Air conditioner for vehicle with heat pump cycle

a technology for air conditioners and vehicles, applied in the direction of compression machines with several condensers, light and heating apparatus, transportation and packaging, etc., can solve the problems of difficult to achieve emission reduction, difficult to sufficiently clean exhaust gas, and inability to achieve the effect of reducing fuel consumption, preventing excessive heating capacity, and effective reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

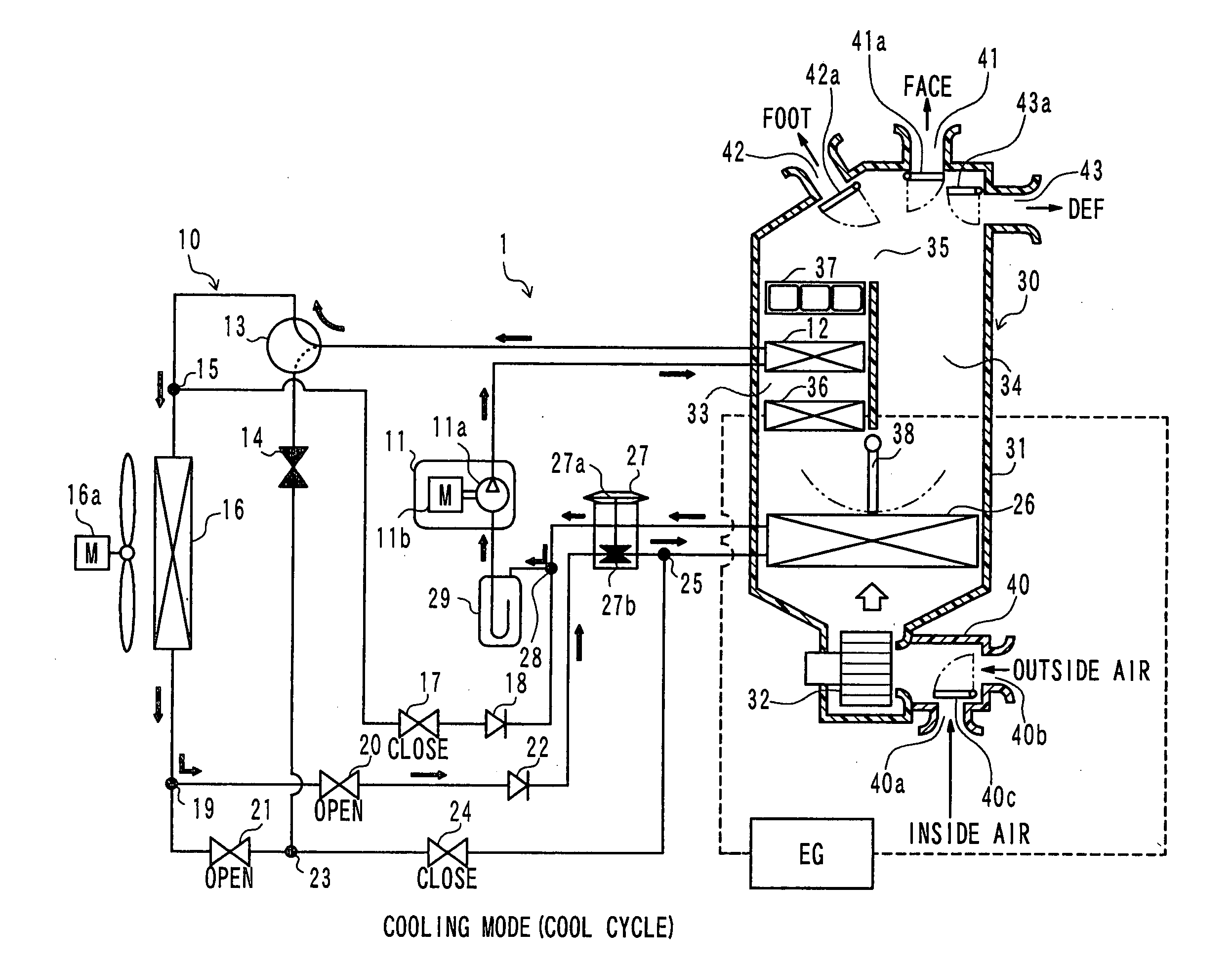

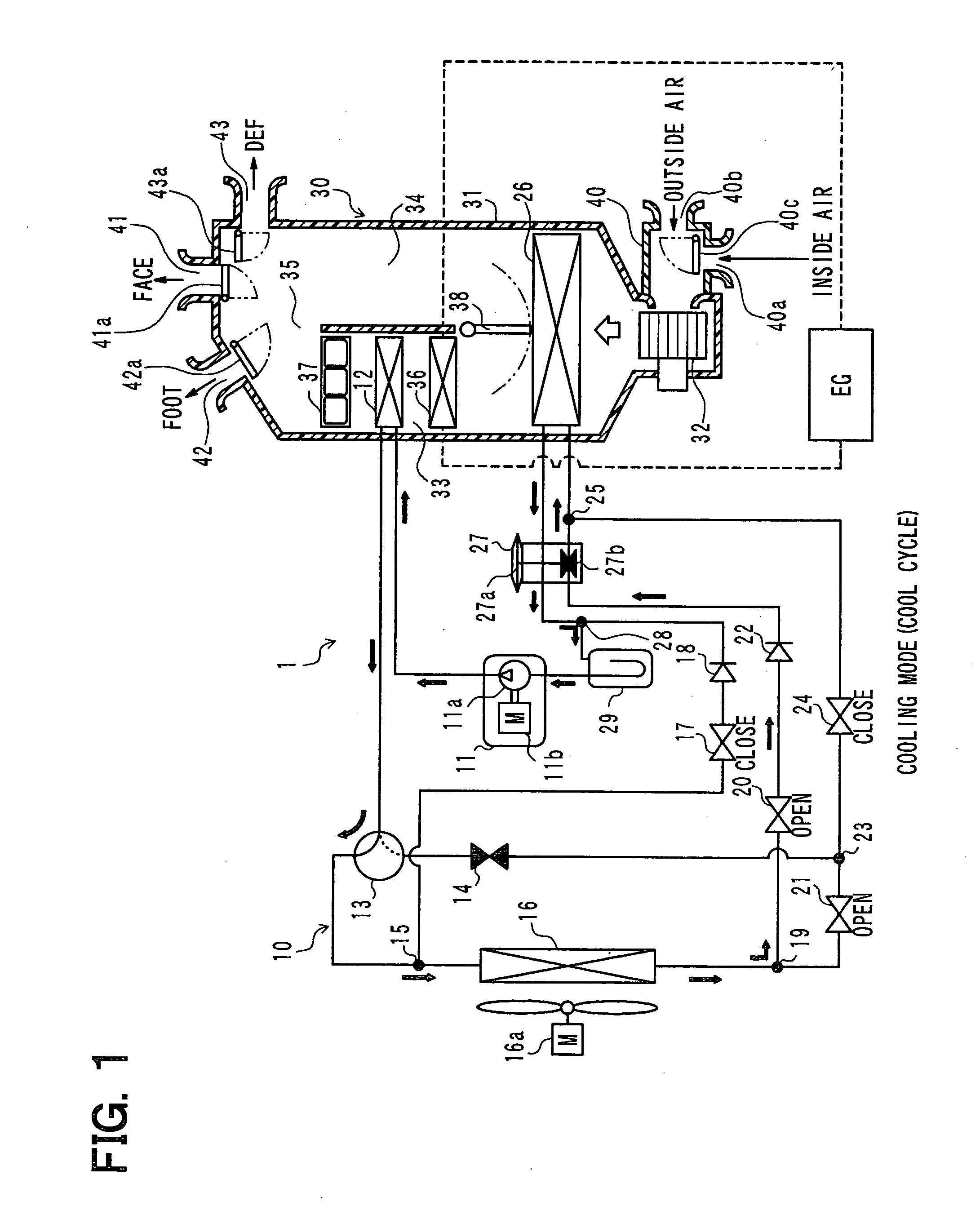

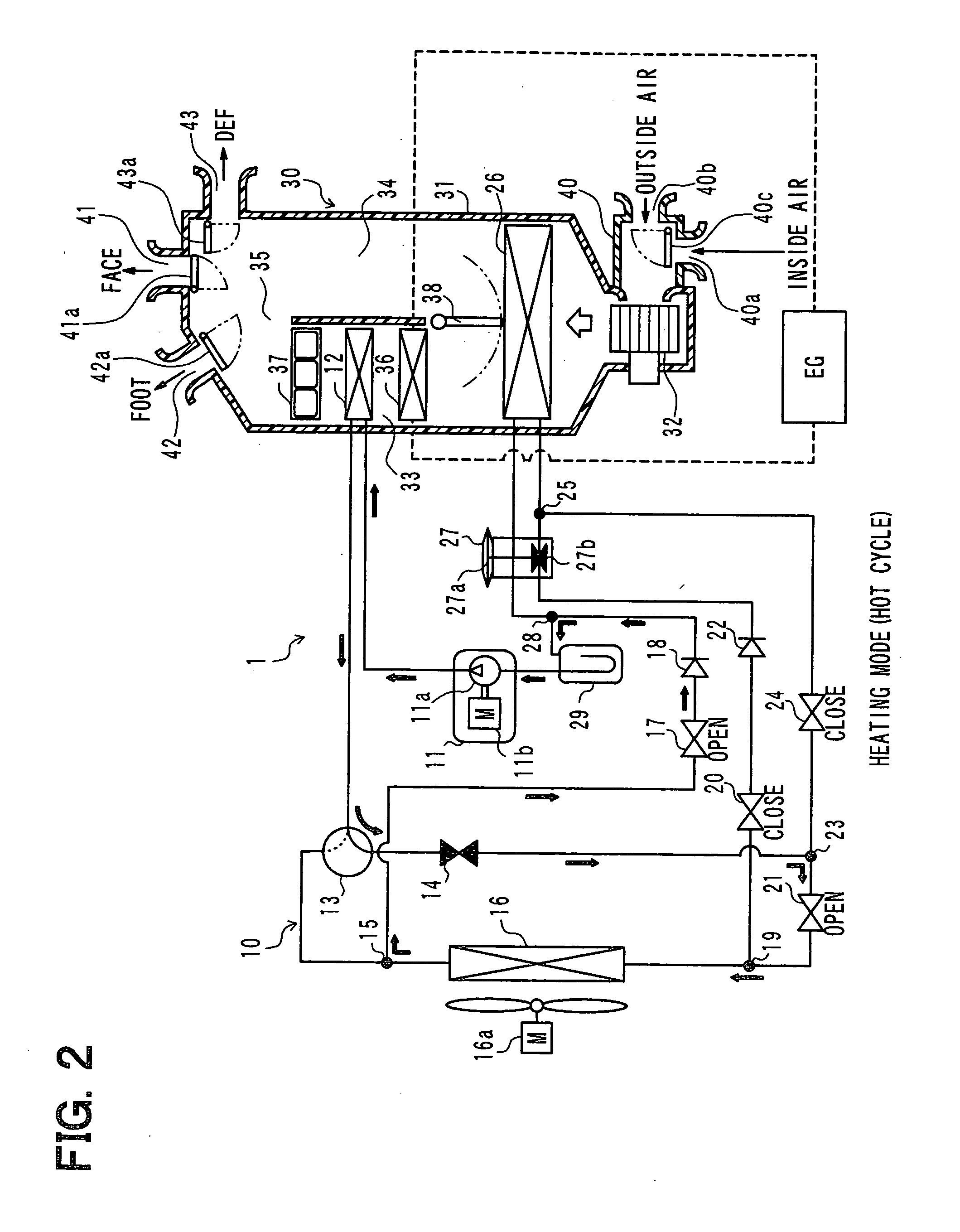

[0058]A first embodiment of the invention will be described below with reference to FIGS. 1 to 9. In the present embodiment, an air conditioner for a vehicle of the invention is applied to the so-called hybrid car which obtains a driving force for a vehicle traveling from an internal combustion engine (engine) EG and an electric motor for traveling. FIGS. 1 to 4 show an entire configuration diagram of an air conditioner 1 for a vehicle, according to the first embodiment and the following embodiments described later.

[0059]The air conditioner for a vehicle includes a vapor compression refrigeration cycle 10 which can switch among refrigerant circuits in a cooling mode (COOL cycle) for cooling the vehicle interior, in a heating mode (HOT cycle) for heating the vehicle interior, and in a first dehumidification mode (DRY_EVA cycle) and in a second dehumidification mode (DRY_ALL cycle) for dehumidifying the vehicle interior. FIGS. 1 to 4 indicate the flows of refrigerant in the cooling mo...

second embodiment

[0223]In the above first embodiment, heating using the heater core 36 (i.e., heating using the engine coolant as a heat source) is selected at the extreme-low outside air temperature lower than −5° C. In contrast, in a second embodiment, as shown in FIG. 10, heating by the heater core 36 (i.e., heating using the engine coolant as a heat source) is selected when the vehicle interior preset temperature Tset is set to a very high temperature higher than 31° C.

[0224]That is, when the heat pump cycle is selected while the vehicle interior preset temperature Tset is set to a very high temperature, the operating rate of the heat pump cycle becomes high, thereby rapidly causing the frost formation on the outdoor heat exchanger 16. The frost formation on the outdoor heat exchanger 16 reduces the heat exchange efficiency of the outdoor heat exchanger 16, degrading the heating capacity.

[0225]In the present embodiment, when the vehicle interior preset temperature Tset is set to a very high temp...

third embodiment

[0236]In the above first embodiment, the heating using the heater core 36 (i.e., heating using the engine coolant as a heat source), and the dehumidification using the cooler cycle are performed at the extreme-low outside air temperature lower than −5° C. However, in a third embodiment, as shown in FIG. 11, heating is performed using both of the heater core 36 (i.e., heating using the engine coolant as a heat source) and the heat pump cycle at a low outside air temperature lower than −2° C.

[0237]Now, the process in step S6 of the present embodiment will be described in detail below. FIG. 11 is a flowchart showing a main part of the process in step S6. The control process shown in the flowchart of FIG. 11 is carried out when the air conditioner switch 60a and the automatic switch 60b are turned on (ON), or the like.

[0238]In step S70, it is determined whether the present air conditioning control is pre-air conditioning or not. When the present air conditioning control is determined no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com