High-temperature steam jetting type oil sand and oil sludge treatment device

A high-temperature steam and treatment device technology, applied in sludge treatment, water/sludge/sewage treatment, pyrolysis treatment of sludge, etc., can solve the problems of high treatment cost, long time, low recycling rate, etc. Tank temperature, easy to control, direct effect of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

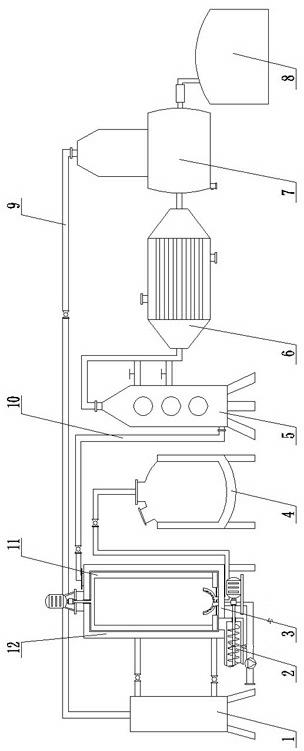

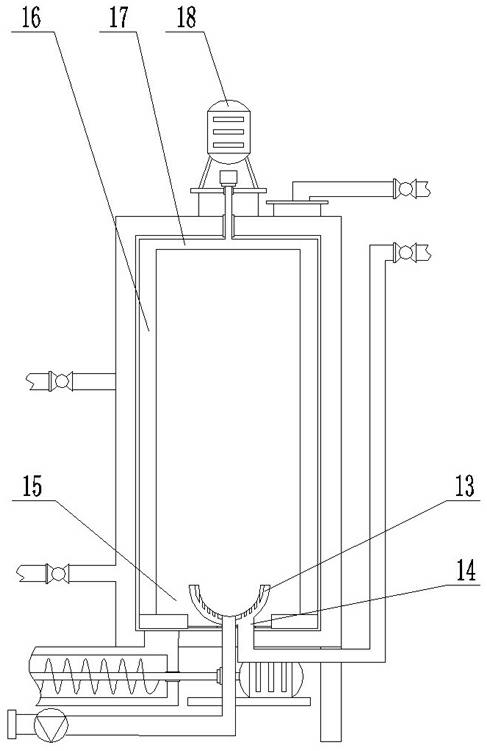

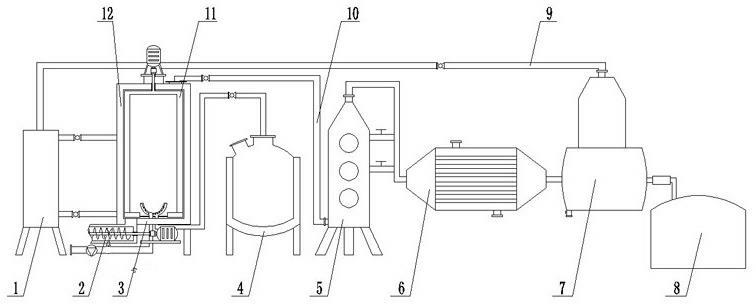

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0011] see figure 1 , figure 2 , the cracking evaporation tank 3 is a vertical tank body, the tank body is provided with a heat exchange interlayer 12, the heat transfer interlayer 12 is built into the heat transfer oil communicated with the heating oil furnace 1, and the lower part of the tank is equipped with an evaporation pan 13, the evaporation There is a spray hole in the center of the disc 13, and the spray hole is connected to the feed pump 19 through the feed nozzle 15, and the high-temperature steam nozzle 14 connected to the superheated steam boiler 4 is evenly arranged on the periphery of the spray hole, and the pyrolysis evaporation tank 3 A rotary scraper 11 is also installed, and an exhaust port is provided on the top of the tank, which is connected to the fractionation tower 5 through a gas pipeline 10, and a spiral slagging device 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com