Vapour compressing refrigeration system including injector

A vapor compression and refrigeration system technology, applied in irreversible cycle compressors, refrigerators, compressors, etc., can solve the problems of cost increase and complex structure, and achieve the effect of simple and practical defrosting operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

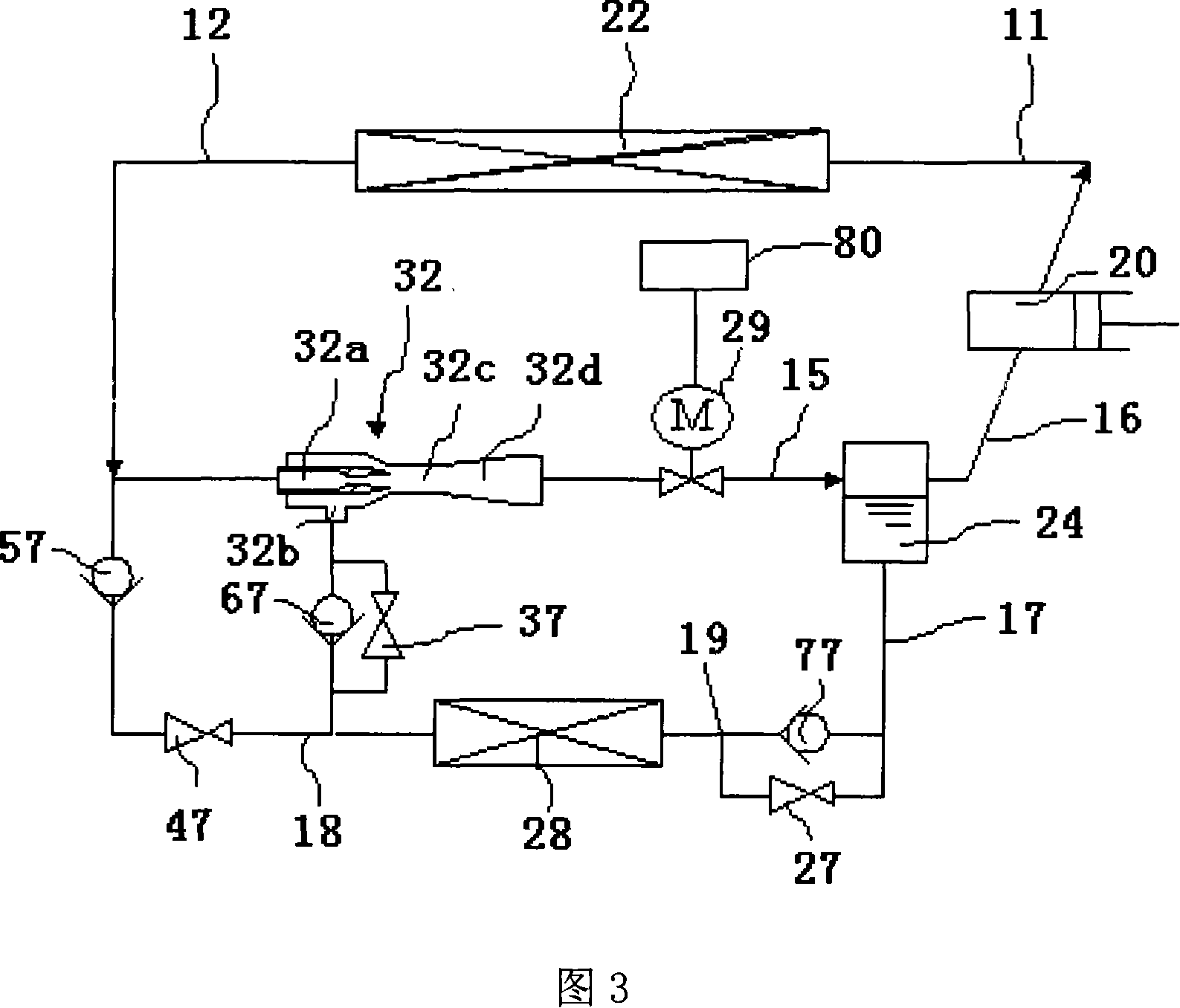

[0018] Referring to Fig. 3, the vapor compression refrigeration system comprising an ejector of the present invention includes a compressor 20, the outlet end of the compressor 20 is connected to a radiator 22, the inlet end of the compressor 20 is connected to a gas-liquid separator 24, and the gas-liquid separator 24 is connected to the diffuser section 32d of the ejector 32 through a valve 29, and the valve 29 is connected to the controller 80;

[0019] The radiator 22 communicates with the nozzle 32a of the ejector 32 through the pipeline 12, and connects the first throttling element 47 through the pipeline 17, the first throttling element 47 communicates with the evaporator 28 through the pipeline 18, and the pipeline 18 passes through The second throttling element 37 and the second one-way valve 67 connected in parallel with the second throttling element 37 are connected to the ejector suction chamber 32b, and the evaporator 28 passes through the pipeline 19, the third th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com