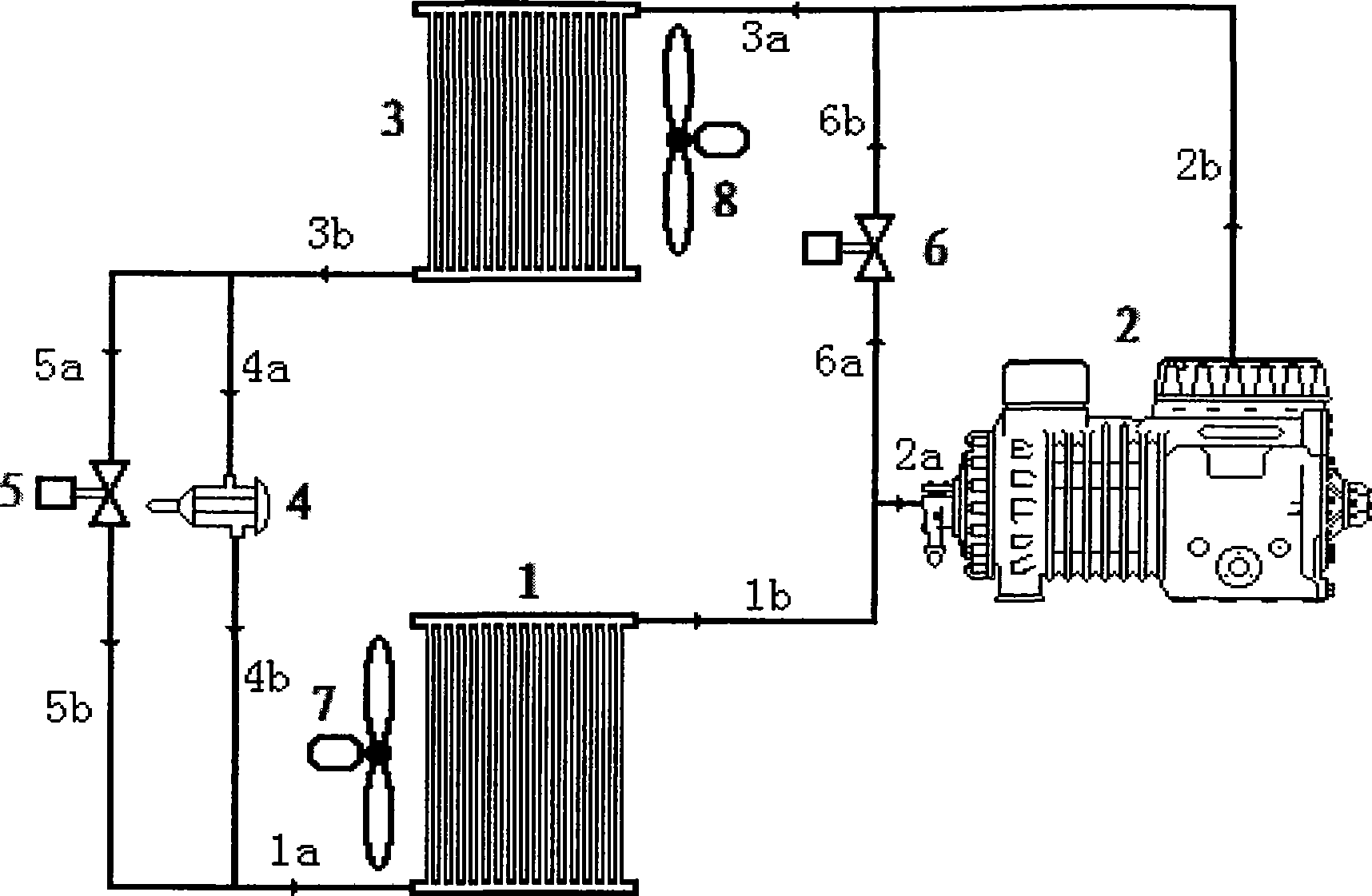

Split type refrigeration and heat pipe heat exchanging cycle coupling apparatus and cycle method

A heat pipe heat exchange and split-type technology, which is applied in refrigerators, indirect heat exchangers, refrigeration and liquefaction, etc., can solve problems such as the impact on the safe and stable operation of electronic and electrical equipment, achieve enhanced reliability and stability, and improve service life , the effect of saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The implementation method of the split refrigeration and heat pipe heat exchange cycle coupling device of the present invention is as follows: when the temperature difference between the closed environment and the outdoor atmospheric environment is greater than 10°C, the liquid circuit solenoid valve 5 and the steam circuit solenoid valve 6 are opened, the compressor stops working, and the evaporator Fan 7 and condenser fan 8 work as usual. At this time, the split cooling and heat pipe heat exchange cycle coupling device system works in the heat pipe heat exchange cycle mode, the outdoor condenser 3 is used as the split heat pipe condensation section, and the indoor evaporator 1 is used as the split heat pipe evaporation section. The refrigerant absorbs the heat in the closed environment and evaporates in the split heat pipe evaporation section 1, and the refrigerant vapor passes through the steam pipeline 1b-6a, passes through the steam solenoid valve 6, and then enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com