Rainproof fireproof socket

A flame-proof and socket technology, applied in the base/shell, contact parts, etc., can solve the problems of electrical insulation performance decline, poor contact, internal system failure, etc., and achieve the effect of excellent electrical performance, improved reliability, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

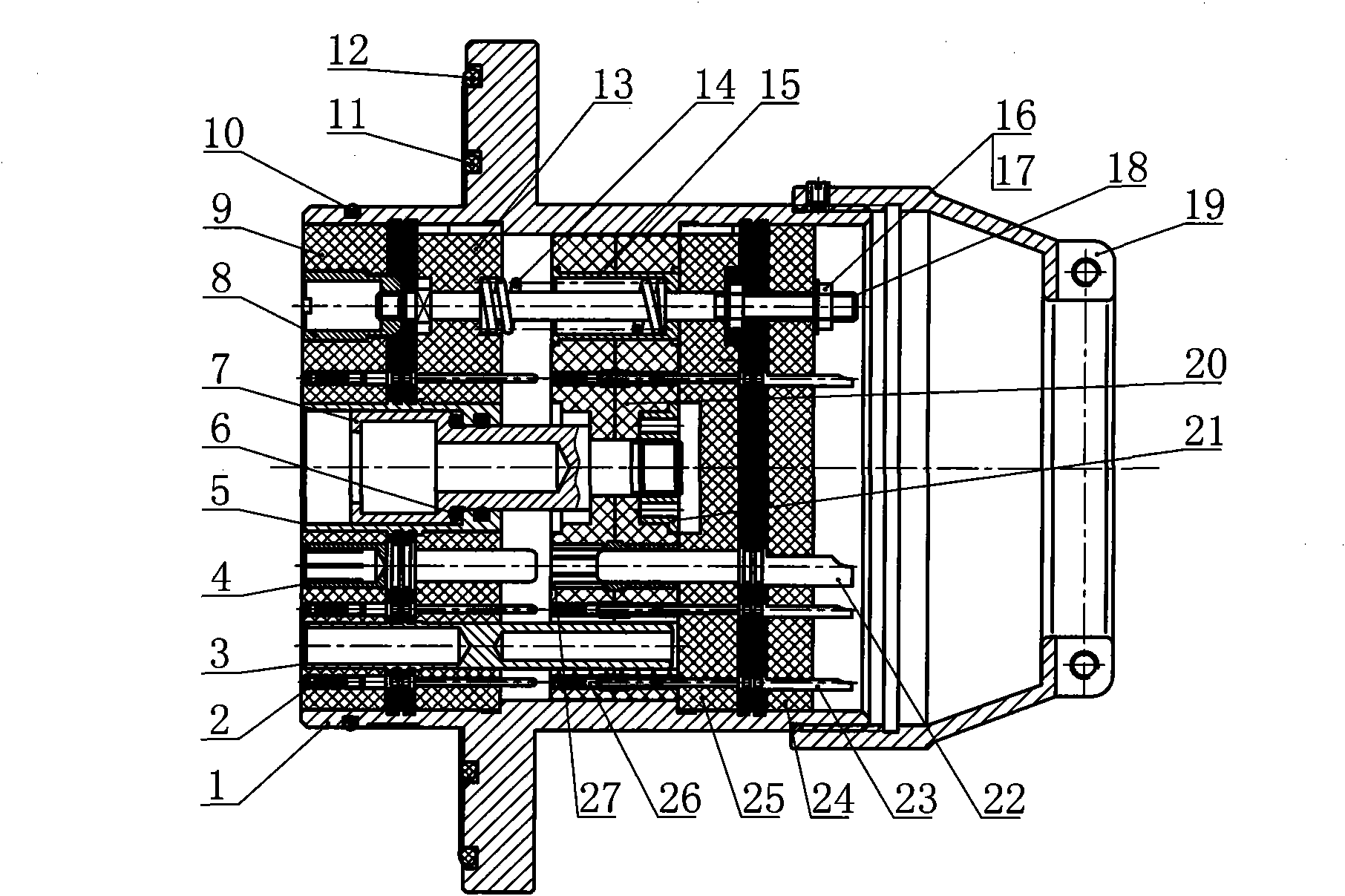

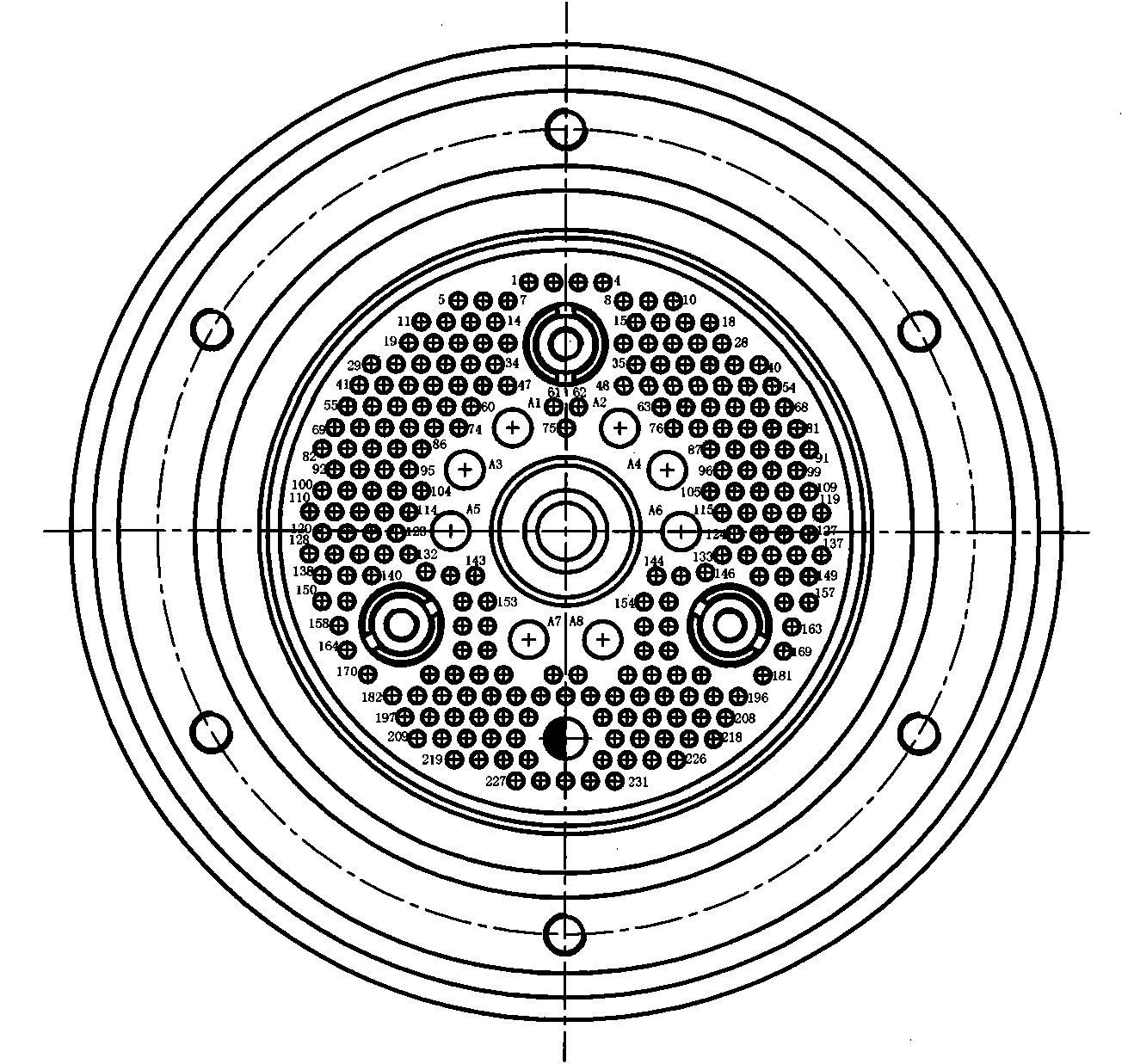

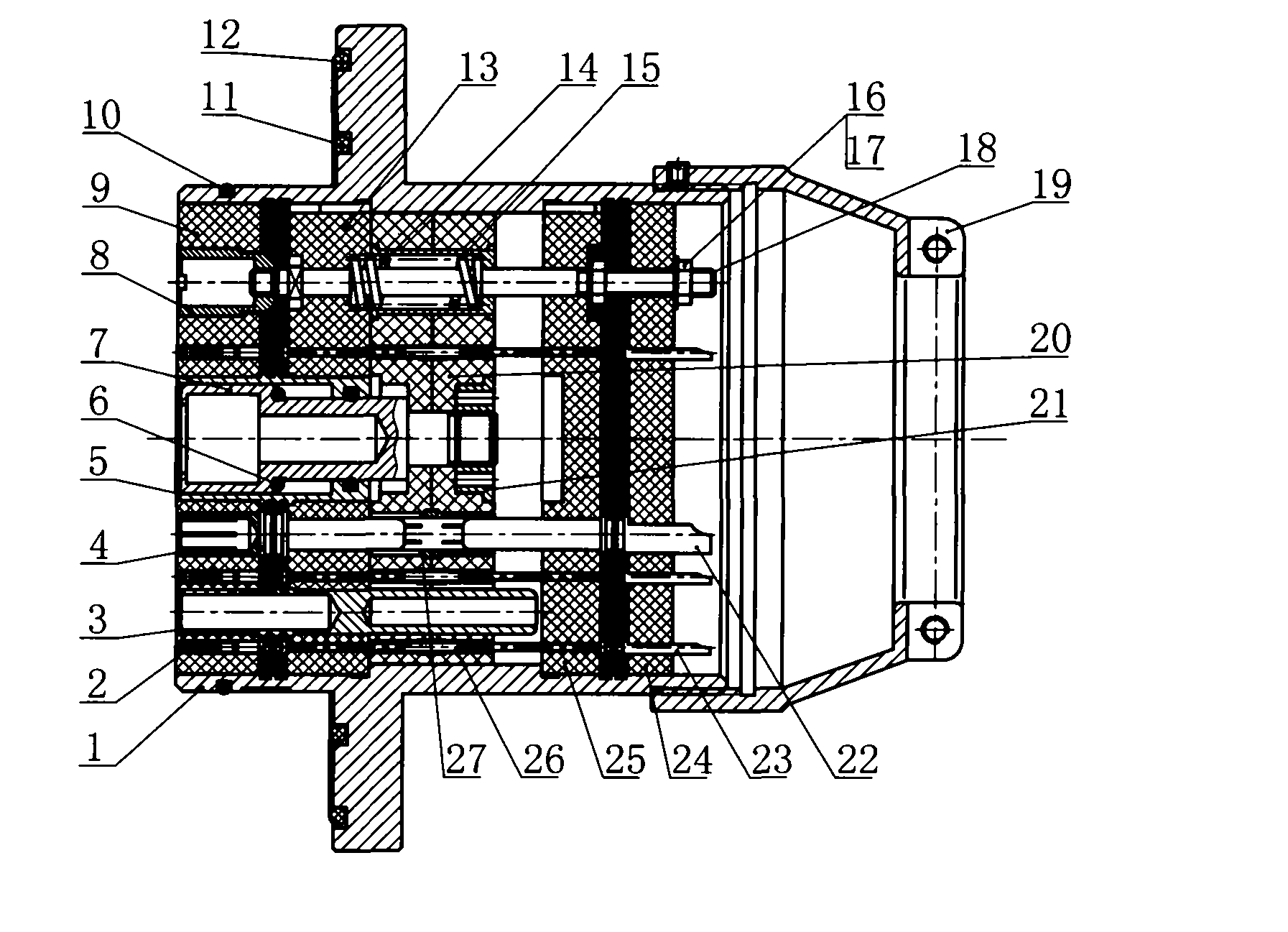

[0017] Below in conjunction with above-mentioned embodiment accompanying drawing, the present invention is described in further detail:

[0018] The rainproof and flameproof socket of the present invention comprises a shell 1, an upper sealing layer, a conversion layer, a lower sealing layer, an O-ring A10, an O-ring B11, an O-ring C12 and a tail attachment 19. Among them, the upper sealing layer is composed of jack assembly 2, guide sleeve A3, jack 4, sealing sleeve 5, guide sleeve B8, upper base 9 and lower base 13; the conversion layer is composed of O-ring 6, locking sleeve 7. Separation spring 14, separation sleeve 15, intermediate base 20, screw sleeve 21, transfer socket 26A and transfer socket 27B; the lower sealing layer is composed of nut 16, washer 17, fixed rod 18, pin A22, The pin B23, the lower base 24 and the upper base 25 are composed. The adapter socket A26 is composed of a contact ring 28, a protective tube A29 and a protective tube B30.

[0019] figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com