Method for extraction and separation of carbon-containing coal residues based on ionic liquid

An ionic liquid and residue technology, which is applied in the processing of tar pitch/petroleum pitch/natural pitch, tar pitch/petroleum pitch/natural pitch, and petroleum industry by selective extraction, achieving low production cost, simple process equipment, and high extraction efficiency. The effect of improved separation selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

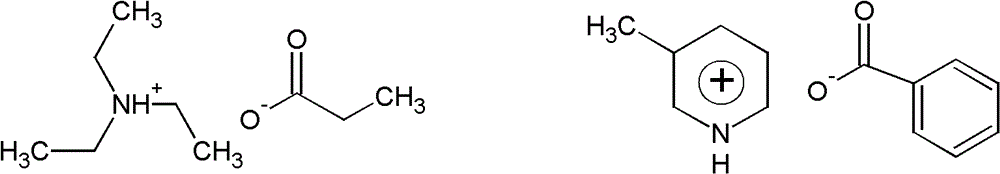

[0019] Weigh about 1.0217g coal direct liquefaction residue and add it into a beaker containing 10.0166g [TEtA][Of] ionic liquid. After heating, when the temperature is stable at 30°C, place the beaker containing the mixed solution on a magnetic heating stirrer and stir continuously for about 15 minutes, then stop heating and stirring, and filter out the insoluble matter with a solution filter. In the mixed solution obtained by suction filtration, add about 10 times the deionized water of the volume of the ionic liquid, and obviously there is solid precipitation and layering, and then filter with a solution filter to obtain a solid phase substance, and obtain 0.1079g of a solid product after drying, that is It is a mixture of asphaltenes, the yield is about 10.60%, the H / C is about 0.81, and the S content is about 0.20%. It can be used as a raw material for preparing mesophase pitch.

Embodiment 2

[0021] Weigh about 1.0029g coal tar distillation residue and add it into a beaker containing 8.0097g [TEtA][OP] ionic liquid. After heating, when the temperature stabilizes at 40°C, place the beaker containing the mixed solution on a magnetic heating stirrer and stir continuously for about 30 minutes, then stop heating and stirring, and filter out the insoluble matter with a solution filter. Add deionized water about 12 times the volume of the ionic liquid to the mixed solution obtained by suction filtration, obviously there is solid precipitation and layering, and the solid phase substance is obtained by filtering with a solution filter again, and 0.5793g of a solid product is obtained after drying, namely It is a mixture of asphaltenes, the yield is about 57.76%, the H / C is about 0.96, and the S content is about 0.288%. It can be used as a raw material for preparing mesophase pitch.

Embodiment 3

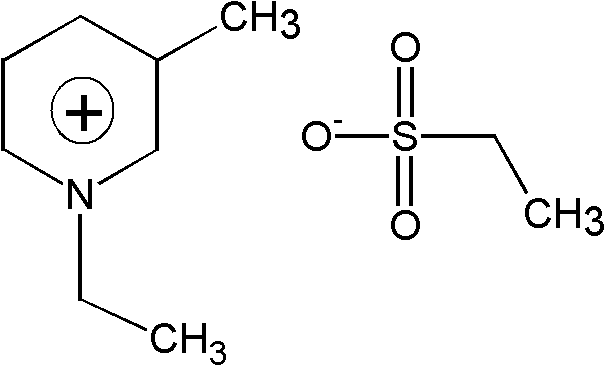

[0023] Weigh about 1.0061g coal direct liquefaction residue and add it into a beaker filled with 10.0575g [MPy][OAc] ionic liquid. After heating, when the temperature stabilizes at 30°C, place the beaker containing the mixed solution on a magnetic heating stirrer and stir continuously for about 30 minutes, then stop heating and stirring, and filter out the insoluble matter with a solution filter. In the mixed solution obtained by suction filtration, add about 10 times the deionized water of the volume of the ionic liquid, obviously there is solid precipitation and layering, and the solid phase substance is obtained by filtering with a solution filter again, and 0.3087g solid product is obtained after drying, that is It is a mixture of asphaltenes, the yield is about 30.68%, the H / C is about 0.76, and the S content is about 0.10%. It can be used as a raw material for preparing mesophase pitch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com