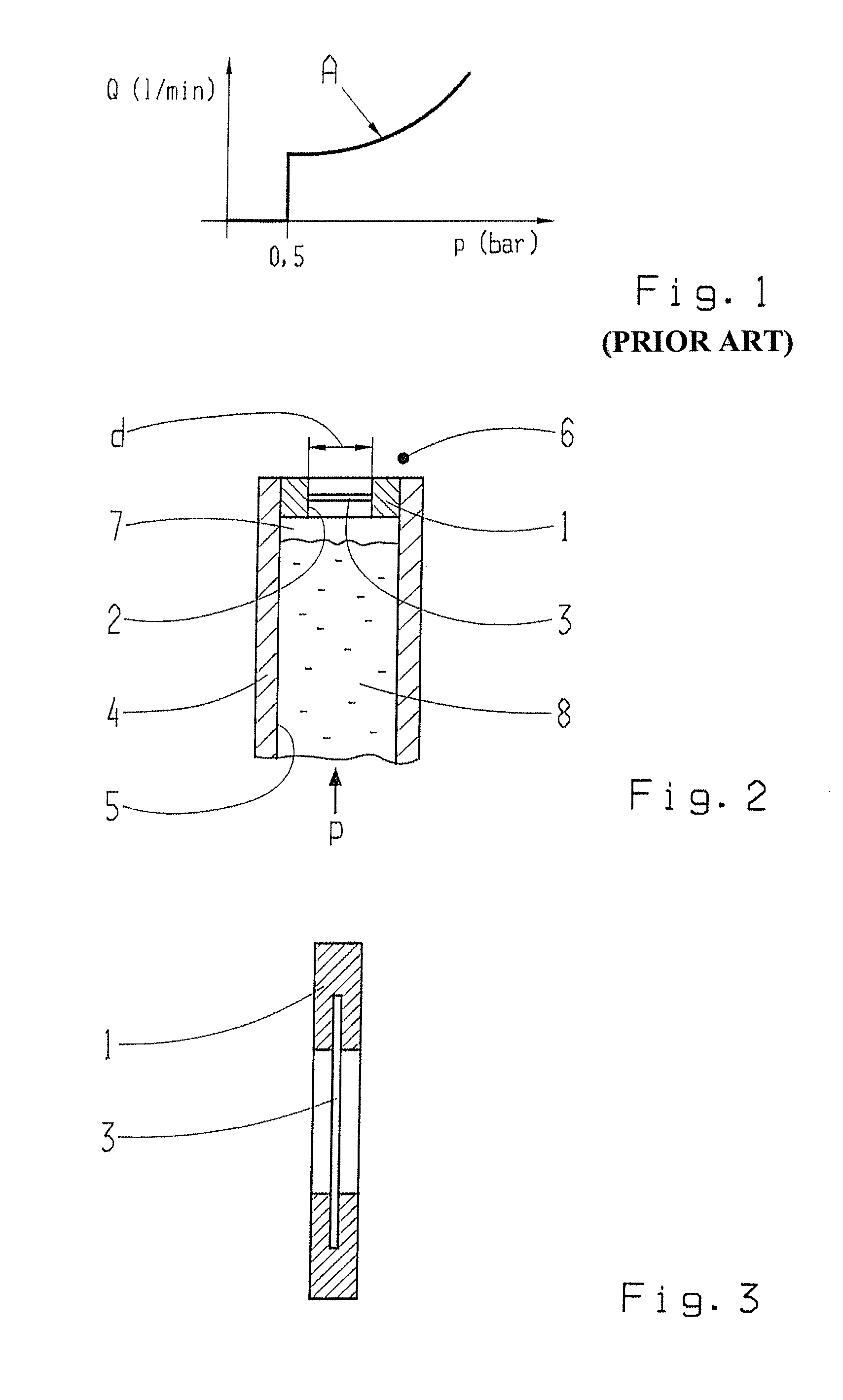

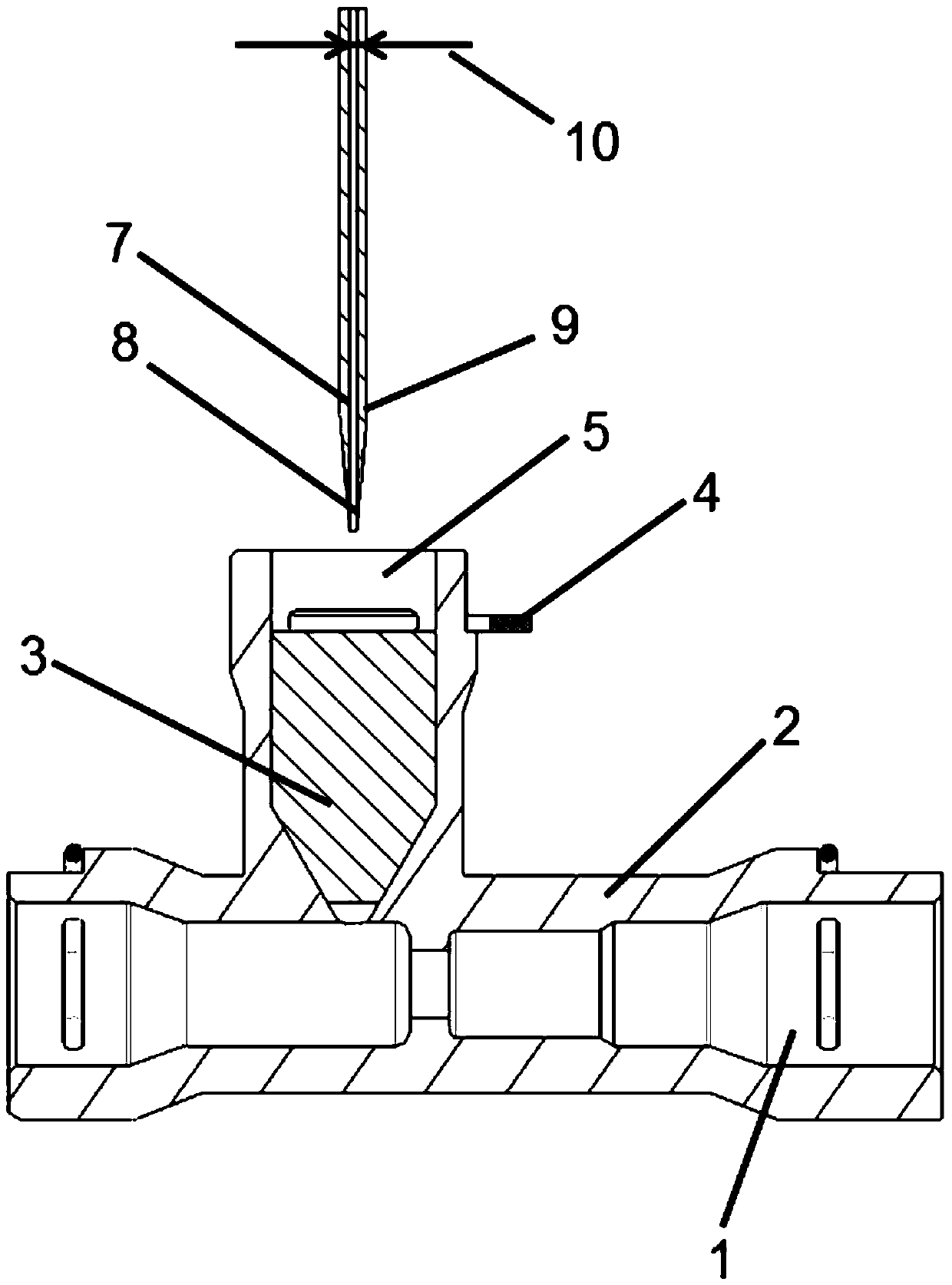

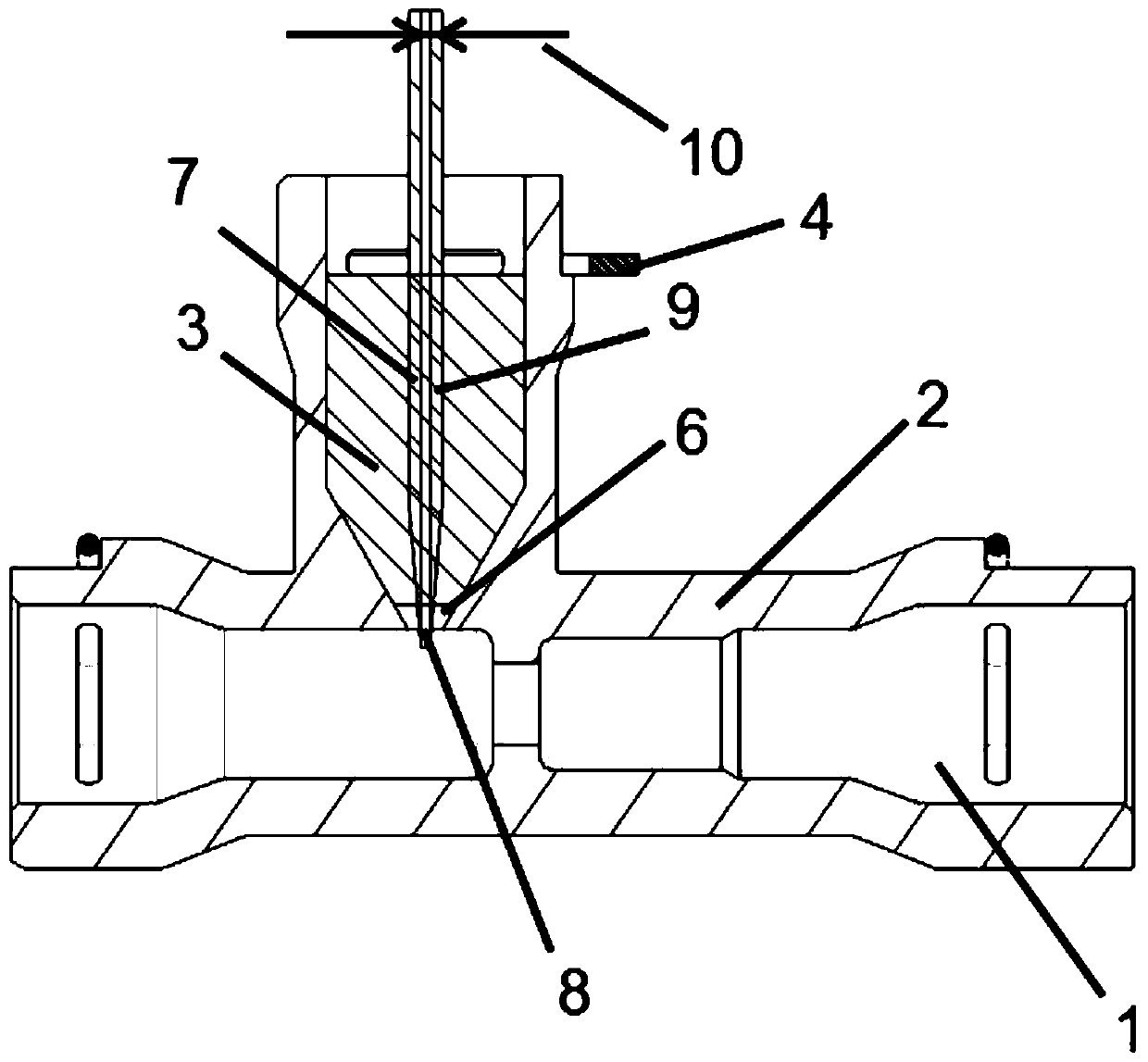

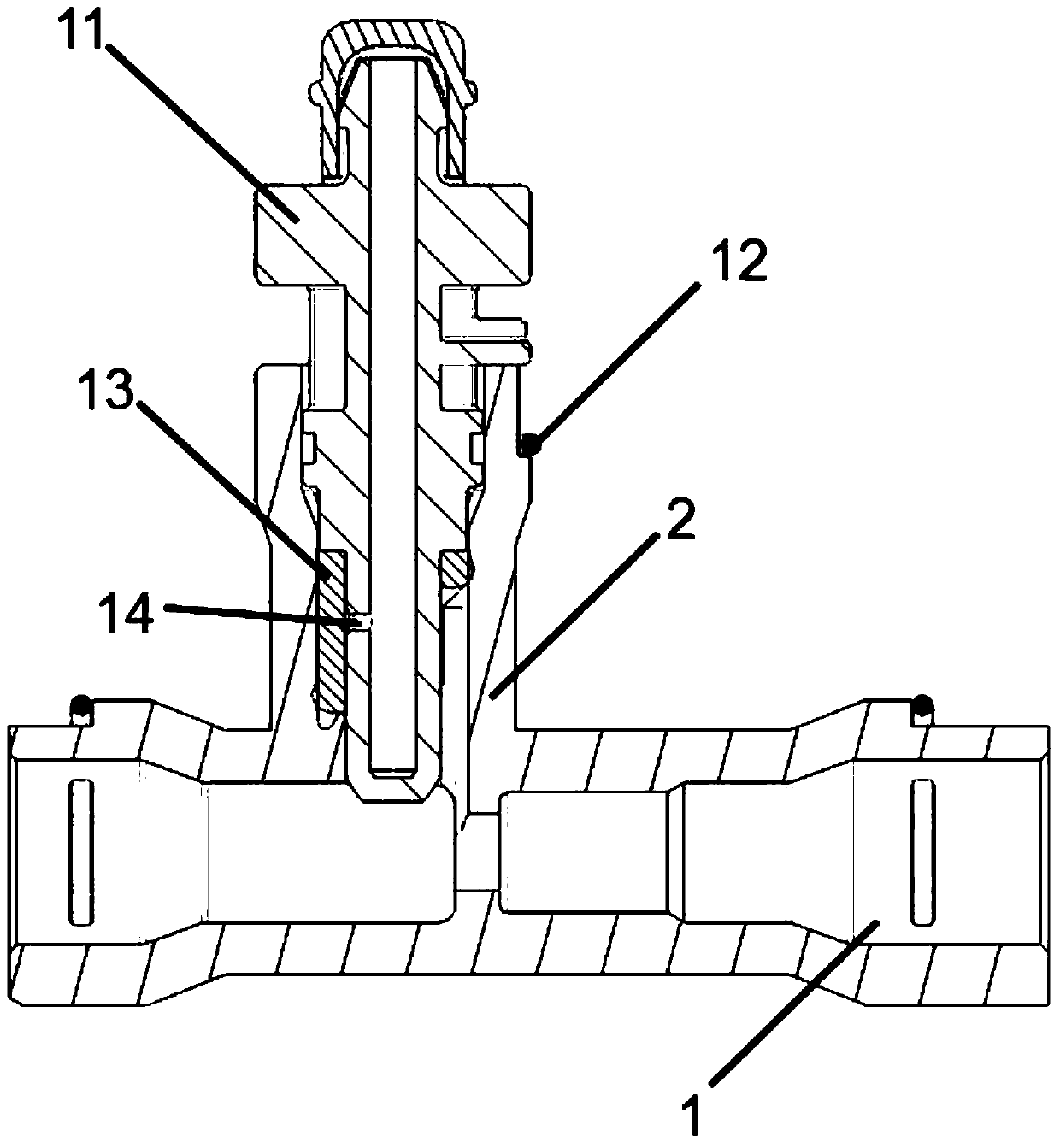

Carburetor arrangement of a portable handheld work apparatus

InactiveUS6938884B2Improve effectivenessImprove performanceUsing liquid separation agentLow pressure fuel injectionHand heldCarburetor

The invention relates to a carburetor arrangement of a portable handheld work apparatus and includes a carburetor (1), an accelerator pump (2) and a venting pump (3). The venting pump (3) acts on the accelerator pump (2) via a venting line (4). A check valve (5) is mounted in the venting line (4) in such a manner that its outlet end (6) is directed in the direction of the venting pump (3). A pretensioning device (7) is provided which holds a valve body (8) of the check valve (5) closed below a selected difference pressure between the outflow end (6) and an opposite-lying inflow end (9). A support device (10) which acts on the valve body (8) and is actuable, at one end, by pressure at the outflow end (6) without considering pressure at the other end (9) or by pressure on the inflow end (9) without considering the pressure on the other end (6).

Owner:ANDREAS STIHL AG & CO KG

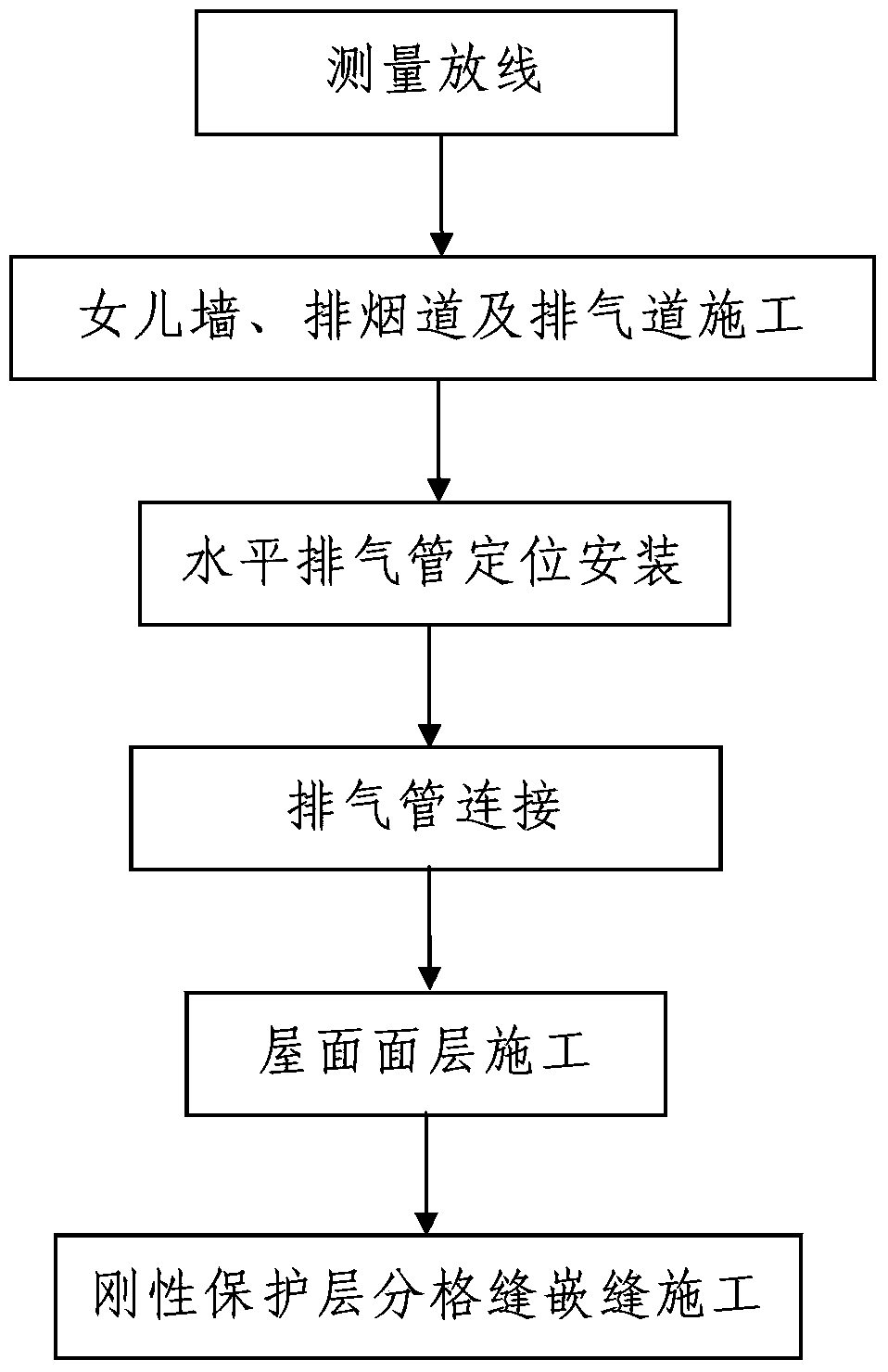

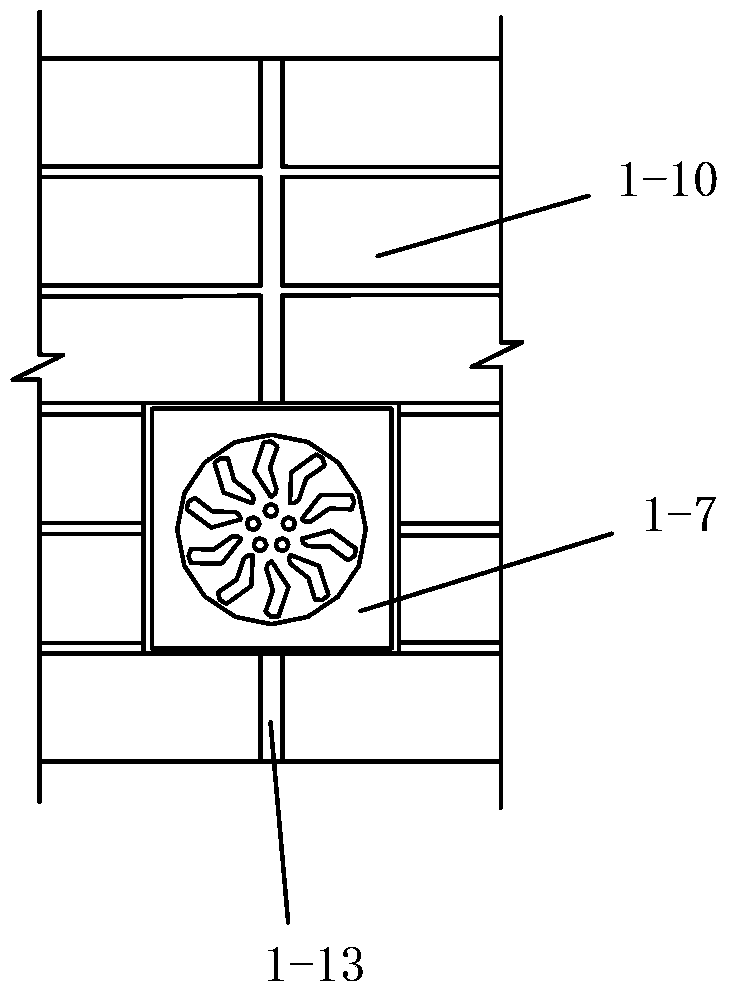

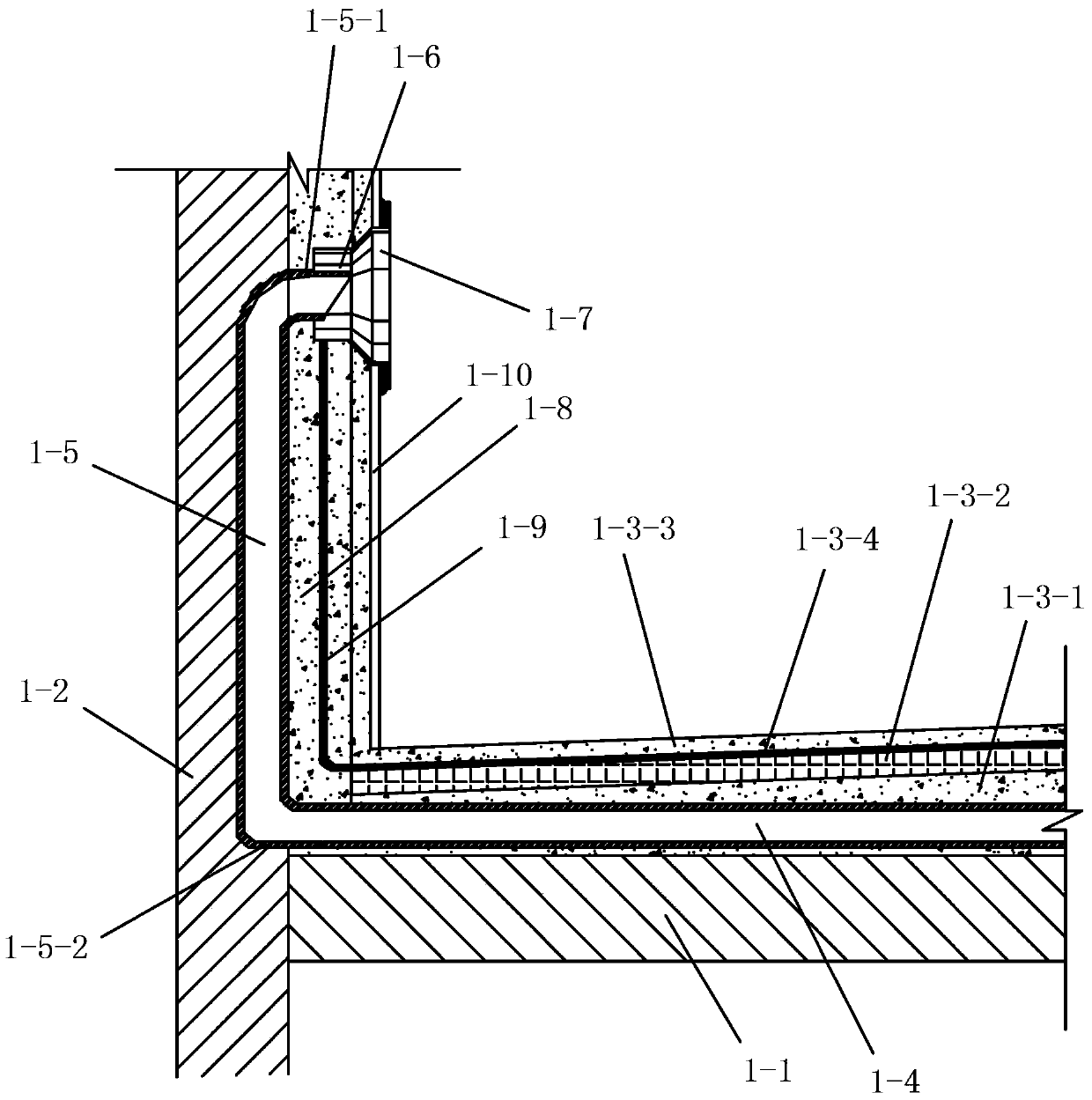

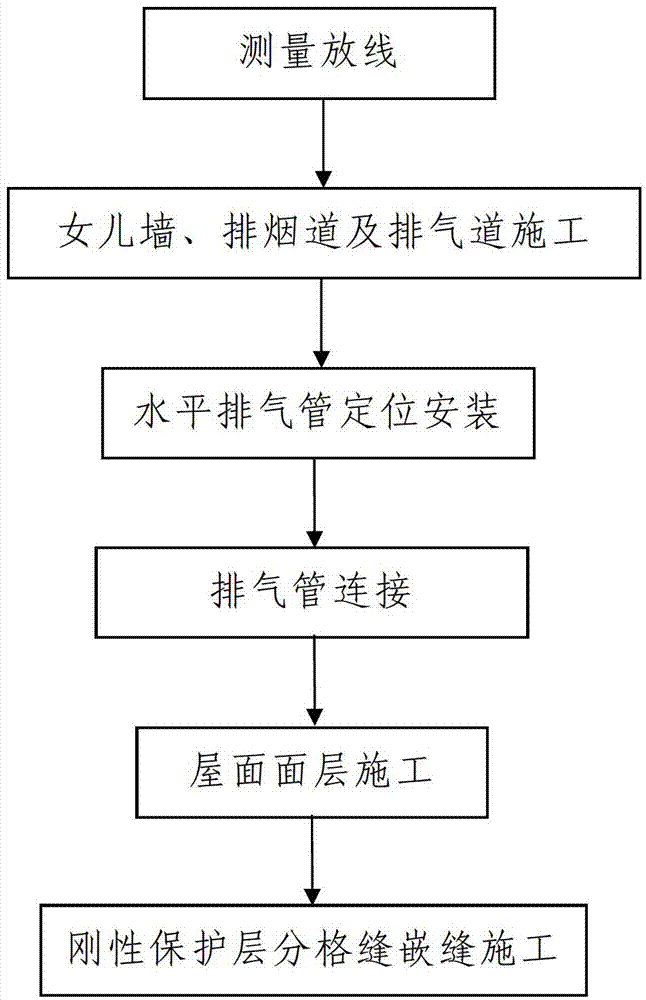

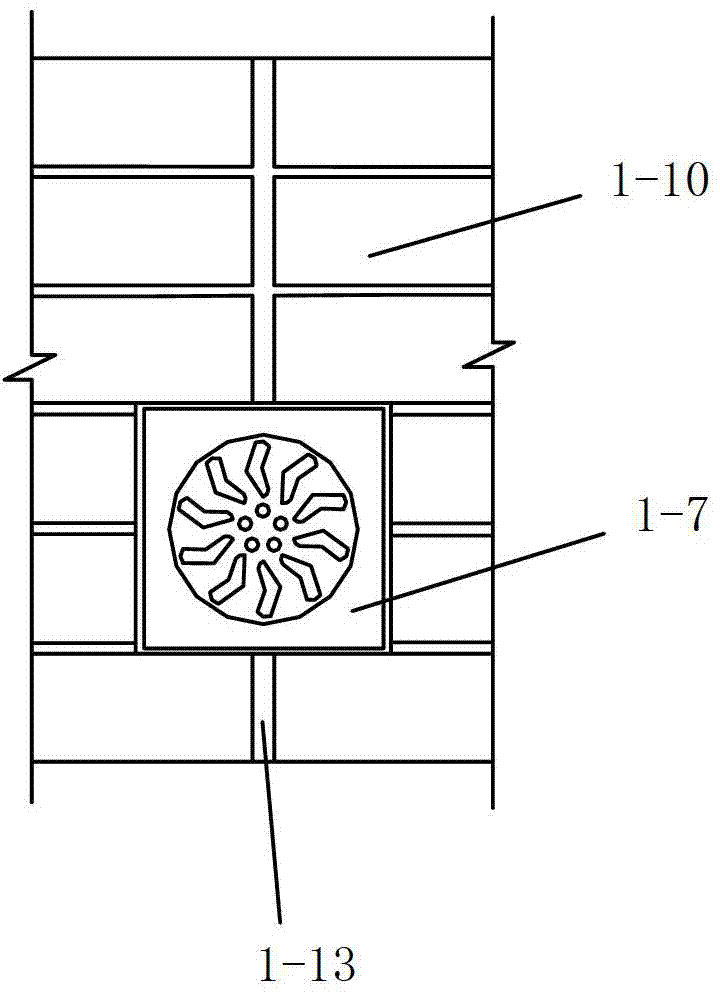

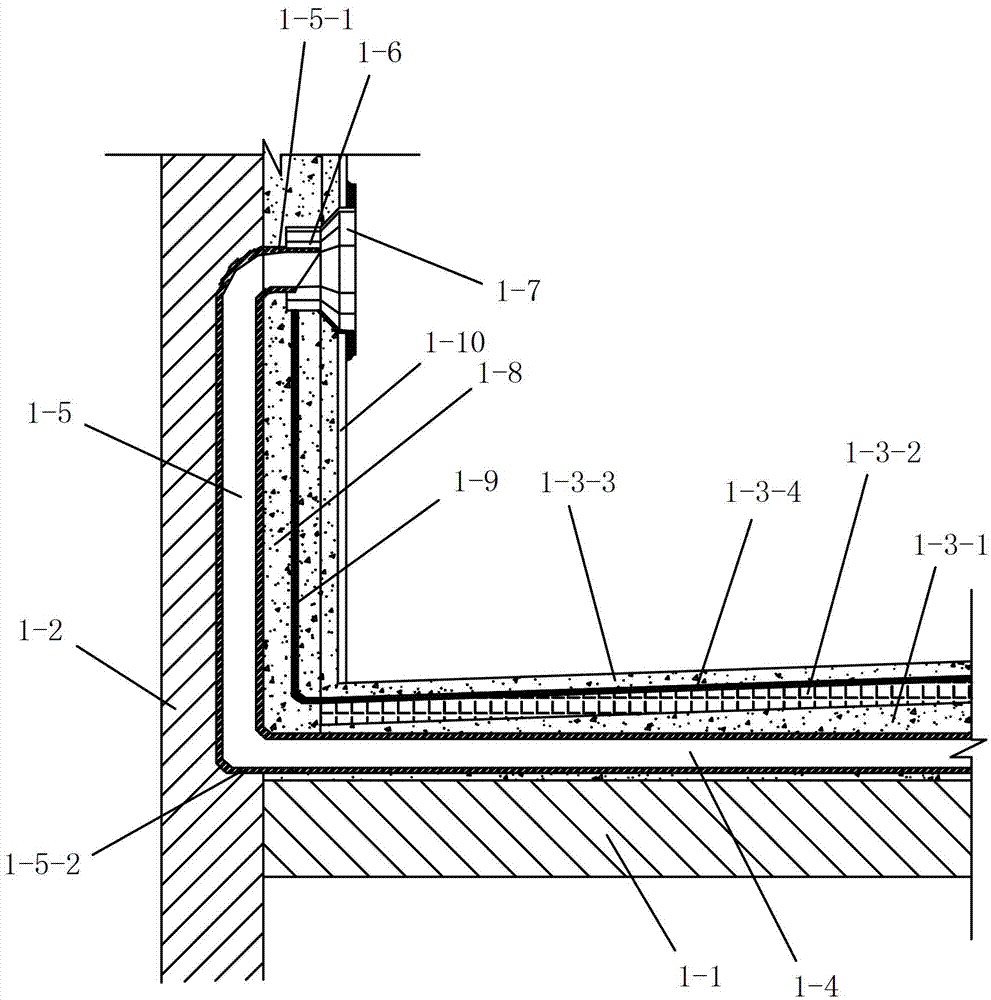

Building roof construction process

InactiveCN103362254ASimple stepsReasonable designLighting and heating apparatusBuild-up roofsInsulation layerSurface layer

The invention discloses a building roof construction process. A construction roof comprises a roof structure plate, a parapet wall and a roof surface layer, wherein the parapet wall is arranged above the roof structure plate, the roof surface layer is paved on the roof structure plate, a roof exhaust system is arranged on the construction roof and comprises a plurality of first horizontal exhaust pipes, the first horizontal exhaust pipes are respectively laid in a slope finding layer or a heat insulation layer in the roof surface layer, two ends of each first horizontal exhaust pipe are respectively connected with a vertical exhaust pipe, and the vertical exhaust pipes are embedded in the side walls of the parapet wall and a discharge flue or the side wall of an exhaust passage. The construction process of a construction roof comprises the steps of 1, surveying and setting out; 2, parapet wall, discharge flue and exhaust passage construction; 3, horizontal exhaust pipe positioning installation; 4, exhaust pipe connection; 5, roof surface layer construction; and 6, rigid protecting layer mesh division and caulking construction. The construction process has the advantages that the steps are simple, the operability is high, the realization is convenient, in addition, the work efficiency is high, the construction effect is good, and the construction quality of the construction forming building roof can be effectively ensured.

Owner:陕西建工集团有限公司 +1

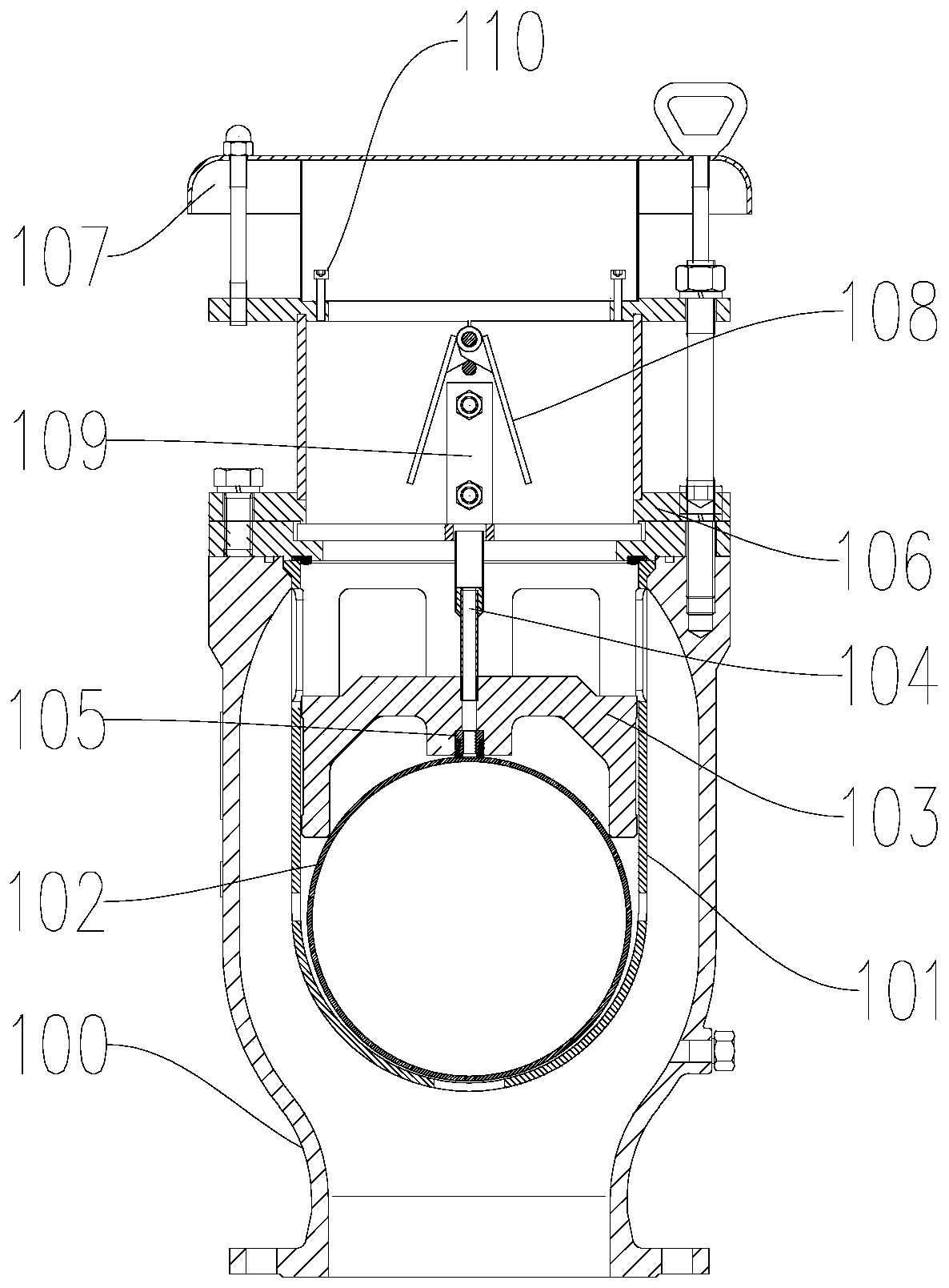

Air valve

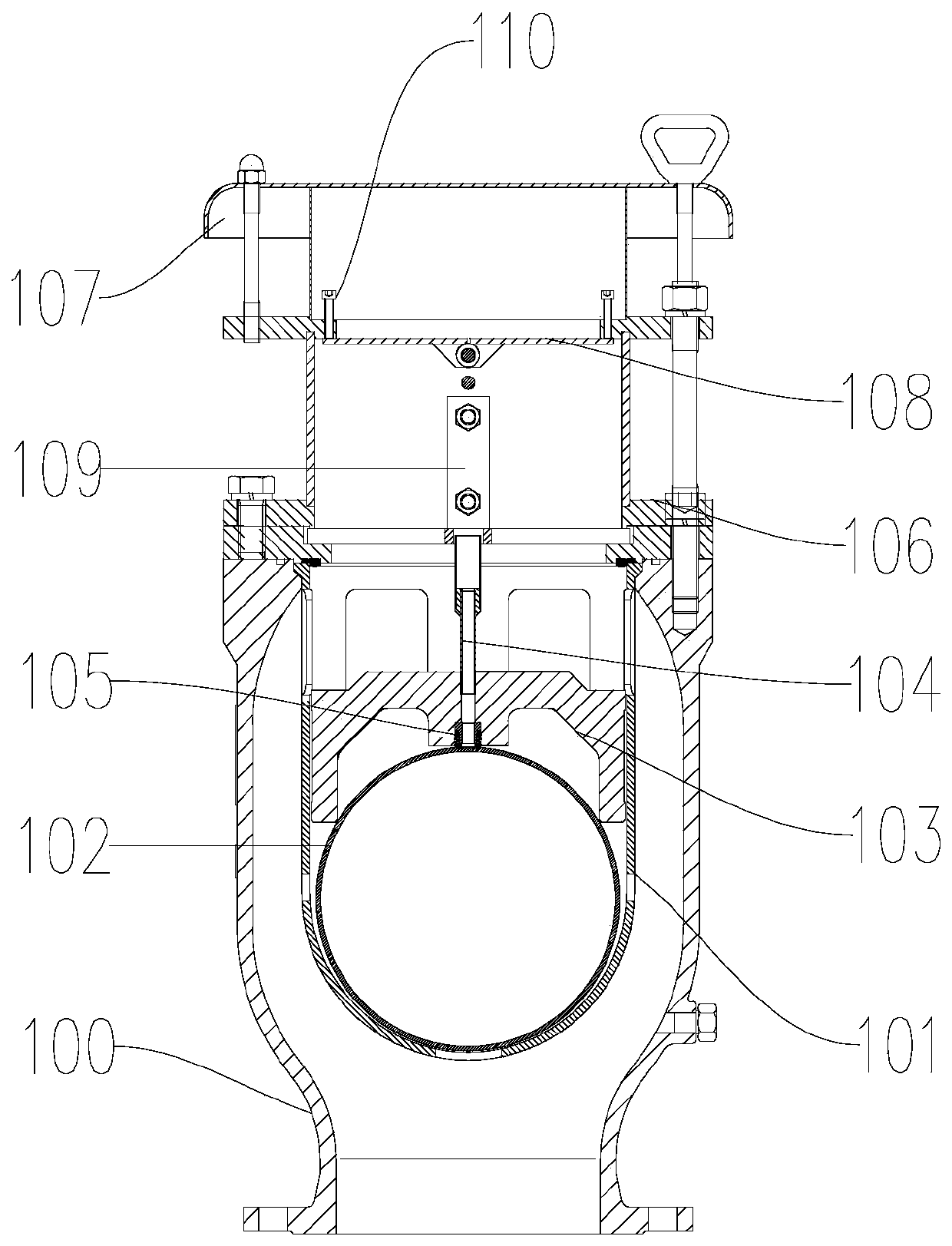

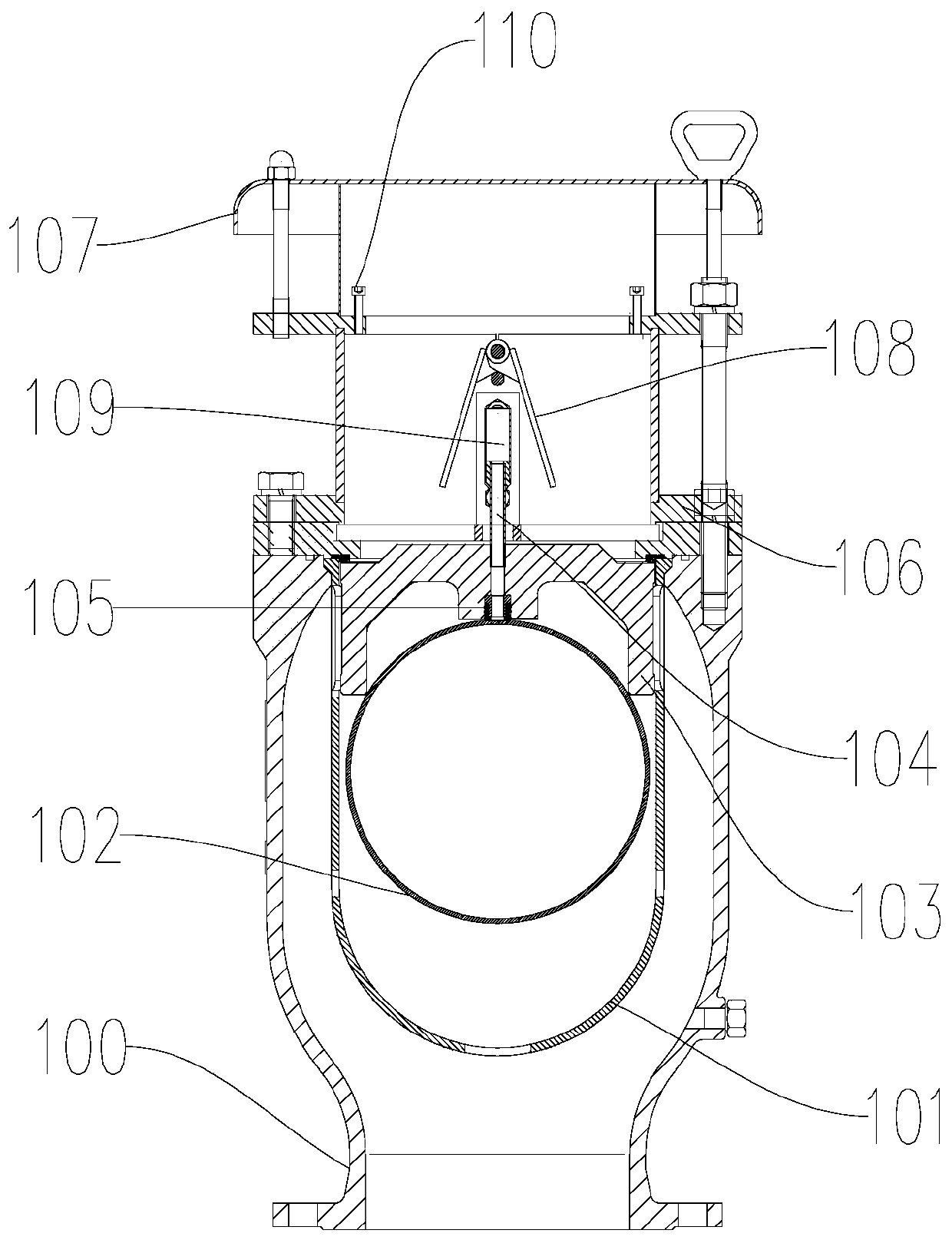

InactiveCN110701369ASimplify split and combined structureCompact structureOperating means/releasing devices for valvesAeration devicesEngineeringMechanical engineering

The invention discloses an air valve. The air valve comprises a valve body, wherein a valve cavity with a bottom opening is formed in the valve body, a rapid exhaust passage communicating with the valve cavity is arranged at the upper end of the valve body, a valve element mechanism capable of moving up and down is arranged in the valve cavity, the rapid exhaust passage can be closed or opened inthe process of moving up or down of the valve element mechanism, and a signal feedback device used for detecting a signal of the movement position of the valve element mechanism is arranged in the rapid exhaust passage. According to the air valve, through the signal feedback device arranged in the rapid exhaust passage and used for detecting the signal of the movement position of the valve elementmechanism, real-time monitoring of the movement position of the valve element mechanism is achieved, and timely feedback is sent to a technician when a problem occurs, so that the condition that timely processing cannot be achieved after the valve element mechanism is stuck is avoided.

Owner:WATTS VALVE CHANGSHA

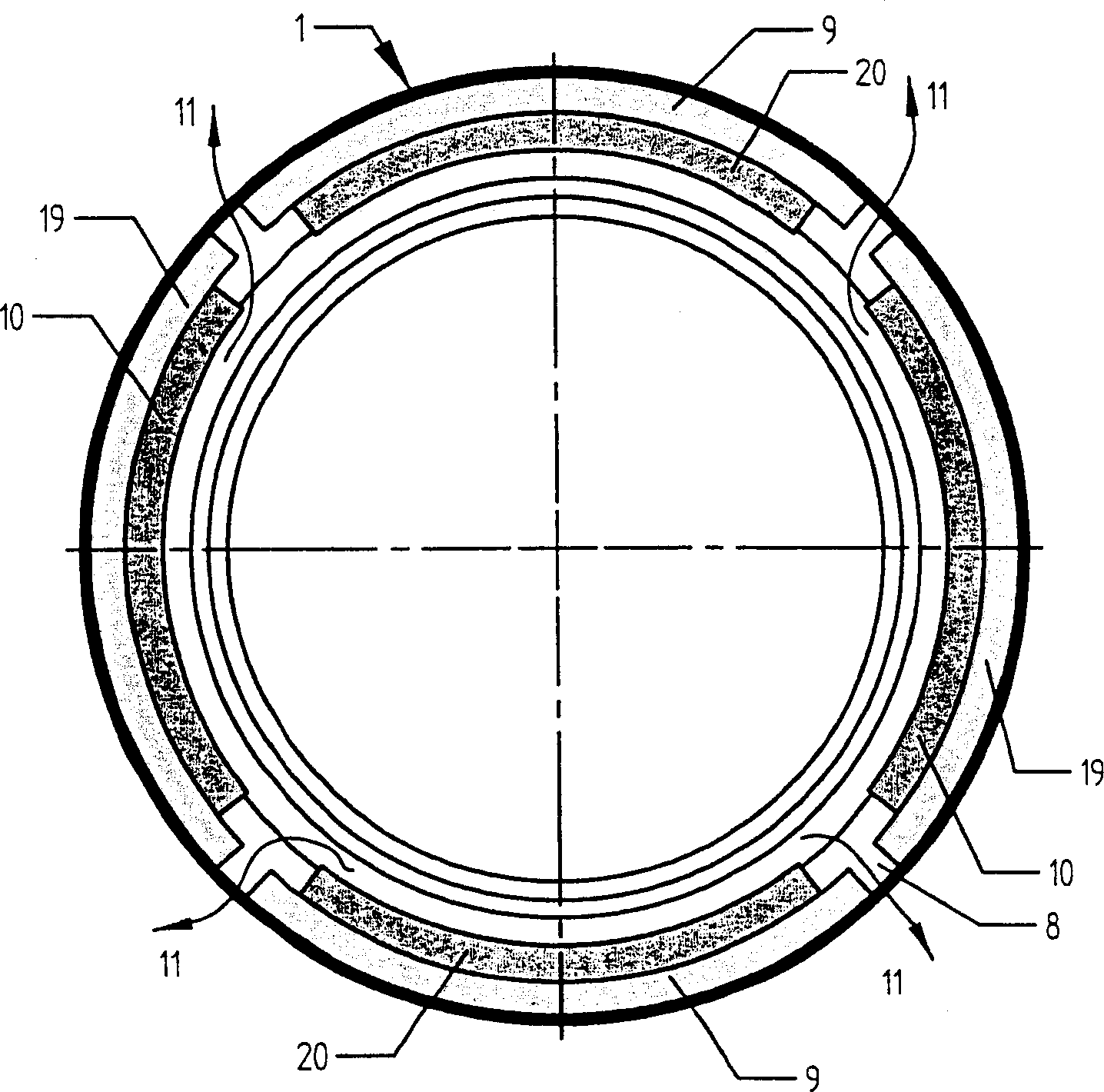

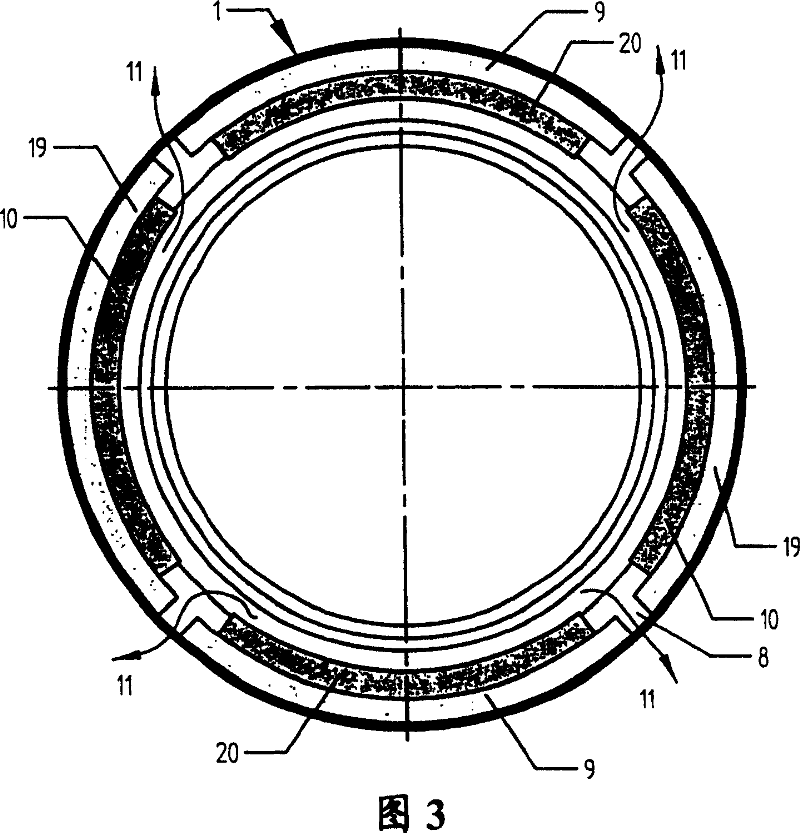

Radial lip seal device

Owner:CARL FREUDENBERG KG

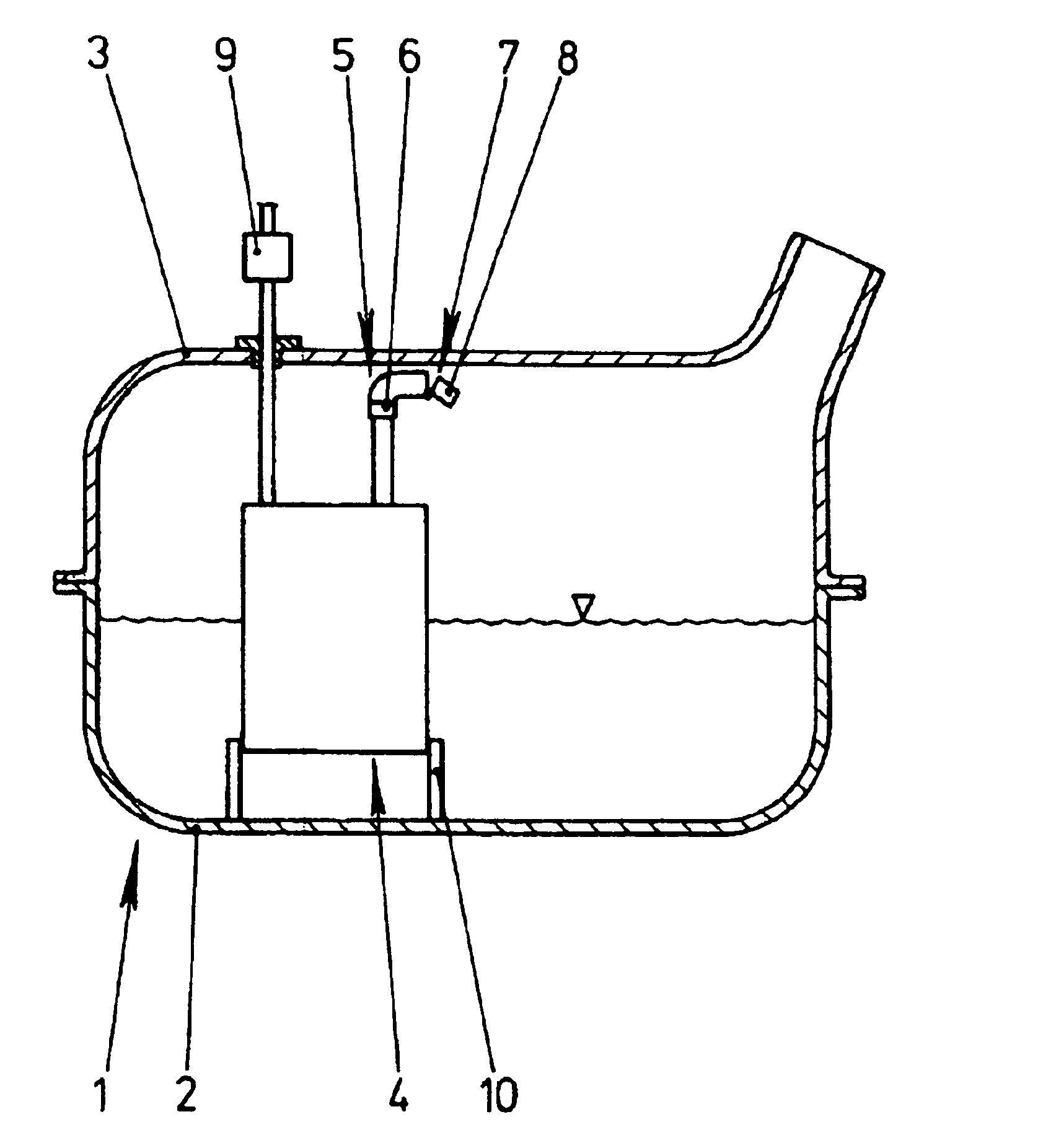

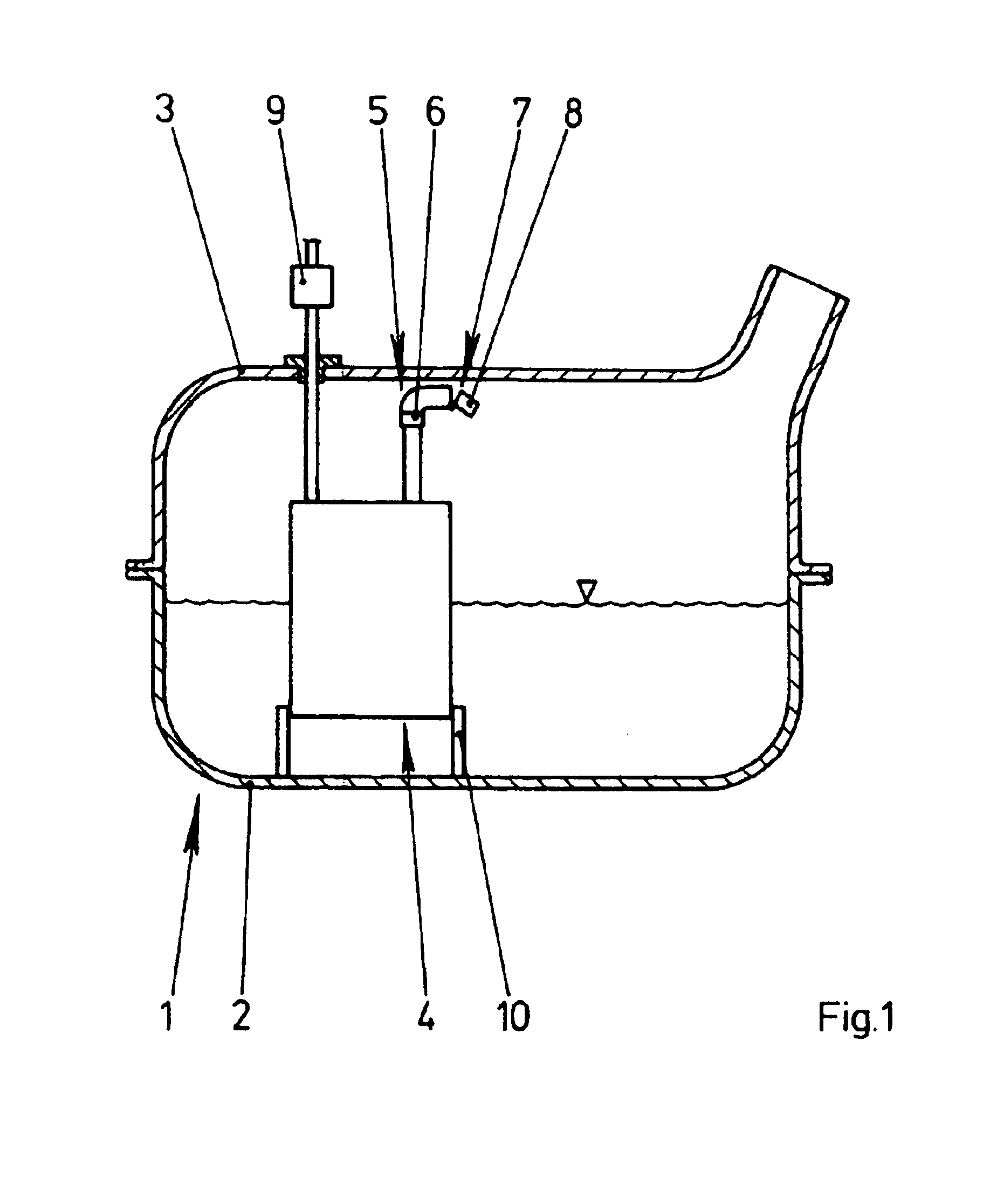

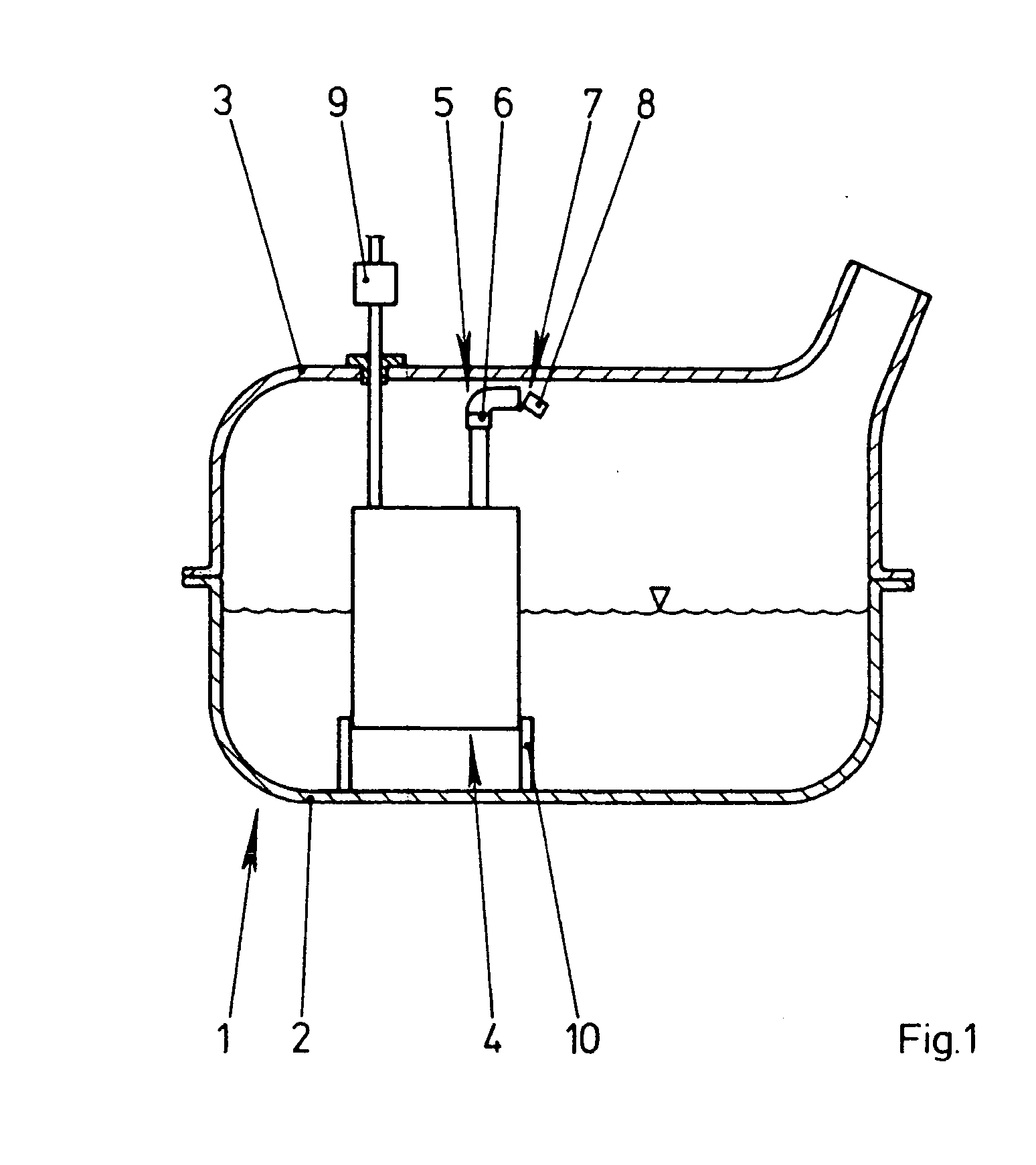

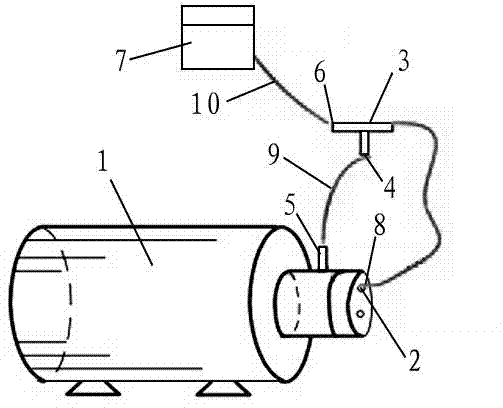

Venting device

InactiveUS7047949B2Reliable exhaustAvoid shakingLarge containersPipeline systemsFuel tankEngineering

In a venting device for a fuel tank (1), a venting line (5) has a movable section (6) and a spring element (14). The free end of the venting line (5) is prestressed against an upper wall of the fuel tank (1). This ensures that a valve (7) which is arranged at the free end of the venting line (5) is always arranged in the vicinity of the upper wall of the fuel tank (1).

Owner:SIEMENS AG

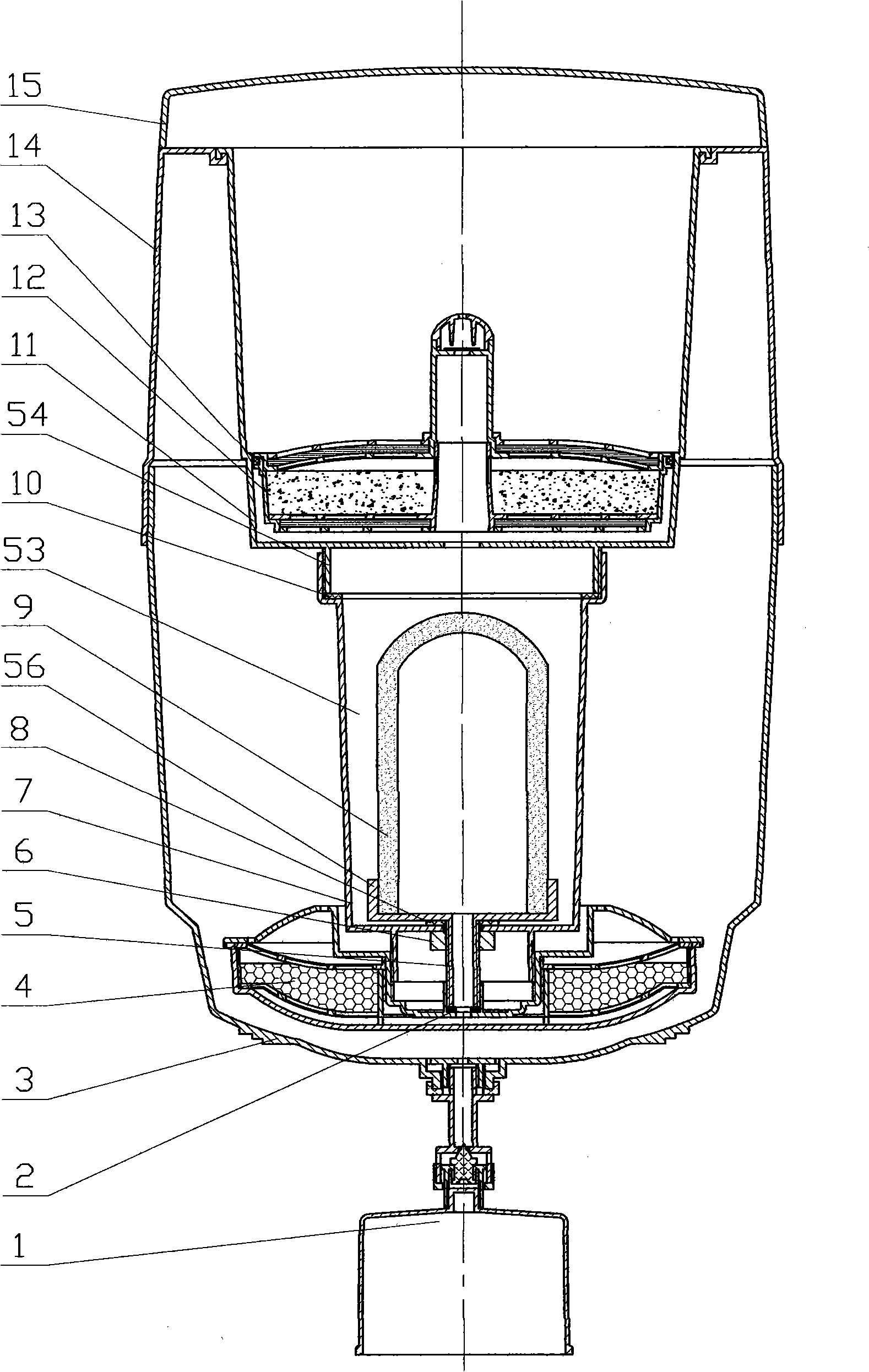

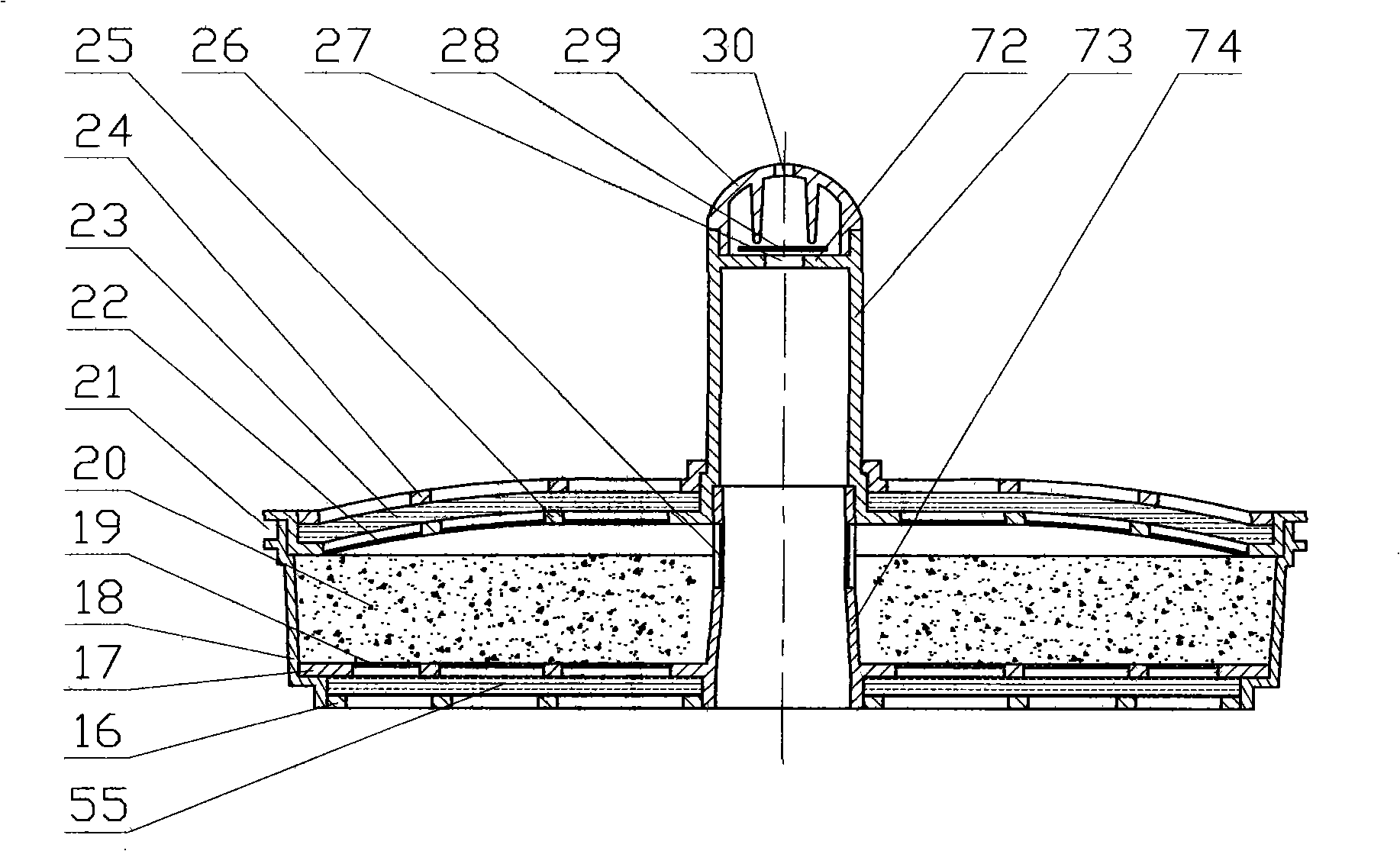

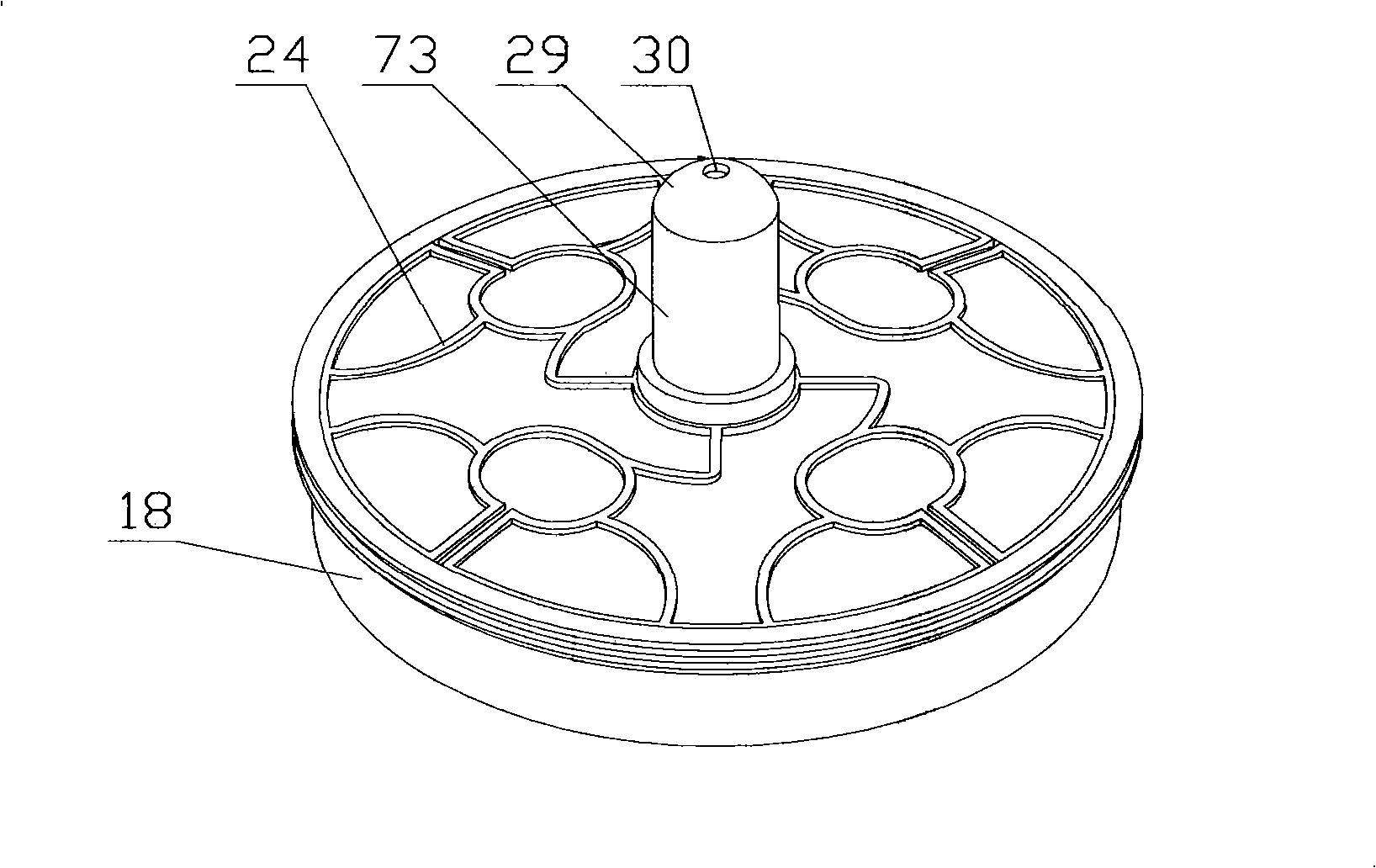

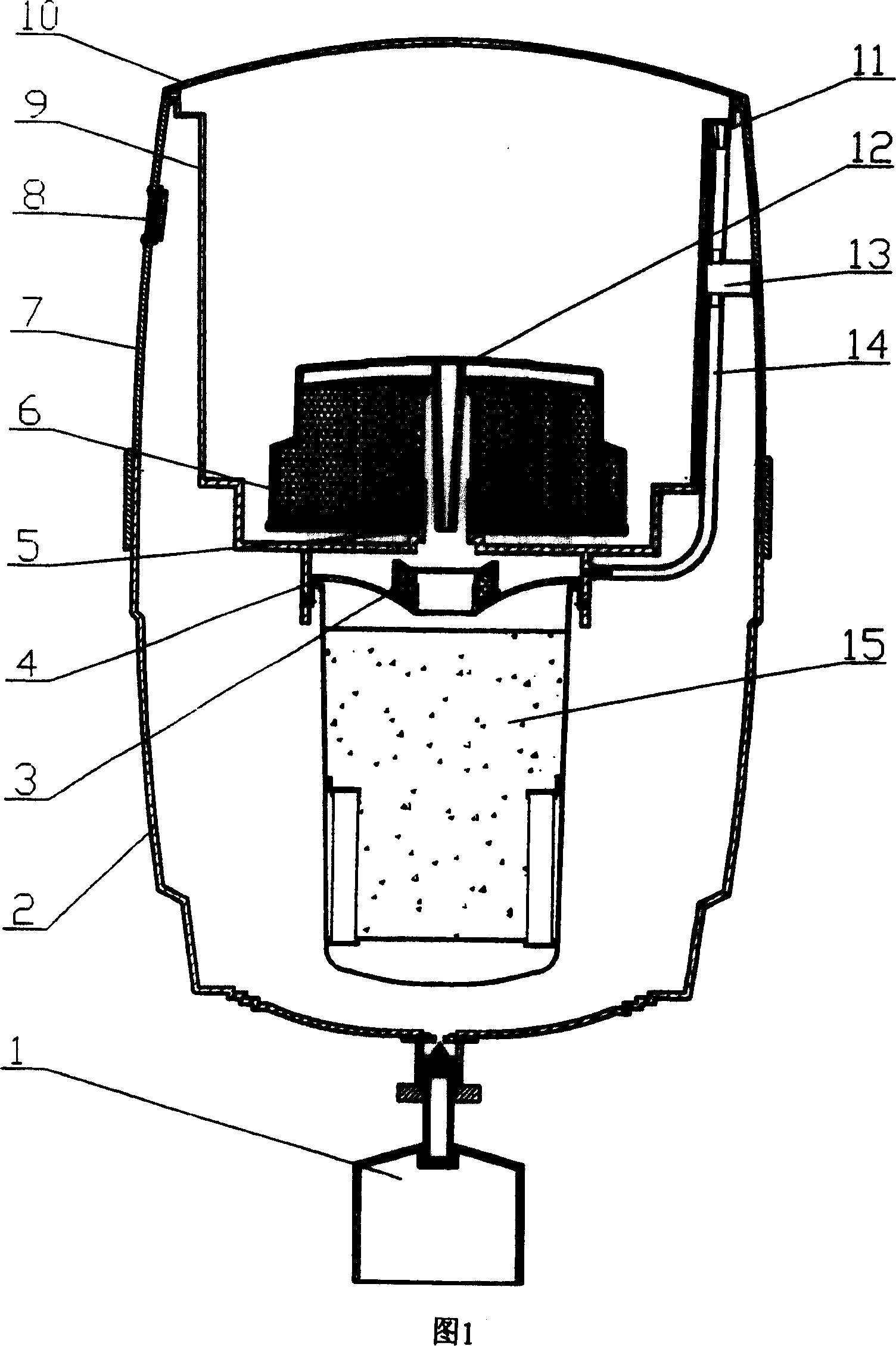

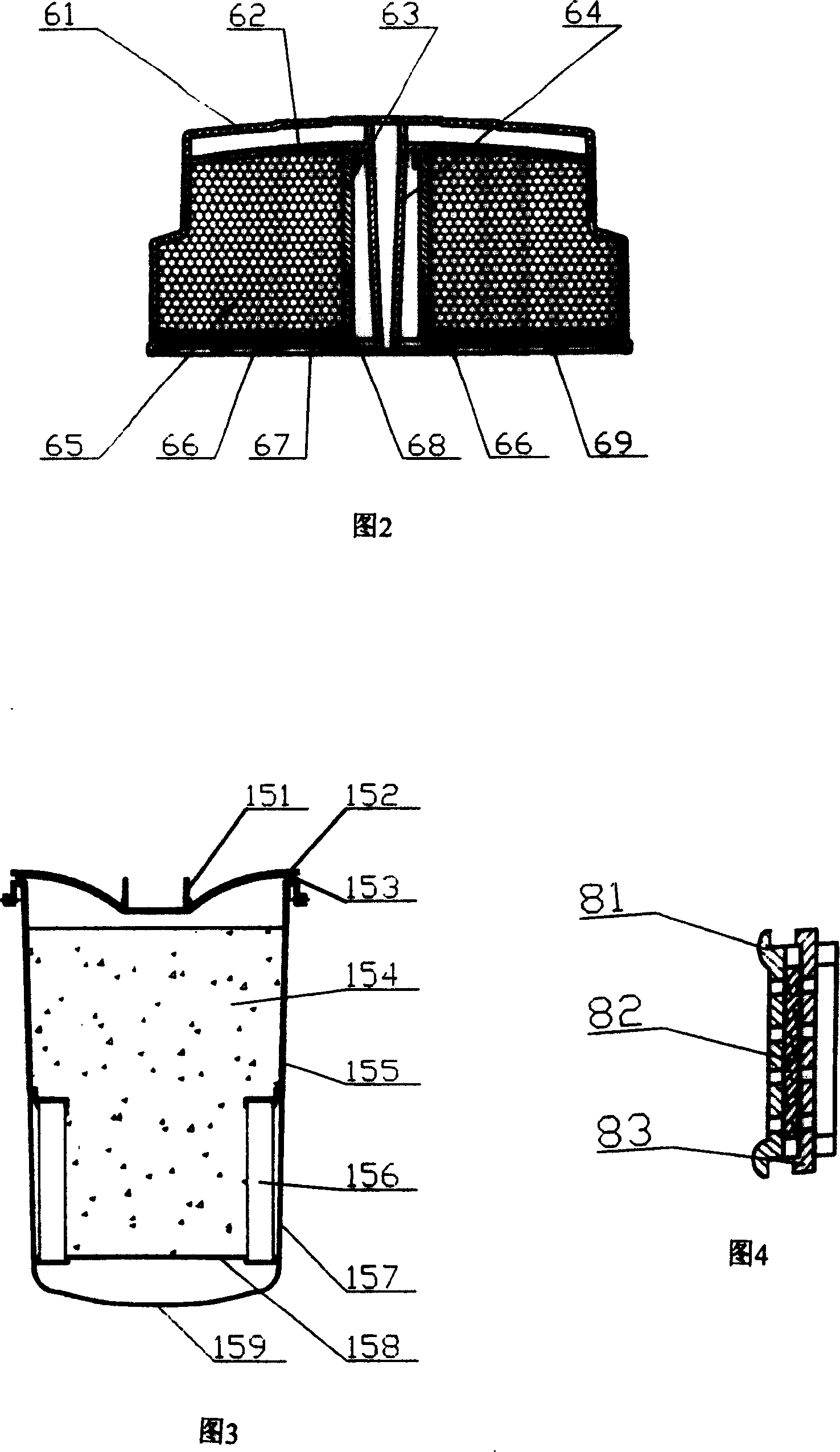

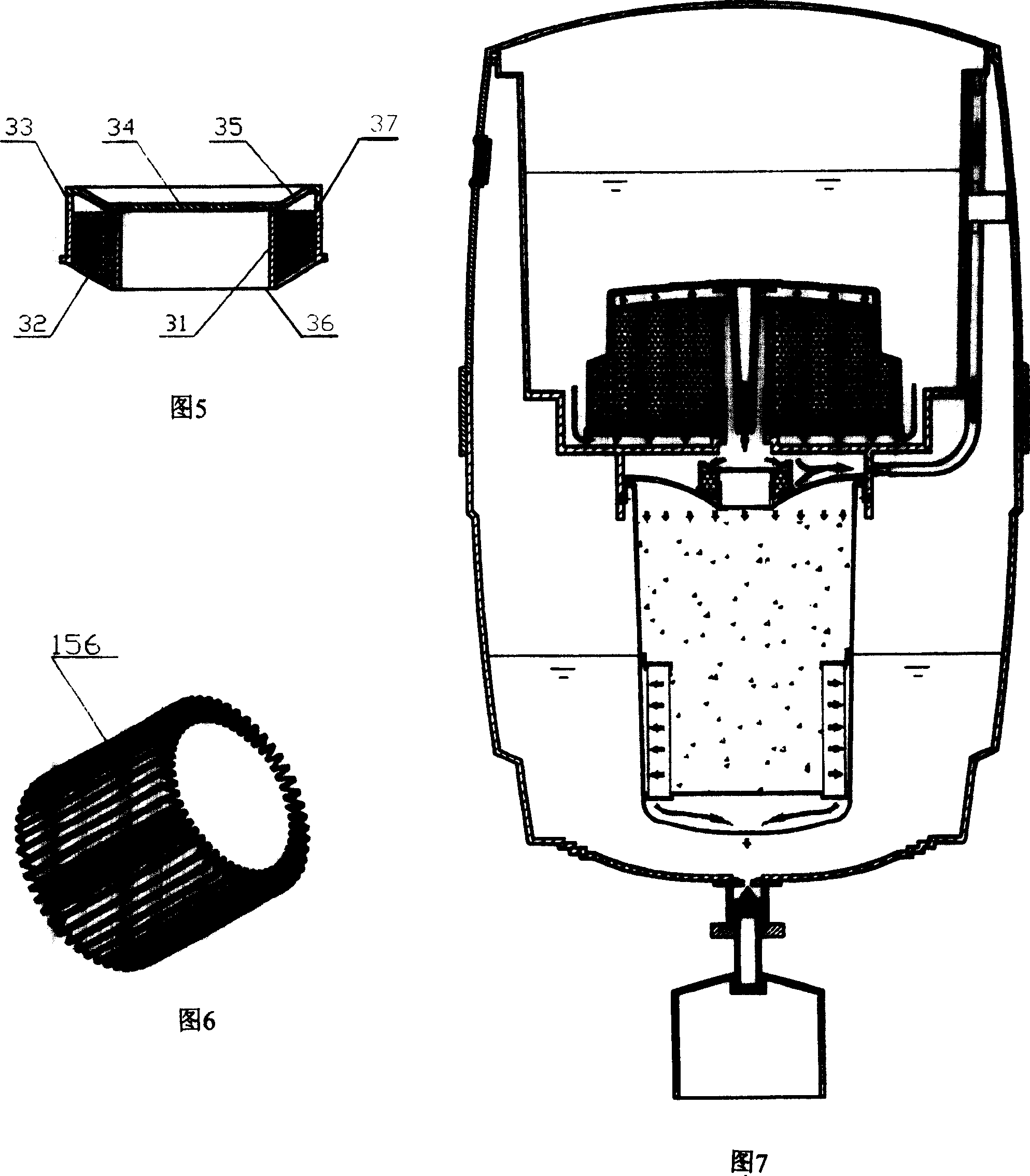

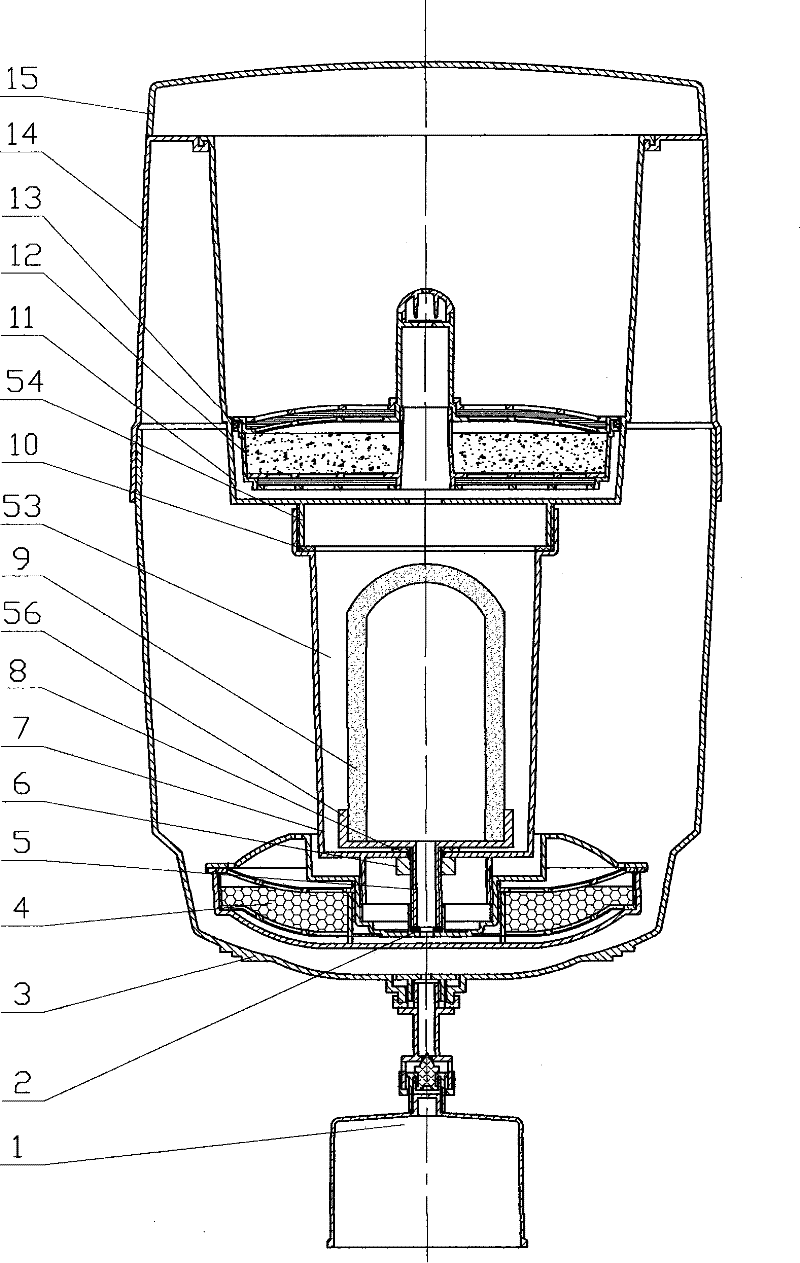

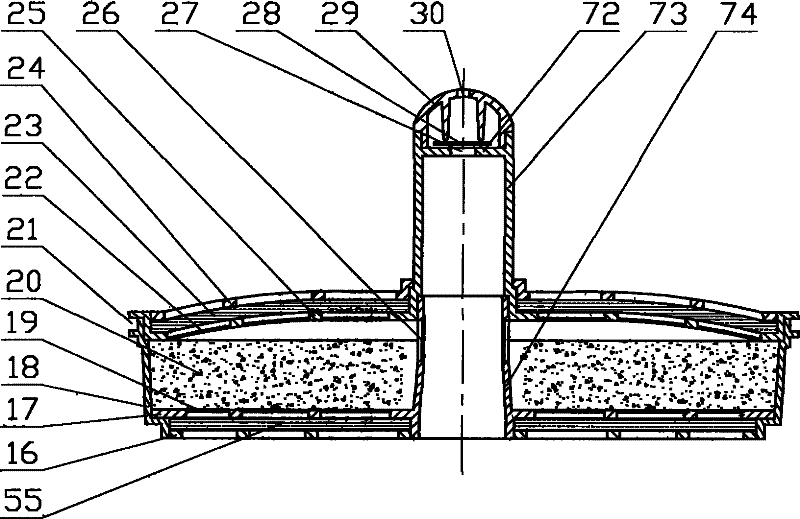

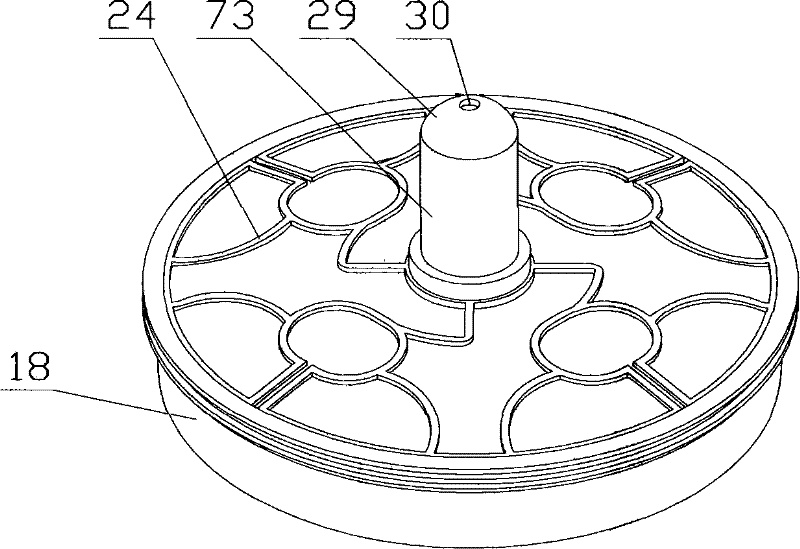

Jet deflection type special water purifier of water drinking machine

InactiveCN101269854AReliable exhaustStable and reliable water outletWater/sewage treatment by ion-exchangeLoose filtering material filtersWater qualityWater flow

The invention relates to a special water clarifier of a turn back flow water fountain, which comprises an upper cover, an upper barrel and a lower barrel. The bottom of the lower barrel is provided with a float valve or a ball cock which can control the water level in a water hopper of the water fountain, the bottom of the upper barrel is provided with an upper filter element which is provided with an exhaust pipe, a lower filter element is arranged under the bottom of the upper barrel, the bottom of the lower filter element is connected with a turn back flow filter element which includes a shell body with a closed bottom, a lower screen is arranged at the lower part in the shell body, an upper screen is arranged at the upper part in the shell body, and granular filter material is filled between the lower screen and the upper screen. The special water clarifier has the beneficial effects that: firstly, the exhaust of the filter element is reliable, gas in the turn back flow filter element needs to be exhausted when the turn back flow is started for the first time only, so the yielding water of the water clarifier is reliable; secondly, the water filtering power of the water clarifier is enough, the lower filter element adopts micropore ceramics with higher filtering precision, so the filtering effect is increased; thirdly, because water flows through the upper filter element, the lower filter element, and the turn back flow filter element for being purified and treated repeatedly, the water quality of the yielding water is ensured more easily.

Owner:黄瑞中

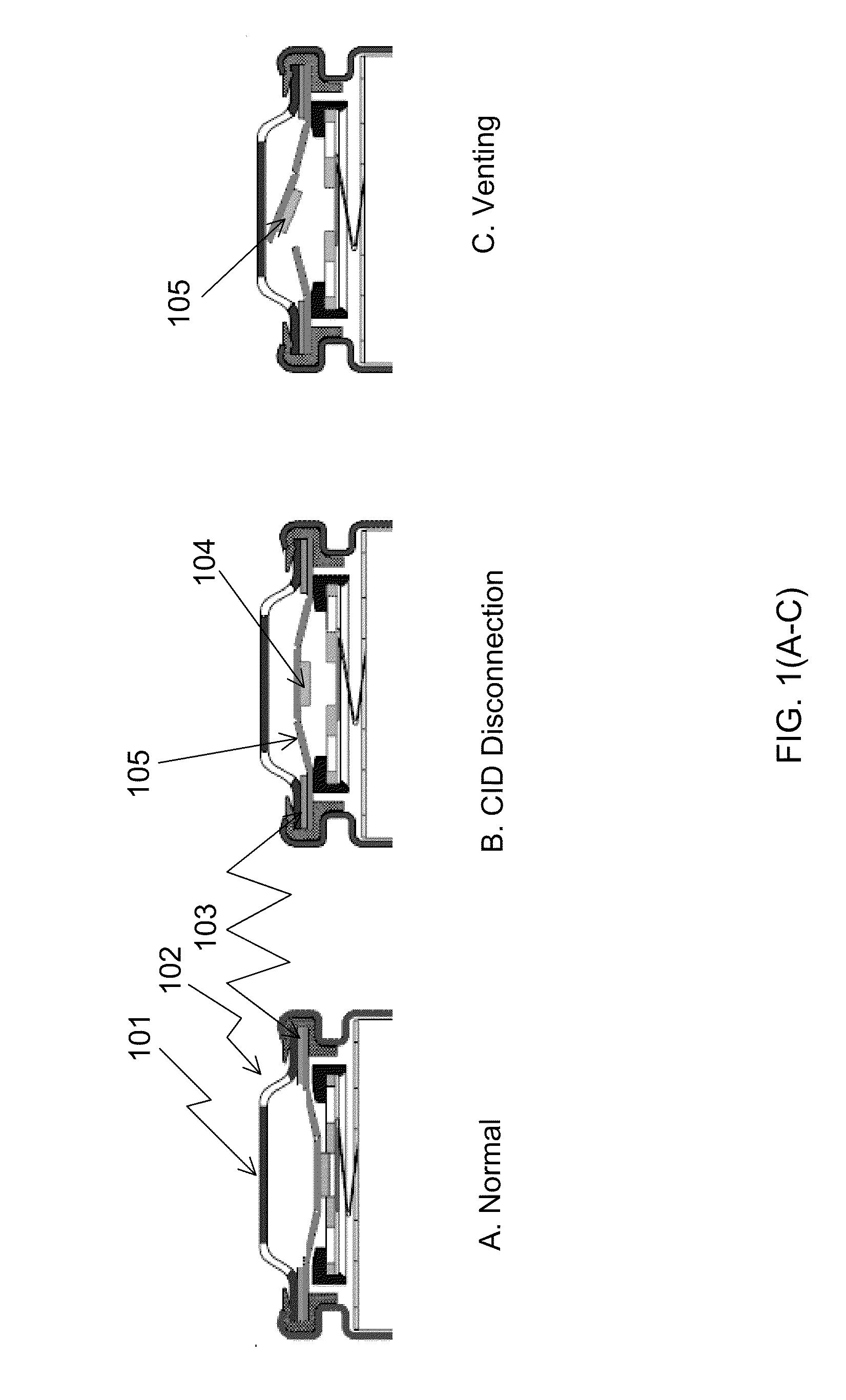

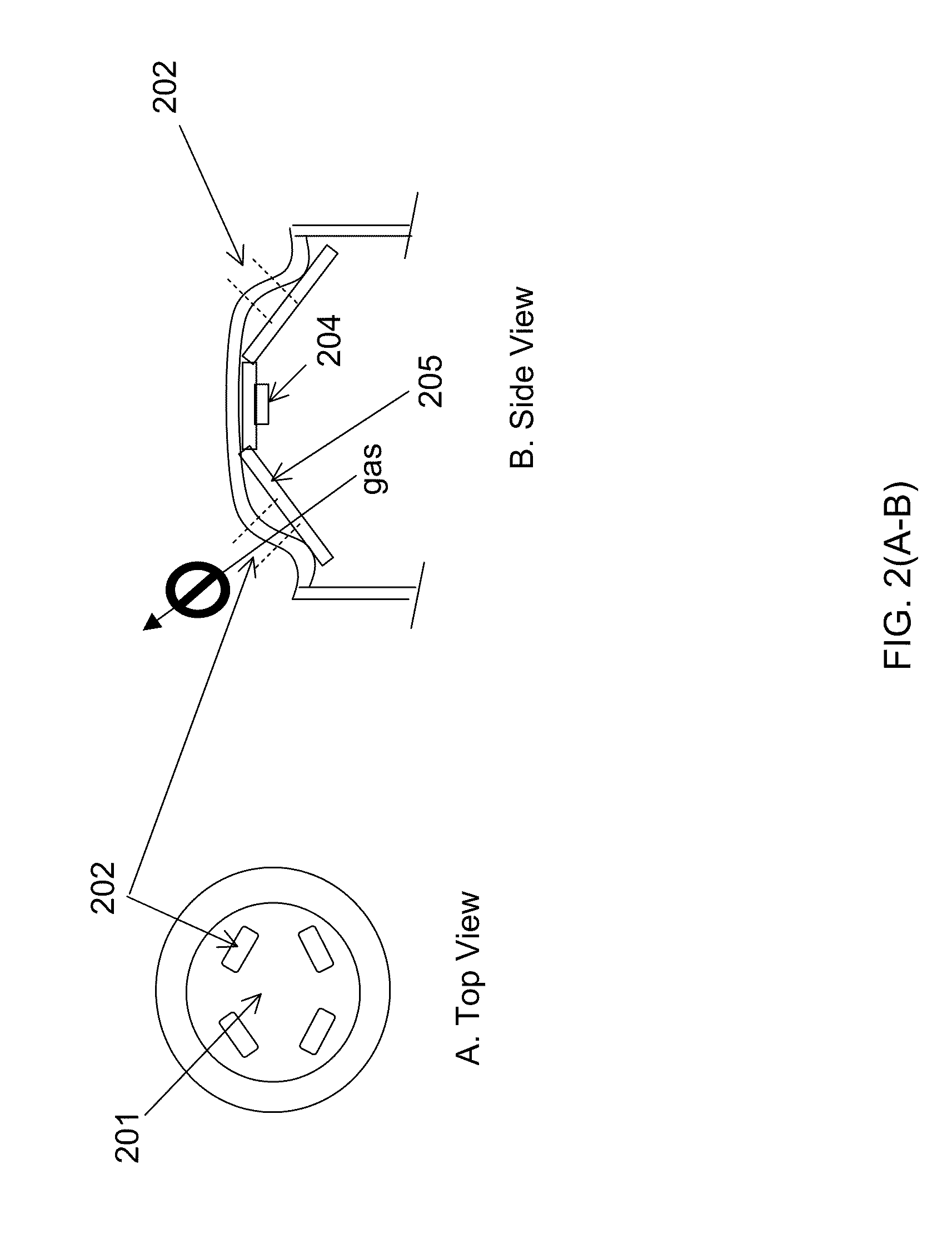

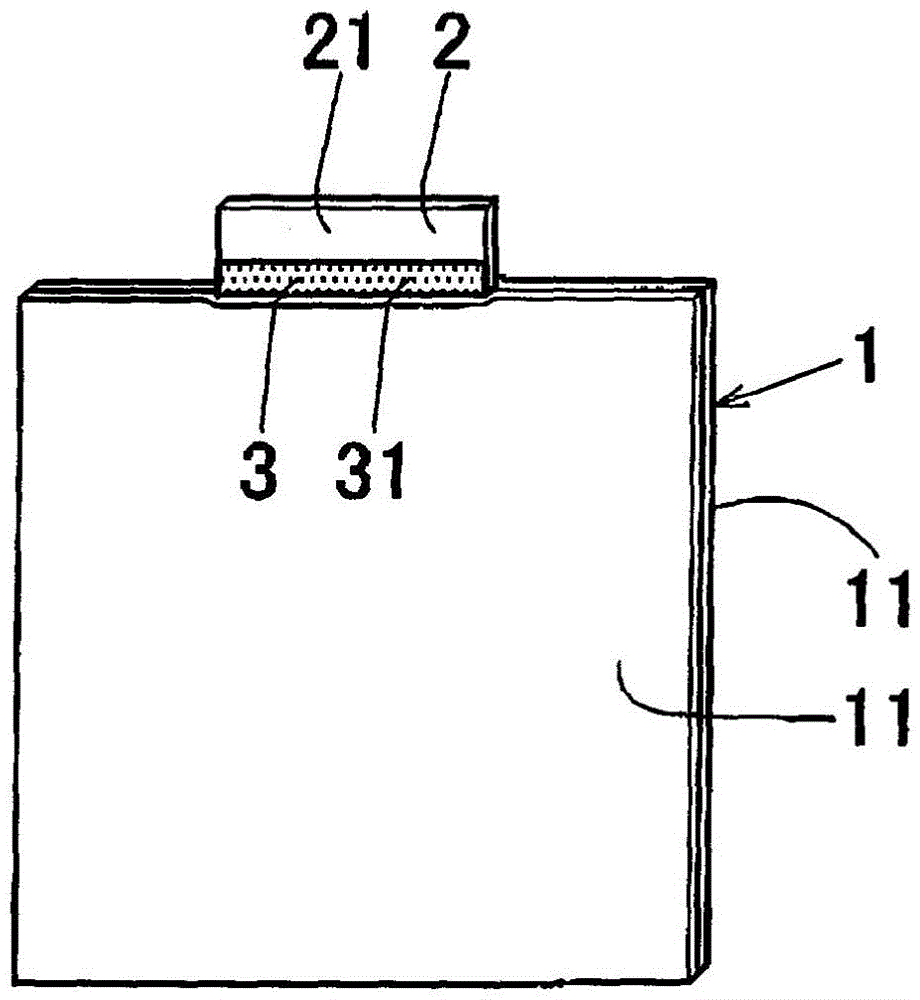

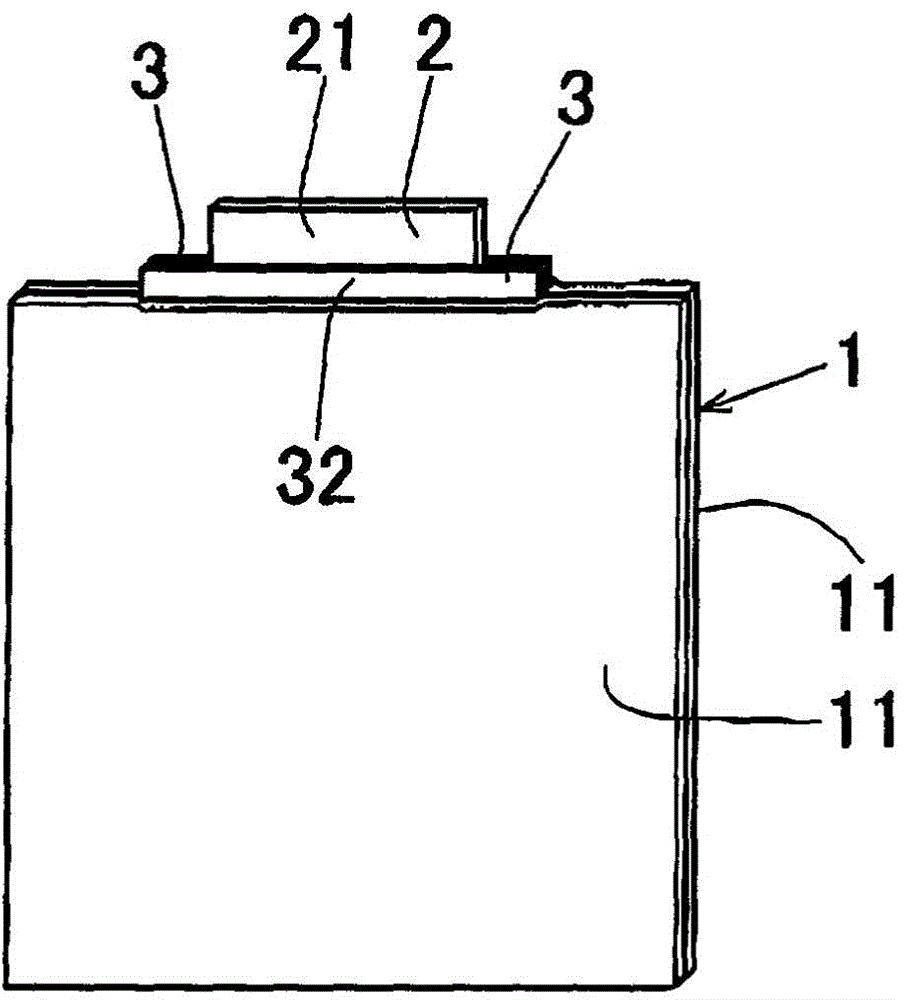

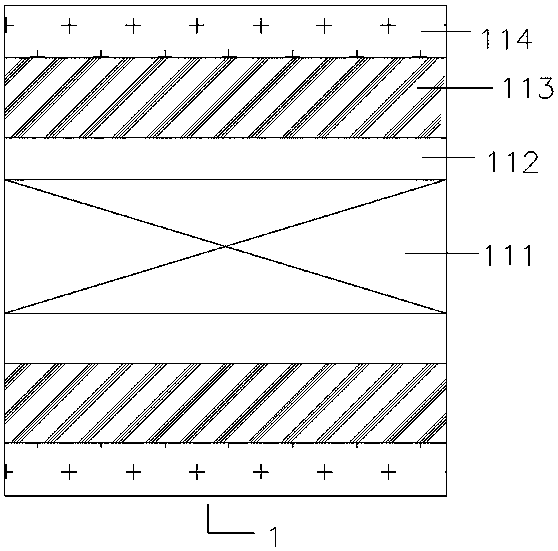

Double acting venting mechanism for battery cells

InactiveUS20110217572A1Reliable exhaustRaise security concernsVent arrangementsBatteriesExternal pressureEngineering

Embodiments of the invention provide battery cells having a double acting venting mechanism that provides reliable venting even in response to various undesirable events. Embodiments of the invention ensure that safe venting can take place, as necessary, even if the battery cell encounters internal and / or external pressure and / or deformation.

Owner:LENOVO (SINGAPORE) PTE LTD

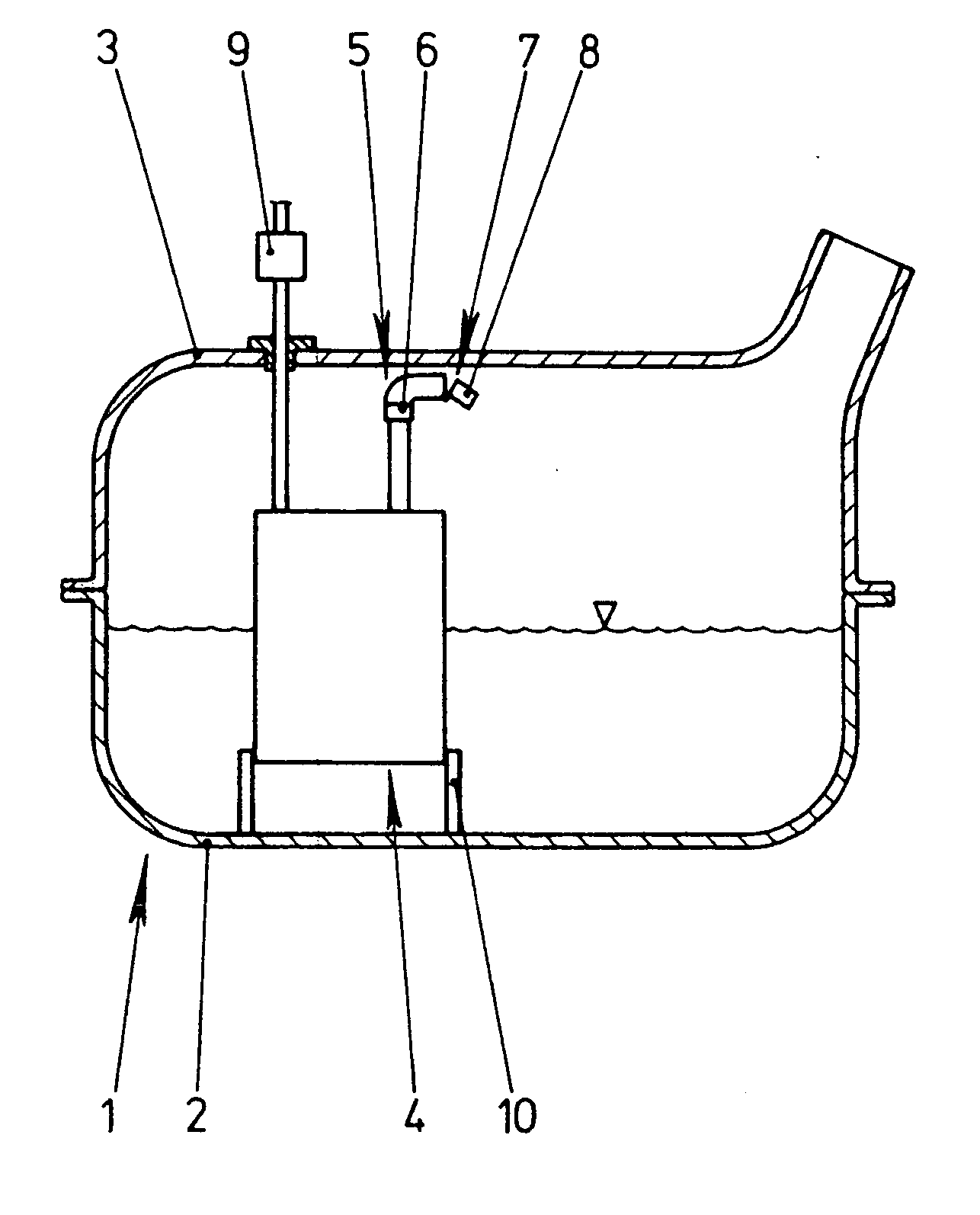

Venting device

InactiveUS20050016601A1Reliable exhaustAvoid shakingLarge containersMachines/enginesFuel tankEngineering

In a venting device for a fuel tank (1), a venting line (5) has a movable section (6) and a spring element (14). The free end of the venting line (5) is prestressed against an upper wall of the fuel tank (1). This ensures that a valve (7) which is arranged at the free end of the venting line (5) is always arranged in the vicinity of the upper wall of the fuel tank (1).8

Owner:SIEMENS AG

An automatic overflow device for circuit breaker hydraulic mechanism

ActiveCN102926988BEasy to installReliable exhaustPositive displacement pump componentsLiquid fuel engine componentsOutgassingFuel tank

The invention discloses an automatic discharge device of a circuit breaker hydraulic mechanism. The automatic discharge device of the circuit breaker hydraulic mechanism comprises an oil pump, wherein a low pressure oil pipe outlet of the oil pump is connected with a tee, a port of the tee is connected onto an oil return hole of the lower pressure oil pipe, the other port of the tee is connected onto an oil tank, an exhaust bolt is arranged on the low pressure oil pipe outlet of the oil pump, the exhaust bolt is connected with the tee, a port of the tee is connected onto the oil return hole of a lower pressure oil pipe through a new pipeline, and the other port of the tee is connected onto an exhaust screw which is arranged on the upper portion of the oil tank through a pipeline. The automatic discharge device of the circuit breaker hydraulic mechanism has the advantages of convenient installation and reliable exhaust, can eliminate fault that a circuit breaker oil pump can not be pressed (frequently started) because of gas collection, and can be normally pressed and the like.

Owner:JIAXING ELECTRIC POWER BUREAU +1

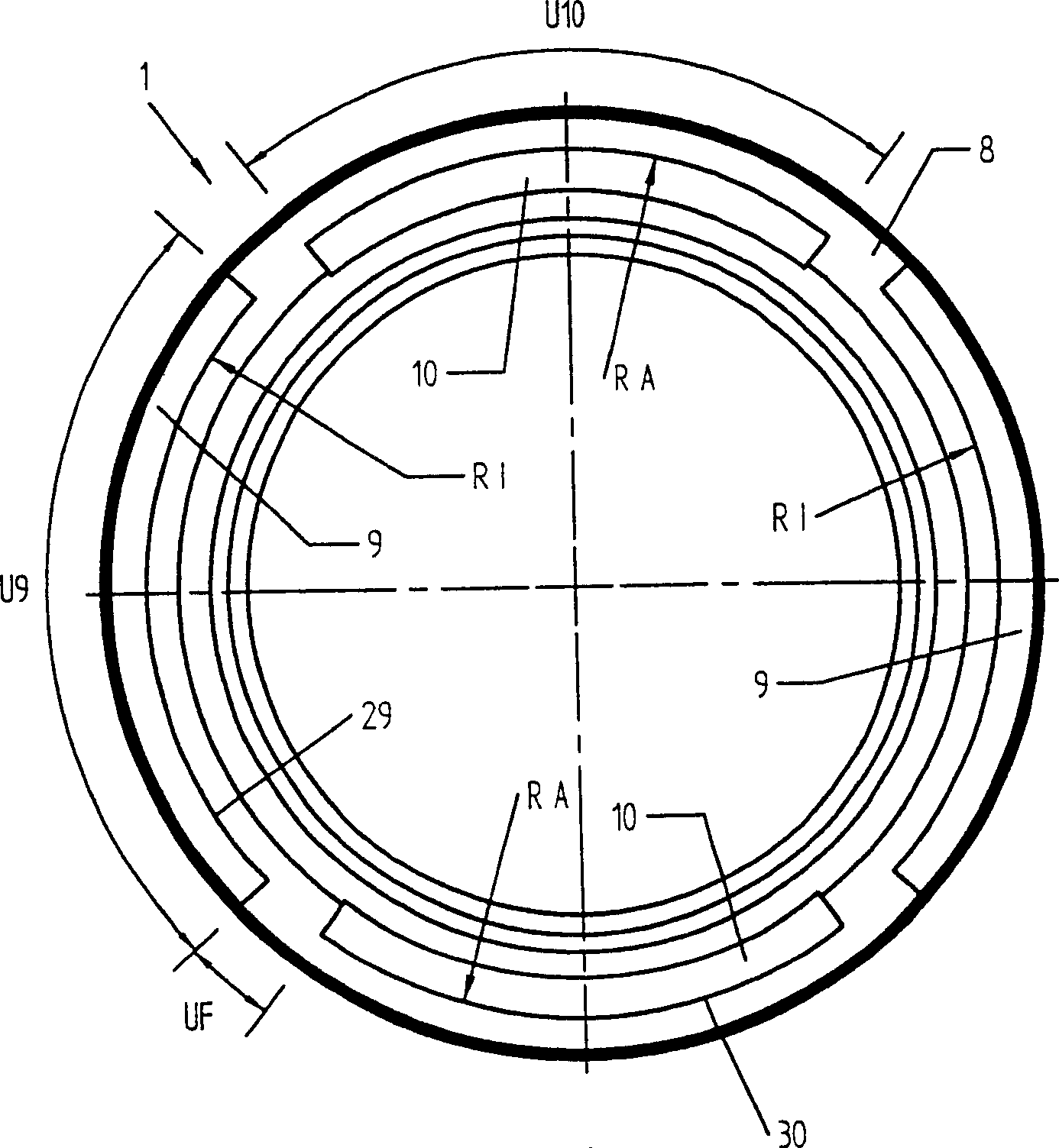

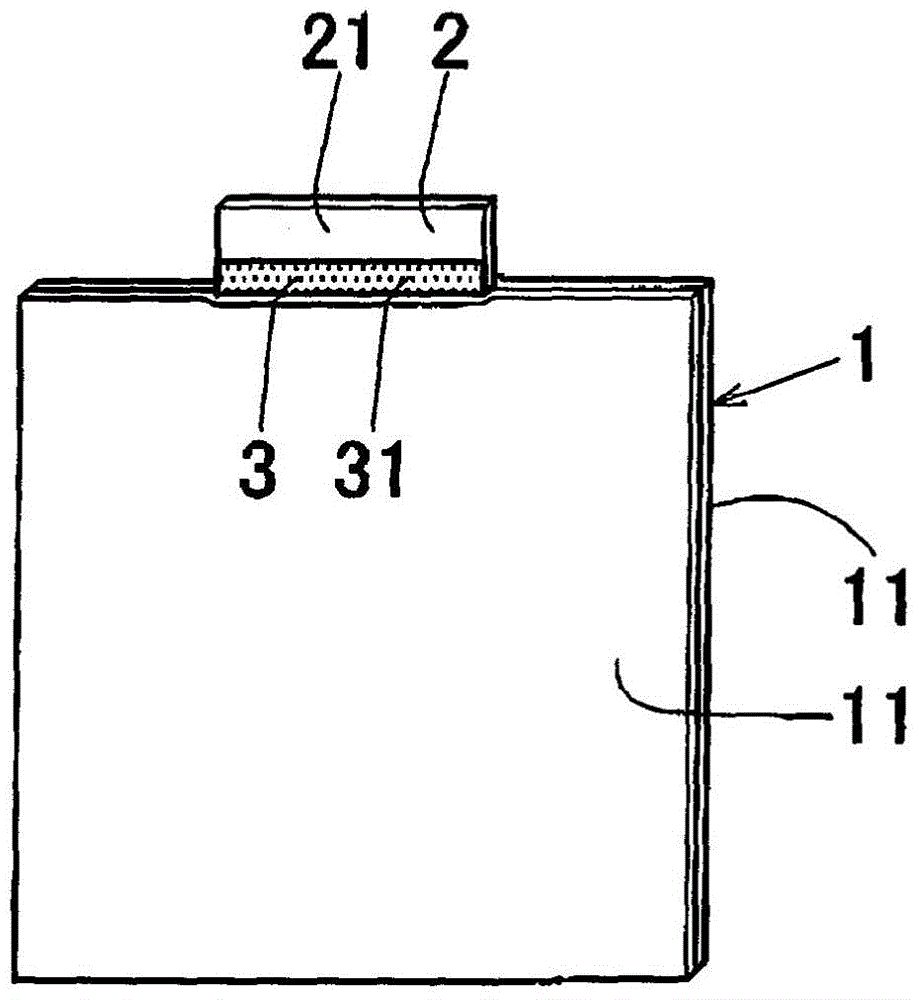

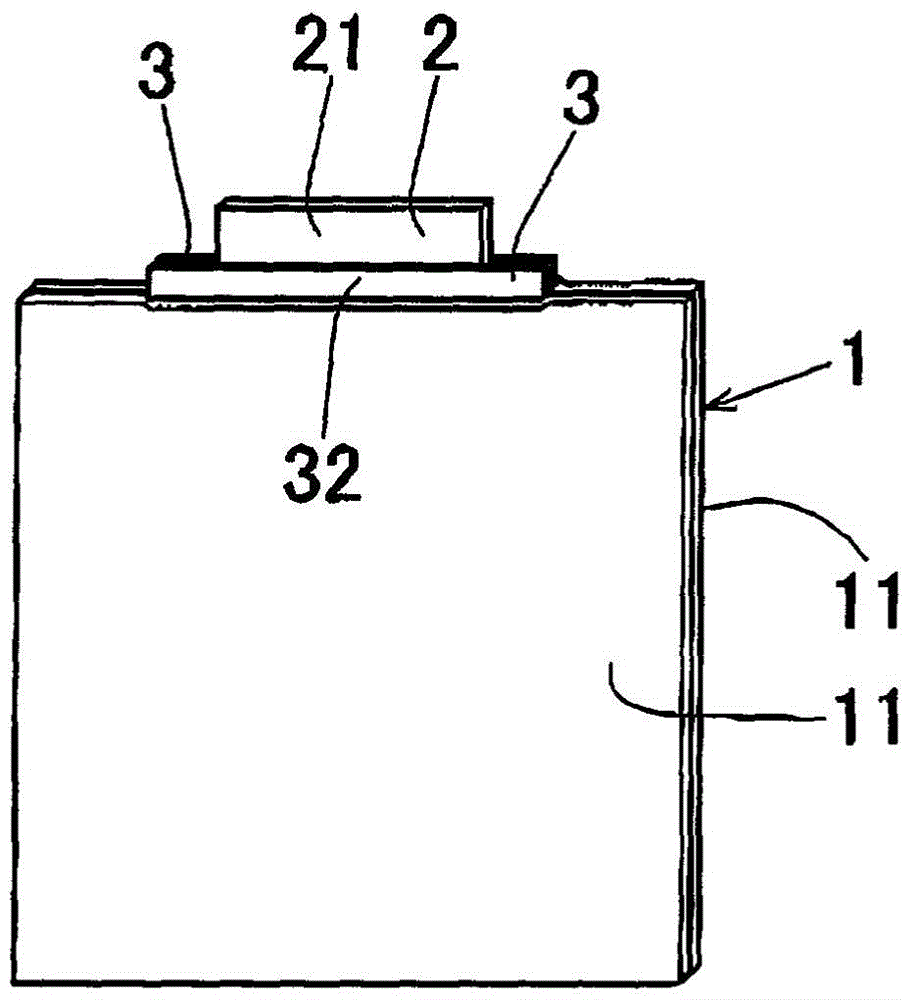

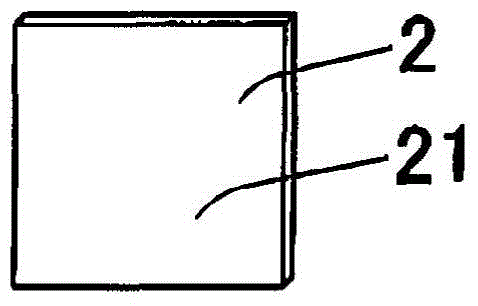

External body for electrochemical devices

ActiveCN103855332AEnough to installHigh strengthLaminationLamination apparatusInternal pressureChemical compound

The invention provides a laminated-type external body for electrochemical devices, and a porous metal sheet as a safety valve can be installed in sufficient strength. The laminated-type external body for electrochemical devices is taken as an object, two external films (11) composed of high-molecular compounds are stacked to make two single-face-side sealant layers be oppositely arranged, and the periphery parts of the stacked external films (11) are sealed. On end of a safety valve (2) which is formed by a porous metal sheet (21) and can prevent the rise of internal pressure is arranged in the interior of the external body, and the other end is arranged outside the external body. The safety valve (2) is clamped between the periphery parts corresponding to the stacked external films (11), and the safety valve (2) is fixed on the sealant layers of the external films (11) through a bonding layer containing high-molecular compounds.

Owner:株式会社乐索纳克包装

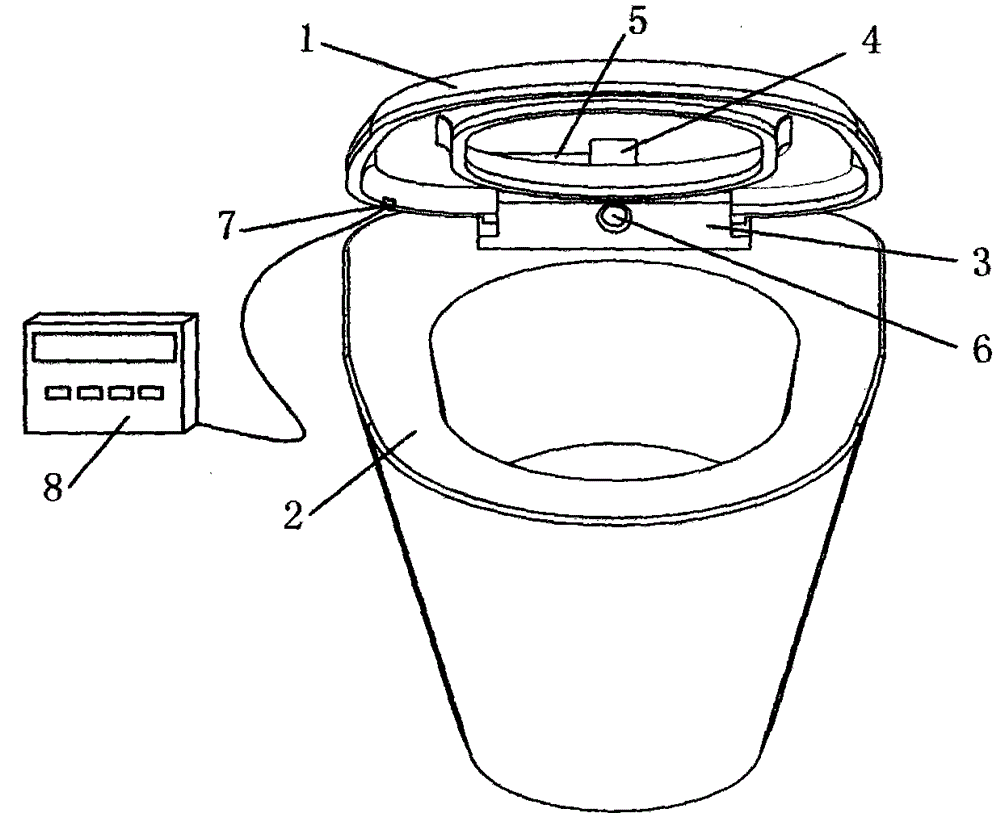

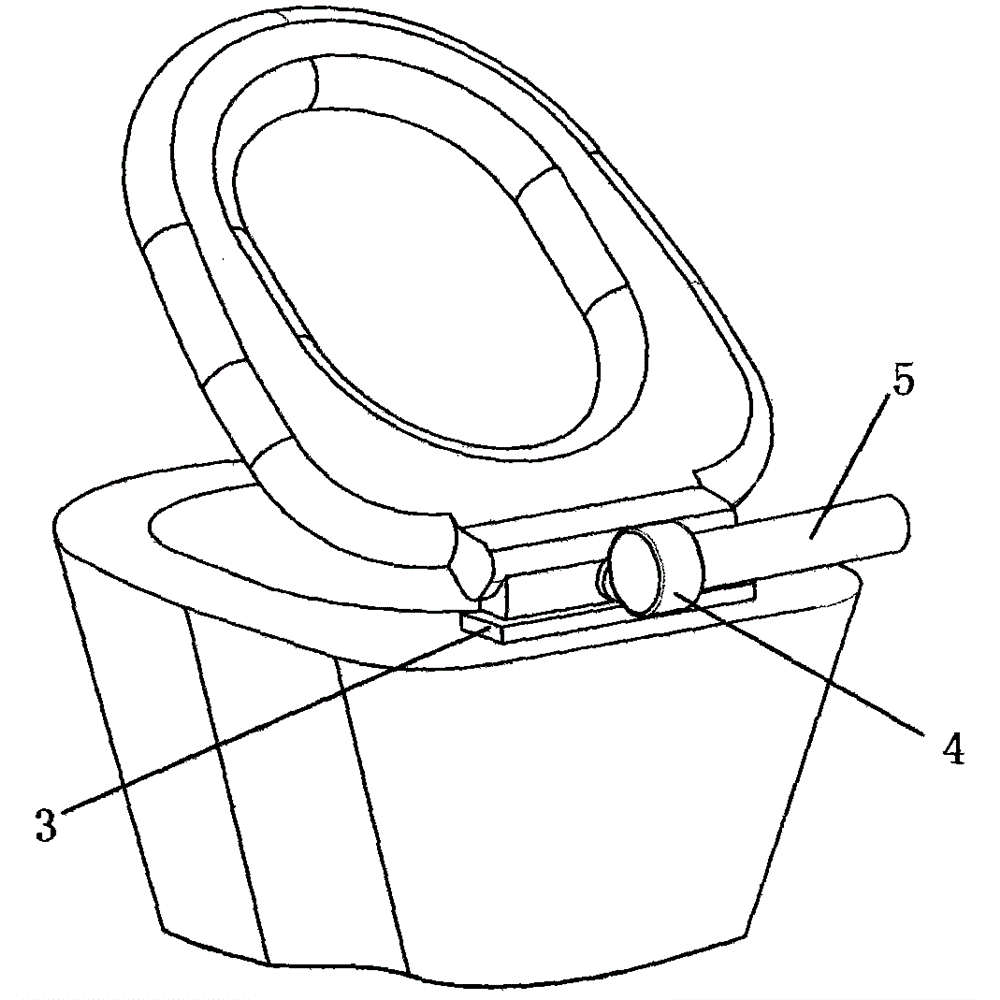

Peculiar smell eliminating closestool

InactiveCN104631591ALow structural requirementsEasy dischargeLavatory sanitoryShortest distanceEngineering

The invention discloses a peculiar smell eliminating closestool which comprises a closestool body, a seat cushion, a support and a short-distance exhaust system close to the edge of a urinal of the closestool. The short-distance exhaust system comprises a miniature exhaust fan, an exhaust pipe and a control switch, wherein a through hole is formed in the support, the miniature exhaust fan is connected to the through hole, and the exhaust pipe is connected between the miniature exhaust fan and an outside exhaust duct. On the premise that wide-range modification is not conducted on the overall structure of an existing closestool, peculiar smell is directly discharged out along the edge of the urinal in a direct discharging mode, air pollution in a toilet is avoided, the whole exhaust process is reliable and effective, and the peculiar smell eliminating closestool is good in peculiar smell eliminating effect and powerful in functions and is suitable for direct installation and usage like an existing closestool.

Owner:JIAXING WEISIBO NETWORK TECH

Hydraulic cylinder

InactiveCN108374812AShorten speedEffective anti-riot treatmentFluid-pressure actuator componentsHydraulic cylinderEngineering

The invention relates to a hydraulic cylinder. The hydraulic cylinder comprises a cylinder barrel, wherein a reinforcing rib is arranged in the cylinder barrel and is provided with a sealing layer; apiston rod is arranged in an inner cavity of the cylinder barrel; the bottom part of the piston rod is connected with a piston; a supporting ring is arranged between the piston and the sealing layer and is connected with a Y-shaped sealing ring; clamping keys are connected to the bottom part of the piston and are provided with clamping key caps; an oil filter is arranged between the clamping key caps and is connected with a buffering device which is connected with the cylinder bottom; an oil nozzle is arranged on the cylinder bottom and is connected with an oil pipe; the oil pipe is fixed witha fixing part and divides the cylinder barrel and the cylinder bottom; ventilating holes are arranged in the fixing part; a cylinder cover is arranged at the junction of the piston rod and the cylinder barrel and is internally provided with a double-layer sealing ring; a blocking ring is arranged on the double-layer sealing ring and is connected with a guide sleeve; a U-shaped sealing ring is arranged on the guide sleeve; a bulge is arranged on the cylinder barrel at the lower end of the guide sleeve and is connected with an exhausting device. The hydraulic cylinder has the advantages of strong sealing performance, good stability and safety, no leakage and long service life.

Owner:马鞍山纽盟知识产权管理服务有限公司

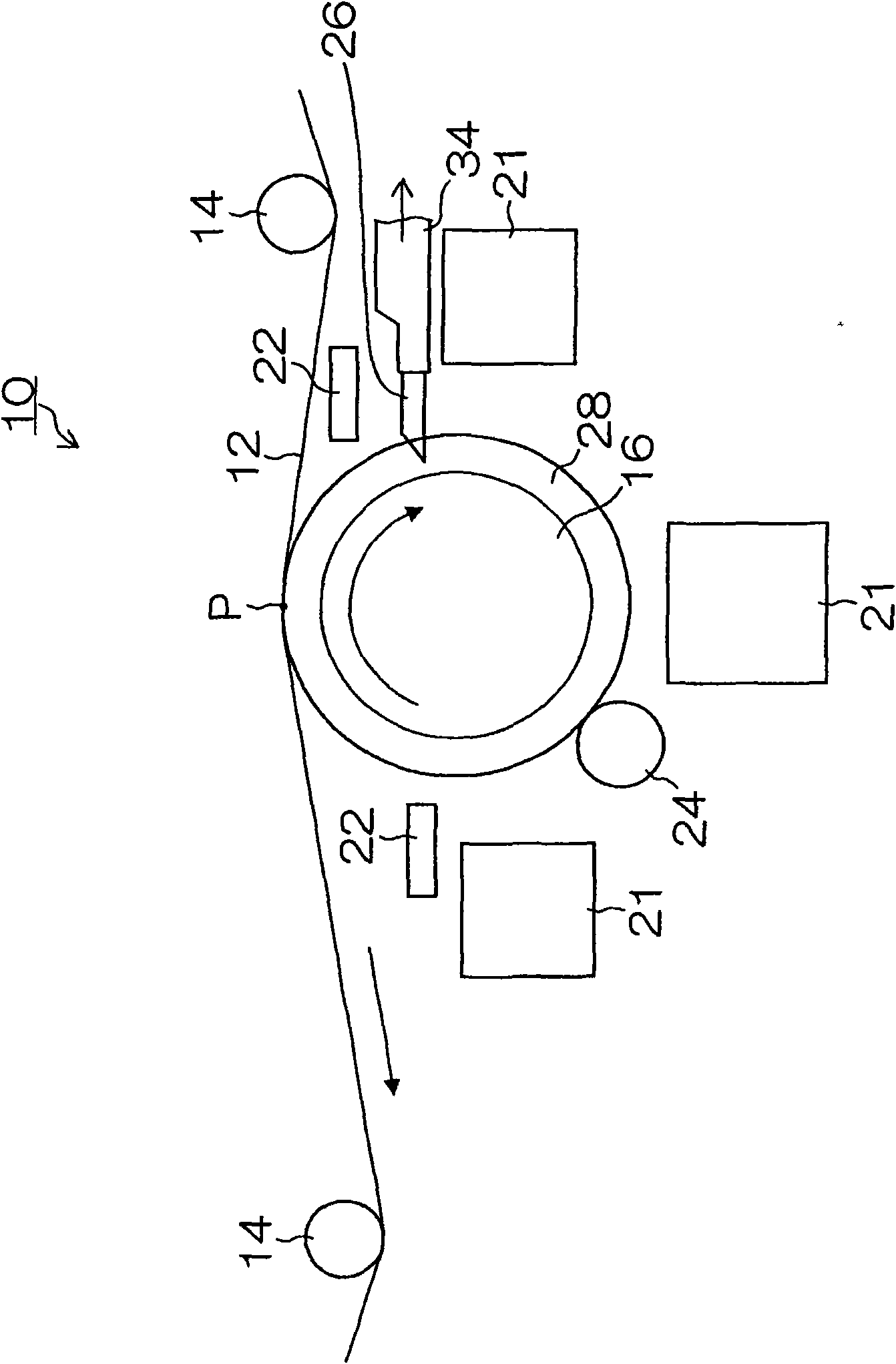

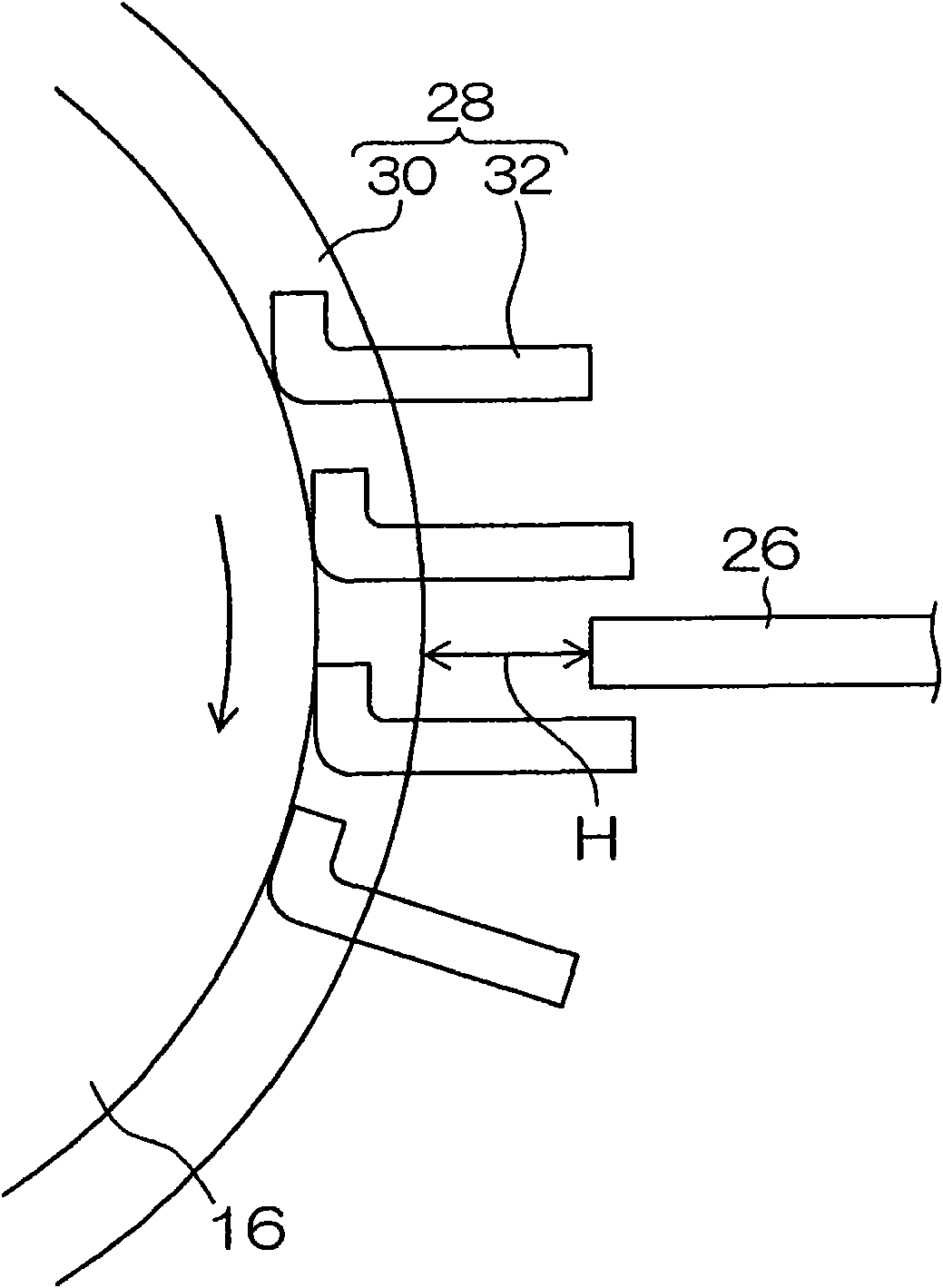

Grinding treatment method and device

InactiveCN101602179AReliable removalAvoid removalPolishing machinesLapping machinesProduction rateMetallurgy

The present invention provides a grinding treatment method and device for improving production ratio by removing dust in grinding treatment, making orientation of fluff of the grinding cloth accordant in link and realizing long service time. The grinding treatment is characterized by comprising: an orientation film forming process of moving strip flexible film with orientation film forming material layer in length direction, simultaneously contacting the grinding cloth bonded on the grinding roller with surface of the orientation film forming material layer to form the orientation film; a grinding cloth dust removing process of contacting the a dust removing member with surface of the cloth to remove dust on the cloth after the contact of the cloth and the strip flexible film; and a dust air-discharging process of removing the dust removed in the grinding cloth dust removing process with air.

Owner:FUJIFILM CORP

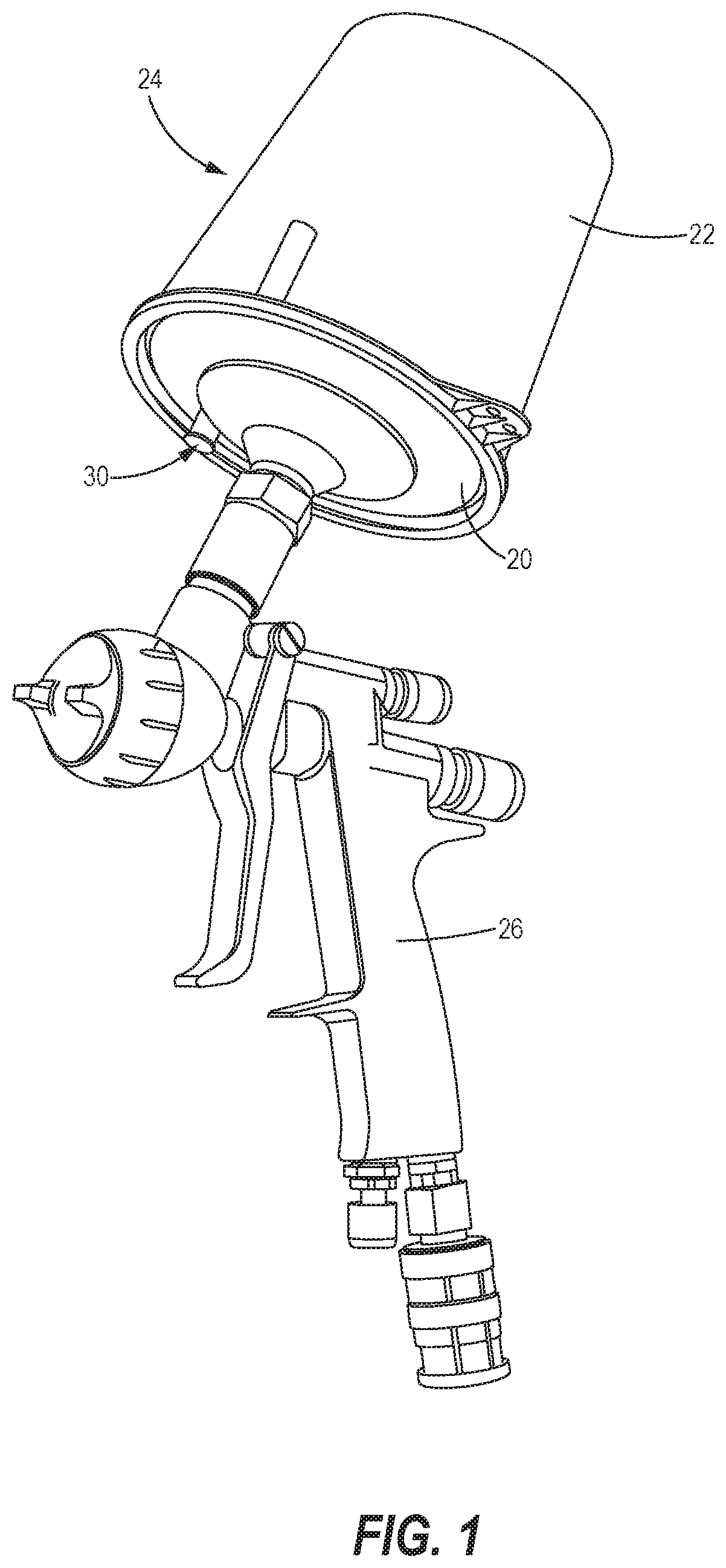

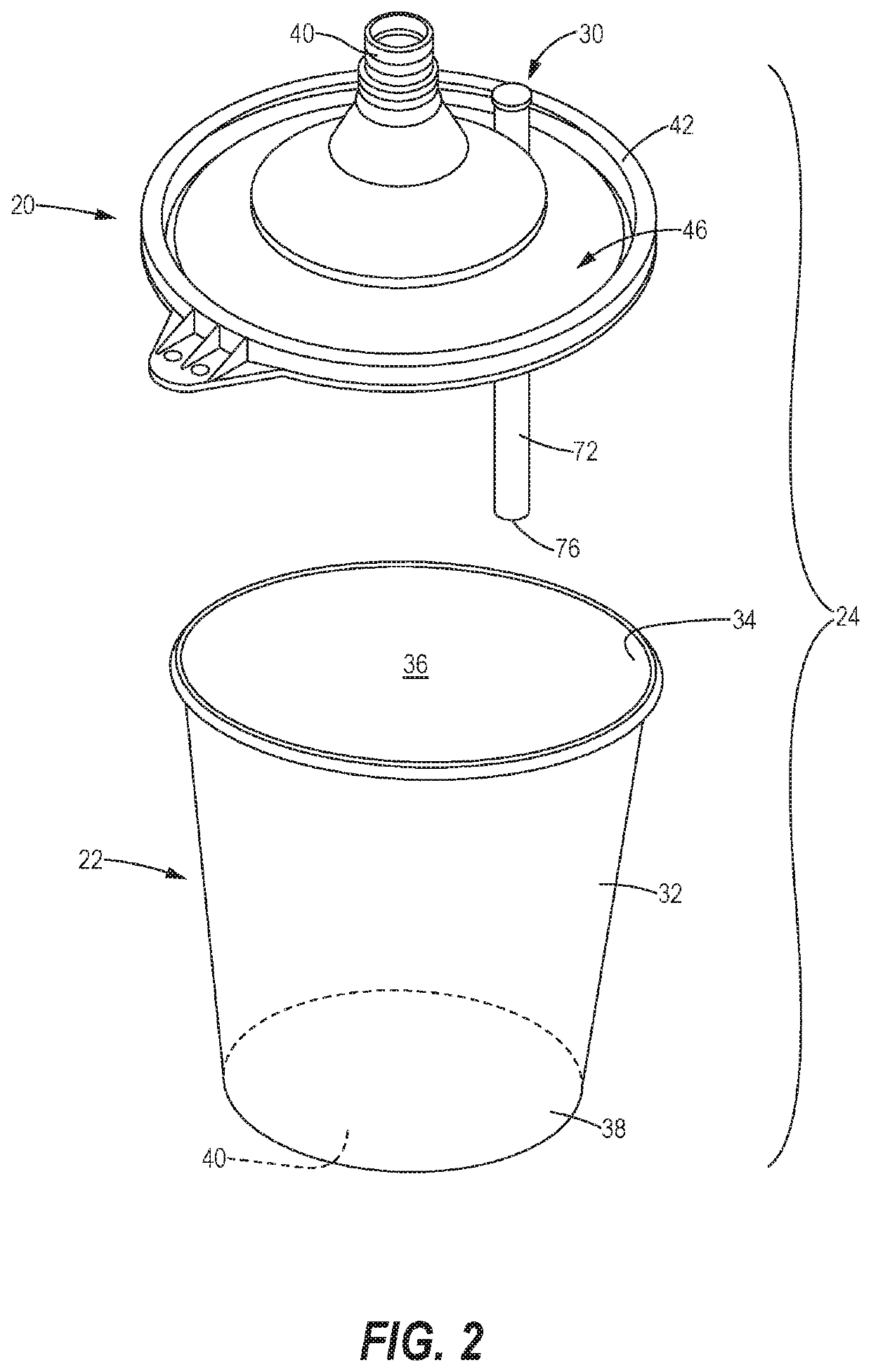

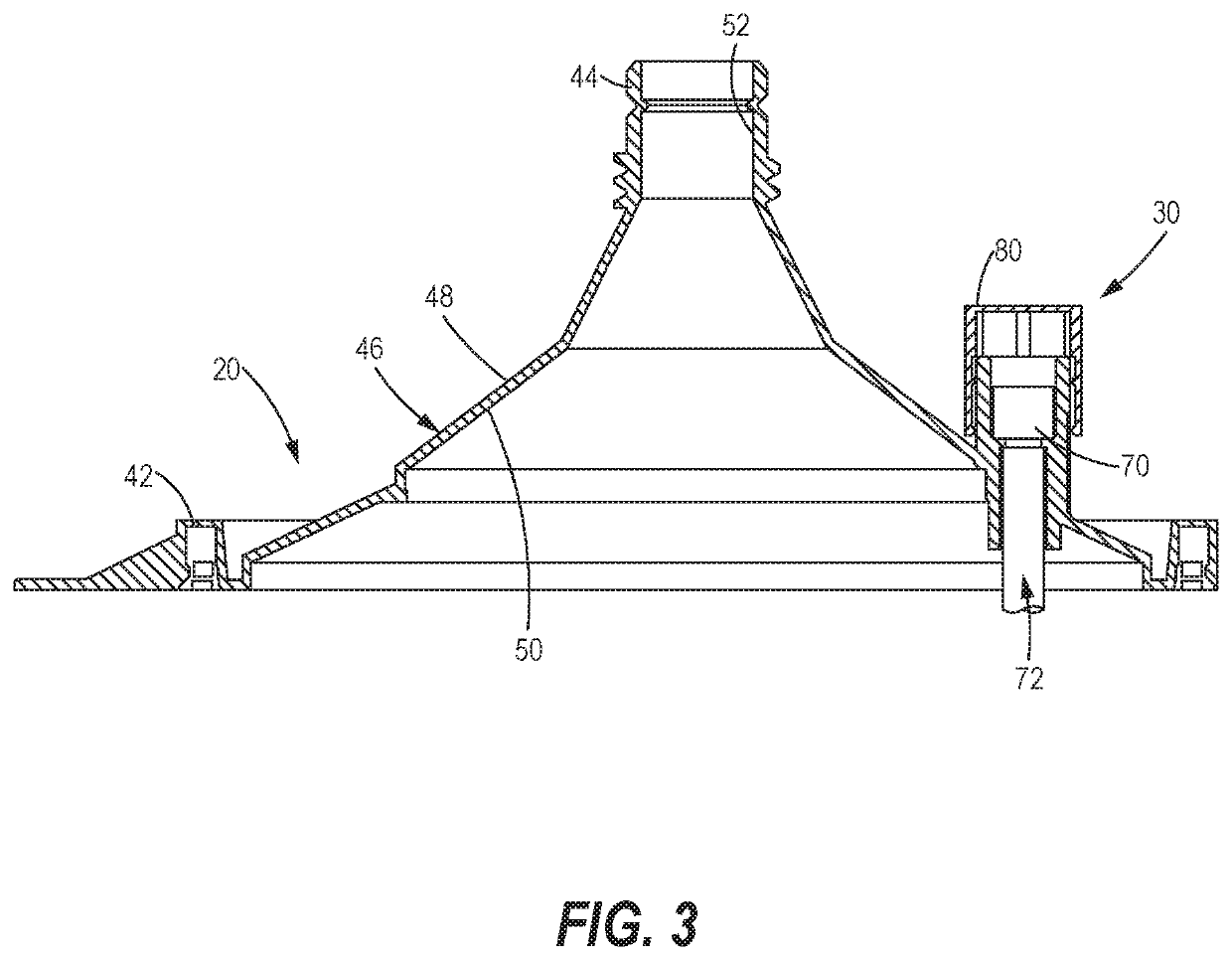

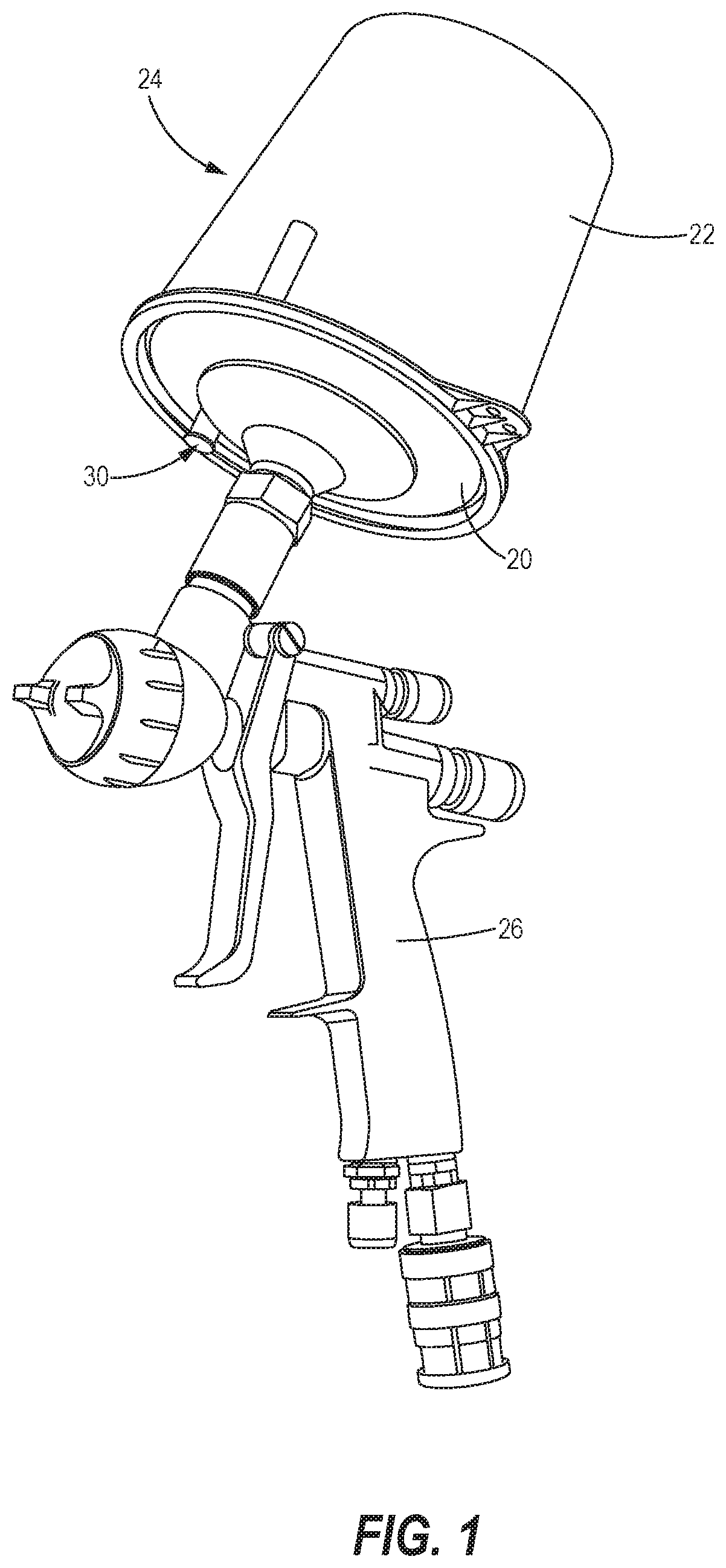

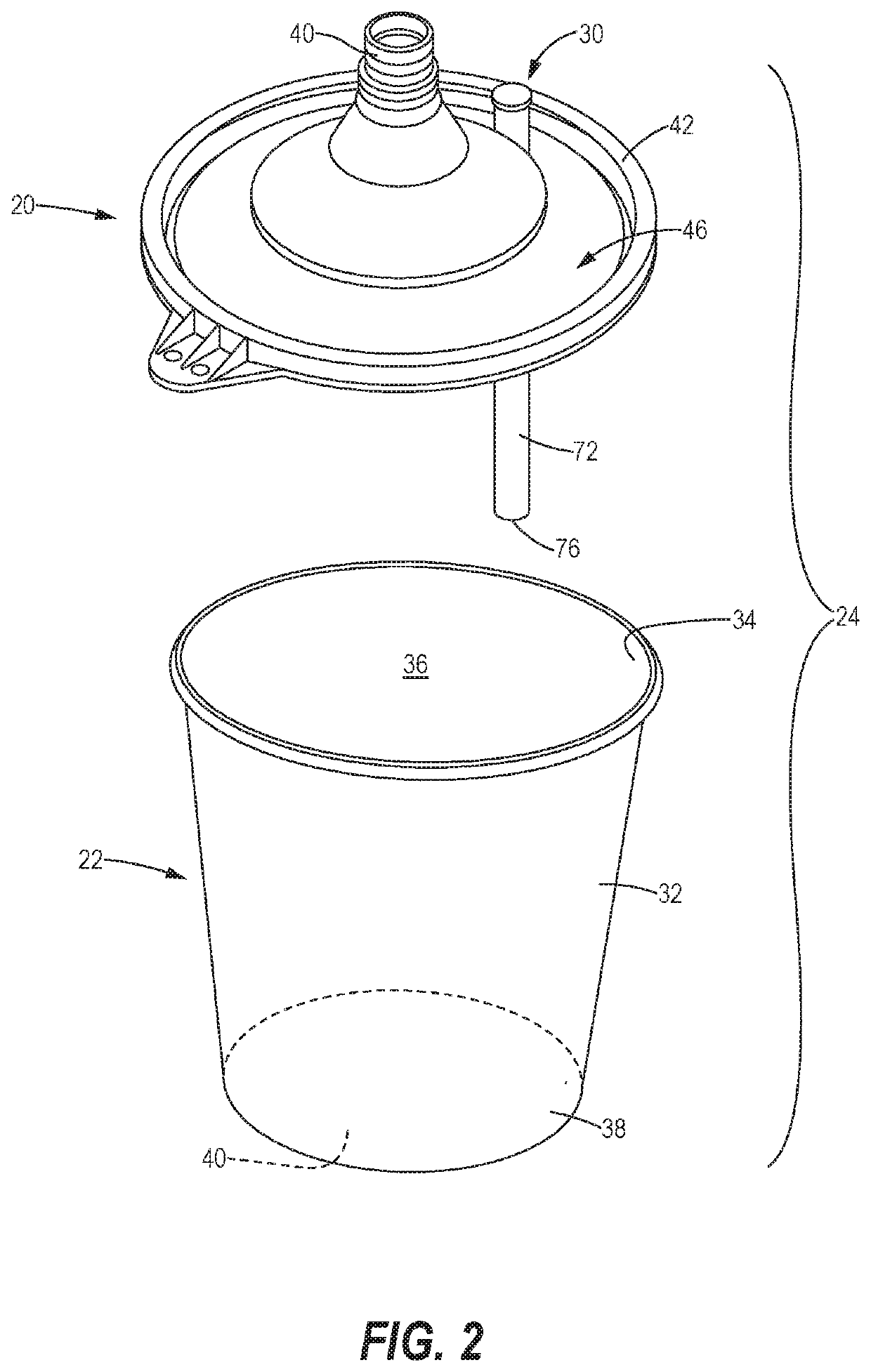

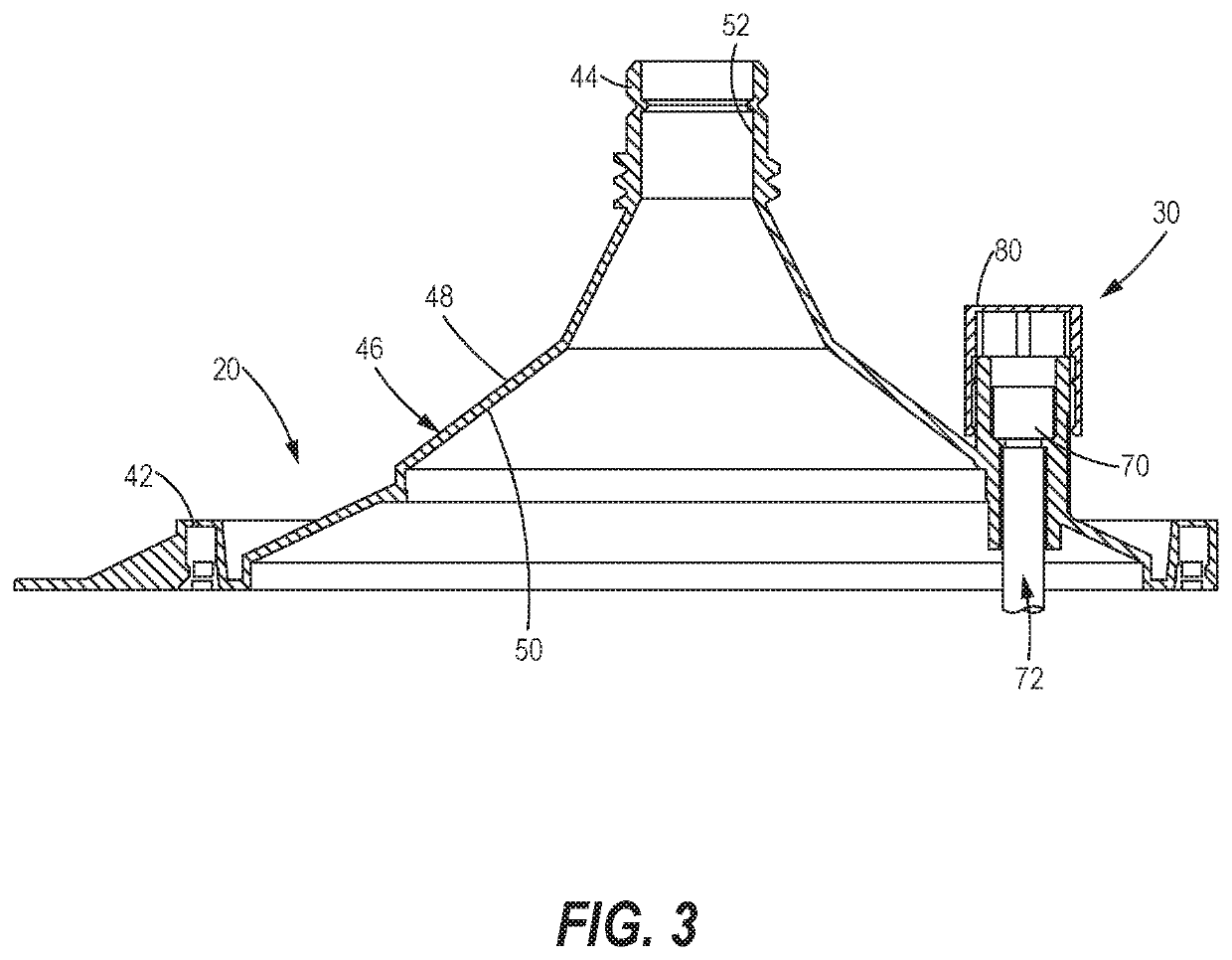

Lid with ventilation system

ActiveUS10919676B2Reliable preventionReliable exhaustClosuresLiquid spraying apparatusEngineeringMechanics

A lid, for attachment to a container holding a liquid for use with a liquid spraying device, a vent duct defining a vent conduit extending through a lid body from a duct inlet end to a duct outlet end. A valve is disposed in the vent duct and is configured to permit air flow in a first direction, from the duct inlet end to the duct outlet end, while preventing liquid flow in a second direction opposite the first direction. A cap extends over the duct inlet end, the cap including a cap interior surface defining an interior air chamber, communicating with the vent conduit, and at least a first passage, communicating between the interior air chamber and a first cap inlet. A tube is coupled to the duct outlet end and has a tube outlet end fluidly communicating with an interior of the container.

Owner:EMM HLDG BV

Lid With Ventilation System

ActiveUS20200346824A1Reliable preventionReliable exhaustClosuresLiquid spraying apparatusEngineeringMechanics

A lid, for attachment to a container holding a liquid for use with a liquid spraying device, a vent duct defining a vent conduit extending through a lid body from a duct inlet end to a duct outlet end. A valve is disposed in the vent duct and is configured to permit air flow in a first direction, from the duct inlet end to the duct outlet end, while preventing liquid flow in a second direction opposite the first direction. A cap extends over the duct inlet end, the cap including a cap interior surface defining an interior air chamber, communicating with the vent conduit, and at least a first passage, communicating between the interior air chamber and a first cap inlet. A tube is coupled to the duct outlet end and has a tube outlet end fluidly communicating with an interior of the container.

Owner:EMM HLDG BV

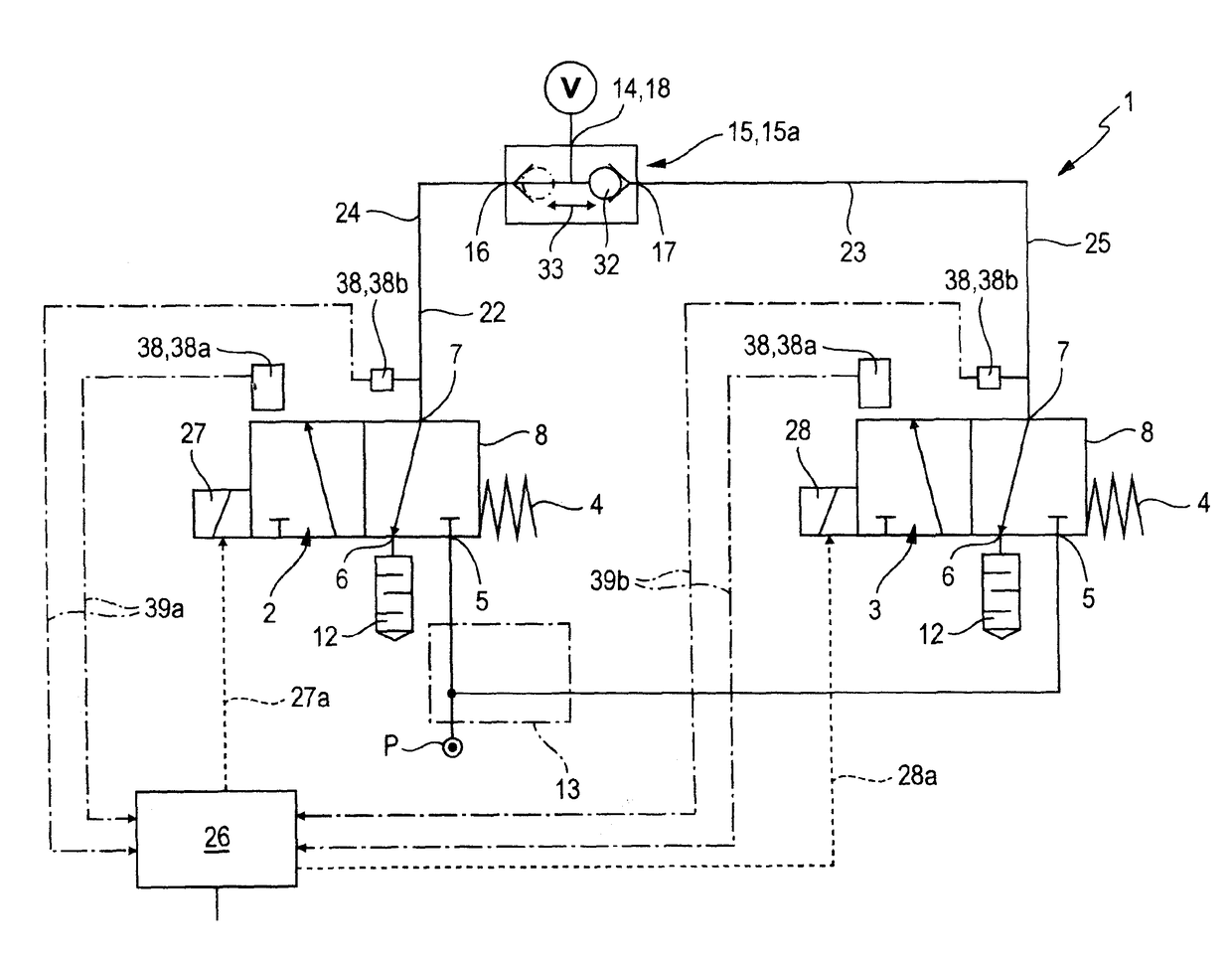

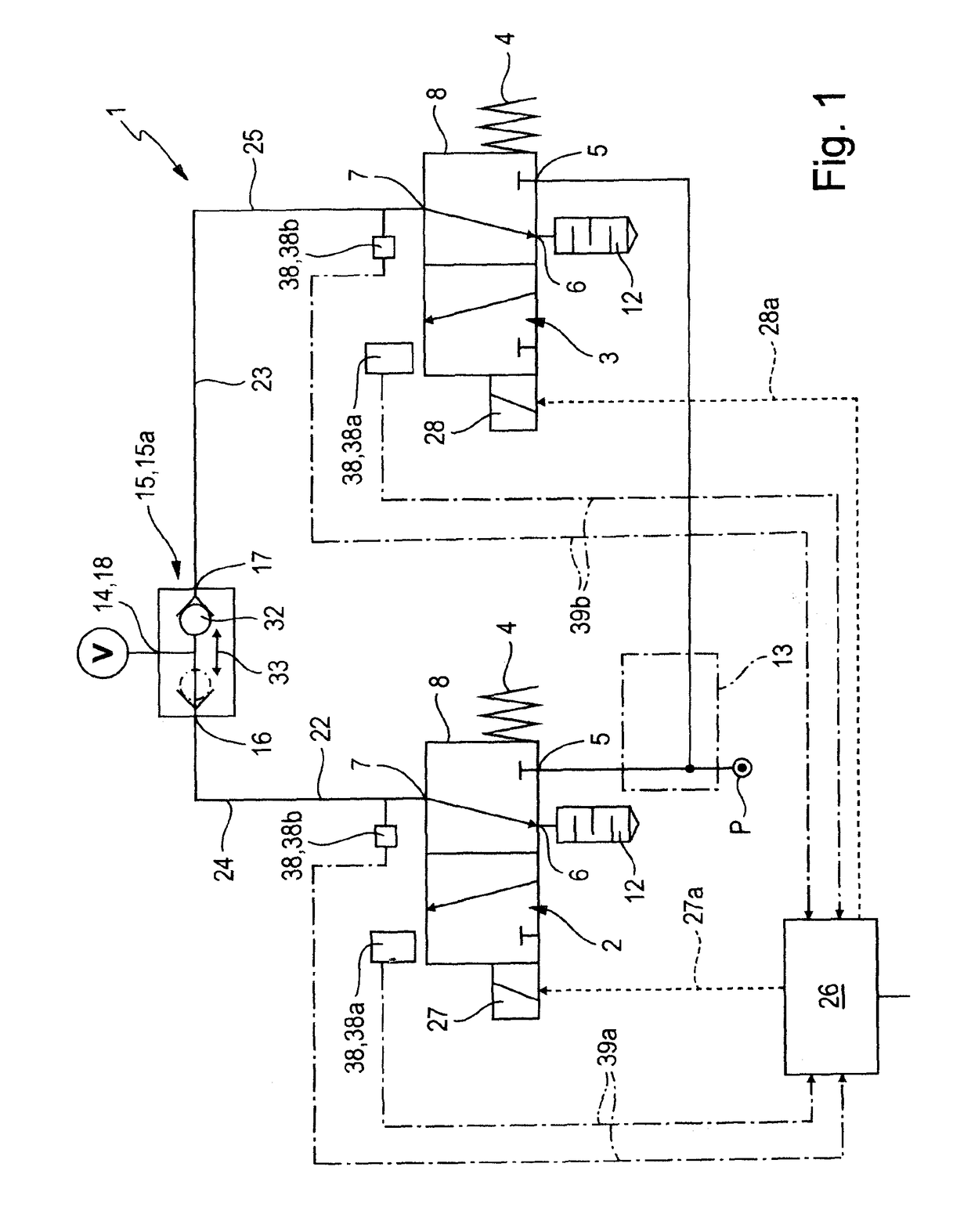

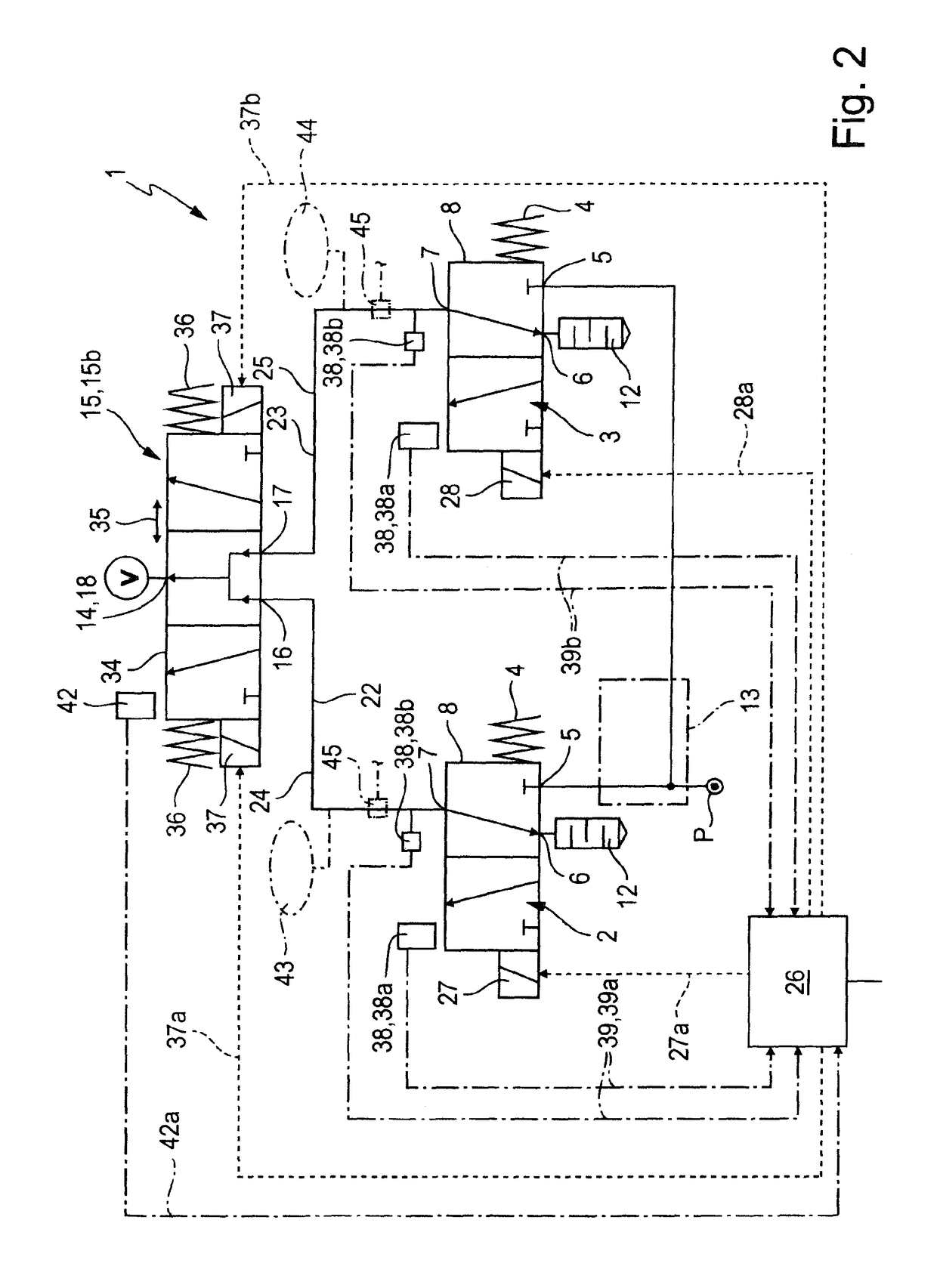

Compressed-air system having a safety function and method for operating such a compressed-air system

ActiveUS10066651B2Reliable exhaustWithout adversely affecting operationFluid-pressure actuator safetyFluid-pressure actuator testingEngineeringAeration

A compressed-air system having a safety function and a method for operating such a compressed-air system. The compressed-air system contains two working valves, which each can selectively assume an aerating position that aerates a load and a venting position that vents the load. Both working valves are redundantly connected on the output side to the load by means of a separating device. The separating device allows one or the other of the working valves to be separated, while the aeration of the load is maintained, in order to subject the one or the other working valve to an examination of the switching function of the one or the other working valve.

Owner:FESTO AG & CO KG

Water purifier special for water dispenser

InactiveCN100352769CNo secondary pollutionNo maintenanceBeverage vesselsWater/sewage treatment using germicide/oligodynamic-processWater flowTurbidity

A special water cleaner for water drinking appliance is composed of an upper drum with upper filter core, a lower drum with lower filer core containing the filtering material for removing iodine smell, an iodine resin box between upper and lower filter cores for disinfecting, water tap at the water outlet of lower drum, and an air-water separator on the air exhaust tube of upper drum.

Owner:QINYUAN GRP CO LTD

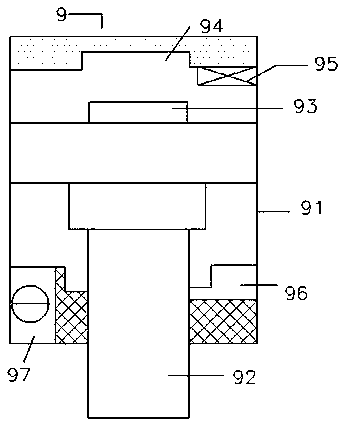

Carburetor arrangement of a portable handheld work apparatus

InactiveUS20050051912A1Reliable exhaustWork lessUsing liquid separation agentLow-pressure fuel injectionHand heldEngineering

The invention relates to a carburetor arrangement of a portable handheld work apparatus and includes a carburetor (1), an accelerator pump (2) and a venting pump (3). The venting pump (3) acts on the accelerator pump (2) via a venting line (4). A check valve (5) is mounted in the venting line (4) in such a manner that its outlet end (6) is directed in the direction of the venting pump (3). A pretensioning device (7) is provided which holds a valve body (8) of the check valve (5) closed below a selected difference pressure between the outflow end (6) and an opposite-lying inflow end (9). A support device (10) which acts on the valve body (8) and is actuable, at one end, by pressure at the outflow end (6) without considering pressure at the other end (9) or by pressure on the inflow end (9) without considering the pressure on the other end (6).

Owner:ANDREAS STIHL AG & CO KG

Jet deflection type special water purifier of water drinking machine

InactiveCN101269854BReliable exhaustStable and reliable water outletWater/sewage treatment by ion-exchangeLoose filtering material filtersWater filterWater quality

The invention relates to a special water clarifier of a turn back flow water fountain, which comprises an upper cover, an upper barrel and a lower barrel. The bottom of the lower barrel is provided with a float valve or a ball cock which can control the water level in a water hopper of the water fountain, the bottom of the upper barrel is provided with an upper filter element which is provided with an exhaust pipe, a lower filter element is arranged under the bottom of the upper barrel, the bottom of the lower filter element is connected with a turn back flow filter element which includes a shell body with a closed bottom, a lower screen is arranged at the lower part in the shell body, an upper screen is arranged at the upper part in the shell body, and granular filter material is filled between the lower screen and the upper screen. The special water clarifier has the beneficial effects that: firstly, the exhaust of the filter element is reliable, gas in the turn back flow filter element needs to be exhausted when the turn back flow is started for the first time only, so the yielding water of the water clarifier is reliable; secondly, the water filtering power of the water clarifier is enough, the lower filter element adopts micropore ceramics with higher filtering precision, so the filtering effect is increased; thirdly, because water flows through the upper filter element, the lower filter element, and the turn back flow filter element for being purified and treated repeatedly, the water quality of the yielding water is ensured more easily.

Owner:黄瑞中

Building roof construction process

InactiveCN103362254BSimple stepsReasonable designLighting and heating apparatusBuild-up roofsInsulation layerSurface layer

Owner:陕西建工集团有限公司 +1

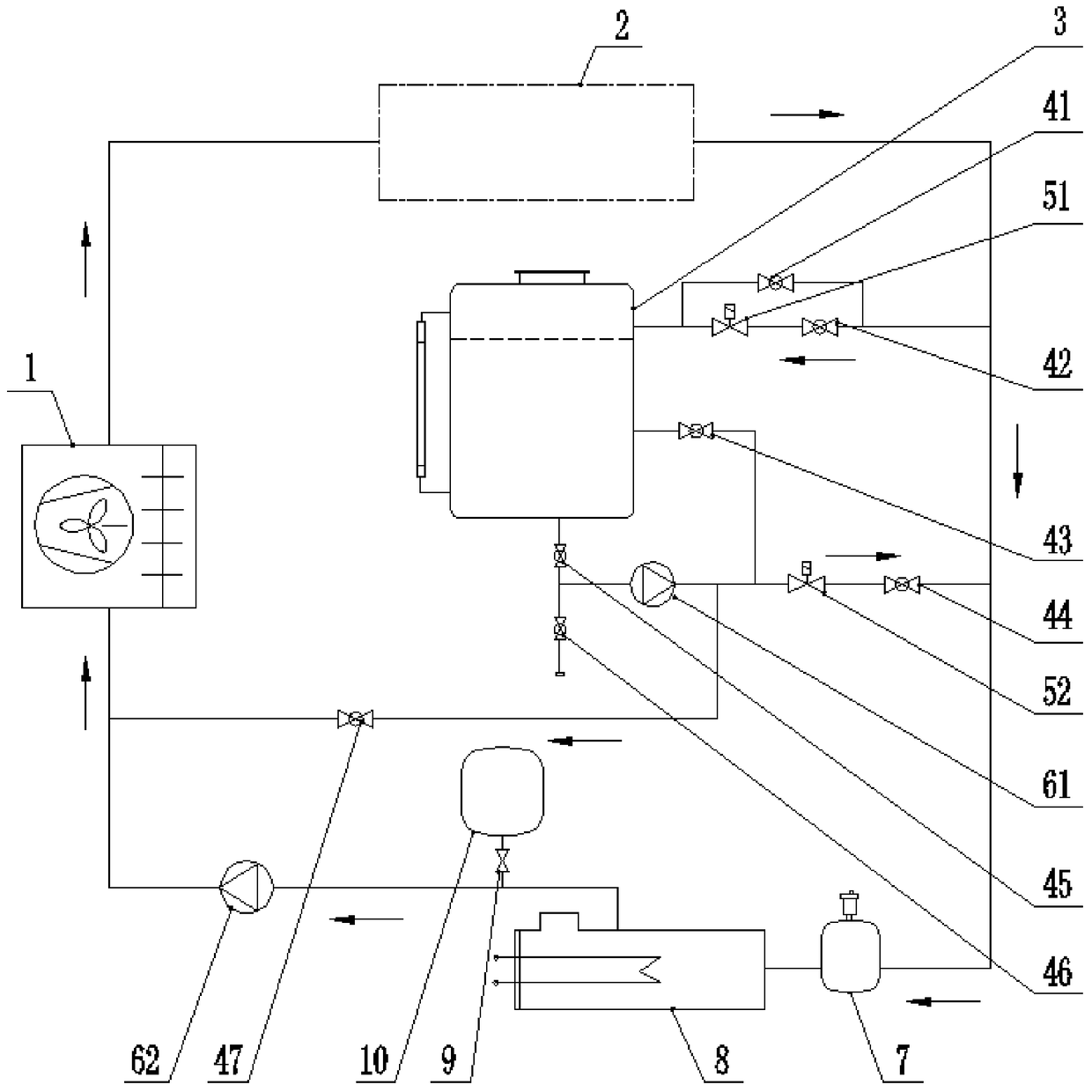

Constant pressure, liquid replenishment and exhaust device of closed liquid cooling system

ActiveCN104703444BLow costRealize functionCooling/ventilation/heating modificationsExpansion tankPressure stabilization

Owner:合肥天鹅制冷科技有限公司

Outer body for electrochemical element

ActiveCN103855332BEnough to installHigh strengthLaminationLamination apparatusInternal pressureCompound (substance)

The present invention provides a laminated exterior body for electrochemical elements capable of attaching a porous metal sheet as a safety valve with sufficient strength. The present invention is aimed at a laminated type electrochemical element exterior body, in which two exterior films (11) whose sealant layer on one side is made of a polymer compound are laminated in a state where both sealant layers face each other, and The outer periphery of the laminated exterior film (11) is sealed. One end side of the safety valve (2) for preventing internal pressure rise made of porous metal sheet (21) is arranged inside, and the other end side is arranged outside, and the safety valve (2) is sandwiched between two laminated sheets In the state between the corresponding outer edges of the exterior film (11), the safety valve (2) is fixed to the sealant layer of the exterior film (11) via the adhesive layer (3) containing a polymer compound.

Owner:株式会社レゾナックパッケージング

Radial lip seal device

Owner:CARL FREUDENBERG KG

Breather of a hydraulic or electrohydraulic control device

InactiveUS9068580B2Reliable exhaustLiquid degasificationThin material handlingHydraulic control unitBreather

A venting device for a hydraulic control unit, designed as a diaphragm in a bore in the control unit, so that collected air can escape, via the diaphragm, to outside the housing. A membrane, which is permeable to air and oil when under pressure, closes the diaphragm bore with respect to the outside. The housing bore and the diaphragm form an inside space that can be vented, via the membrane. The inside space being delimited, during operation, by the diaphragm and an oil column which passes from the control unit into the housing bore and is continually maintained at a defined pressure at which oil, in the housing bore, either does not pass through the membrane or only a minute amount passes therethrough. The oil column remains in the housing bore so that only air, contained in the oil, is vented to the outside without any air being drawn into the control unit from outside.

Owner:ZF FRIEDRICHSHAFEN AG

Breather of a hydraulic or electrohydraulic control device

InactiveUS20140041733A1Reliable exhaustLighting and heating apparatusSpace heating and ventilation detailsHydraulic control unitInterior space

A venting device for a hydraulic control unit, designed as a diaphragm in a bore in the control unit, so that collected air can escape, via the diaphragm, to outside the housing. A membrane, which is permeable to air and oil when under pressure, closes the diaphragm bore with respect to the outside. The housing bore and the diaphragm form an inside space that can be vented, via the membrane. The inside space being delimited, during operation, by the diaphragm and an oil column which passes from the control unit into the housing bore and is continually maintained at a defined pressure at which oil, in the housing bore, either does not pass through the membrane or only a minute amount passes therethrough. The oil column remains in the housing bore so that only air, contained in the oil, is vented to the outside without any air being drawn into the control unit from outside.

Owner:ZF FRIEDRICHSHAFEN AG

Multi-line pump driven fiber impregnation system

The invention relates to a fiber impregnation system. The fiber impregnation system comprises a fiber impregnation box (110) and a driving pump (120) connected with the fiber impregnation box (110) by one or more refluxing hoses (122), wherein the refluxing hoses (122-1, 122-2 and 122-3) are used for recycling resin from the fiber impregnation box and refilling the fiber impregnation box with the resin under the driving action of the driving pump; and preferentially, the driving pump (120) is a peristaltic pump or a diaphragm pump. Besides, the invention also relates to equipment for performing pultrusion on fibers (100) to obtain a section material (200) by use of the fiber impregnation box. According to the fiber impregnation system, the fiber impregnation box and the peristaltic pump provided with at least one pump head are combined, and the quantity of pumps, pump heads and pipelines is increased as required by production and processing, thus, the fiber impregnation box is not required to be closely connected with a corresponding molding and solidifying device, and a yarn guiding plate can be arranged in the fiber impregnation box; and the fiber impregnation box and the corresponding molding and solidifying device can be separable and vacuumizing operation is carried out, and thus, the fiber exhaust efficiency is improved.

Owner:COVESTRO DEUTSCHLAND AG

Venting device and method for venting a fluid guide line

Owner:SCHAEFFLER TECH AG & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com