Dampness removing structure, steam cooking device and humidity control method

A cooking device and humidity control technology, which is applied to steam cooking utensils, timing control ignition mechanisms, cooking utensils, etc., can solve the problems of difficult humidity control of steam cooking devices, difficulty in steaming food, and low accuracy, and achieves constant temperature and constant temperature. Good humidity effect, avoid inaccurate humidity control, stable internal environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

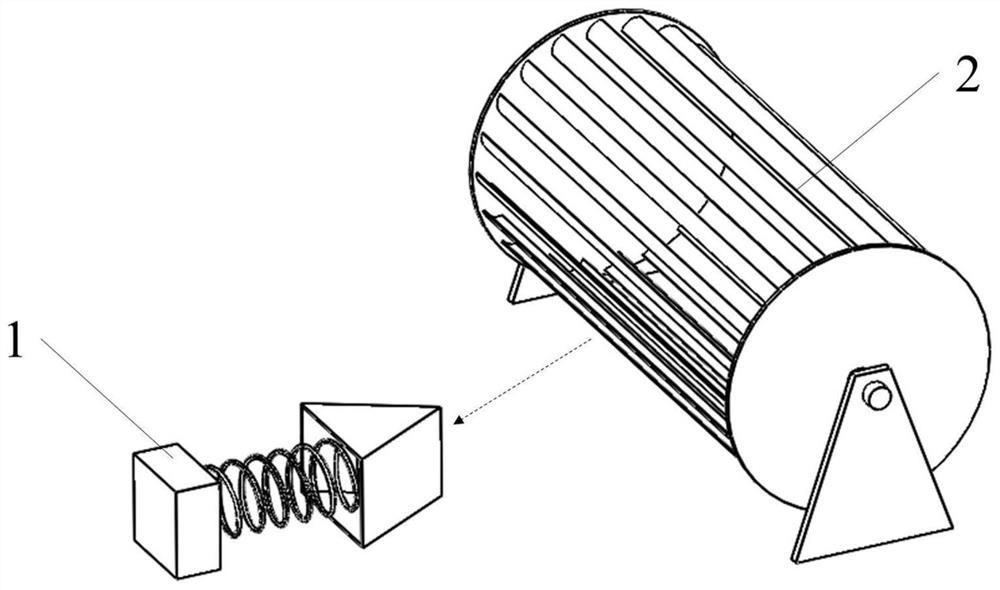

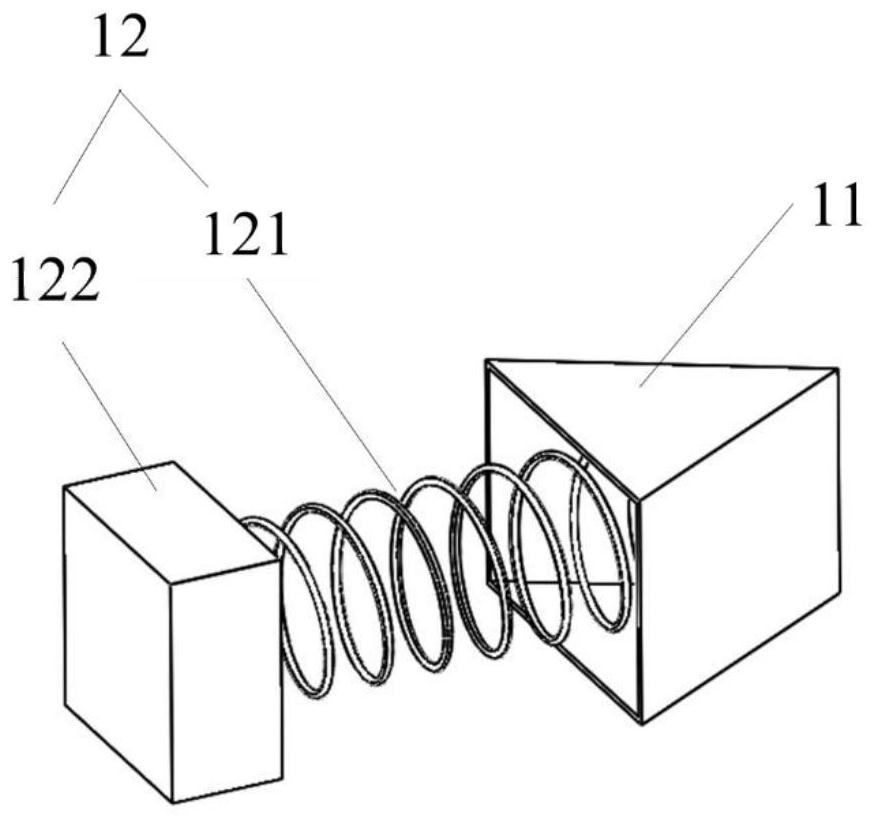

[0056] This embodiment provides a dehumidification structure for steam cooking devices, such as figure 1 with figure 2 As shown, it includes a gas blocking module 1 and a driving module 2; the gas blocking module 1 is arranged above the exhaust port of the steam cooking device, and is used to adjust the opening of the exhaust port, and the driving module 2 is arranged on the on steam cooking appliances;

[0057] The driving module 2 is activated to drive the gas blocking module 1 to move, change the opening of the exhaust port, and adjust the gas discharge volume.

[0058] Specifically, the air blocking module 1 is arranged on the steam cooking device, and is located above the outside of the exhaust port. At this time, the air blocking module 1 does not completely cover the exhaust port, and the driving module 2 is arranged on the steam cooking device; thus, the driving module 2 is started to drive the moving parts in the gas blocking module 1 to move, thereby changing the ...

Embodiment 2

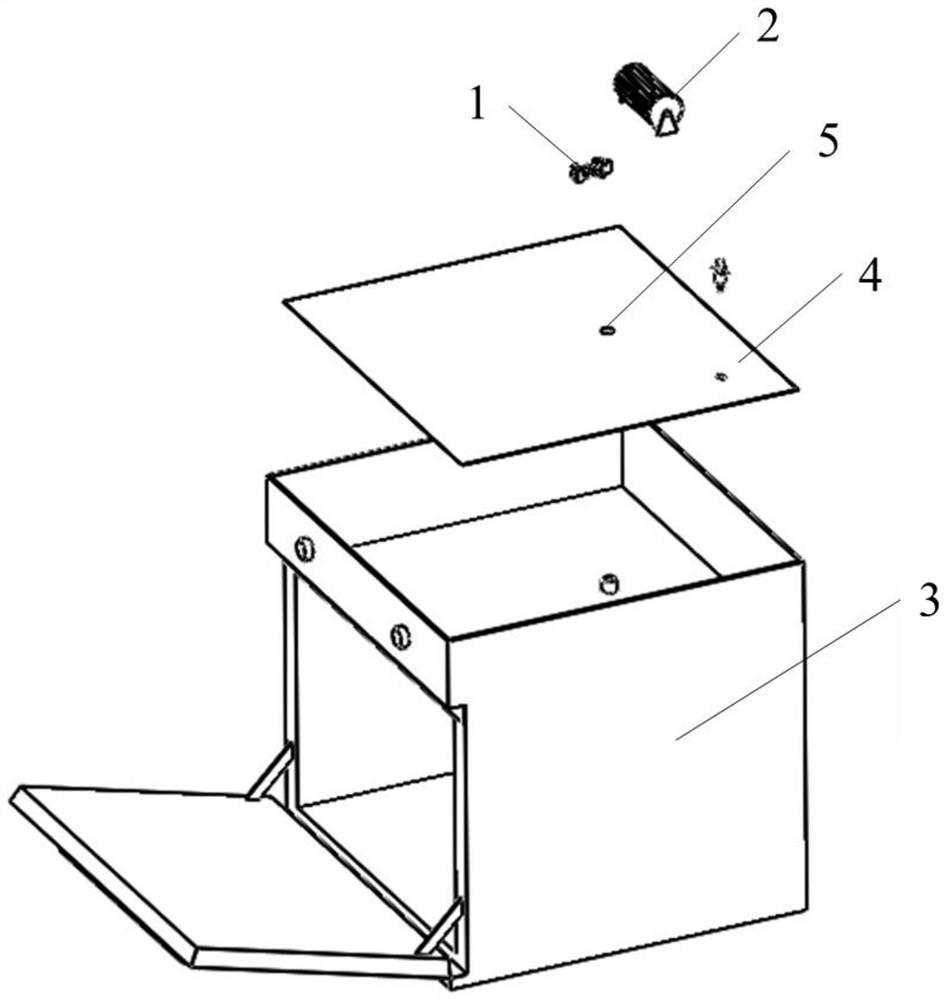

[0075] This embodiment provides a steam cooking device, which includes the dehumidification structure of Embodiment 1, a housing 3, a middle plate 4 and an exhaust port 5, the middle plate 4 is horizontally arranged in the housing 3, and the exhaust The air port 5 is set through the middle plate 4, the gas blocking module 1 is set on the middle plate 4 and is located above the exhaust port 5, and the driving module 2 is set on the middle plate 4 superior.

[0076] In this way, the air-blocking module 1 is driven to move by the driving module 2, and the opening of the exhaust port 5 is changed, so as to realize rapid dehumidification.

[0077] In a specific implementation, the steam cooking device further includes an exhaust hood, an oxygen concentration detection component, and the like.

[0078] In this embodiment, a dehumidification structure is arranged on the middle plate of the steam cooking device. The dehumidification structure includes a gas-blocking module and a driv...

Embodiment 3

[0080] This embodiment provides a humidity control method, which is applied to the steam cooking device in Embodiment 2, and includes the following steps:

[0081] S1, start the steam cooking device, select the cooking mode, and input the preset temperature and preset humidity;

[0082] S2, preheating the inner tank of the cooking device to the preset temperature, when the preset temperature is reached, adjusting the humidity of the inner tank to the preset humidity, that is, adjusting the oxygen concentration of the inner tank is the oxygen concentration corresponding to the preset humidity;

[0083] S3, collecting the real-time temperature of the inner container, and obtaining a real-time oxygen concentration controllable range according to the real-time temperature, preset humidity, and controllable humidity corresponding to the cooking mode;

[0084] Wherein, the controllable humidity corresponding to the cooking mode is obtained according to the cooking mode;

[0085] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com