Method for preparing supported molybdenum-oxide-based and tungsten-oxide-based oxidation desulfurization catalysts

A tungsten oxide-based, oxidative desulfurization technology, used in coal processing, petroleum processing and petrochemical fields, can solve the problems of loss of oil, difficult to completely separate oil and water, and immiscibility of oil and water, and achieve the effect of improving activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Under Ar gas atmosphere, MoO 3 / SiO 2 and WO 3 / SiO 2 Catalyst preparation

[0019] Preparation of Supported MoO by Equal Volume Impregnation Method 3 / SiO 2 and WO 3 / SiO 2 Catalyst: Weigh 0.920g of ammonium molybdate or 0.852g of ammonium metatungstate and dissolve it in 9ml of deionized water to make a solution, add it dropwise to 3g of white carbon black, stir well, let stand at room temperature for 12h, and dry at 120°C for 4h , the temperature was raised to 500°C at a rate of 2°C / min, and SiO was prepared after calcination for 5 hours. 2 Loaded MoO 3 or WO 3 Catalyst, denoted as MoO 3 / SiO 2 or WO 3 / SiO 2 , where MoO 3 or WO 3 The loading amount of is 20% by mass fraction (based on the total mass of the catalyst).

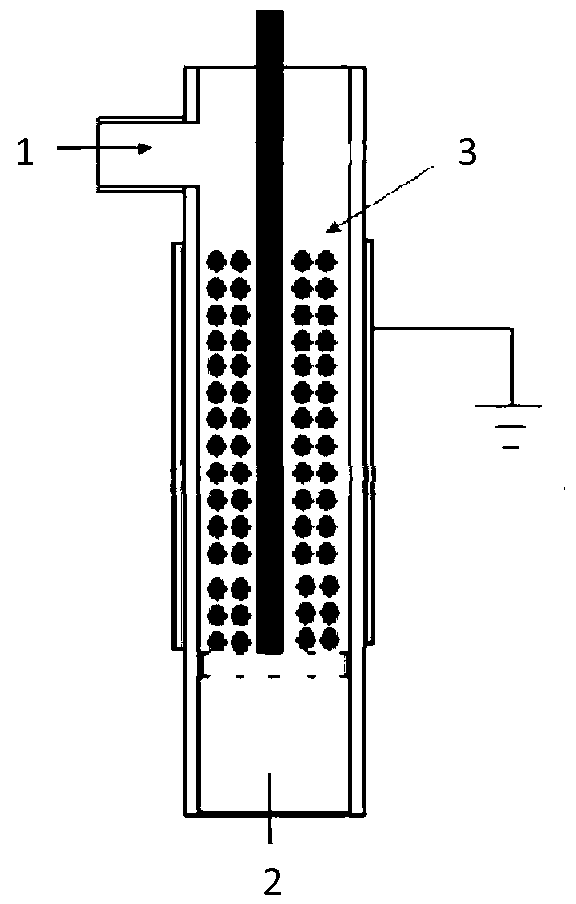

[0020] Under Ar gas atmosphere, MoO was treated with plasma 3 / SiO 2 catalyst. reaction in a dielectric barrier discharge plasma reactor ( figure 1 ) in. The catalyst filling volume is 2mL; the inlet Ar gas flow rate is...

Embodiment 2

[0021] Example 2: In H 2 Atmosphere, MoO 3 / SiO 2 and WO 3 / SiO 2 Catalyst preparation

[0022] Preparation of Supported MoO by Equal Volume Impregnation Method 3 / SiO 2 and WO 3 / SiO 2 Catalyst: Weigh 0.920g of ammonium molybdate or 0.852g of ammonium metatungstate and dissolve it in 9ml of deionized water to make a solution, add it dropwise to 3g of white carbon black, stir well, let stand at room temperature for 12h, and dry at 120°C for 4h , the temperature was raised to 500°C at a rate of 2°C / min, and SiO was prepared after calcination for 5 hours. 2 Loaded MoO 3 or WO 3 Catalyst, denoted as MoO 3 / SiO 2 or WO 3 / SiO 2 , where MoO 3 or WO 3 The loading amount of is 20% by mass fraction (based on the total mass of the catalyst).

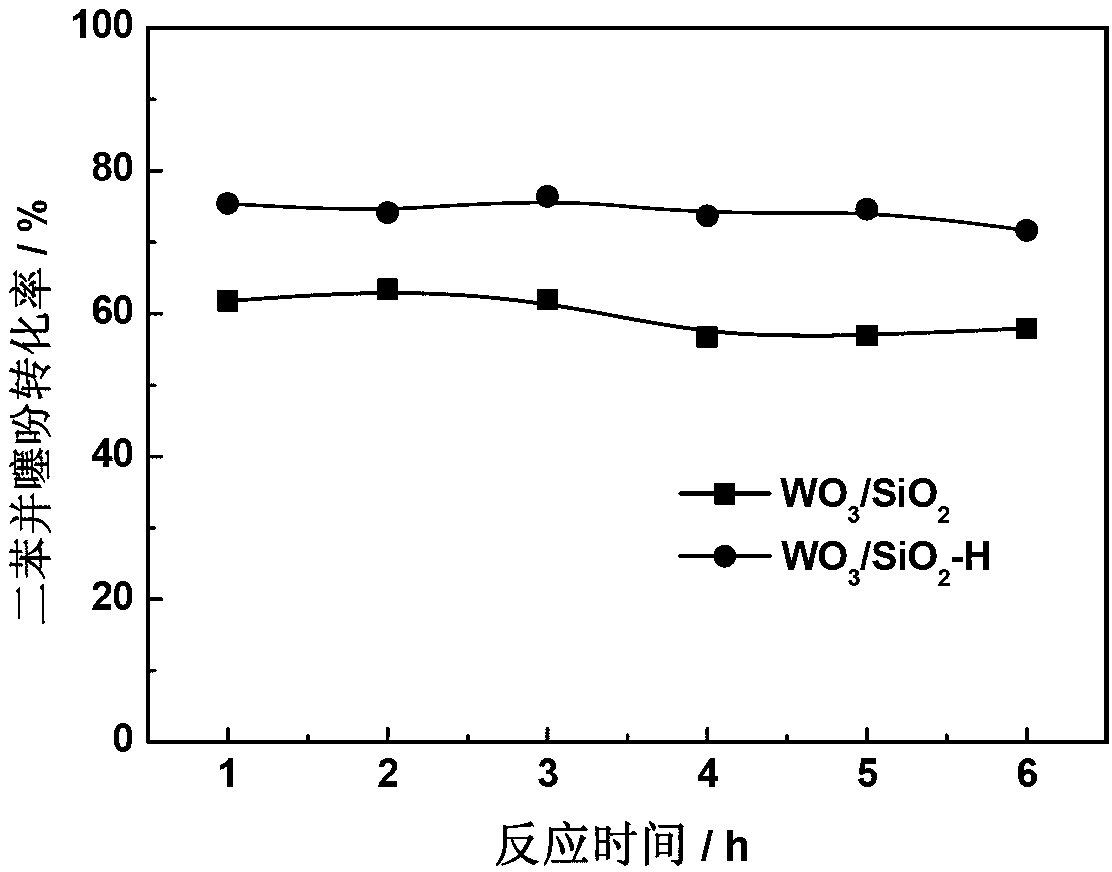

[0023] in H 2 Under gas atmosphere, MoO was treated with plasma 3 / SiO 2 and WO 3 / SiO 2 catalyst. reaction in a dielectric barrier discharge plasma reactor ( figure 1 ) in. Catalyst filling volume 2mL; inlet H 2 The gas...

Embodiment 3

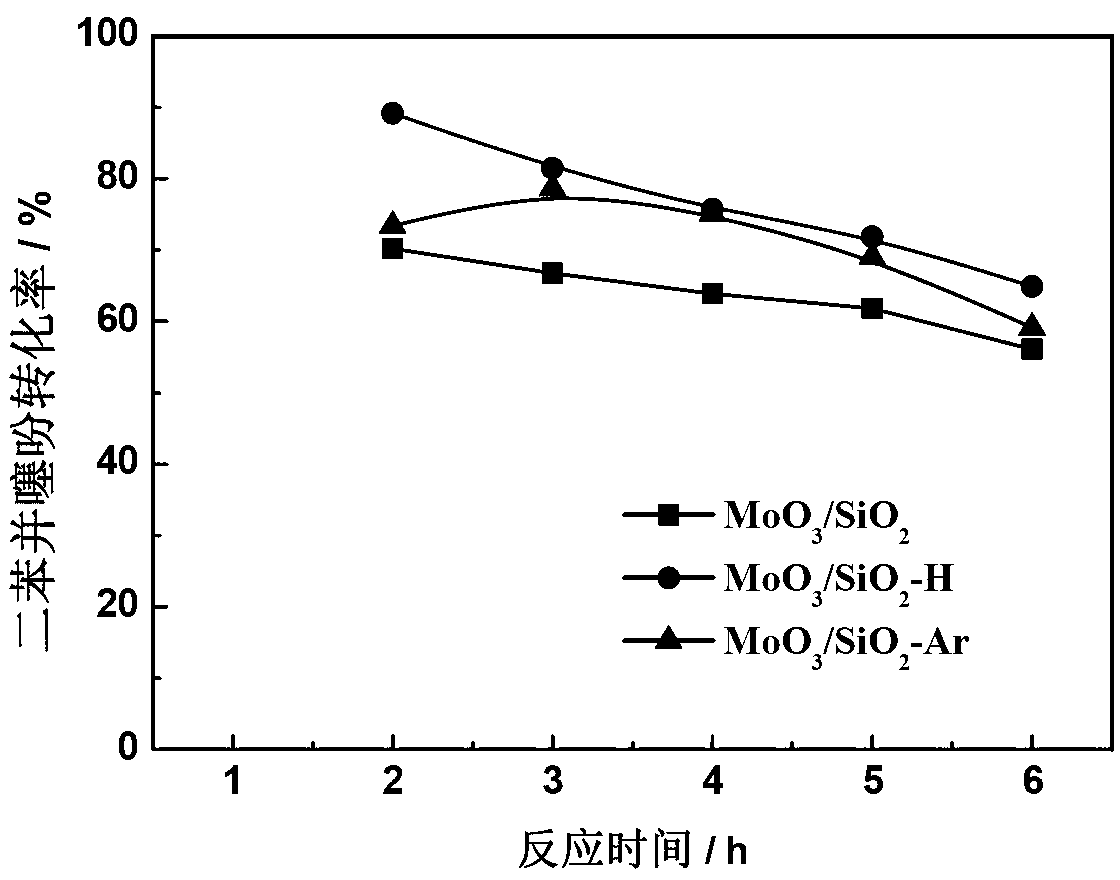

[0024] Example 3: MoO 3 / SiO 2 -Ar and MoO 3 / SiO 2 Activity Evaluation of -H Catalyst

[0025] 0.2g of MoO 3 / SiO 2 -Ar or MoO 3 / SiO 2 The -H catalyst was packed in a fixed-bed reactor with an inner diameter of 8 mm, and the toluene solution of dibenzothiophene with a mass fraction of 0.2% was used as a simulated oil product, and cumene peroxide was used as an oxidant to carry out continuous oxidative desulfurization reaction. Other reaction conditions are: O / S molar ratio=4, normal pressure, reaction temperature 50°C, WHSV=32h -1 . Depend on figure 2 It can be seen that under the same conditions, the oxidative desulfurization activity of the plasma-treated catalyst is higher than that of MoO 3 / SiO 2 There is a significant improvement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com