Radial lip seal device

A sealing device, radial shaft technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of complex structure and large space, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

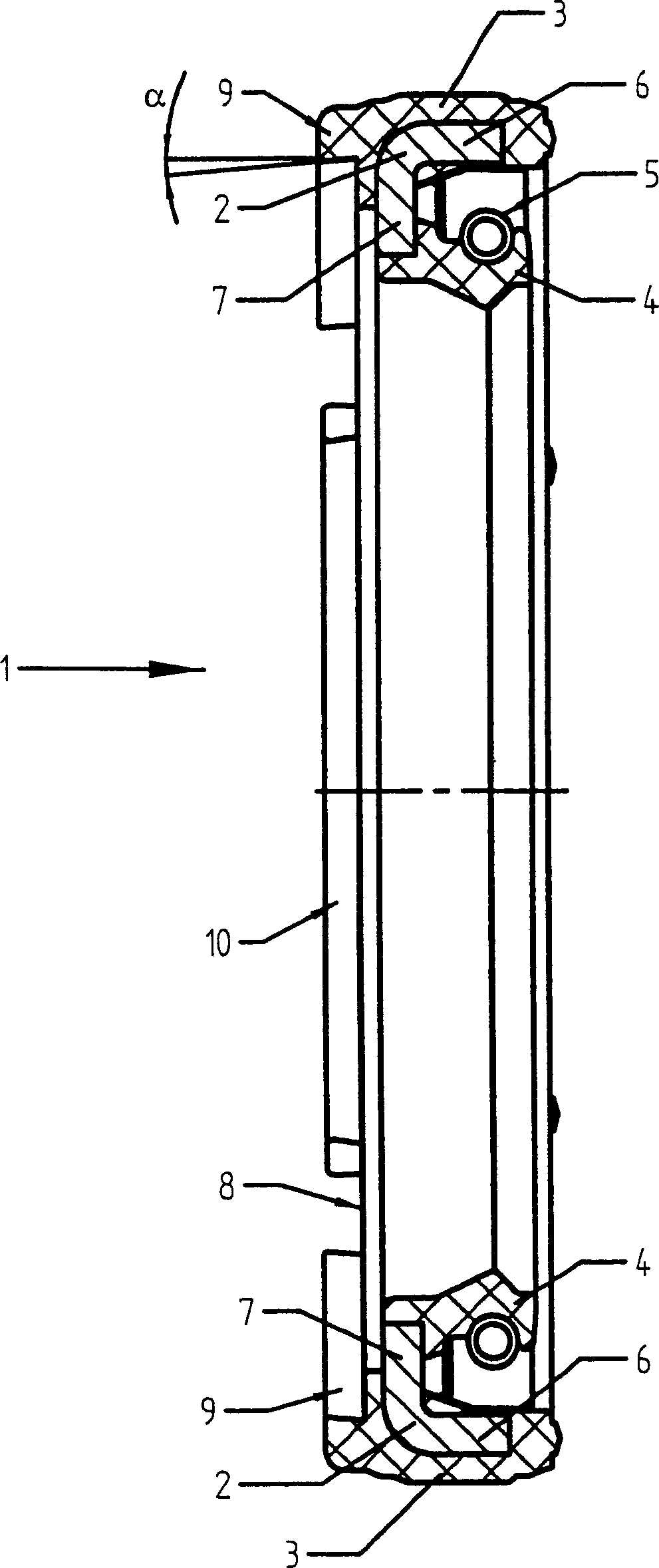

[0017] figure 1 A sealing ring 1 for a radial shaft seal is shown. The radial shaft sealing ring 1 forms a sealing assembly comprising a base body 2 of metal with an outer adhesive layer 3 of elastomer and a radially inwardly facing sealing lip 4 . The sealing lip 4 is likewise made of an elastomer and is additionally pressed against a shaft (not shown in detail) via a spring ring 5 . Seen in cross section, the base body 2 has an axial branch 6 and a radial branch 7 . Branches 6 and 7 are of equal length in the example shown.

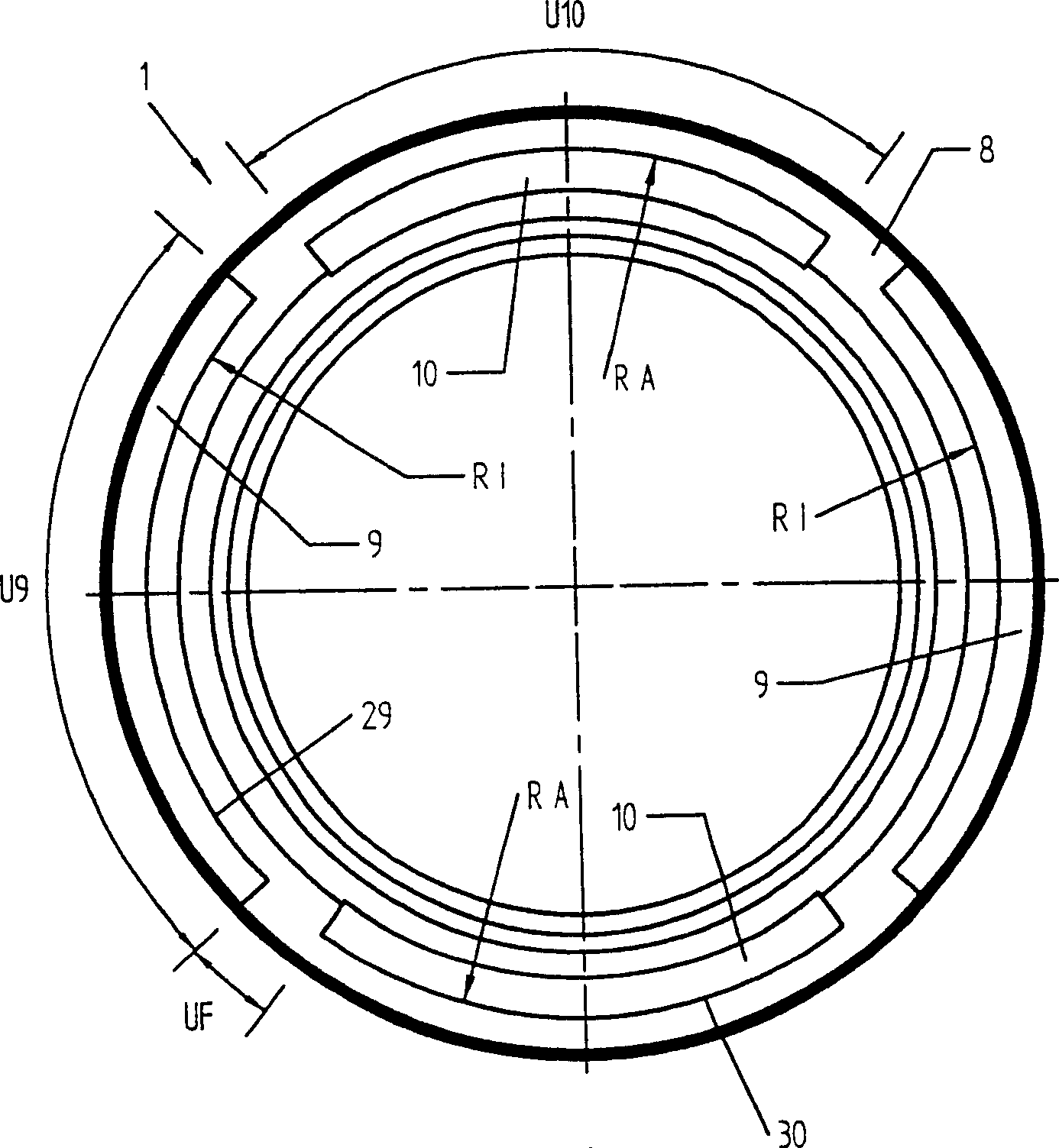

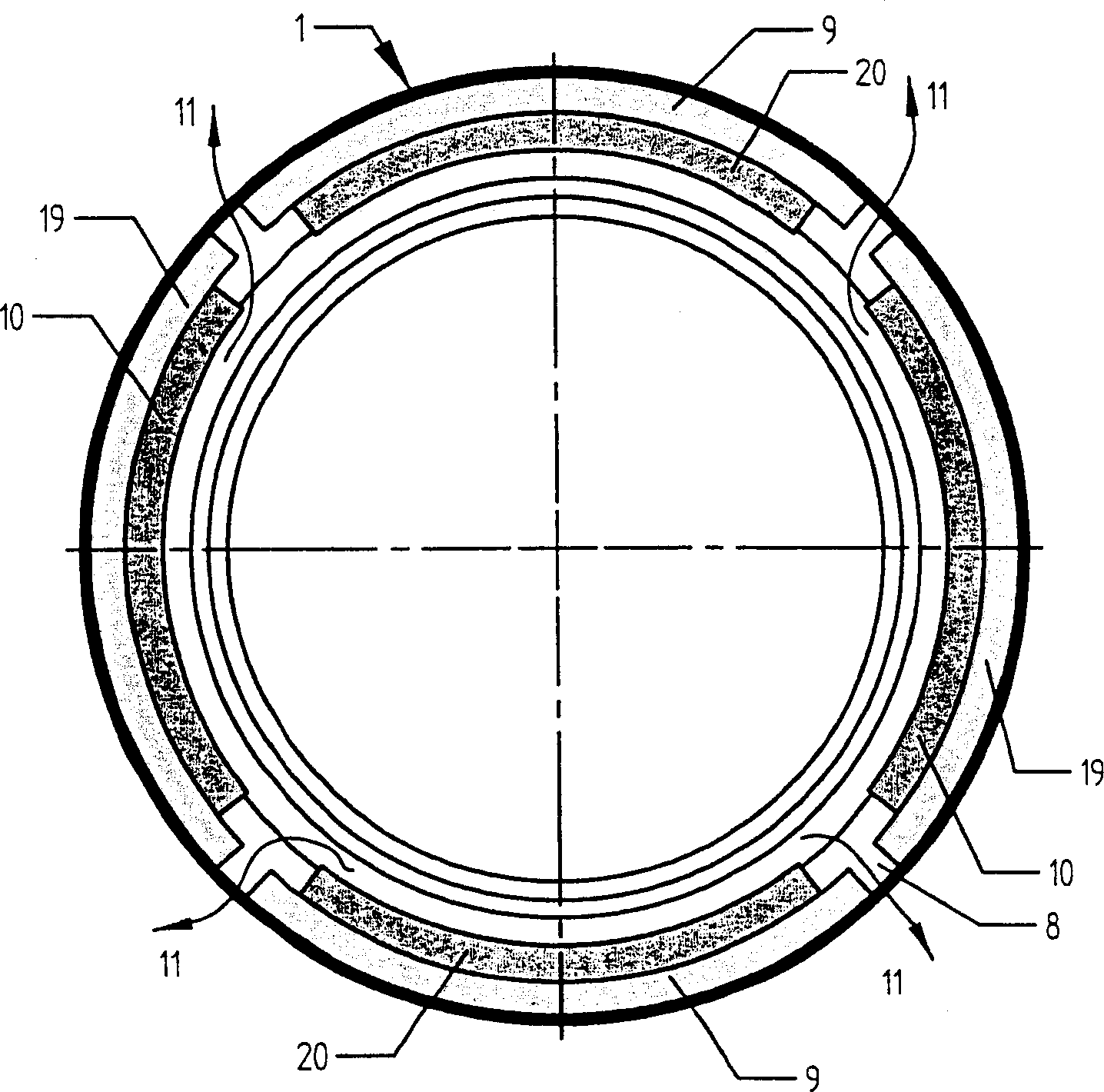

[0018] The inner surface 8 of the sealing ring 1 after the assembly of the two sealing rings is provided with four annular segments 9 and 10 which, in the assembled state of the two sealing rings 1 , engage with each other in a non-positive and form-fitting manner. Two of the ring segments 9 are offset radially outward and are referred to as outer ring segments 9 , while the inner ring segment 10 is offset radially inward. belongs to figure 1 The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com