Steam generator and steam oven

A technology of steam generator and steam furnace, which is applied in the direction of steam generation, steam generation method, steam boiler, etc. It can solve the problems of slow steam speed and long cooking cycle, reduce the possibility of fouling and high heat exchange efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

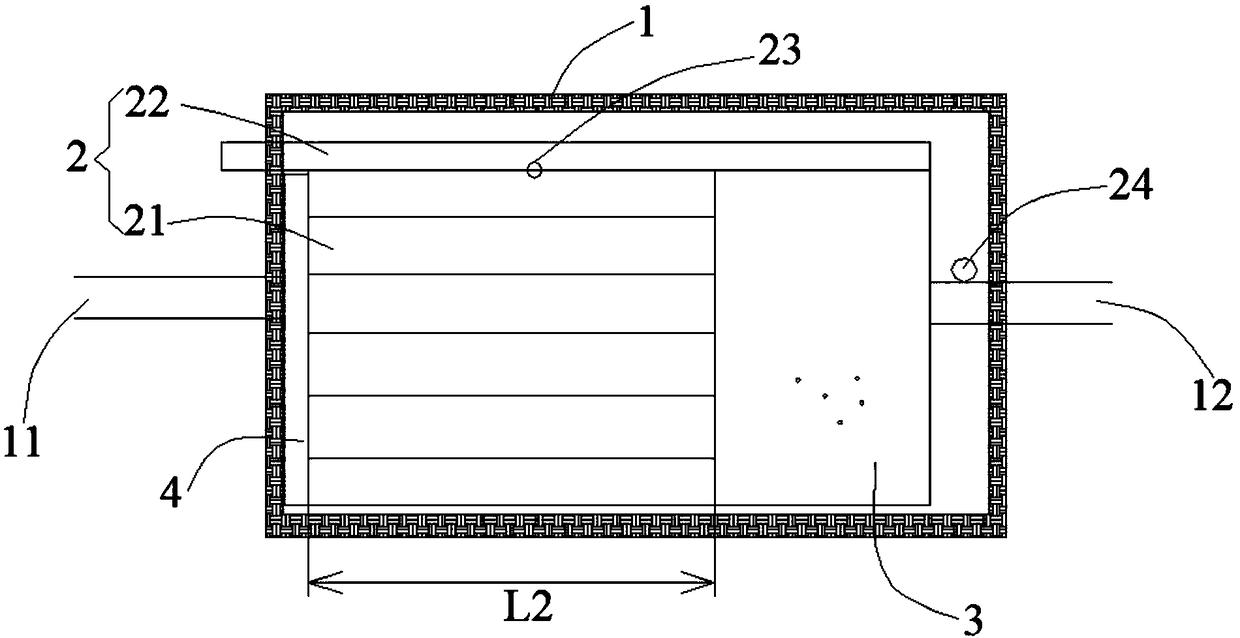

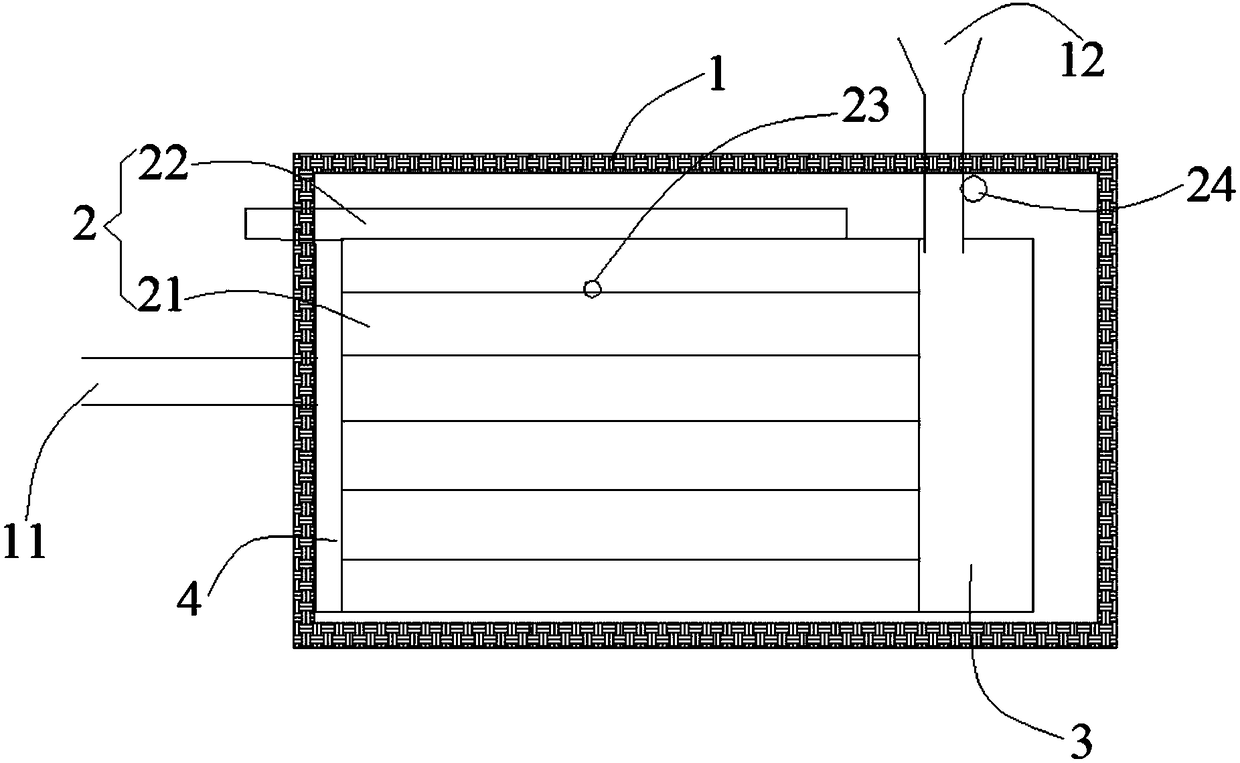

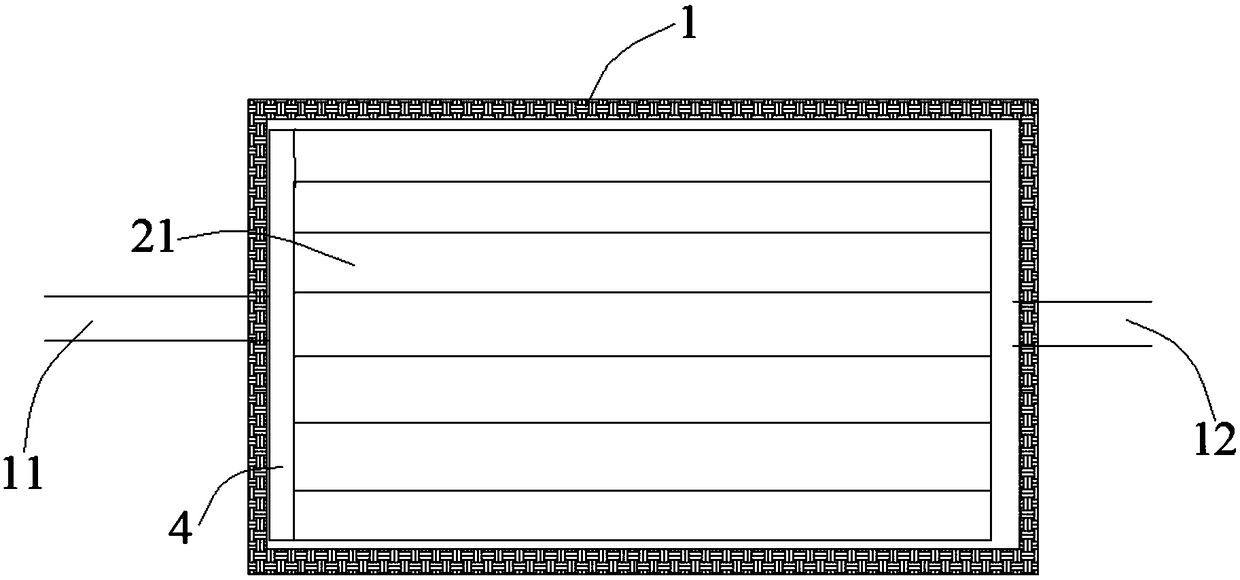

[0037] like figure 1 - image 3 As shown, the steam generator 100 provided in this embodiment includes a casing 1 provided with a water inlet 11 and an exhaust port 12, and a steam generating unit 2 disposed in the casing 1. The steam generating unit 2 includes a plurality of The gasification chamber of the channel 21 and the heating body 22 for heating the gasification chamber, the heating body 22 is in thermal contact with the gasification chamber; after the liquid enters the shell 1 through the water inlet 11, it is divided by the microchannels 21 and can be Under the action of the heating body 22 , the gas is rapidly vaporized in each microchannel 21 . The exhaust port 12 is used to discharge the steam generated in the steam generating unit 2 .

[0038] On the one hand, the steam generator 100 provided in this embodiment adopts the flow splitting technology to divide the water flow into several small water flows through a plurality of microchannels 21 . Since the inner d...

Embodiment 2

[0073] like Image 6 and Figure 7 As shown, the steam furnace provided in this embodiment includes a water tank 300, the steam generator 100 provided in the first embodiment, and a water pump 200 for transporting the water in the water tank 300 to the steam generator 100. The control between the water pump 200 and the steam furnace The system is connected, and the exhaust port 12 of the steam generator communicates with the cooking cavity of the steam oven.

[0074] The steam furnace provided in this embodiment includes the above-mentioned steam generator 100, and can achieve the beneficial effects that the above-mentioned steam generator 100 can achieve.

[0075] Specifically, the water pump 200 may be an AC water pump 200, and the AC water pump 200 is connected to the water tank 300 and the gasification chamber through a pipeline system.

[0076]The water is pumped from the water tank 300 to the gasification chamber by the AC water pump 200, and the heating body 22 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com