Vertical roller washing machine

A washing machine and vertical drum technology, applied in the field of washing machines, can solve the problems of inability to obtain strong washing, inconvenient to pick and place clothes, and many times of tumbling, and achieve the effects of small occupied space, reduced time, and increased effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

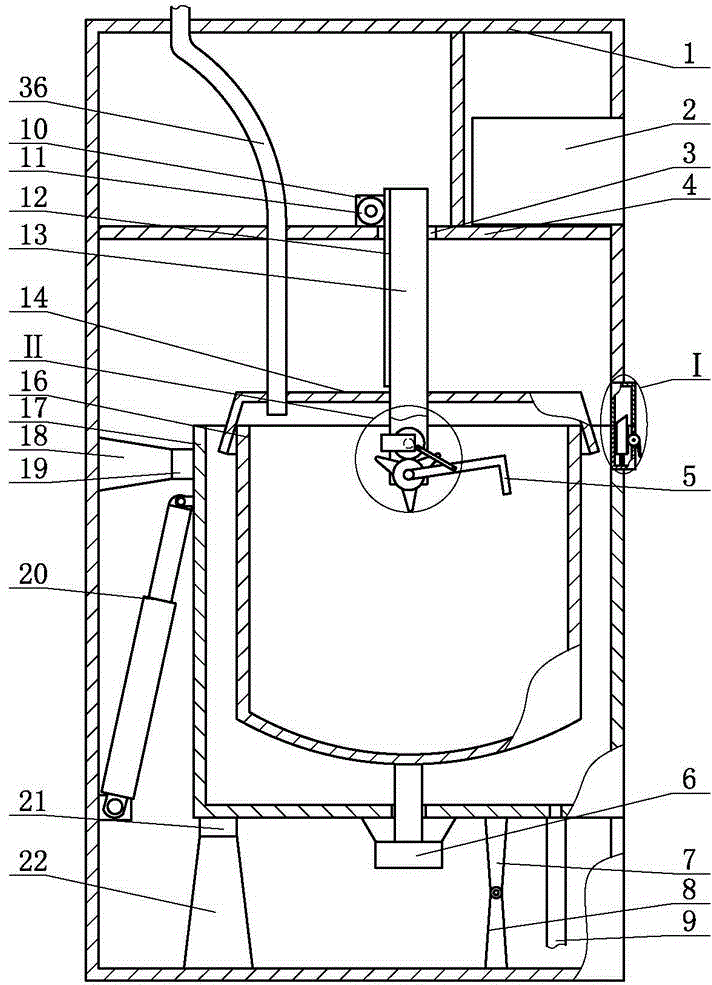

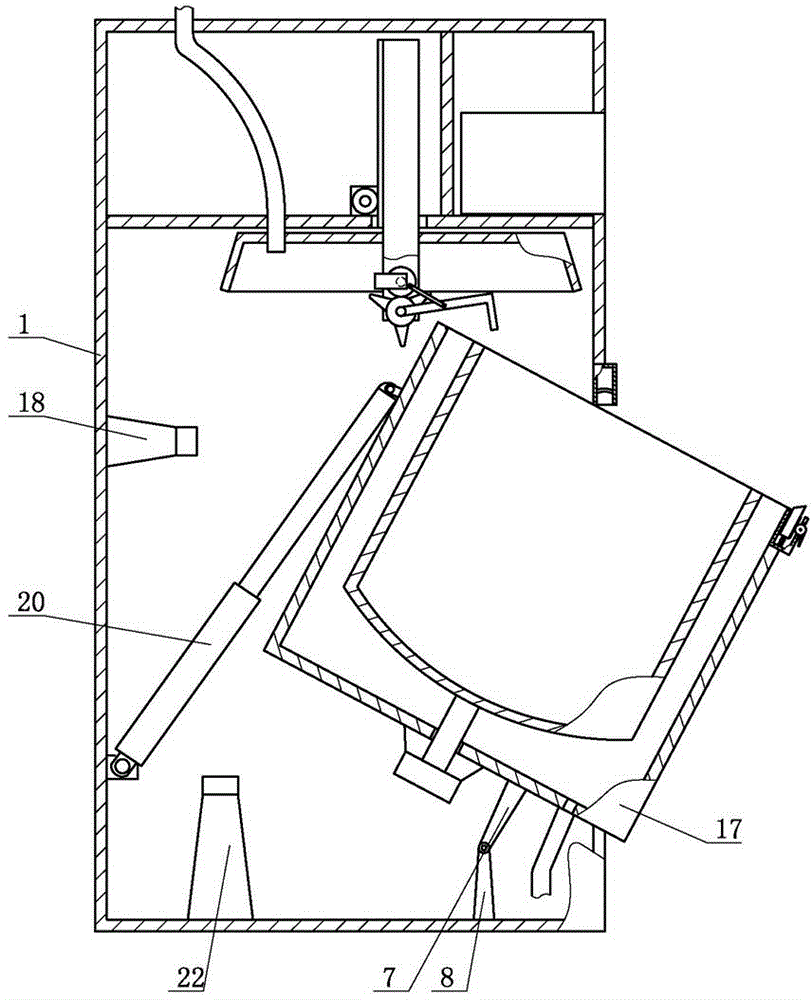

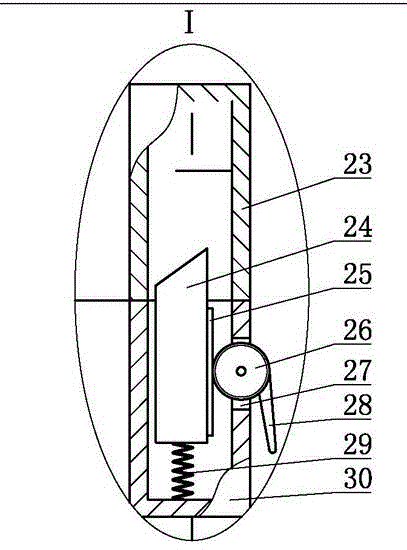

[0009] A vertical drum washing machine, such as figure 1 As shown, it includes a washing bucket and a shell 1, the washing bucket is located in the shell 1, a washer bracket 13 is arranged in the washing bucket, and a dialing shaft 15 is installed on the washing machine bracket 13, and the dialing shaft 15 is located in the washing bucket, and the washing The shaft 14 is connected with the rotary motor 31, and the dial 34 is arranged on the shaft 15 for dialing. This structure drives the washing shaft 15 to rotate through the rotating motor 31, stirs and beats the clothes through the washing sheet 34, so that the clothes form a top-to-bottom flip cycle in the washing bucket, and can clean all layers in the washing bucket. The clothes are all acted on, so that the clothes and the washing piece 34 are fully collided, thereby increasing the washing effect and reducing the time of washing clothes; the washing piece 34 does not occupy the space in the washing tub, and the amount of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com