Constant pressure, liquid replenishment and exhaust device of closed liquid cooling system

An exhaust device and liquid cooling technology, applied in the direction of cooling/ventilation/heating transformation, etc., to achieve the effect of low unit cost, simple operation and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

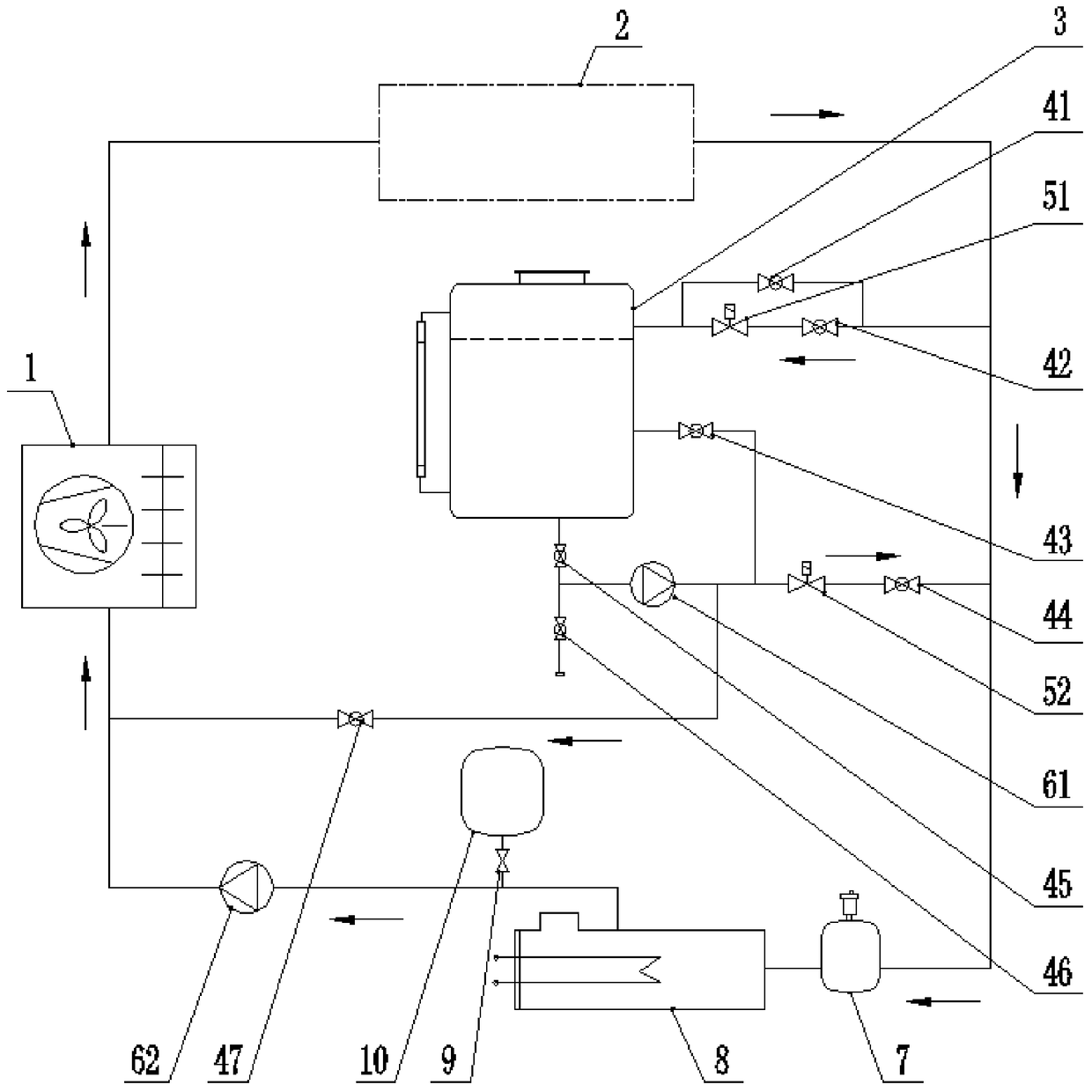

[0012] see figure 1 , a constant pressure, liquid replenishment and exhaust device for a closed liquid cooling system, including an air-coolant heat exchanger 1, a load heating element 2, a liquid storage tank 3, a liquid replenishment pump 61, a spiral microbubble separator 7, Electric heating water tank 8, expansion tank 10, liquid supply pump 62, first and second solenoid valves 51, 52, first, second, third, fourth, fifth, sixth, seventh ball valves 41, 42, 43, 44, 45, 46 , 47 and stop valve 9, the outlet of the air-coolant heat exchanger 1 is connected with the inlet of the load heating element 2, the liquid storage tank 3 is respectively provided with upper, middle and bottom interfaces, and the upper interface of the liquid storage tank 3 passes through the The first solenoid valve 51 and the second ball valve 42 communicate with the outlet of the load heating element 2, the first ball valve 41 is connected in parallel between the inlet of the second ball valve 42 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com