Solar thermal collecting pipe and processing method thereof

A technology of solar collector tubes and core tubes, which is applied in the directions of solar collectors, solar thermal energy, solar collector components, etc., and can solve the problems of poor heat transfer efficiency and high cost in the field of medium-temperature solar thermal utilization that cannot be marketed quickly And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

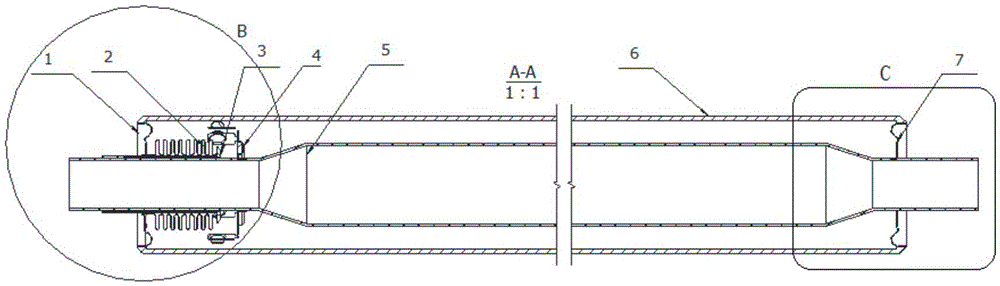

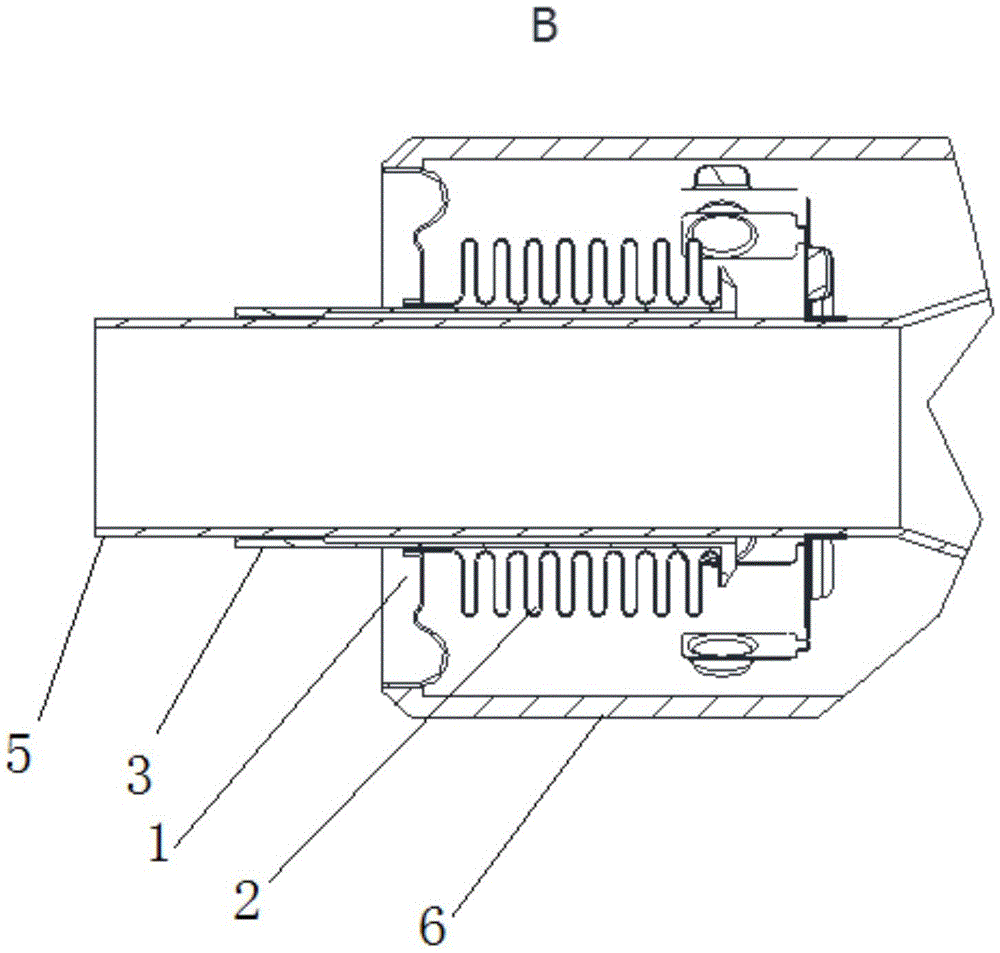

[0079] see Figure 1-Figure 6 , the solar heat collecting tube, comprising a straight-through metal inner tube 5, a cover glass tube 6, a left end cover 1 and a right end cover 7; a vacuum interlayer is formed between the straight-through metal inner tube 5 and the cover glass tube 6; With selective absorption coating; the straight-through metal inner tube 5 passes through the cover glass tube 6 and the two ends of the straight-through metal inner tube 5 extend out of the cover glass tube 6; the two ends of the straight-through metal inner tube 5 The diameter is smaller than the diameter of the middle part, forming the left end variable diameter section, the middle section and the right end variable diameter section; also including the bellows 2 and the connection between the left end variable diameter section and the cover glass tube 6 and located in the cover glass tube 6 Sleeve 3; the variable diameter section at the left end passes through the inner hole of the connecting ...

Embodiment 2

[0083] The right variable diameter section of this embodiment 2 adopts the same structure as the left variable diameter section, that is, the right connecting sleeve, the right bellows, and the metal end cap are used to replace the single metal end cap, that is, between the right variable diameter section and the cover glass tube 6 The right bellows and the right connecting sleeve are provided, and the right bellows and the right connecting sleeve are located in the cover glass tube 6; the reducing section at the right end passes through the inner hole of the right connecting sleeve and is sealed and connected with the inner wall of the right connecting sleeve by welding The right connecting sleeve passes through the right bellows and the left end of the right connecting sleeve is welded to the left end of the right bellows, the right end of the right connecting sleeve is connected to the inner peripheral surface of the right end of the right bellows, and the outer peripheral su...

Embodiment 3

[0085] On the basis of Embodiment 1 or 2, the solar heat collecting tube is equipped with an exhaust tail pipe opening on the side wall of the cover glass tube 6, and the similarities will not be described in detail.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com