Process for preparing coal water slurry from coal dust

A process method and coal powder preparation technology, applied in the direction of block/powder fuel preparation, combustion method, combustion equipment, etc., can solve the problems of restricting the promotion and use of coal-water slurry, high freight costs, and restricting the use of coal-water slurry. Achieve simple and fast operation, reduce transportation costs, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

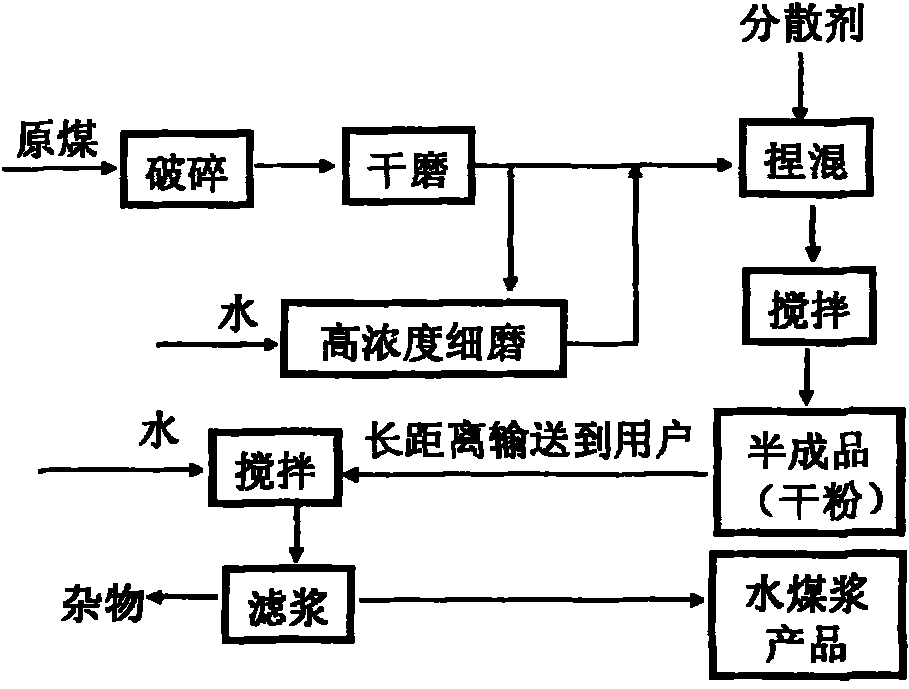

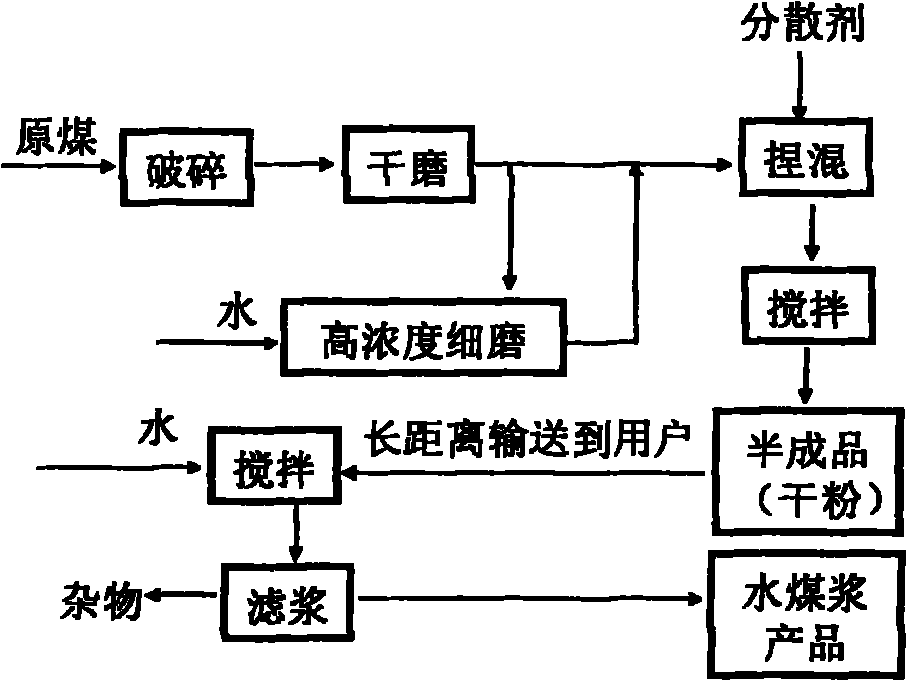

[0010] The process method of the present invention is as follows: firstly, the raw coal is crushed, and then dry-milled; the remaining coal particles after dry-grinding and fine-sieving are added with water for high-concentration fine-grinding, and mixed with the dry-milled fine-sieved coal powder; after that, a dispersant is added After kneading and stirring, it is made into a dry powder semi-finished product; after being transported to the user over a long distance, it is stirred with water; finally, after the pulp is filtered, the sundries are removed to make a coal water slurry product.

[0011] This process breaks the conventional practice of transporting the liquid coal-water slurry to the user from the coal-water slurry factory in the current market. The advantages are as follows: (1) It adopts the combination of dry and wet methods. On the other hand, it can make the semi-finished product of coal-water slurry contain a certain amount of water, which can avoid the hazard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com