Low-temperature plasma exhaust gas purification device

A low-temperature plasma and exhaust gas purification technology, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems such as the inability to adjust the intake air flow and flow rate, the influence of the number of high-energy ions, and the inhomogeneous exhaust gas intake. , to overcome inapplicability and interference, complete cracking, and improve impact ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings will be used for a detailed description, as follows:

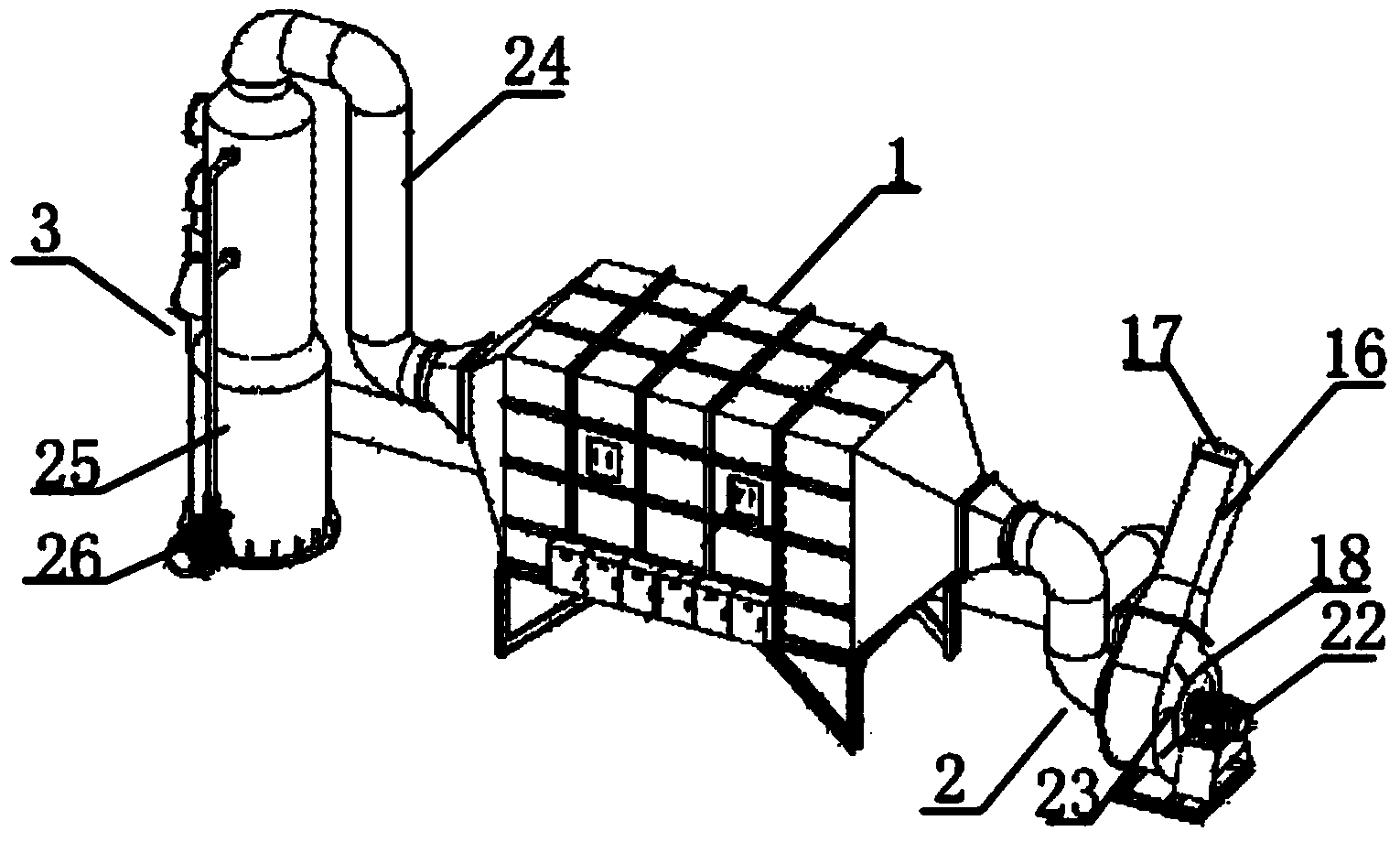

[0022] Such as Figure 1 to Figure 5 As shown, a low-temperature plasma exhaust gas purification equipment includes a low-temperature plasma reaction chamber 1, and the two ends of the low-temperature plasma reaction chamber 1 are respectively provided with an air inlet mechanism 2 and an air outlet mechanism 3, and the cavity of the low-temperature plasma reaction chamber 1 Several free radical emission devices 6 are arranged inside.

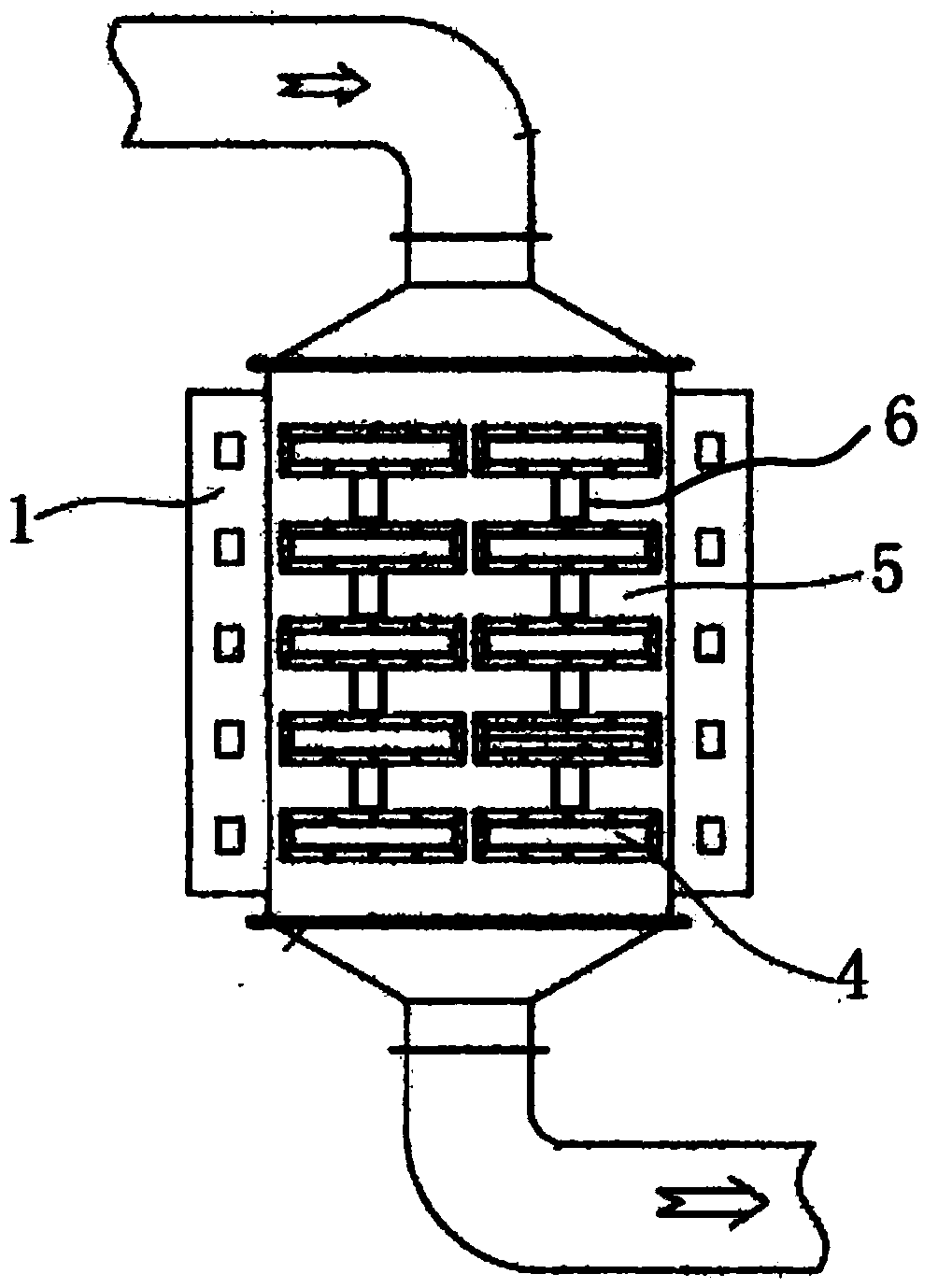

[0023] The cavity of the low-temperature plasma reaction chamber 1 is provided with a plurality of deflectors 4 , an air flow channel 5 is formed between adjacent deflector plates, and a free radical emitting device 6 is embedded in the air flow channel 5 .

[0024] Such as image 3 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com