Coal deep processing method and coal processing method

A technology for deep processing and coal, which is applied in the field of coal processing technology, can solve the problems of simple screening process, poor stability, and reduced credibility, and achieve the effect of improving economic benefits, high product stability, and good screening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] The coal deep processing method and the coal treatment method of the embodiments of the present invention will be described in detail below.

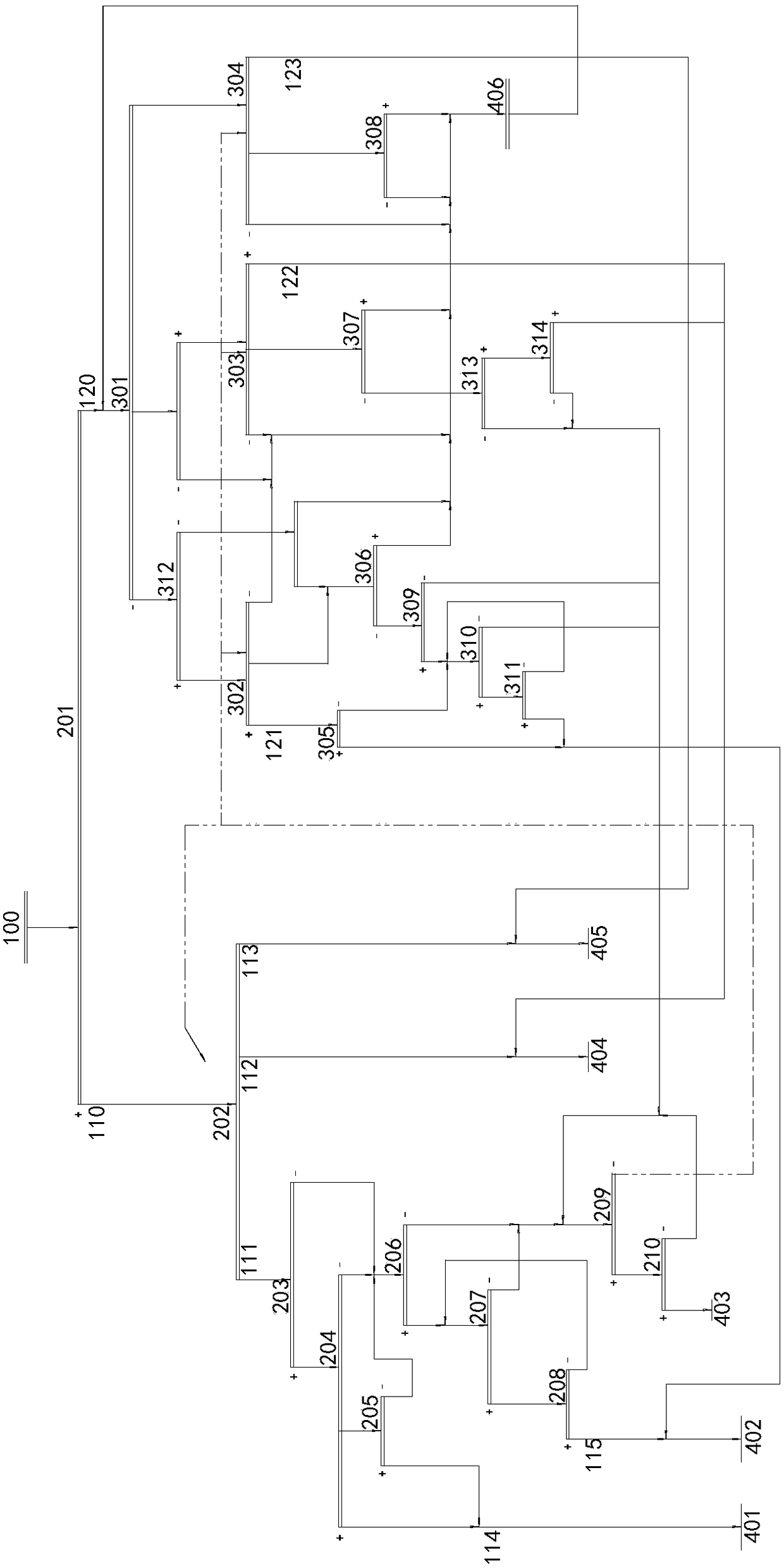

[0027] Please refer to figure 1 This embodiment provides a coal deep processing method, which includes screening and grading raw coal 100 through a screen 201 to obtain a coarse oversize 110 and a coarse undersize 120 . Then, the coarse screen oversize 110 and the coarse screen undersize 120 are further subdivided to obtain more commercial coal varieties. The particle size of the screen 201 is 10-30mm, preferably 10-15mm, more preferably 11-14mm, most preferably 13mm. Specifically include the following steps:

[0028] 1. Screening of coarse sieve 110

[0029] The coarse sieve material 110 is sorted by the jig 202 to obtain the first clean coal 111, the first medium coal 112 and the first gangue 113, wherein the first clean coal 111 is further screened into lump clean coal 114 and fine coal. The clean coal 115, lump clean coal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com