Outer body for electrochemical element

A technology for an electrochemical element and an outer casing, which is applied in the field of an outer casing for electrochemical elements, can solve the problems of reduced production efficiency, complicated safety valve structure, complicated battery structure, etc., and achieves the effect of reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

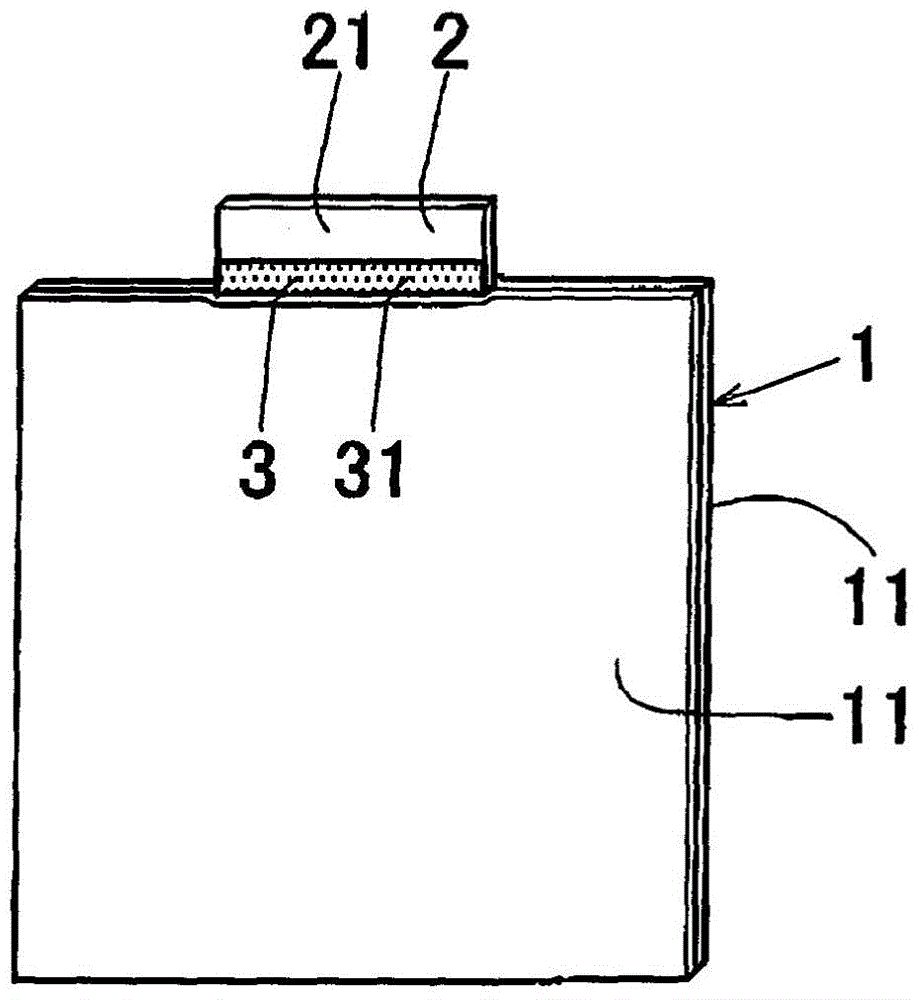

[0099]As the exterior film 11 constituting the exterior body 1 , a three-layer laminate with a thickness of 0.1 mm was prepared in which the sealant layer was made of stretched polypropylene, the middle layer was made of aluminum foil, and the outer layer was made of nylon 6. The size of the exterior film 11 is 100 mm in length and 100 mm in width.

[0100] As the porous metal sheet 21 constituting the safety valve 2 , a porous nickel (Ni) sheet produced by electrolysis was prepared. The sheet had a thickness of 0.05 mm, a length of 30 mm, and a width of 30 mm. And the film is 100 / cm 2 The density formed has a diameter porous sheet with fine pores.

[0101] As the polyolefin-based adhesive (PP adhesive) 31, a composition of 100:1.5 of hot-melt adhesive "Aronmelt (trademark) PPET-1600" manufactured by Toagosei Co., Ltd. and hexamethylene diisocyanate was prepared. Blended adhesive.

[0102] And, on both sides of the porous Ni sheet 21 (adhesion surface with the exterior f...

Embodiment 2

[0117] In the same manner as in Example 1, after the exterior film 11 and the porous Ni sheet 21 were bonded together, as shown in Table 1, the PP adhesive 31 was aged to obtain an exterior body 1, which was used as a sample of Example 2. The aging conditions are: pressure 0.1MPa-0.3MPa, temperature 30°C-50°C, time 2-9 days.

[0118] The sample (exterior body 1) of Example 2 thus obtained was evaluated in the same manner as in Example 1 above for initial adhesiveness, sealing performance, and adhesiveness after storage. The results are shown in Table 2.

Embodiment 3

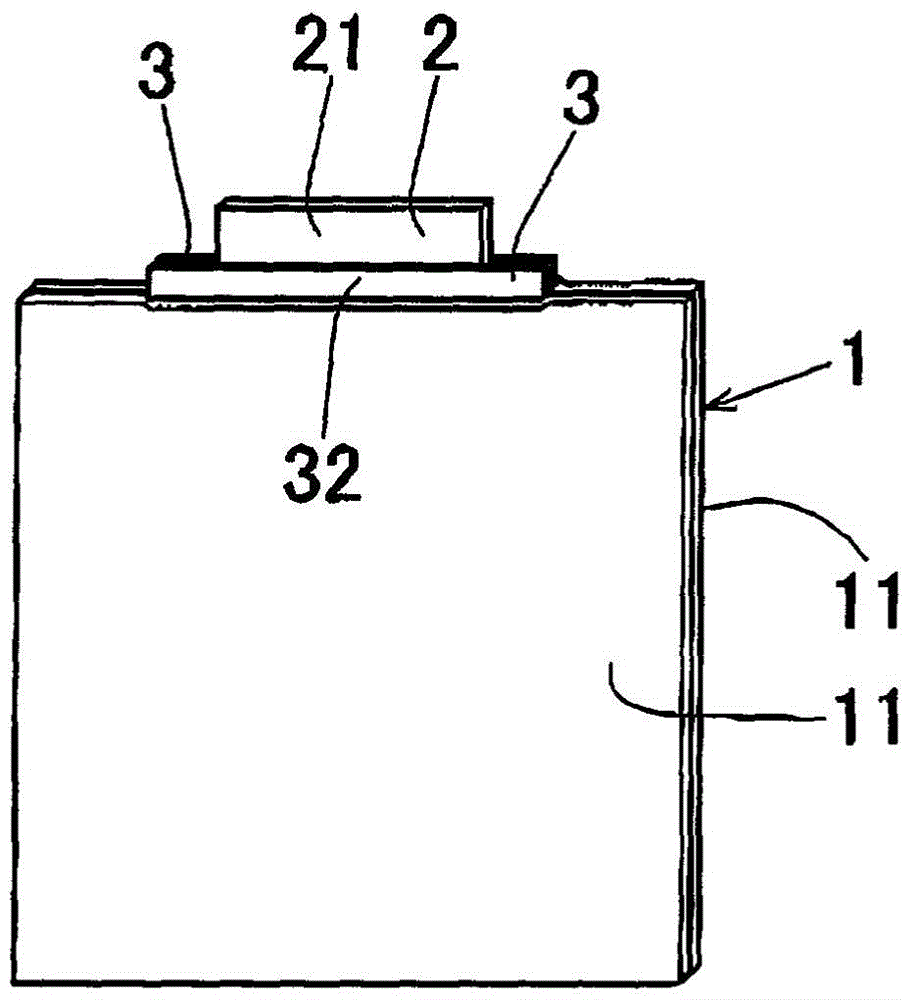

[0120] As the modified polyolefin film 32, the following adhesive film was prepared: a block of hot-melt adhesive "Aronmelt (trademark) PPET2102" manufactured by Toagosei Co., Ltd. The obtained plate (thickness 2mm) was sandwiched, heated and melted with a hot press at 190° C. for 1 minute, degassed, pressed at 3 MPa, and cooled to obtain an adhesive film with a thickness of 105 μm.

[0121] And, to both sides of the porous Ni sheet 21 as the safety valve 2 (adhesive surfaces with the exterior films 11, 11), the modified polyolefin film 32 is welded by thermal bonding (refer to Figure 5 ). The conditions of the thermal welding are: the temperature is 150° C. to 200° C., the pressure is 0.1 MPa to 0.3 MPa, and the time is 2 to 5 seconds.

[0122] In this way, the porous Ni sheet 21 on which the modified polyolefin film 32 is welded is sandwiched by the peripheral parts (one side) of the two outer membranes 11, 11 from both sides, and the outer membranes 11, 11 are overlapped....

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com