Large-scale centralized preparation system for pulverized coal and distribution method

A pulverized coal and large-scale technology, which is applied in the field of efficient and clean large-scale pulverized coal preparation system and distribution, can solve the problems of not considering the safety of pulverized coal preparation and transportation process, the unavoidable and unreasonable consideration of the raw coal transportation link, etc., and achieve improvement The effect of safe and economical running time, ensuring feasibility and safety, reducing floor area and plant power consumption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

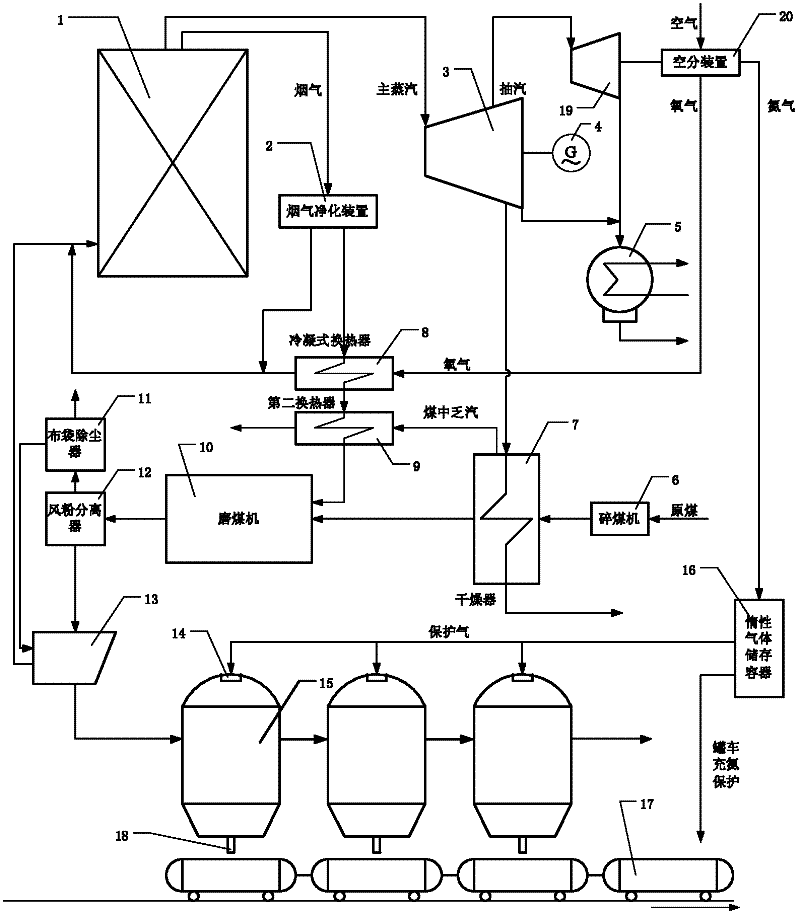

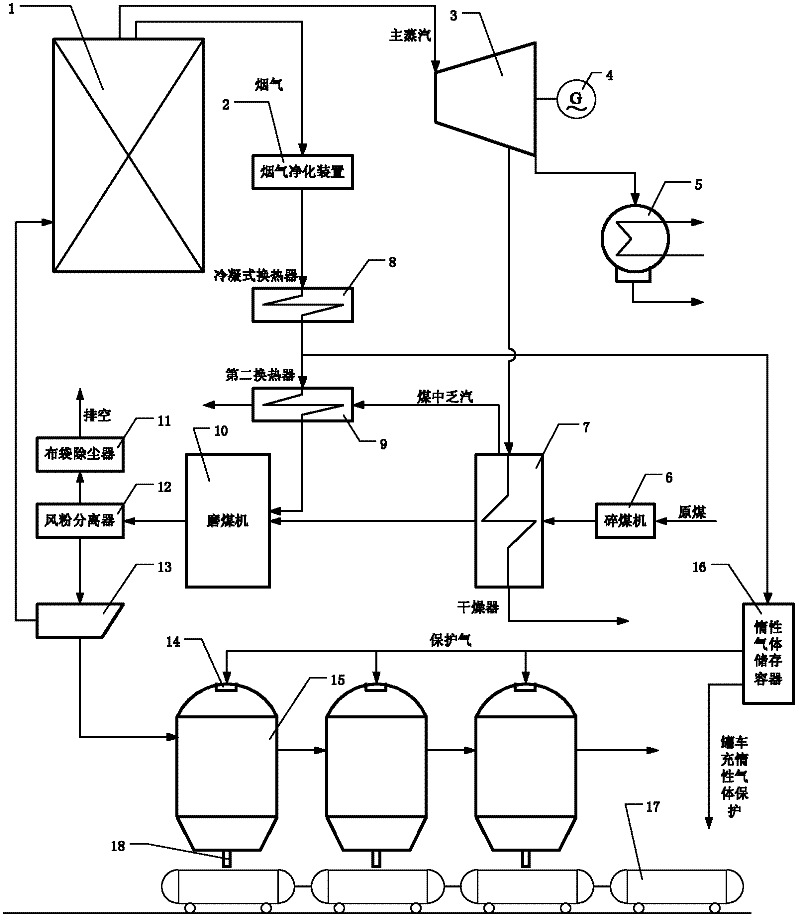

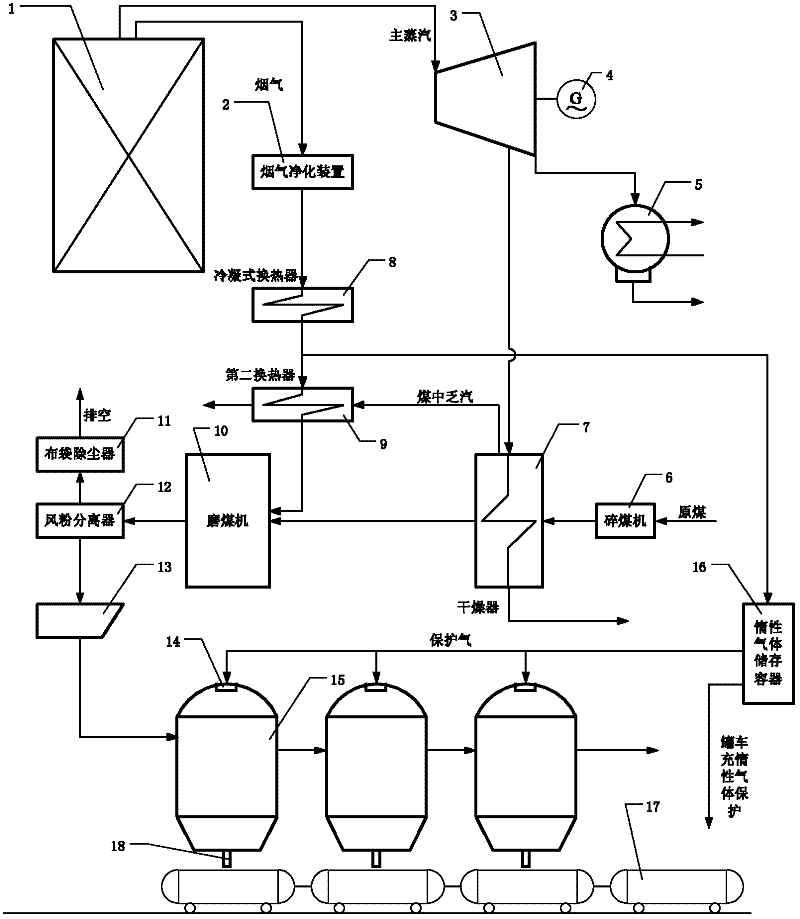

[0034] The present invention is described in further detail below in conjunction with accompanying drawing:

[0035] see figure 1 As shown, the system mainly includes: boiler, large steam turbine, generator, small steam turbine, air separation unit, flue gas purification device, condenser, condensing heat exchanger, second heat exchanger, coal crusher, coal pulverizer Machines, dryers, wind powder separators, bag dust collectors, pulverized coal bins, pulverized coal storage containers, inert gas storage containers, inerting protection devices, tank trucks, and pulverized coal loading and unloading equipment. The boiler organizes oxygen-enriched combustion, and the required oxygen is generated by the air separation unit. The flue gas generated by the combustion passes through each heating surface in turn and then enters the flue gas purification device. The outlet of the flue gas purification device is divided into two parts, one part is sent to the furnace, and the other part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com