Cylindrical ageing storehouse capable of automatically distributing and discharging

An automatic cloth and cylinder technology, applied in the directions of loading/unloading, transportation and packaging, etc., can solve the problems of affecting the aging effect of raw materials, large contact area with air, easy to raise dust, etc., and achieve easy maintenance of raw material moisture and temperature, mechanization and automation The effect of high degree, uniform feeding and cloth distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention belongs to the technical field of raw material storage and processing in brick and tile production, and in particular relates to a cylindrical aging storage that can automatically distribute and unload materials.

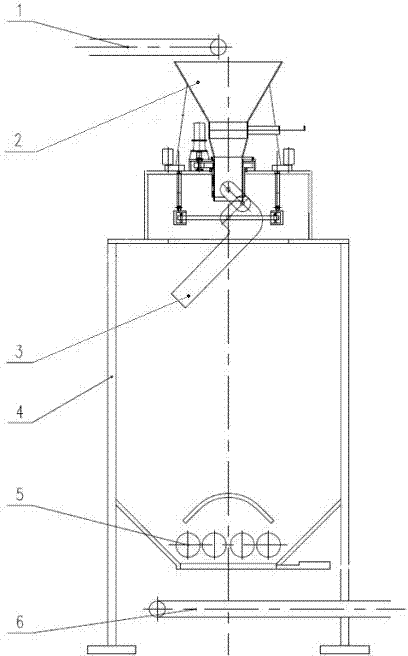

[0021] see Figure 1 to Figure 4 , the specific structure of a cylindrical aging storehouse for automatic material distribution and unloading that the present invention relates to is:

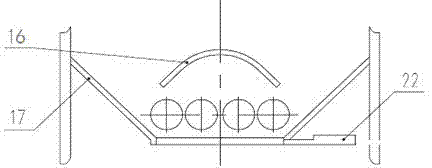

[0022] It includes incoming material belt conveyor 1, silo 2, material distribution system 3, storage body 4, roller unloading device 5 and blanking belt conveyor 6 connected in sequence; among them,

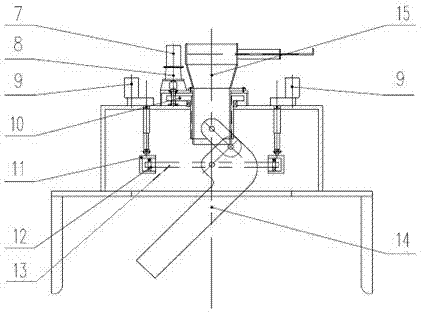

[0023] The distribution system 3 includes a first motor 7, a first reducer 8, an electric cylinder 9, large and small gears 10, a moving block 11, a pulley 12, a connecting rod 13, a distribution chute 14 and a feeding pipe 15; wherein, the first motor 7, The first reducer 8, the large and small gears 10 and the distribution chute 14 are connected in sequence; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com