Monitoring system for ash fouling in power station boiler air preheater and working method of system

A technology of air preheater and monitoring system, which is applied in the direction of instruments and analysis materials, etc. It can solve the problems of deviation of the degree of ash blocking in the air preheater, delay in the best time for processing, and inability to correctly reflect the real condition of the equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

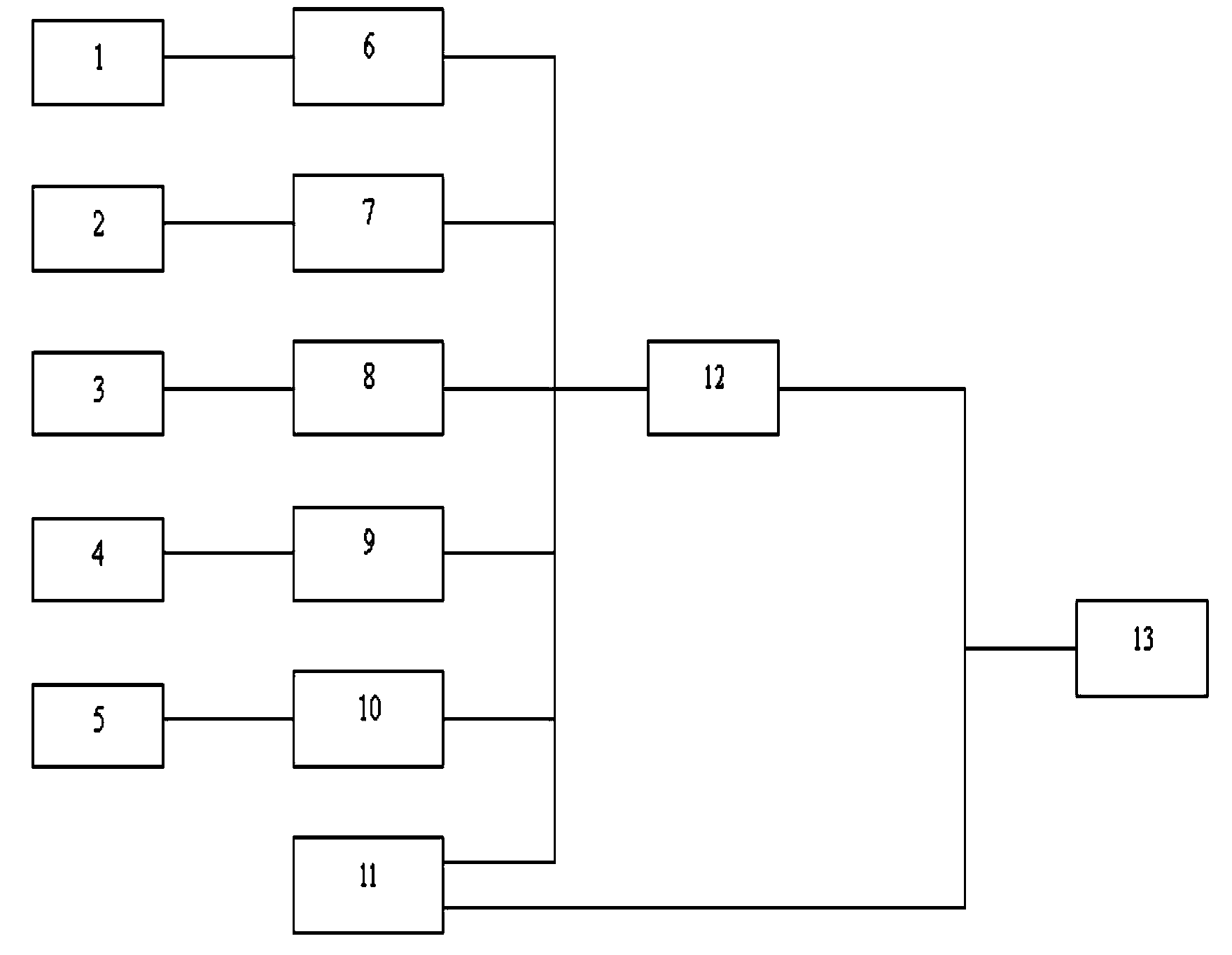

[0042] Such as figure 1 As shown, the incoming coal sampling module 1 obtains the incoming coal sample and sends it to the incoming coal analysis module 6, and the incoming coal analysis module 6 obtains the coal quality composition data and transmits it to the pressure drop calculation module 12. When the online measuring device is used, the coal quality composition data can be directly read, otherwise, manual analysis is used, and the analysis data is entered into the input terminal;

[0043] The ash sampling module 2 obtains the ash sample and sends it to the ash analysis module 7. The ash analysis module 7 obtains the ash combustible content data and transmits it to the pressure drop calculation module 12. When the power plant is equipped with a fly ash online measurement device, The data can be read directly, otherwise, manual analysis is used, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com