Waste heat recovery from smelting reduction ironmaking in heat pipe type rotary hearth furnace and steam production apparatus

A technology of waste heat recovery and rotary hearth furnace, which is applied in the fields of metallurgy, energy saving and environmental protection, to achieve the effects of reducing metal consumables, improving reliability and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

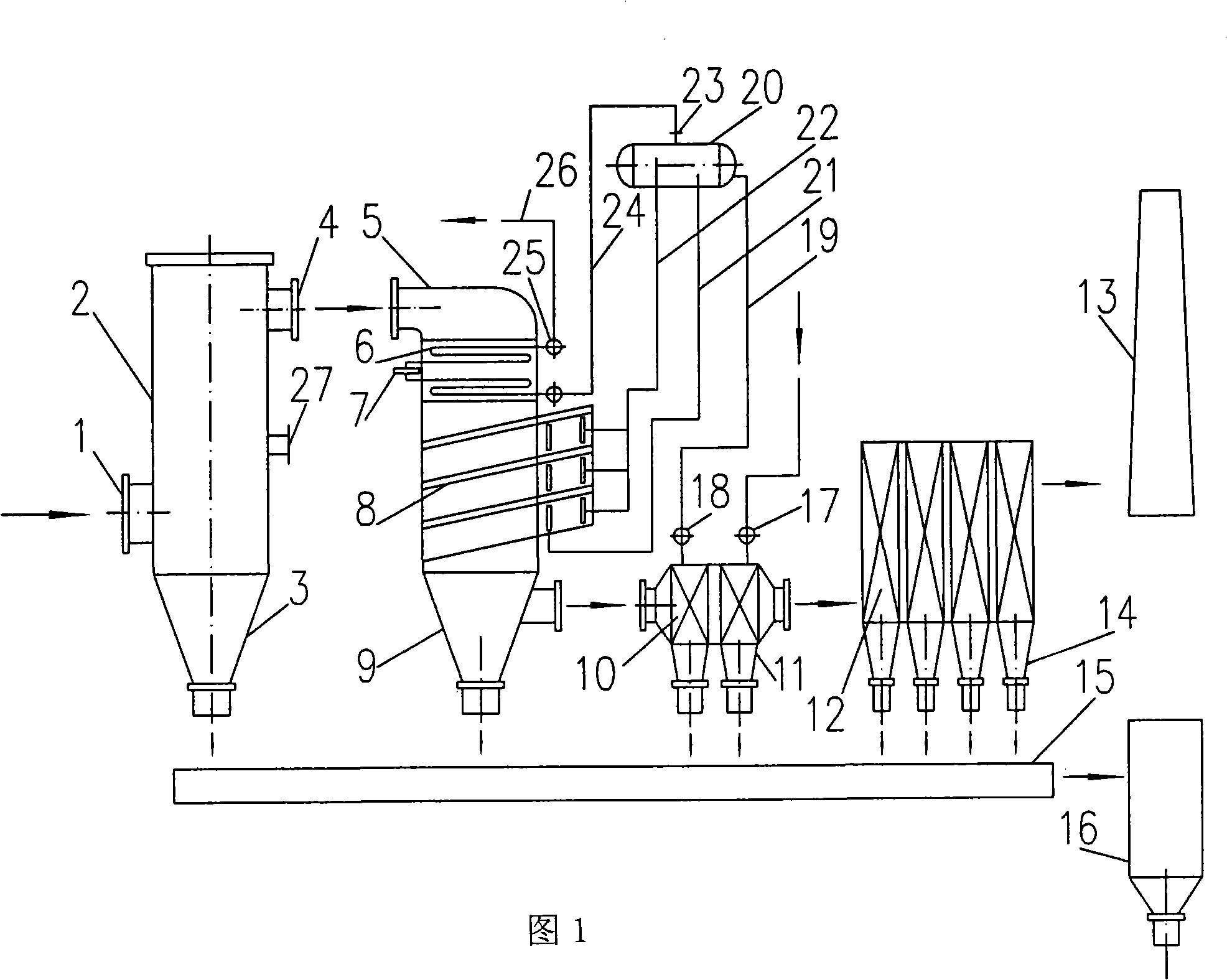

[0024] The present invention will be further described below in conjunction with accompanying drawing:

[0025] One side of the outer wall of the secondary combustion settling chamber 2 of the heat pipe rotary hearth furnace smelting reduction ironmaking waste heat recovery and steam production device is connected to the inlet 1, and the other side is connected to the outlet 4, and the outlet 4 is connected to the high-temperature flue 5; the high-temperature flue 5 A steam superheater 6 and a heat pipe steam generator 8 are arranged on the top, and a heat pipe is used as a heat transfer element in the heat pipe steam generator 8. The bottom end of the high-temperature flue 5 is provided with an ash discharge tee 9, and the horizontal outlets of the ash discharge tee 9 are in turn A heat pipe feedwater preheater 10, a bag filter 12 and a chimney 13 are connected; the steam drum 20 is connected to the heat pipe feedwater preheater 10 through a water pipe 19 and a water outlet 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com