Coal denitration agent

A denitration agent and coal technology, applied in gas treatment, membrane technology, dispersed particle separation, etc., can solve the problem of high operating costs, achieve obvious effects, long effective use time, and good promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

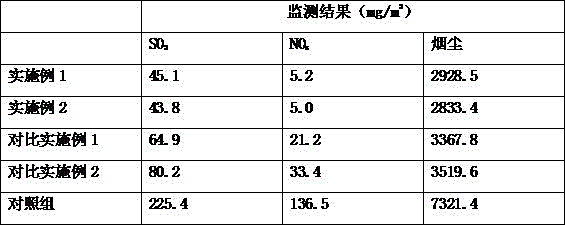

Examples

Embodiment 1

[0021] A kind of coal denitrification agent, is made of the following substances by weight:

[0022] 100 parts of activated carbon, 30 parts of graphene, 30 parts of urea, 60 parts of slaked lime, 15 parts of barium succinate, 15 parts of zinc palmitate soap, 20 parts of alginate, 10 parts of methyl cellulose, 50 parts of modified attapulgite, 15 parts of calcium carbonate, 15 parts of titanium dioxide, 10 parts of calcium stearate, 4 parts of magnesium acetate, 5 parts of zinc acetate; the modified attapulgite is made of the following parts by weight: 80 parts of attapulgite, 3 parts Lanthanum nitrate, 2 parts cerium nitrate, 3 parts praseodymium nitrate, 2 parts neodymium nitrate, 4 parts sodium benzoate, 8 parts polyvinyl benzoic acid, 6 parts phenolic resin, 5 parts urea-formaldehyde resin, 4 parts palm oil, 4 parts stearic acid magnesium.

[0023] Further, the preparation method of the modified attapulgite comprises the following steps:

[0024] (1) Crush the attapulgit...

Embodiment 2

[0032] A kind of coal denitrification agent, is made of the following substances by weight:

[0033] 90 parts of activated carbon, 25 parts of graphene, 25 parts of urea, 55 parts of slaked lime, 13 parts of barium succinate, 13 parts of zinc palmitate soap, 18 parts of alginate, 9 parts of methyl cellulose, 45 parts of modified attapulgite, 10 parts of calcium carbonate, 12 parts of titanium dioxide, 8 parts of calcium stearate, 3 parts of magnesium acetate, 4 parts of zinc acetate; the modified attapulgite is made of the following parts by weight: 75 parts of attapulgite, 2 parts Lanthanum nitrate, 1.5 parts of cerium nitrate, 2 parts of praseodymium nitrate, 1.5 parts of neodymium nitrate, 3 parts of sodium benzoate, 7 parts of polyvinyl benzoic acid, 5 parts of phenolic resin, 4 parts of urea-formaldehyde resin, 3 parts of palm oil, 3 parts of stearic acid magnesium.

[0034] Further, the preparation method of the modified attapulgite comprises the following steps:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com