Lithium ion battery positive electrode slurry and preparation method thereof

A lithium-ion battery, cathode slurry technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of easy agglomeration of conductive agent particles, poor slurry dispersion effect, and difficulty in dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

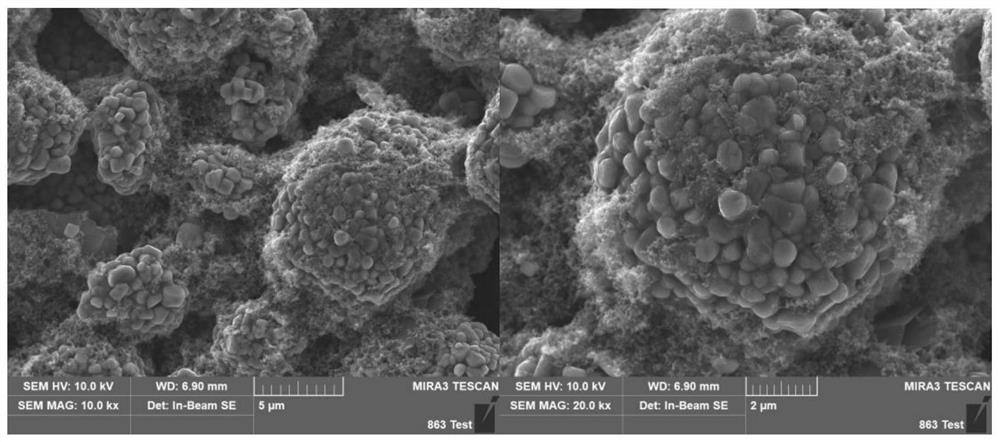

Image

Examples

Embodiment 1

[0068] S1. Weigh 968.3g LiNi 0.5 mn 0.3 co 0.2 o 2 , 15g conductive carbon black, 5g conductive graphite, 11.2g polyvinylidene fluoride (binder A) and 0.5g binder B, 15g conductive carbon black, 5g conductive graphite, 11.2g binder A and 0.5g Binder B is added to the double planetary mixer, and 130g of N-methylpyrrolidone (NMP) is added to mix well, set the revolution speed to 20r / min, keep it for 10min, start the rotation, the speed is 2500r / min, vacuumize to vacuum degree -0.085MPa , the stirring time is 60min;

[0069] S2, add 484.2g LiNi in the product of above-mentioned step S1 0.5 mn 0.3 co 0.2 o 2 , set the revolution speed of the double planetary mixer to 25r / min, after stirring for 20min, start the rotation of the double planetary mixer and set the rotation speed to 3000r / min, vacuumize to -0.085MPa, and stir for 60min;

[0070] S3, add 484.1g LiNi in three times to the product of the above step S2 0.5 mn 0.3 co 0.2 o 2 , set the revolution speed of the do...

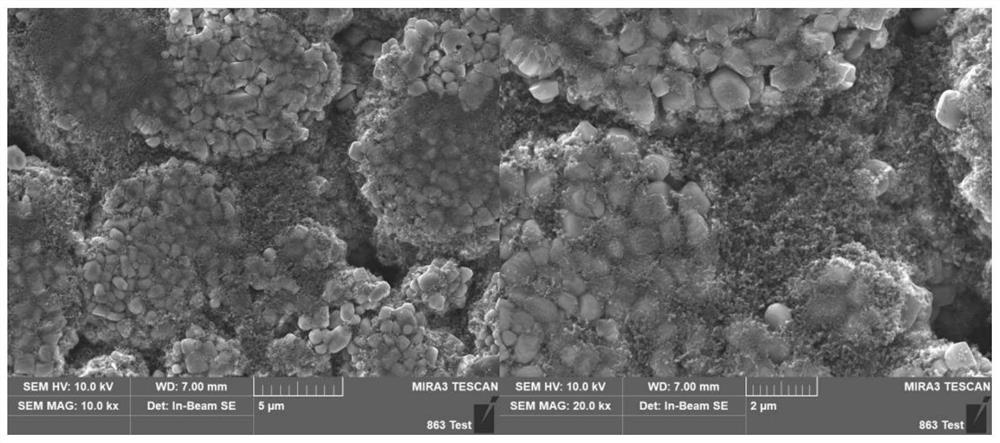

Embodiment 2

[0073] S1. Add 15g conductive carbon black, 5g conductive graphite, 11.2g binder A and 0.5g binder B into the double planetary mixer, and add 130g NMP, mix well, set the revolution speed to 18r / min, keep it for 10min and then start Autorotation, rotation speed 2000r / min, vacuumize to vacuum degree -0.08MPa, time 60min; S2, add 484.2g lithium cobaltate to the product of the above step S1, set the double planetary mixer revolution speed 25r / min, after stirring for 10min, Start and set the rotation speed of the double planetary mixer to 2500r / min, vacuumize to -0.08MPa, and stir for 60min;

[0074] S3. Add 484.1g of lithium cobaltate three times to the product of the above step S2, set the revolution speed of the double planetary mixer to 25r / min, after stirring for 10min, start and set the rotation speed of the double planetary mixer to 2500r / min, and evacuate to a vacuum Degree -0.08MPa, stirring time 60min;

[0075] S4, add 260gNMP to the product of the above step S2, adjust ...

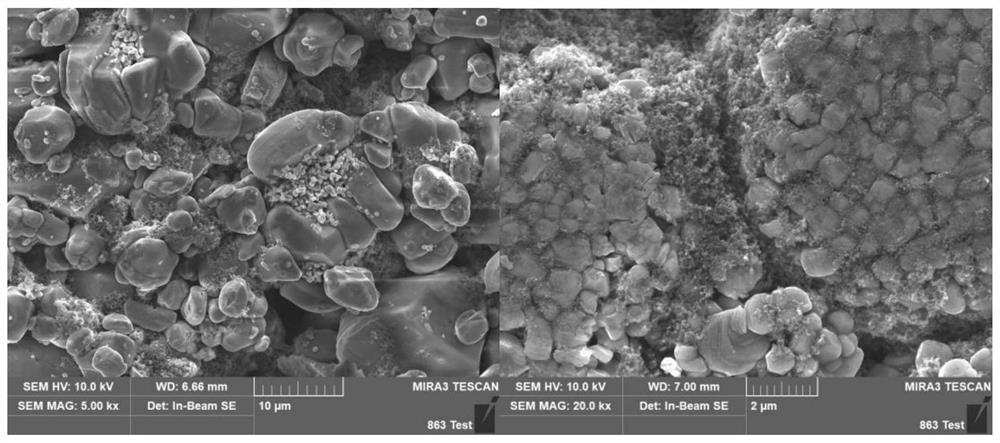

Embodiment 3

[0077] S1. Add 15g of conductive carbon black, 10g of conductive graphite, 11.2g of binder A and 0.8g of binder B into the double planetary mixer, and add 140g of NMP to mix thoroughly, set the revolution speed to 15r / min, keep it for 20min and then start the rotation , the speed is 2500r / min, the vacuum is vacuumed to -0.1MPa, and the time is 60min;

[0078] S2. Add 482g of lithium iron phosphate to the product of the above step S1, set the revolution speed of the double planetary mixer to 20r / min, after stirring for 20min, start and set the rotation speed of the double planetary mixer to 3000r / min, and evacuate to a vacuum degree of -0.1 MPa, stirring time 60min;

[0079] S3. Add 481g of lithium iron phosphate three times to the product of the above step S2, set the revolution speed of the double planetary mixer to 20r / min, after stirring for 20min, start and set the rotation speed of the double planetary mixer to 3000r / min, and evacuate to a vacuum degree -0.1MPa, stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com