Scraper for planetary ball mill

A technology of planetary ball mill and wall scraper, which is applied in the field of wall scraper, can solve the problems that affect the ball milling effect, the grinding ball and the lumped material cannot be ground, and achieve the effect of improving the ball milling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

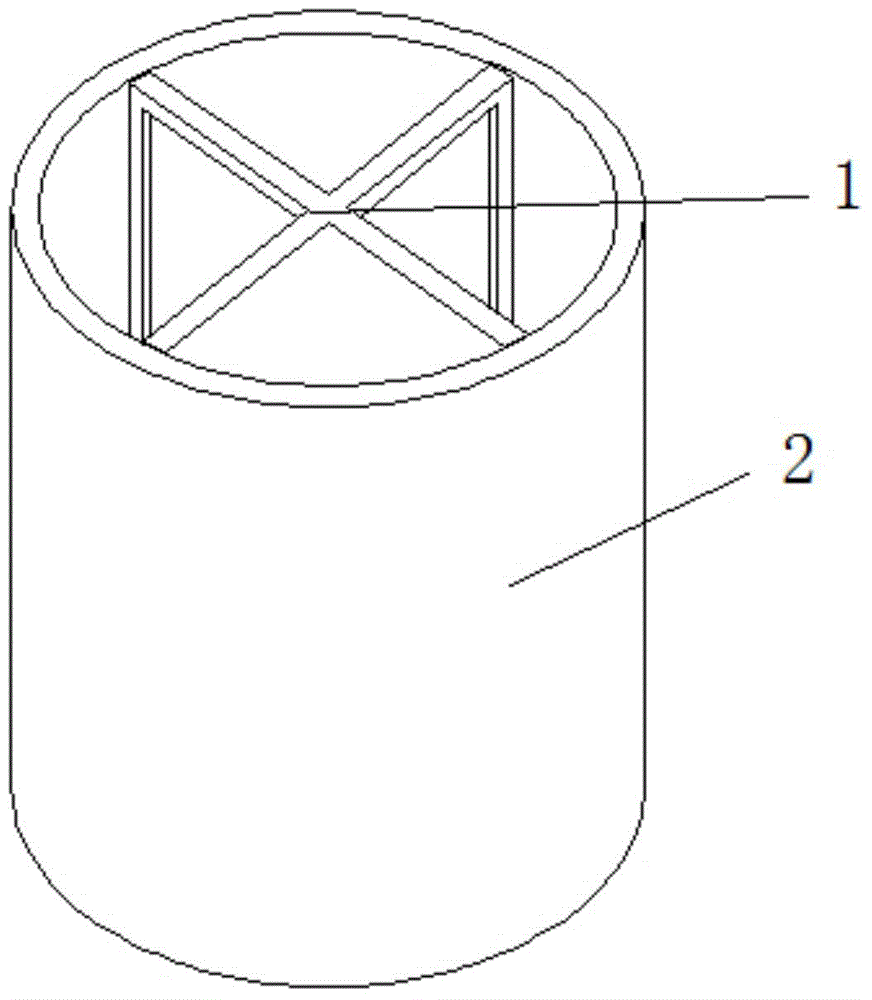

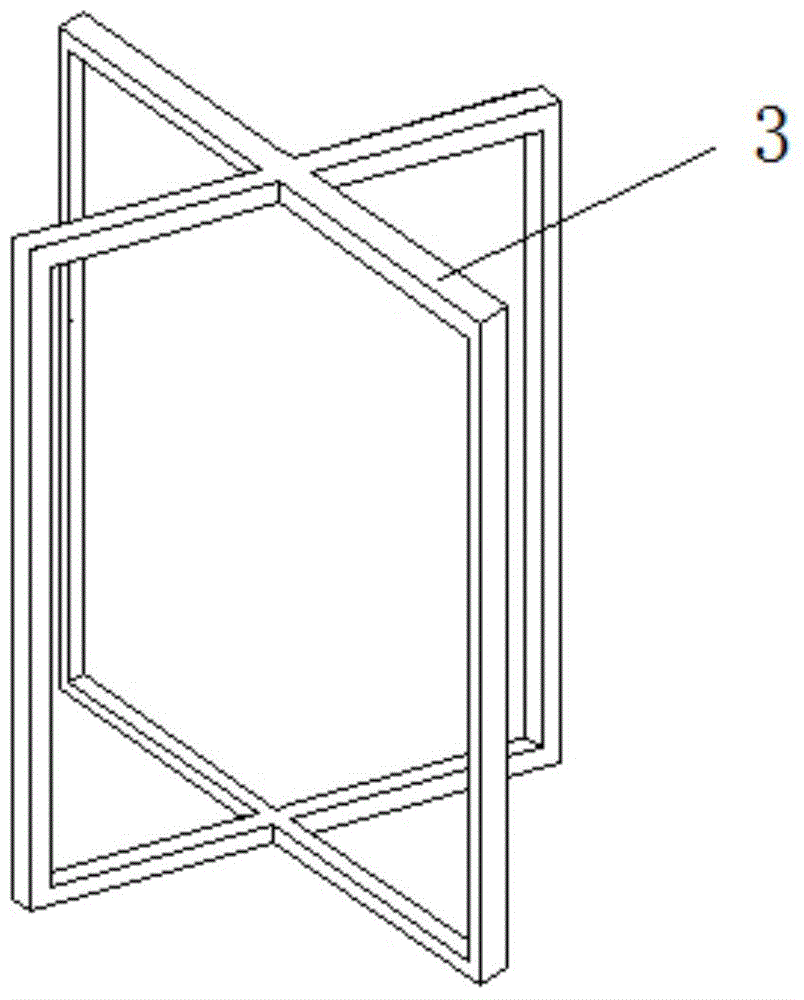

[0017] See figure 1 and figure 2 As shown, a wall scraper for a planetary ball mill has a body 1; the body 1 has a frame structure, and the body 1 is built into the ball mill pot 2 and is close to the inner wall of the ball mill pot 2. The body 1 is arranged crosswise by at least two square frames 3 with the same structure. The body 1 has two square frames. The length and width of the square frame 3 are close to the inner diameter and inner height of the ball mill jar 2 . Reinforcing ribs can be added in the middle of the square frame 3 . The frame edge of the square frame 3 is in the shape of plane, triangle or zigzag.

[0018] Its working process is as follows: first put the device, materials and balls into the ball mill pot 2, and see the status of the device put into the ball mill pot 2 figure 1 , cover the ball milling pot 2, and place the whole ball milling pot on the ball mill. When the ball mill is working, the ball milling pot rotates at a high speed, and the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com