Pulverized coal milling device and method

A pulverized coal preparation and pulverized coal technology, which is applied in the direction of block/powder fuel preparation, combustion method, combustion equipment, etc., can solve the problems of inconvenient storage and transportation, low production efficiency, and large investment, and achieve scientific and reliable principles. Effect of reducing dust leakage and high coal production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

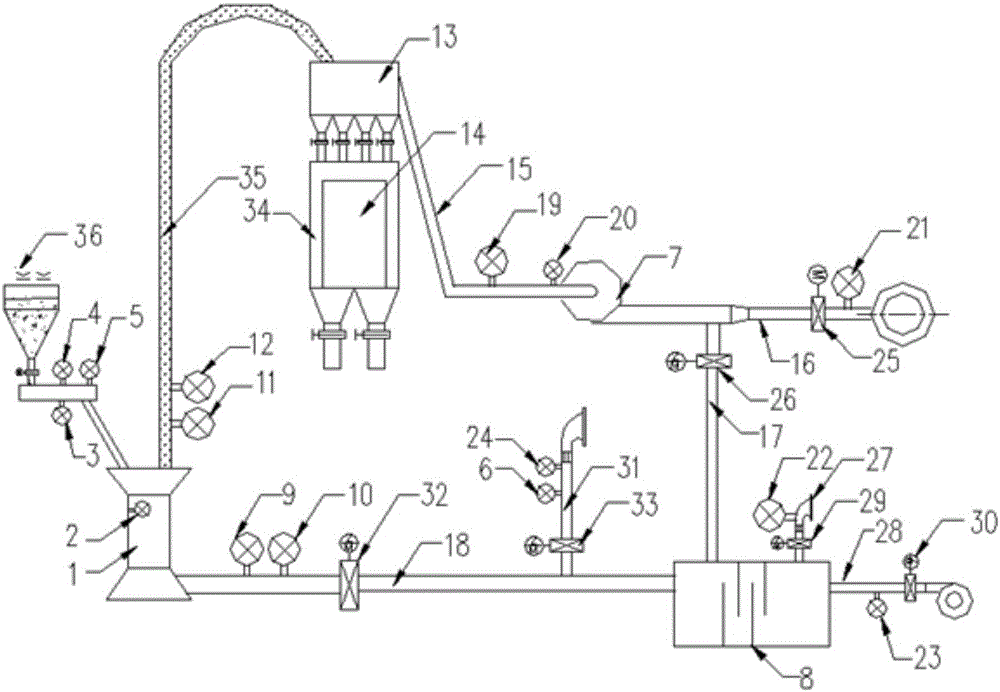

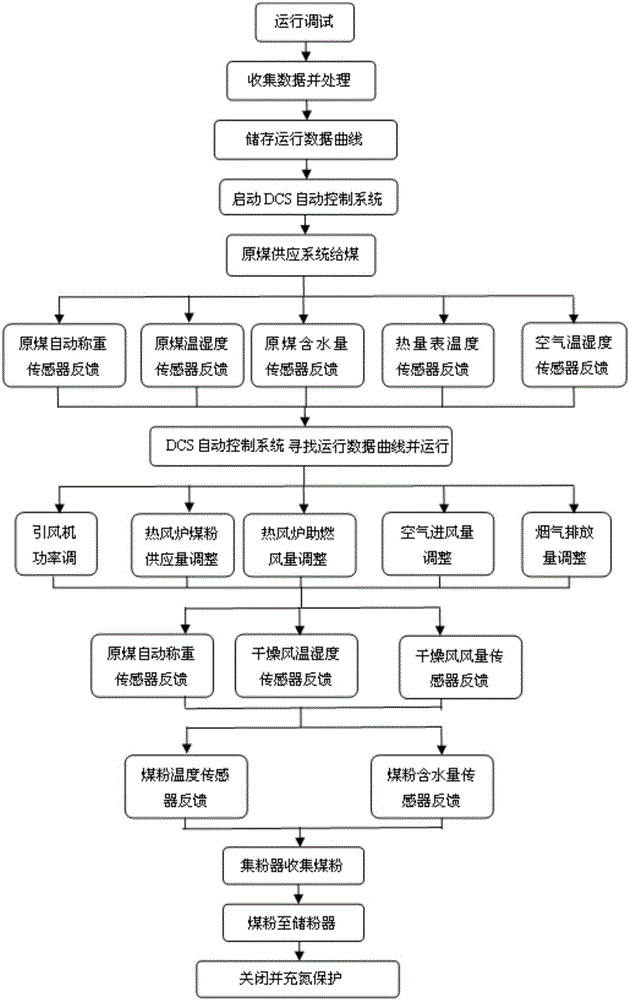

[0017]The main structure of the pulverized coal preparation device involved in this embodiment includes a coal mill 1, a heat meter temperature sensor 2, a raw coal self-weighing sensor 3, a raw coal temperature and humidity sensor 4, a raw coal moisture content sensor 5, an air temperature and humidity sensor 6, and an induced draft fan 7. Hot blast furnace 8, drying air temperature and humidity sensor 9, drying air volume sensor 10, pulverized coal temperature sensor 11, pulverized coal water content sensor 12, powder collector 13, powder storage device 14, induced draft fan front flue 15, exhaust Smoke duct 16, recirculation flue gas duct 17, drying air duct 18, flue gas temperature and humidity sensor 19, induced draft fan power sensor 20, flue gas emission sensor 21, combustion air volume sensor 22, hot blast stove powder supply sensor 23, air Air intake sensor 24, smoke exhaust valve 25, circulation valve 26, combustion-supporting air duct 27, pulverized coal supply duct ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com