MEMS based micro vapor compression refrigeration system for microelectronic and photonic thermal control

a micro-vapor compression refrigeration and photonic thermal control technology, applied in the direction of cooling fluid circulation, lighting and heating apparatus, domestic cooling apparatus, etc., can solve the problems of further reduction in size, need to dissipate, and limited technology for refrigerating devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

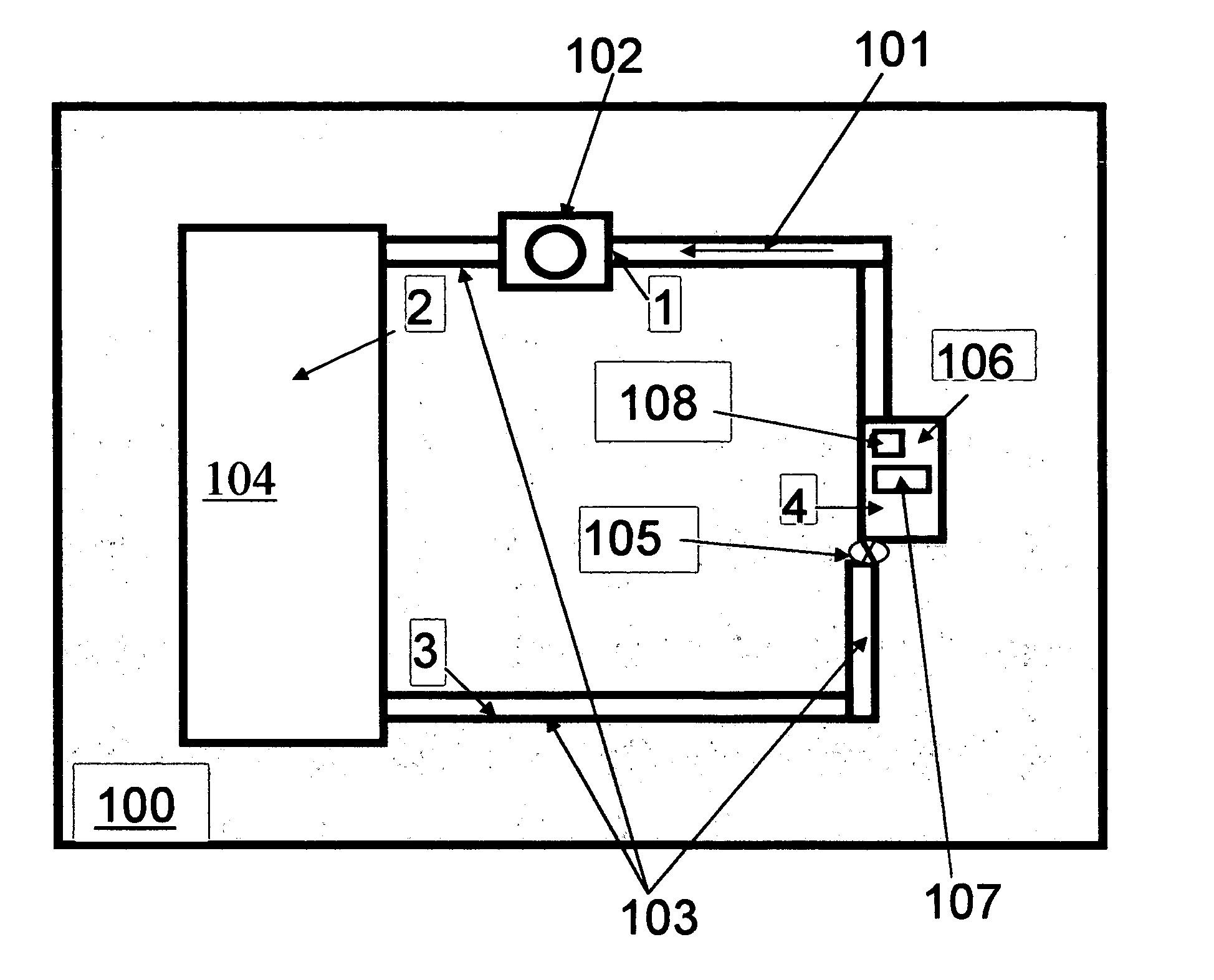

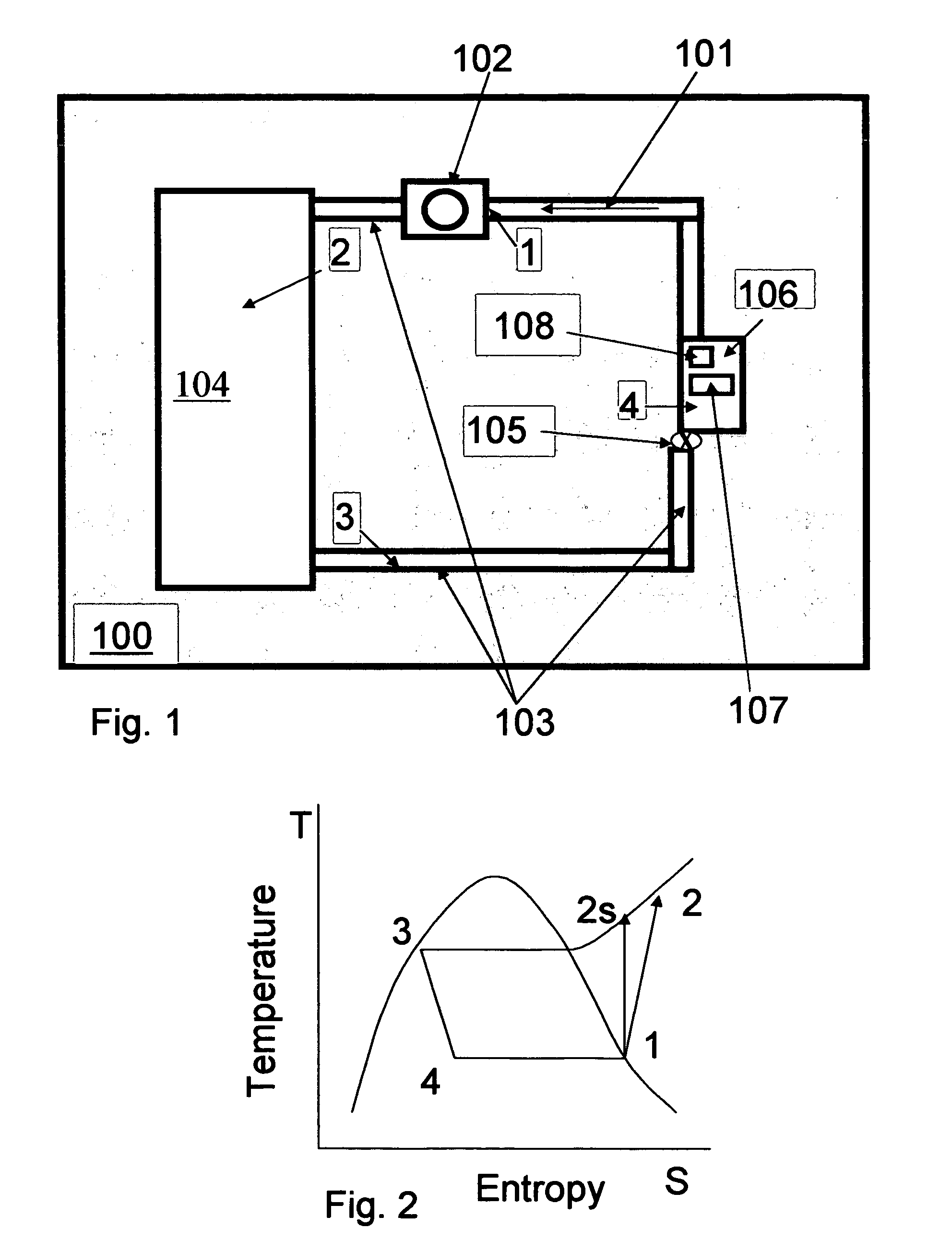

[0012]FIG. 1 shows schematically the MEMS vapor compression refrigerator on a submount 100. The refrigerant fluid 101 is compressed in the micro-compressor section 102 and piped 103 to the condenser 104 where it is condensed to a liquid at a temperature slightly above ambient. The liquid is piped 103 to a pressure reducing orifice expander 105 arranged near the evaporator cavity 106. The photonic or electronic chip 107 is mounted atop an evaporator cavity 106 that has been etched into the substrate material. Heat is conducted from the photonic or electronic chip into the evaporator cavity where it completes the evaporation of the refrigerant and is carried away by the refrigerant fluid. The warmed refrigerant is piped to the compressor section 102 and the cycle repeats. A thermal sensor 108 such as a thermistor or thermocouple measures the temperature for control purposes. The thermodynamic cycle with the corresponding states of the refrigerant is illustrated schematically in FIG. 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com