Venting device and method for venting a fluid guide line

A technology of fluid guidance and exhaust device, which is applied to the direction of valves for ventilation, cocks including cut-off devices, valve devices, etc., which can solve the problems of high cost and achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

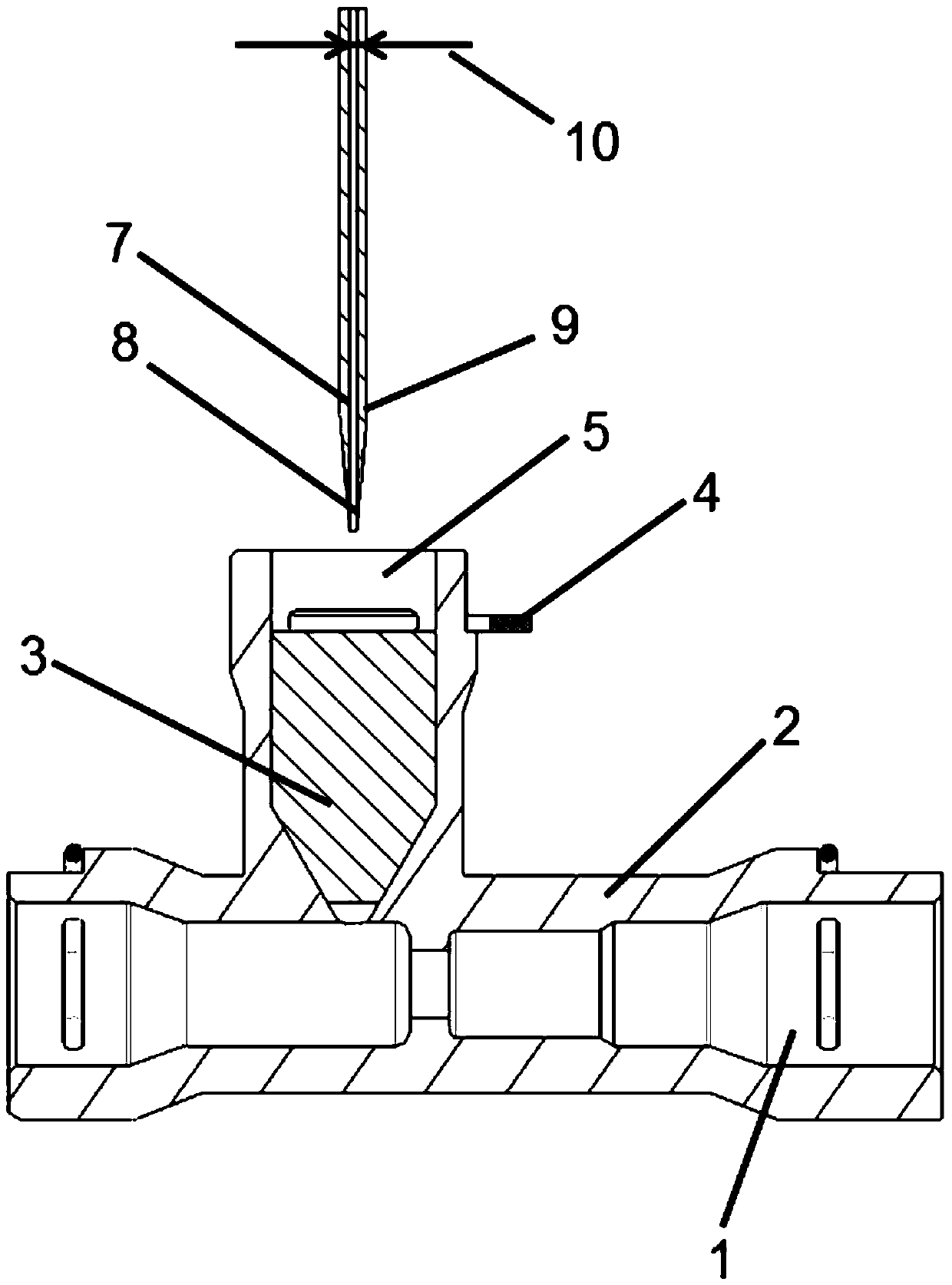

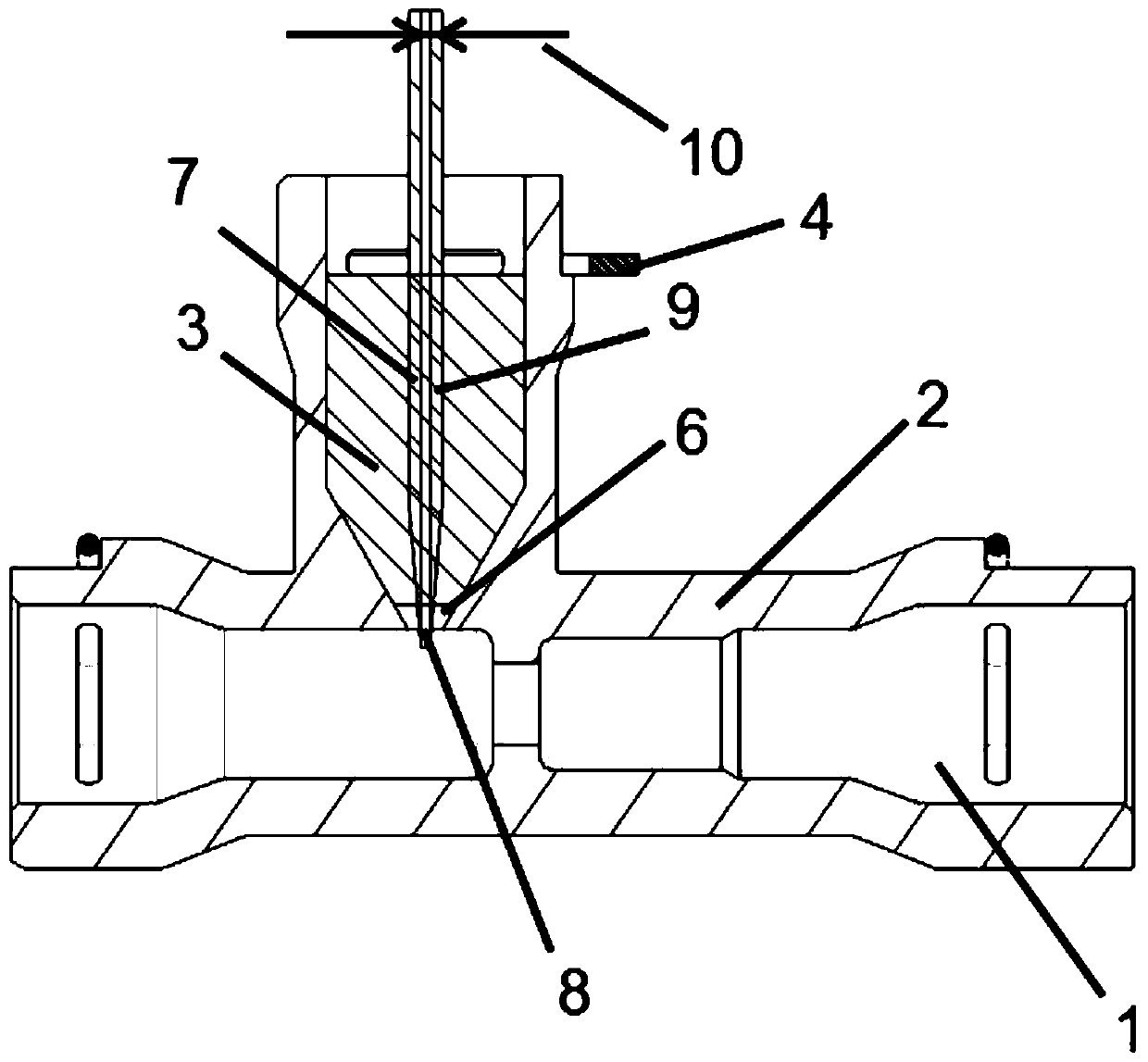

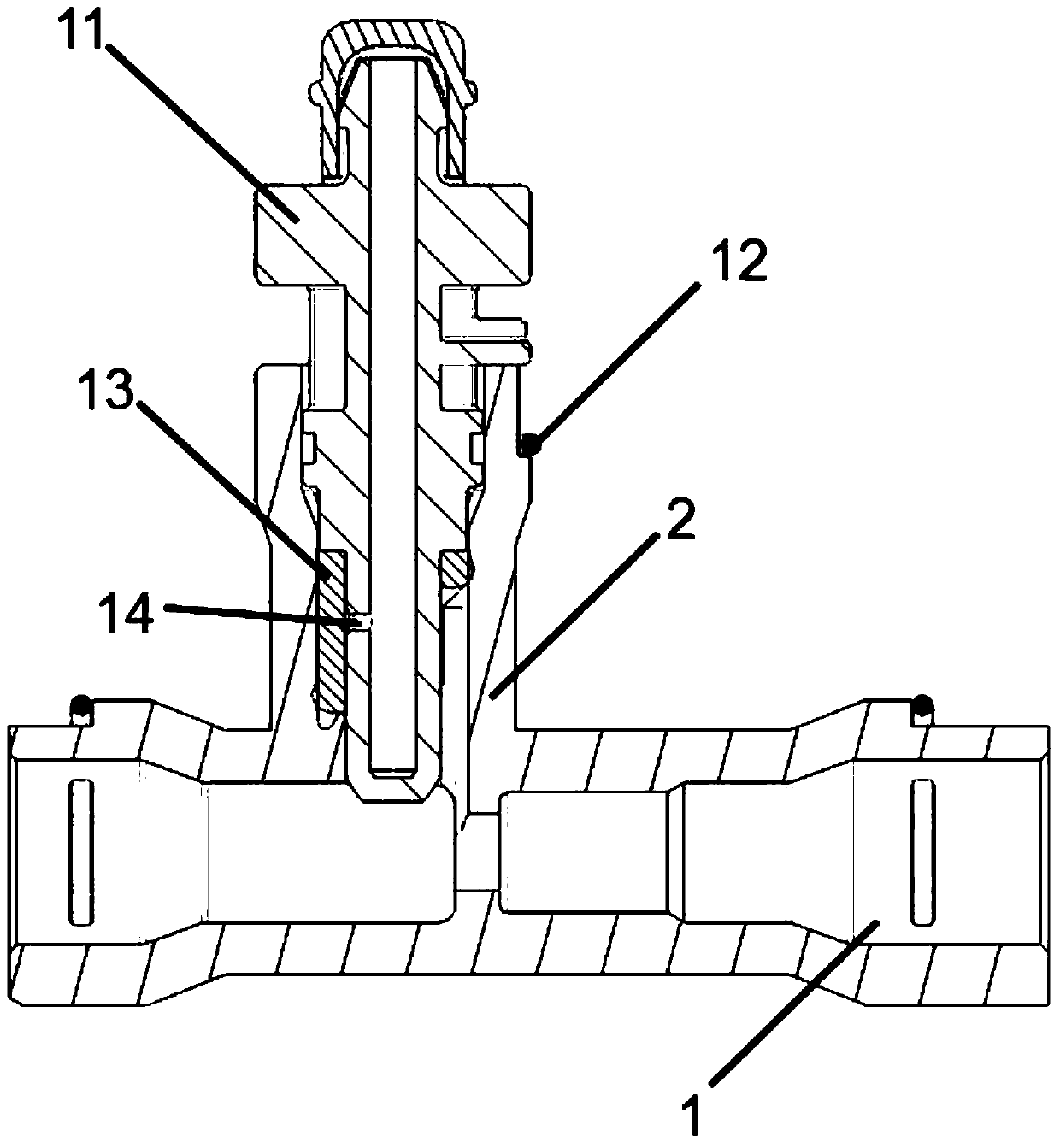

[0022] exist figure 1 shows a line 1 which is used in a hydraulic clutch actuation system of a motor vehicle and through which hydraulic fluid flows. An adapter housing 2 is introduced into the line 1 , which extends perpendicularly to the longitudinal extent of the line 1 . The adapter housing 2 is closed by a rubber seal 3 which completely fills the interior 5 of the adapter housing 2 . In this case, the sealing device 3 is pressed into the adapter housing 2 and held in place by a holder 4 which is placed over the sealing device 3 . The holder 4 is fastened to the adapter housing 2 and penetrates the adapter housing 2 from the outside into the interior 5 of the adapter housing 2 and is positioned there on the seal 3 . The inner space 5 of the adapter housing 2 has a funnel-like shape in the region directly opposite the line 1 . The pressed-in seal 3 is here adapted to the shape of the adapter housing 2 . However, a small cavity 6 remains between the tip of the funnel-li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com