Grinding treatment method and device

A processing method and a technology of a processing device, which are applied in the field of fluff adjustment, can solve problems such as insufficient dust removal, non-uniform directionality of fluff, and non-uniform directionality of oriented films, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] (Fabrication of a long flexible strip equipped with an alignment film forming material layer)

[0071]Long-chain alkyl-modified polyvinyl alcohol (MP-203, Kuraray (manufactured by Kuraray Co., Ltd.) 5% by weight aqueous solution was dried at 90° C. for 4 minutes. In this way, an alignment film forming material layer having a thickness of 2.0 μm was formed.

[0072] (Grinding treatment of alignment film forming material layer)

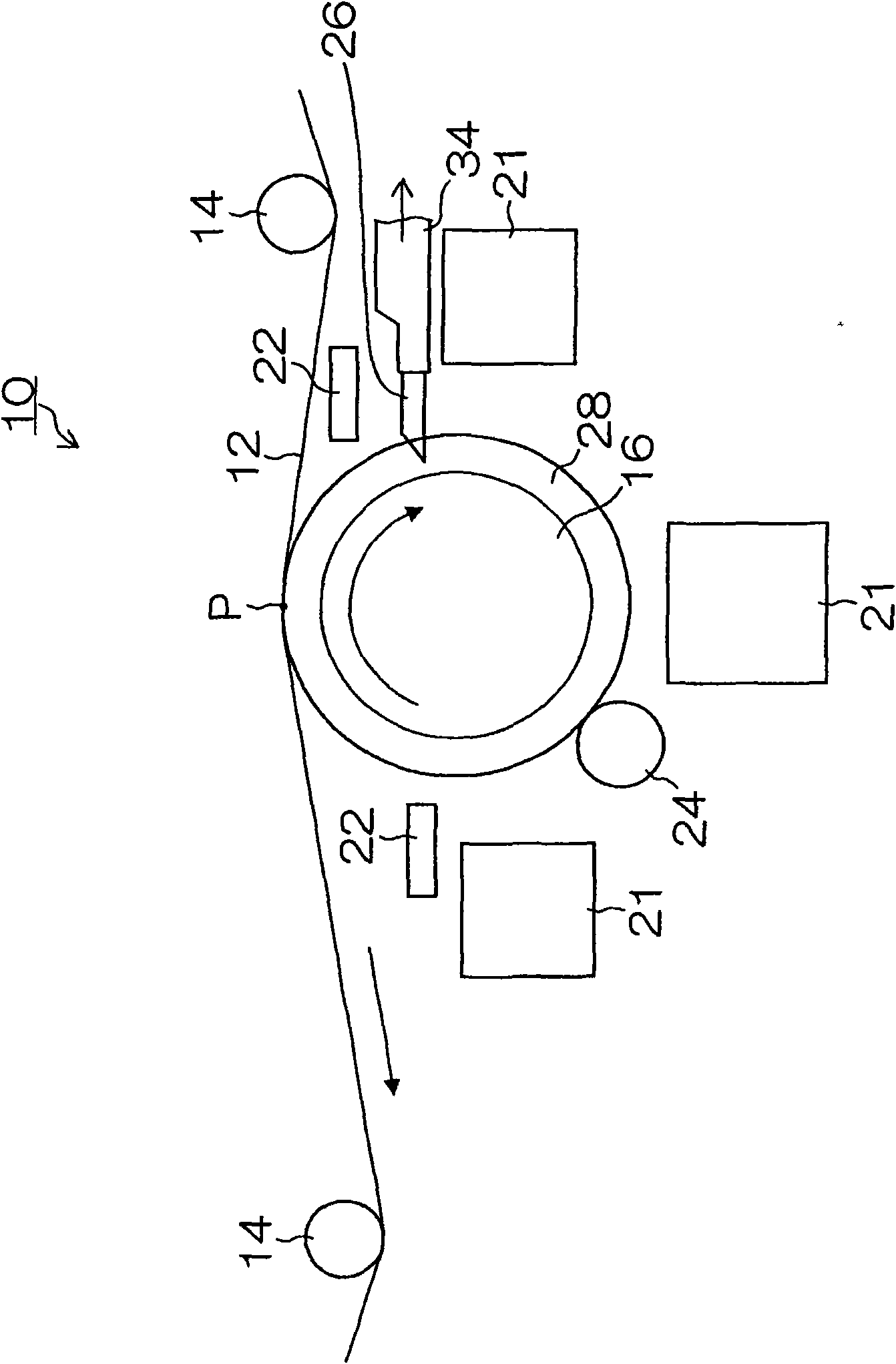

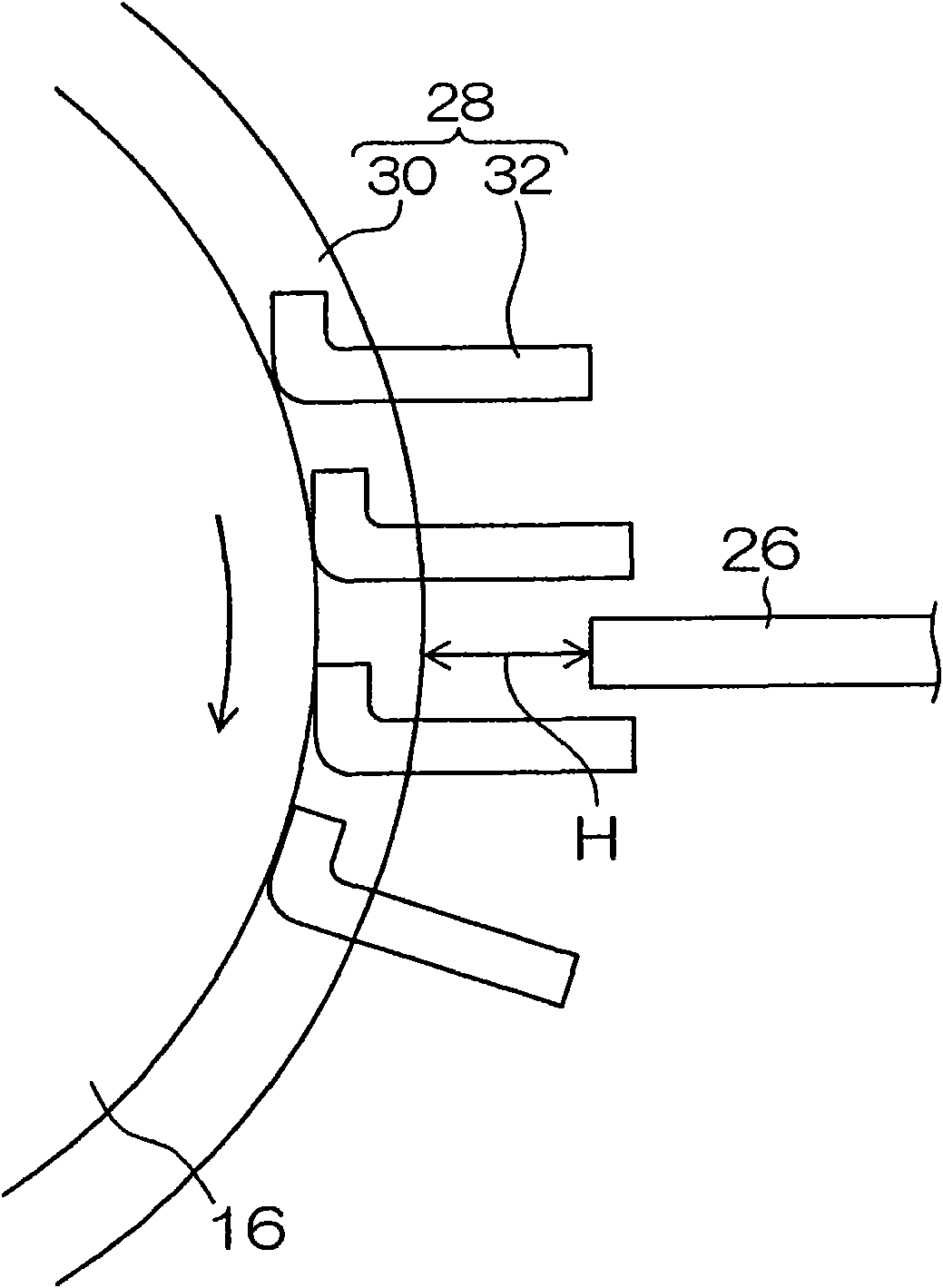

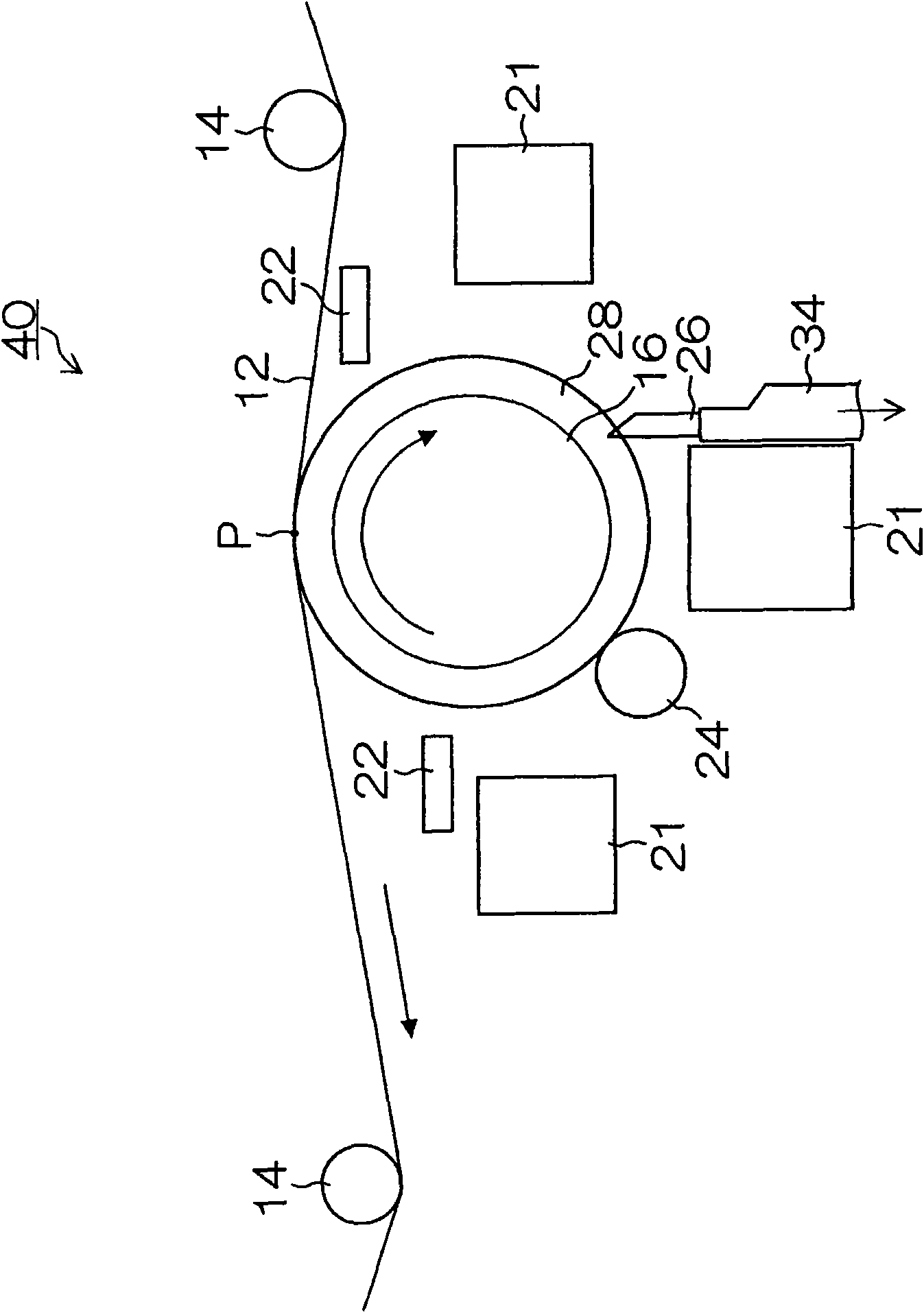

[0073] Used for long flexible films with an alignment film forming material layer figure 1 The device of the present invention implements grinding treatment on the surface of the alignment film forming material layer. The transparent film provided with the material layer for forming an alignment film was continuously conveyed in the direction of the arrow at 20 m / min. The transparent film is conveyed while being pressed from above by a roller (roller outer diameter: 90mm, length: 1650mm), and the grinding roller (outer diameter: 300mm) presse...

Embodiment 2~14

[0076] [Examples 2 to 14, Comparative Example 1]

[0077] In addition to changing the condition of the dust removal part and the condition of the grinding treatment device to Figure 6 Except for the conditions shown, the polishing treatment was performed in the same manner as in Example 1.

[0078] [test results]

[0079] The bright spot defects of the polished transparent films of Examples 1 to 6 and Comparative Example 1 were evaluated based on the frequency of bright spot occurrence using a planar inspection device using a CCD camera. The result is as Figure 6 shown. In addition, the symbols in the table are as follows.

[0080] ◎…high quality

[0081] ○...The quality is within the allowable range

[0082] △…Mass allowable limit

[0083] ×...The quality is outside the allowable range

[0084] The quality of the films of Comparative Examples 1 and 3 without a dust exhaust device and Comparative Example 2 without a dust removal device was not within the allowable ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com