System and method for production of calcium carbide

A calcium carbide and quicklime technology, applied in sustainable manufacturing/processing, carbide, chemical industry, etc., can solve the problems of heavy pollution, waste of sensible heat of blue carbon, and high overall process energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

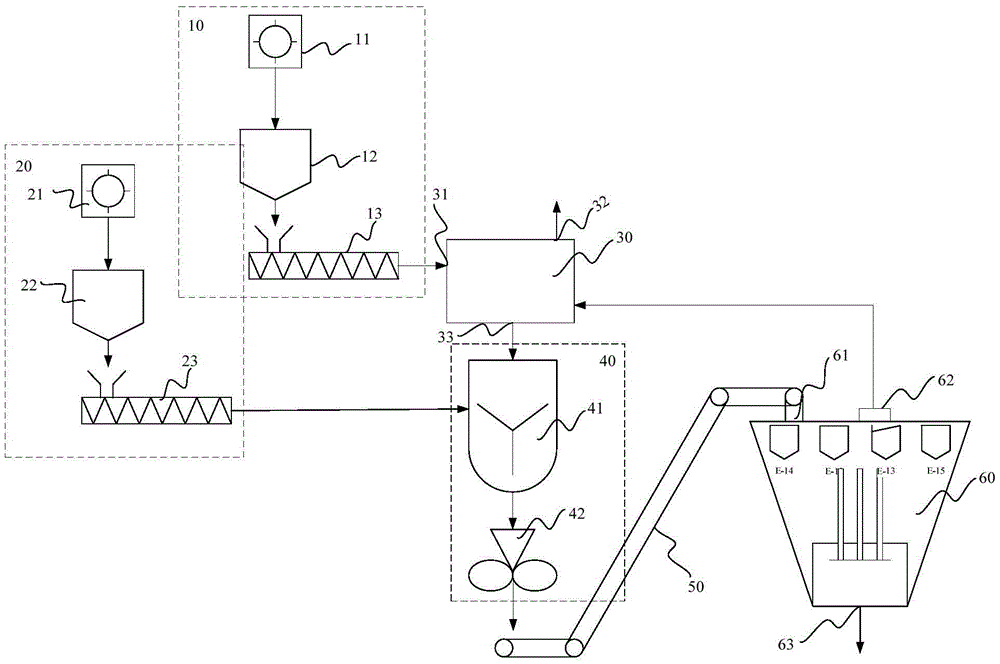

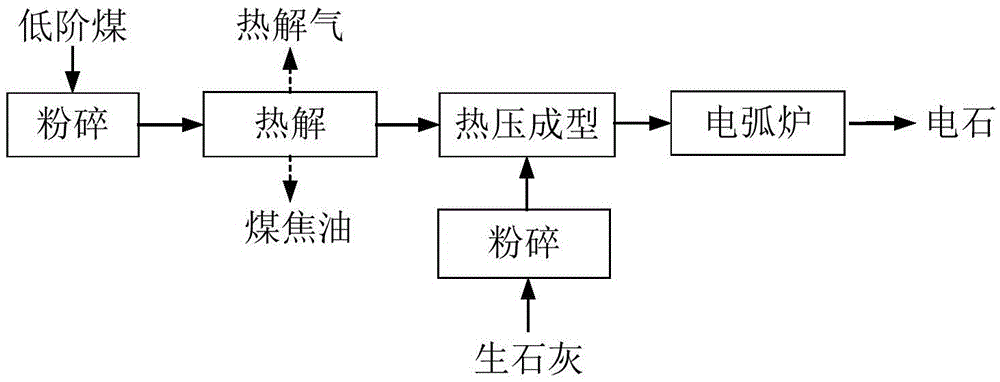

Method used

Image

Examples

Embodiment 1

[0074] A long-flame coal is used as the carbon raw material, and its main properties are shown in Table 1.

[0075] Table 1 Main properties of long-flame coal

[0076]

[0077]

[0078] Quicklime is used as the calcium-based raw material, crushed to <74μm, and the CaO content is 92%.

[0079] The long-flame coal is pulverized and dried with a medium-speed mill to make its particle size <1mm and moisture content <2%.

[0080] The powdered long-flame coal is sent to the fast pyrolysis device for pyrolysis, and the pyrolysis temperature is 650°C. The yield of pyrolysis products is shown in Table 2.

[0081] Table 2 pyrolysis product yield (wt%)

[0082] product

Yield

solid product

64.86

14.38

gas

13.17

Pyrolysis water

7.59

[0083] Powdered quicklime and pyrolysis solid product are mixed at a ratio of 1.67:1 and then hot-pressed to form a ball with a particle size of 32×25×18mm.

[0084] The temperature...

Embodiment 2

[0086] A lignite is used as the carbon raw material, and its main properties are shown in Table 3.

[0087] Table 3 Main properties of lignite

[0088] project

unit

value

Remark

whole water

wt%

59.40

Receive base

wt%

43.79

air dry basis

Volatile matter

wt%

46.84

air dry basis

Ash

wt%

1.94

air dry basis

[0089] Quicklime is used as the calcium-based raw material, crushed to <74μm, and the CaO content is 92%.

[0090] The lignite is pulverized and dried with a medium-speed mill to make its particle size <1mm and moisture content <5%.

[0091] The powdery lignite was sent to the fast pyrolysis device for pyrolysis, and the pyrolysis temperature was 550°C. The yield of pyrolysis products is shown in Table 4.

[0092] Table 4 pyrolysis product yield (wt%)

[0093] product

Yield

53.29

7.18

gas

21....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com