Technique and equipment for preparing Nano granules in high purity by using method of comminution by gas stream

A technology of nanoparticle and jet milling, which is applied in separation methods, dispersed particle filtration, chemical instruments and methods, etc. It can solve difficult problems such as reducing surface free energy, improving fluidity and preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

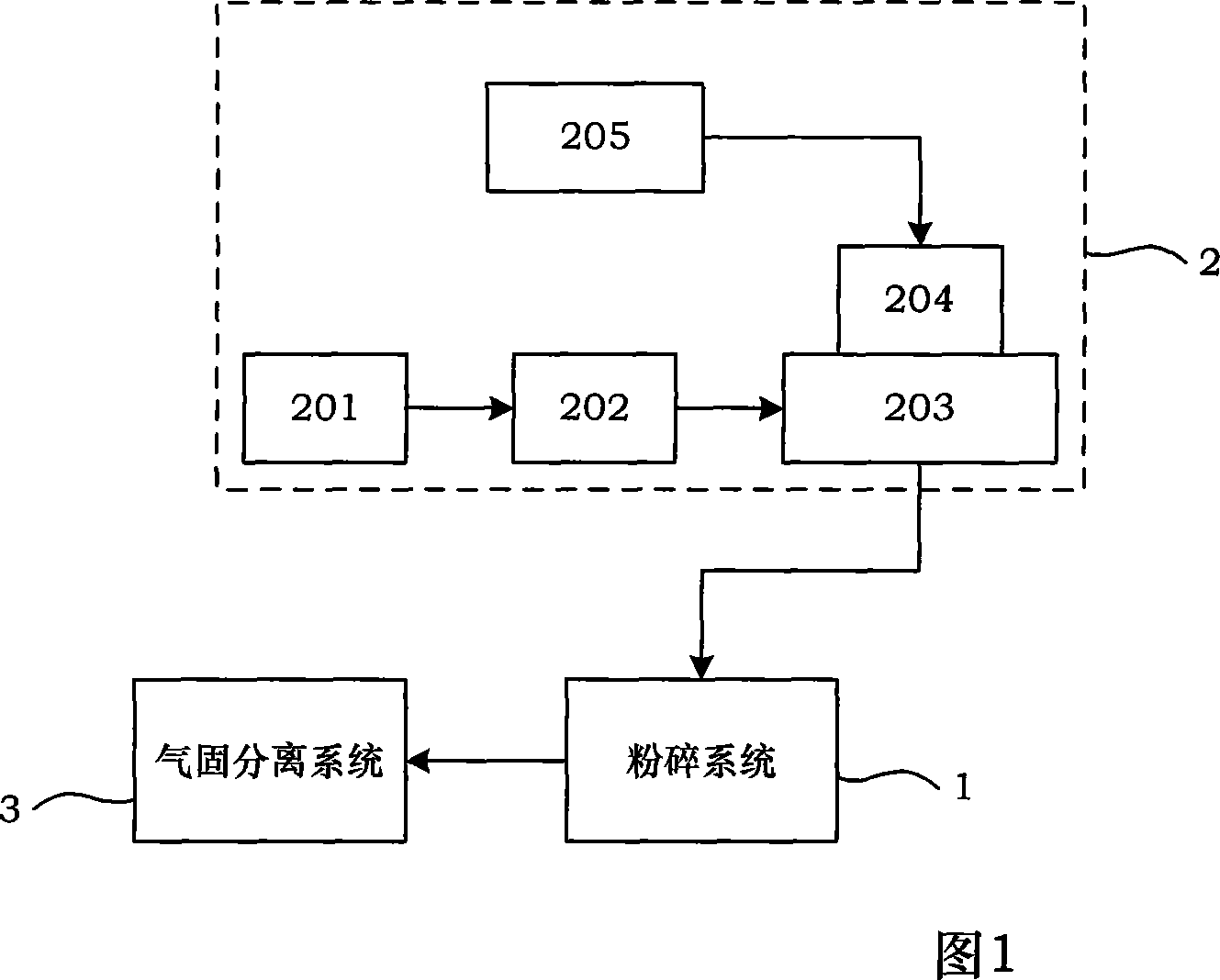

Method used

Image

Examples

Embodiment 1

[0041] Example 1 Preparation of nano-sized alumina particles by airflow pulverization of alumina granulation balls

[0042] The scanning electron microscope photo of the alumina granulation balls before pulverization is shown in Figure 4. In the figure, the alumina granulation balls before pulverization appear as spherical particles of tens of microns, and there are almost no alumina particles with a particle size of less than 1 micron. The particle size of the alumina granulation balls before crushing was measured by a Malvern 2000 particle size analyzer as 1-50 μm.

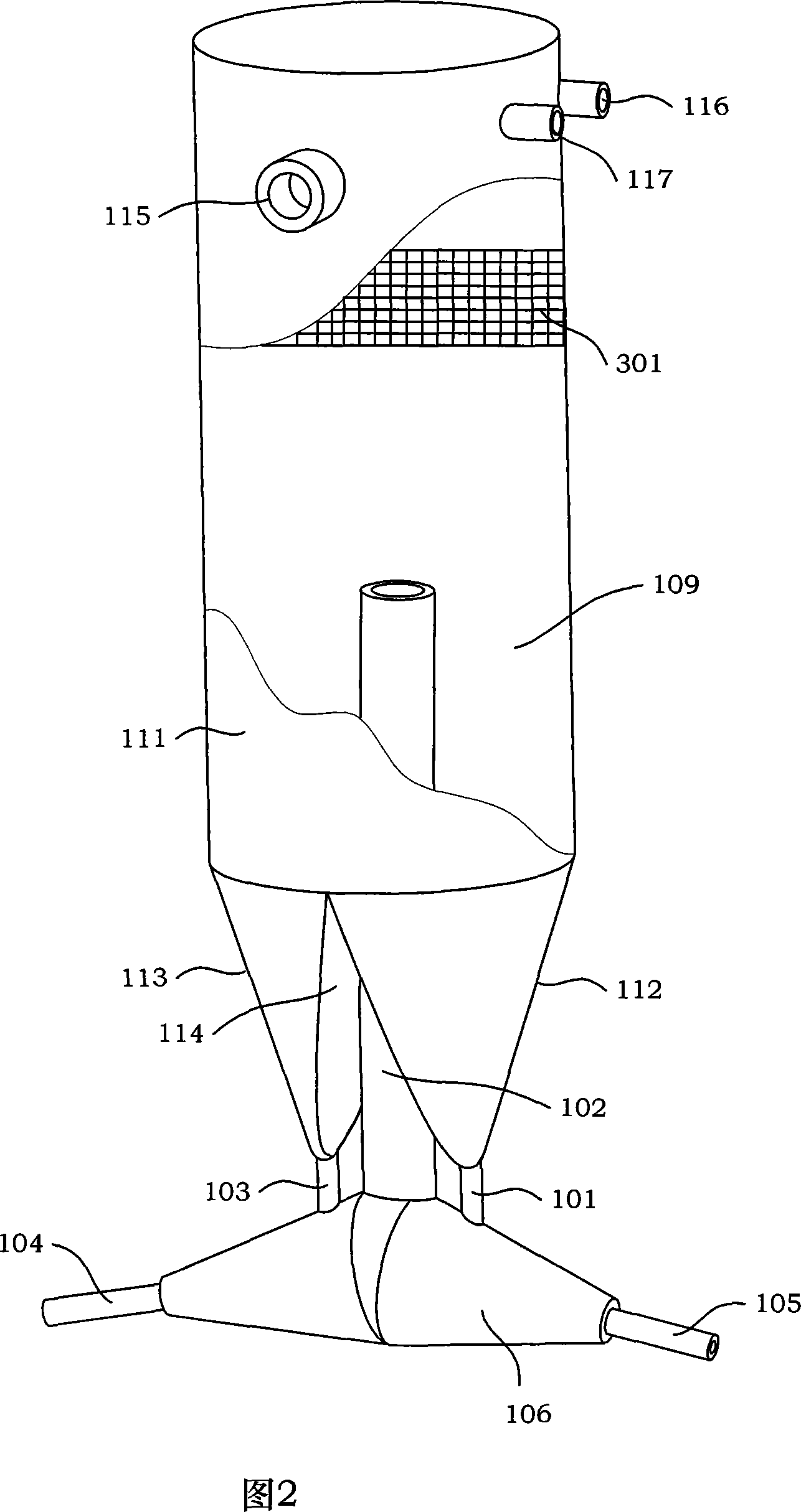

[0043] The steps of pulverizing alumina granulation balls (material) by adopting the preparation process and the preparation device of the present invention include:

[0044] The first step: placing alumina granulation balls (materials) in the crushing chamber 106, the amount of alumina granulation balls placed is 500g;

[0045] Second step: after drying the high-pressure gas (pressure 0.6MPa) produced by the a...

Embodiment 2

[0050] Example 2 Preparation of modified nano-scale alumina particles by airflow milling method for alumina granulation balls

[0051] The first step: same as embodiment 1;

[0052] The second step: similar to Example 1, except that the temperature of the dry high-pressure gas is 60°C;

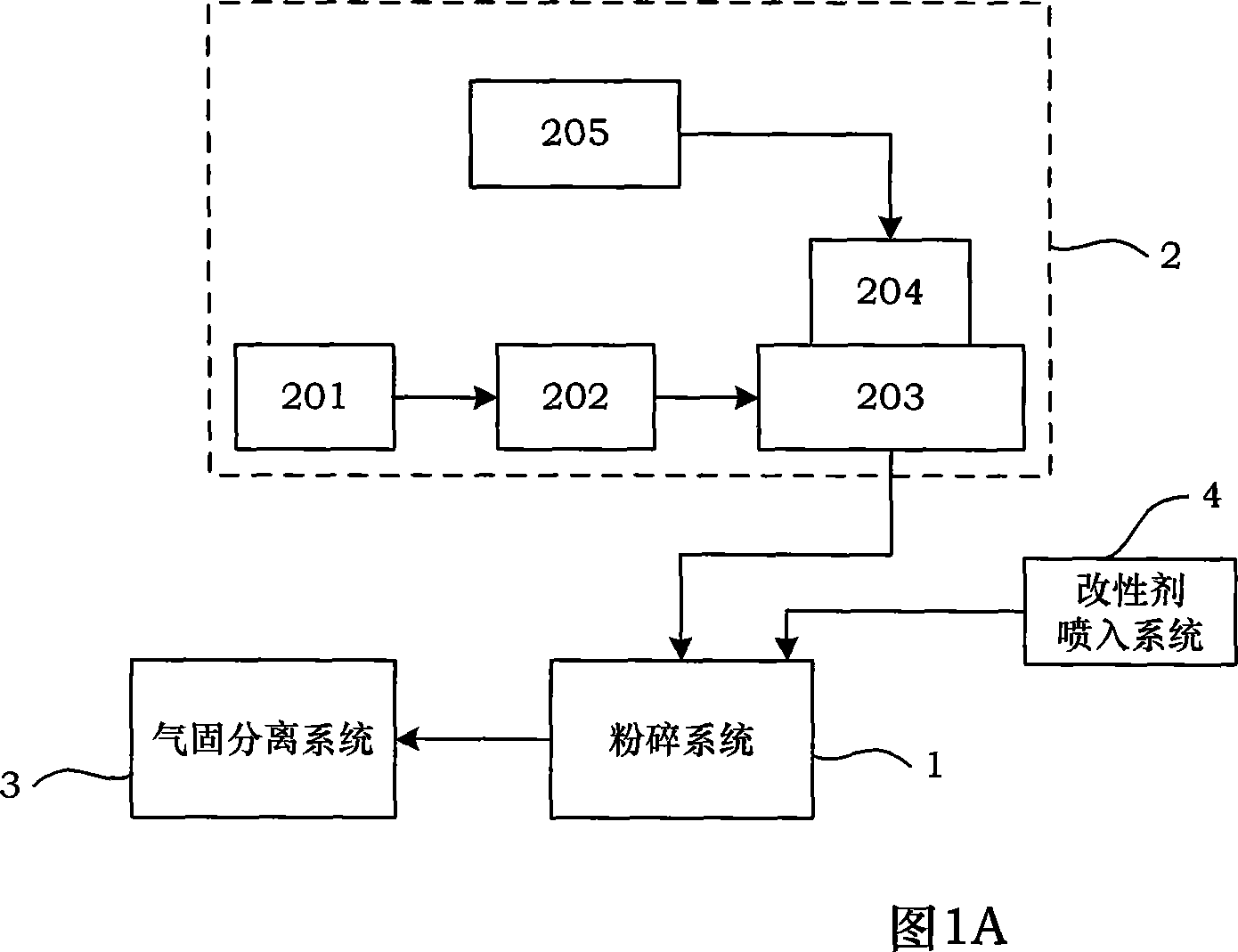

[0053] The third step: similar to Example 1, the difference is that the crushing system 1 is connected with the modifier injection system 4 (see Figure 1A), and the titanate coupling agent NDZ-401 is sprayed at the same time as the crushing The surface modification treatment is carried out on the alumina material to increase the fluidity of the particles and prevent the agglomeration of the particles after crushing. The amount by weight of the titanate coupling agent NDZ-401 is 1.5% of the material.

[0054] For the modified nano-scale alumina particles prepared above, the particle size of 45% of the particles in the pulverized alumina granulation balls was measured by Malvern 2000 particle ...

Embodiment 3

[0057] Example 3 Preparation of nano-scale silicon dioxide particles by jet milling method for silicon dioxide

[0058] The first step, second step are identical with embodiment 1;

[0059] The third step: similar to Example 1, except that the crushing time is 2 hours.

[0060] For the nano-scale silicon dioxide (SiO2) prepared above 2 ) particles were measured by Malvern 2000 particle size analyzer after pulverization of silica (SiO 2 ) in the particle size of 54% in 20 ~ 1000nm.

[0061] In the preparation process of the present invention, the longer the crushing time, the smaller the particle size of the material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com