Patents

Literature

33results about How to "Stably ejected" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ink-jet ink composition for etching resist

ActiveUS20110024392A1Excellent adhesion to metalStably ejectedImpression capsDecorative surface effectsPhosphoric Acid EstersPolymer science

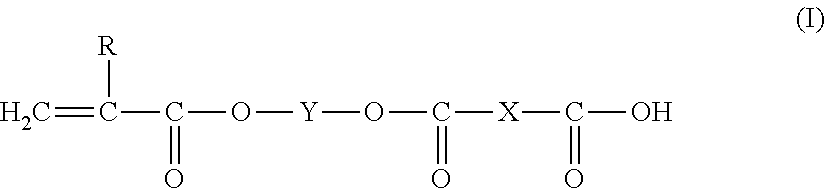

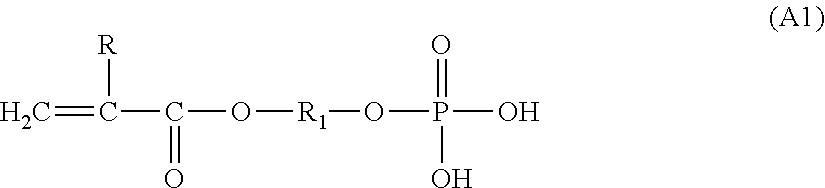

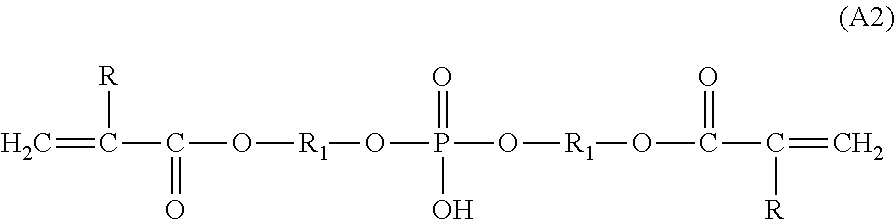

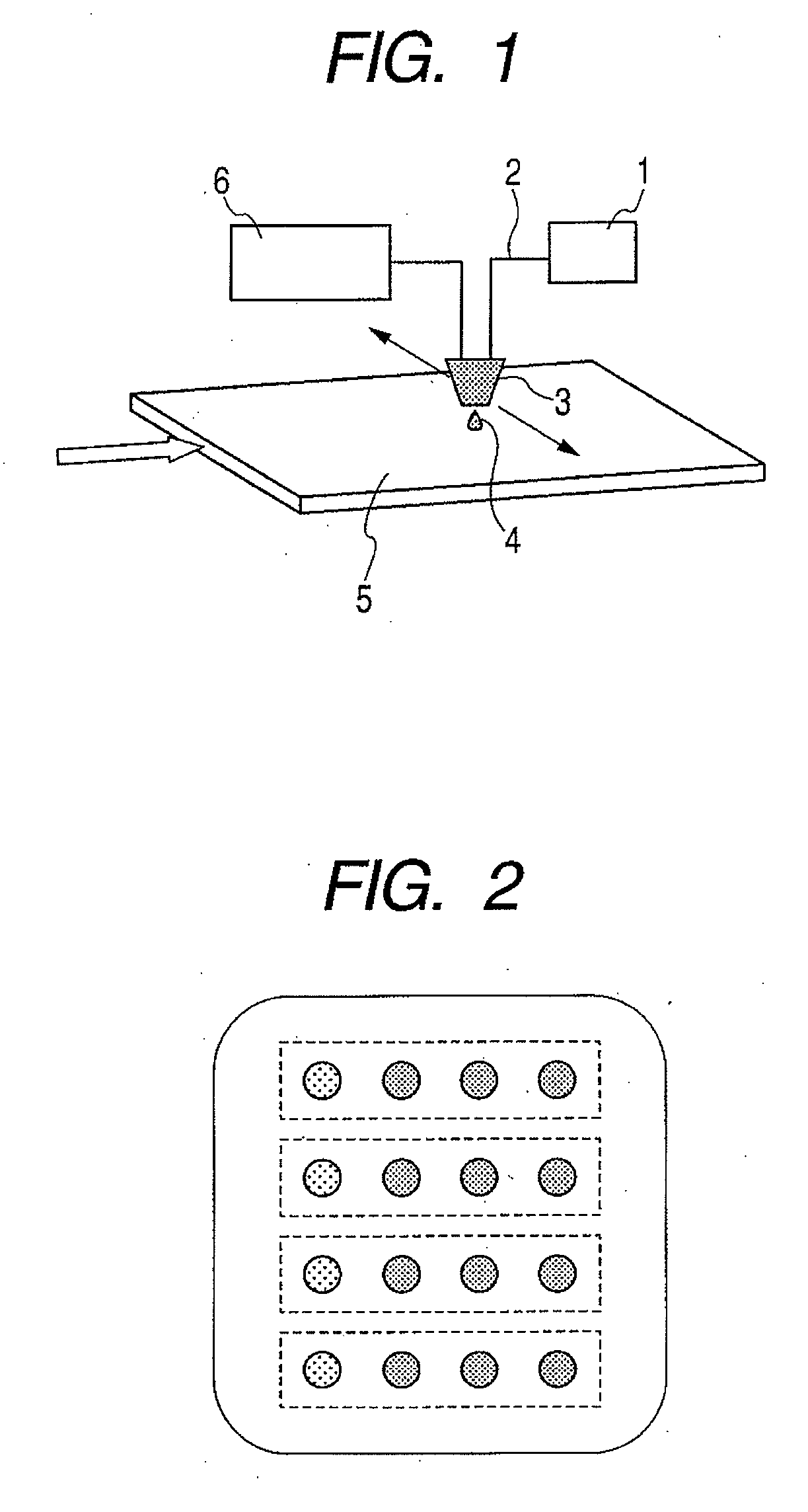

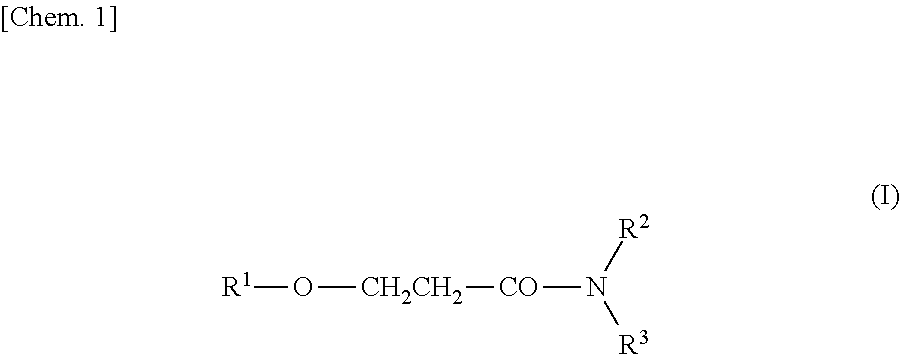

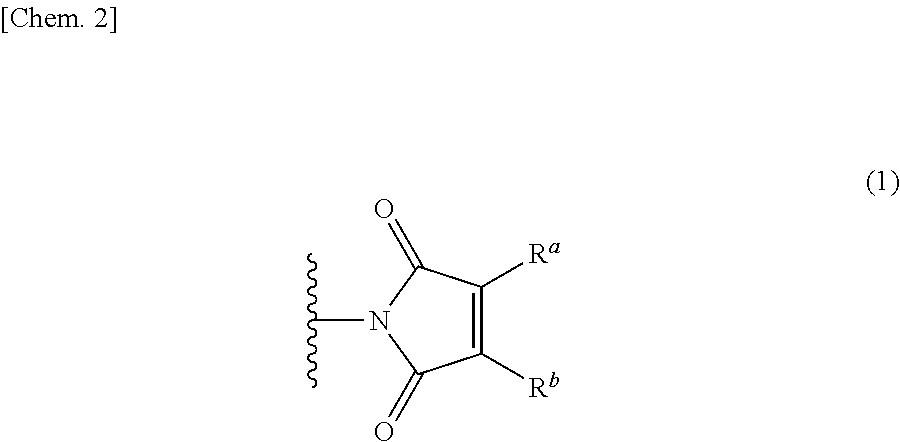

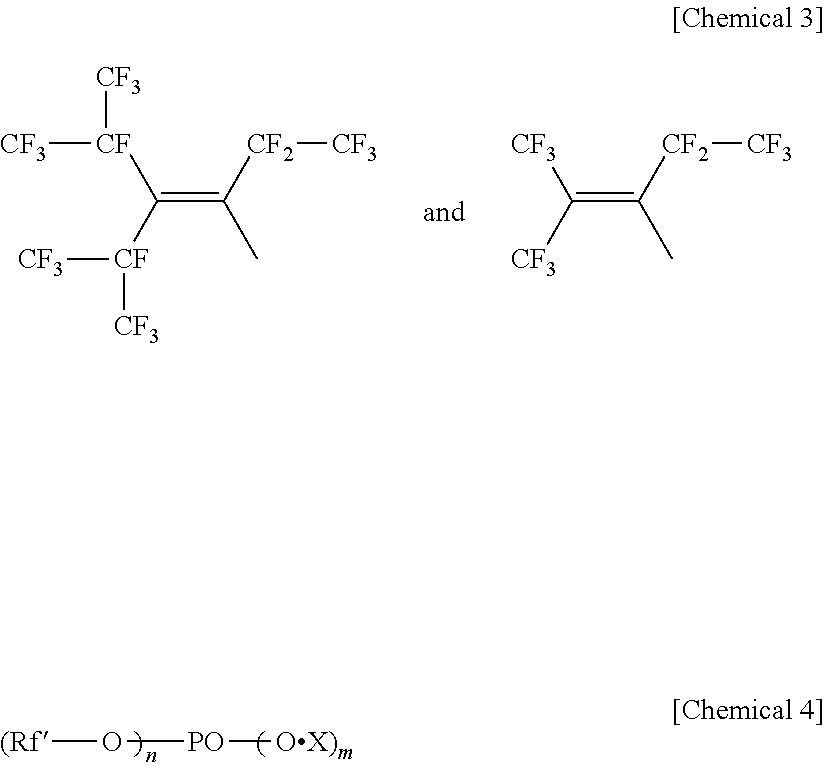

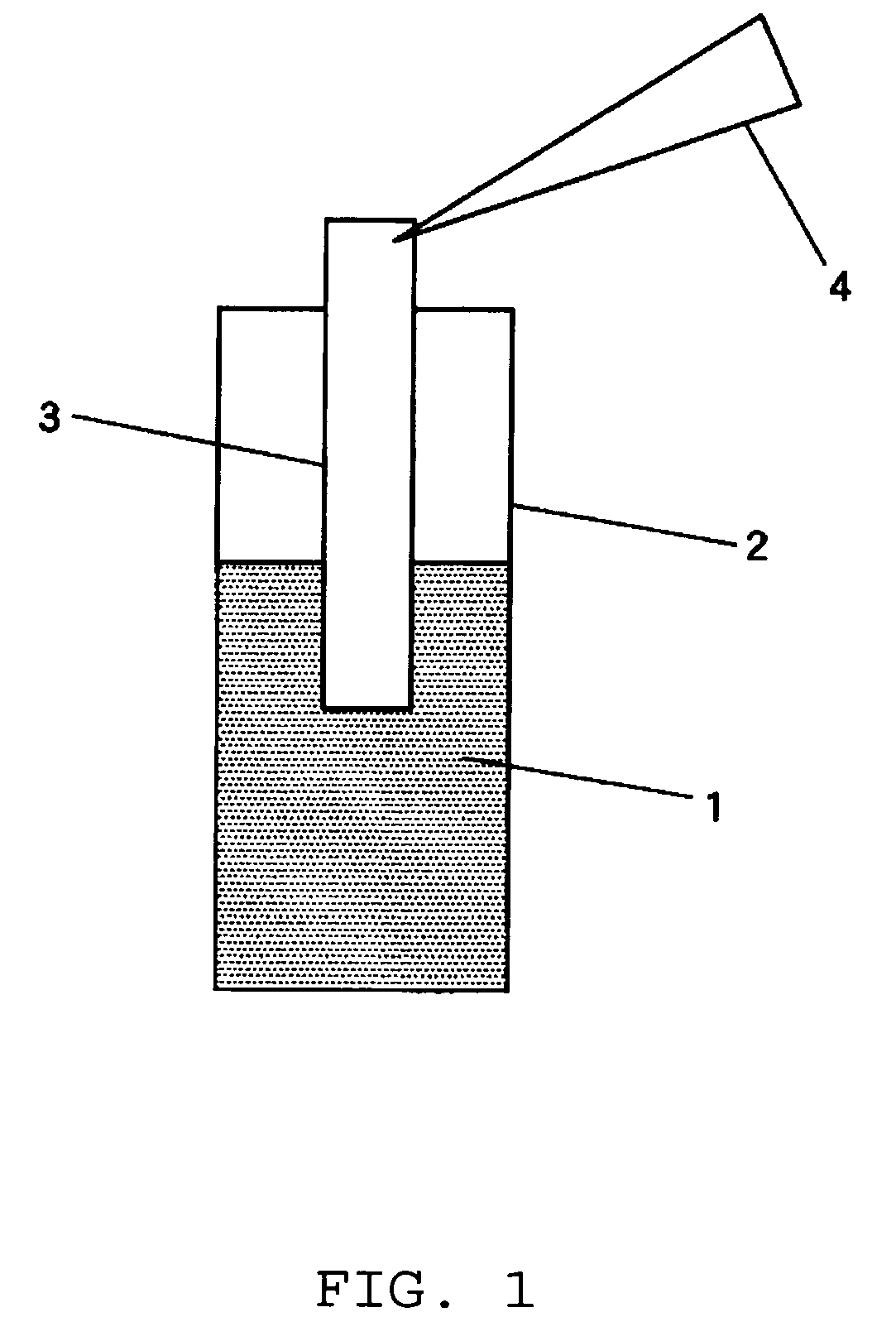

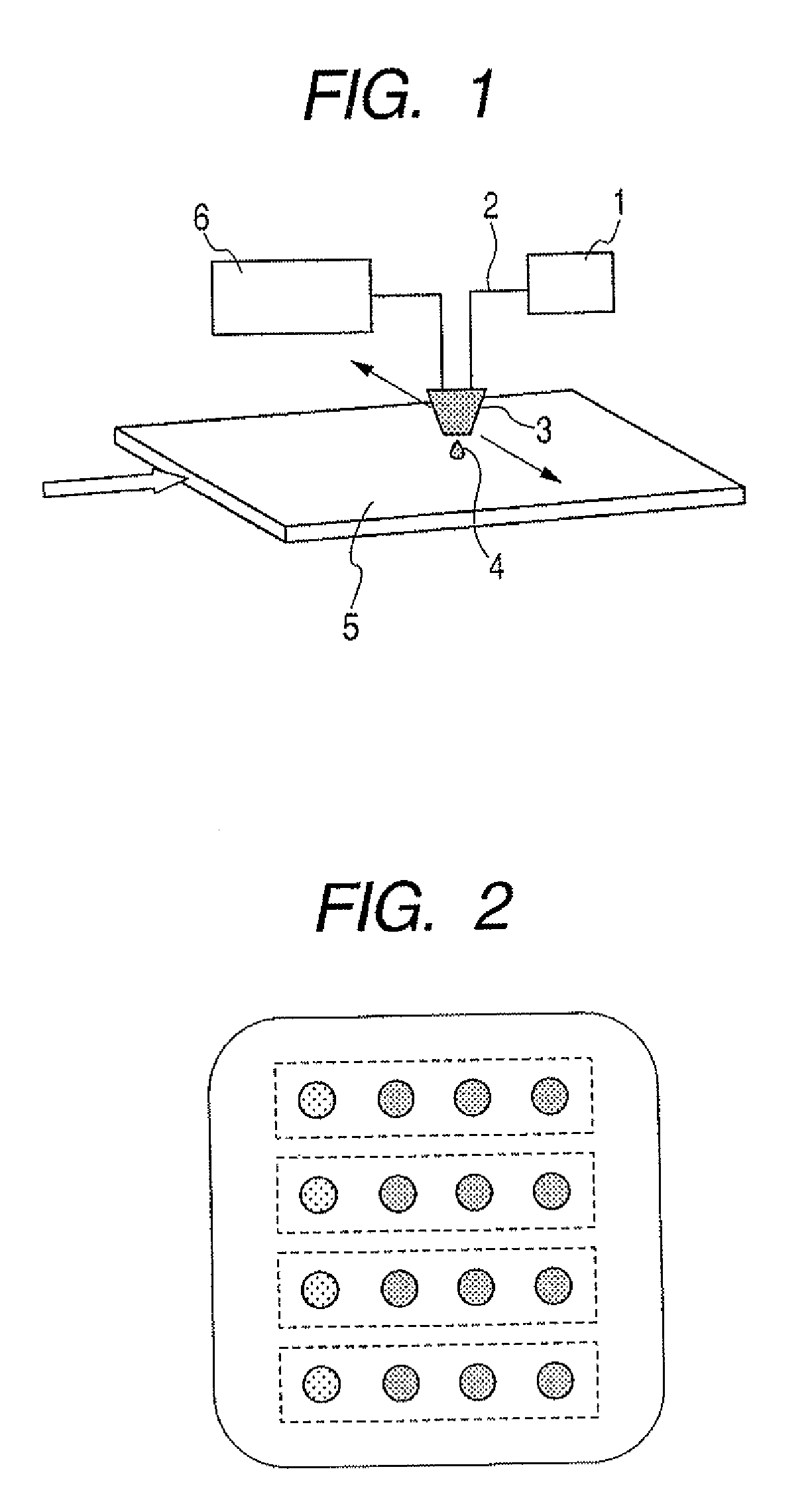

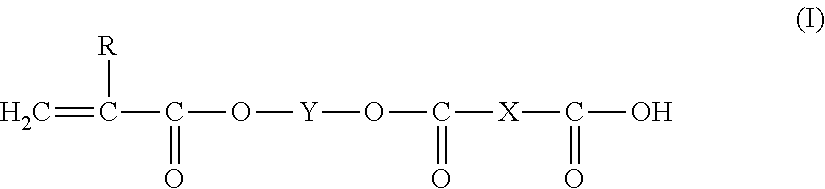

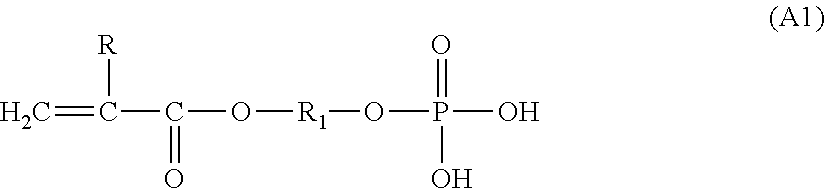

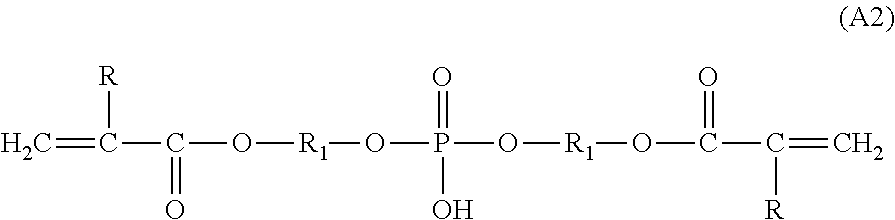

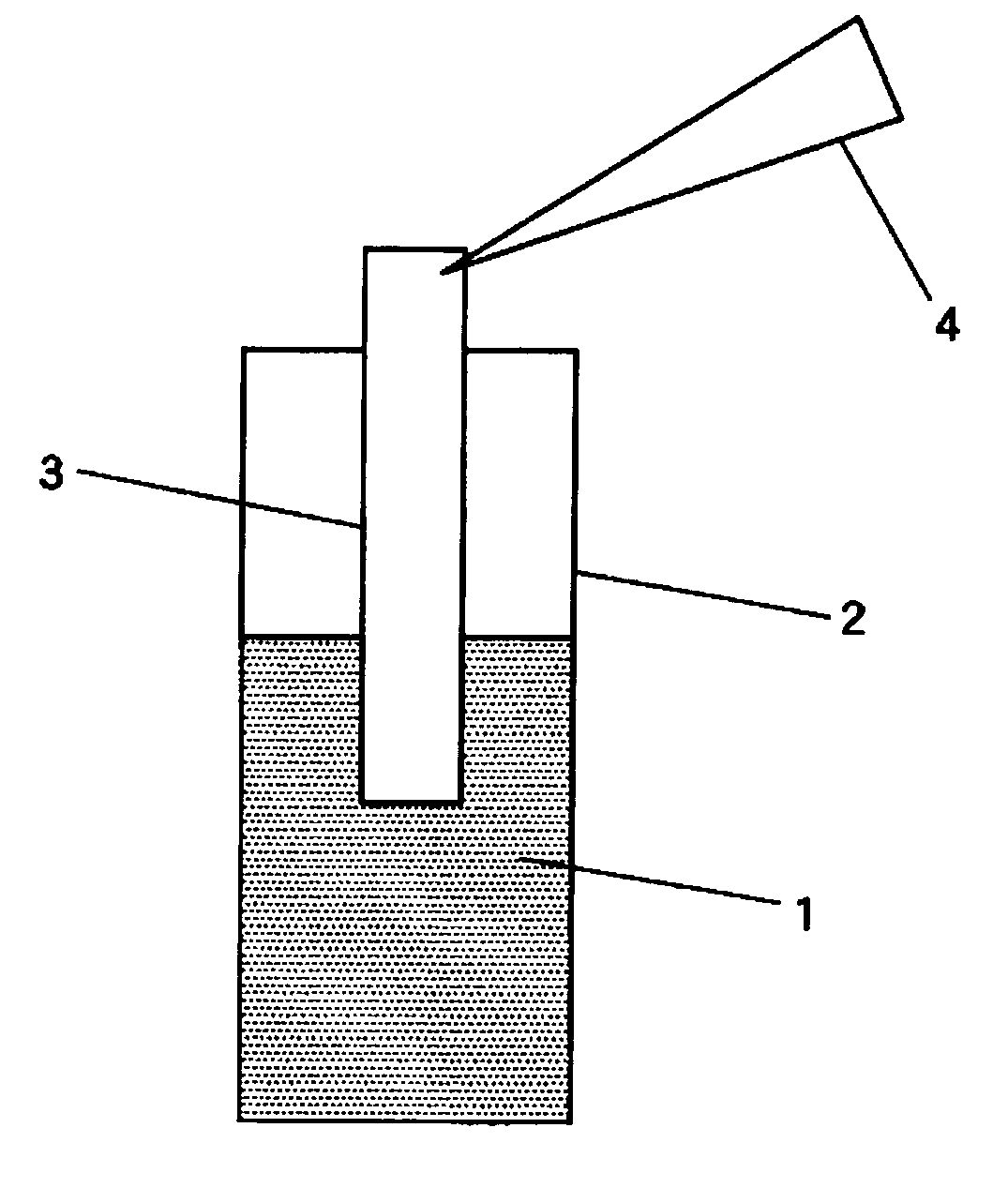

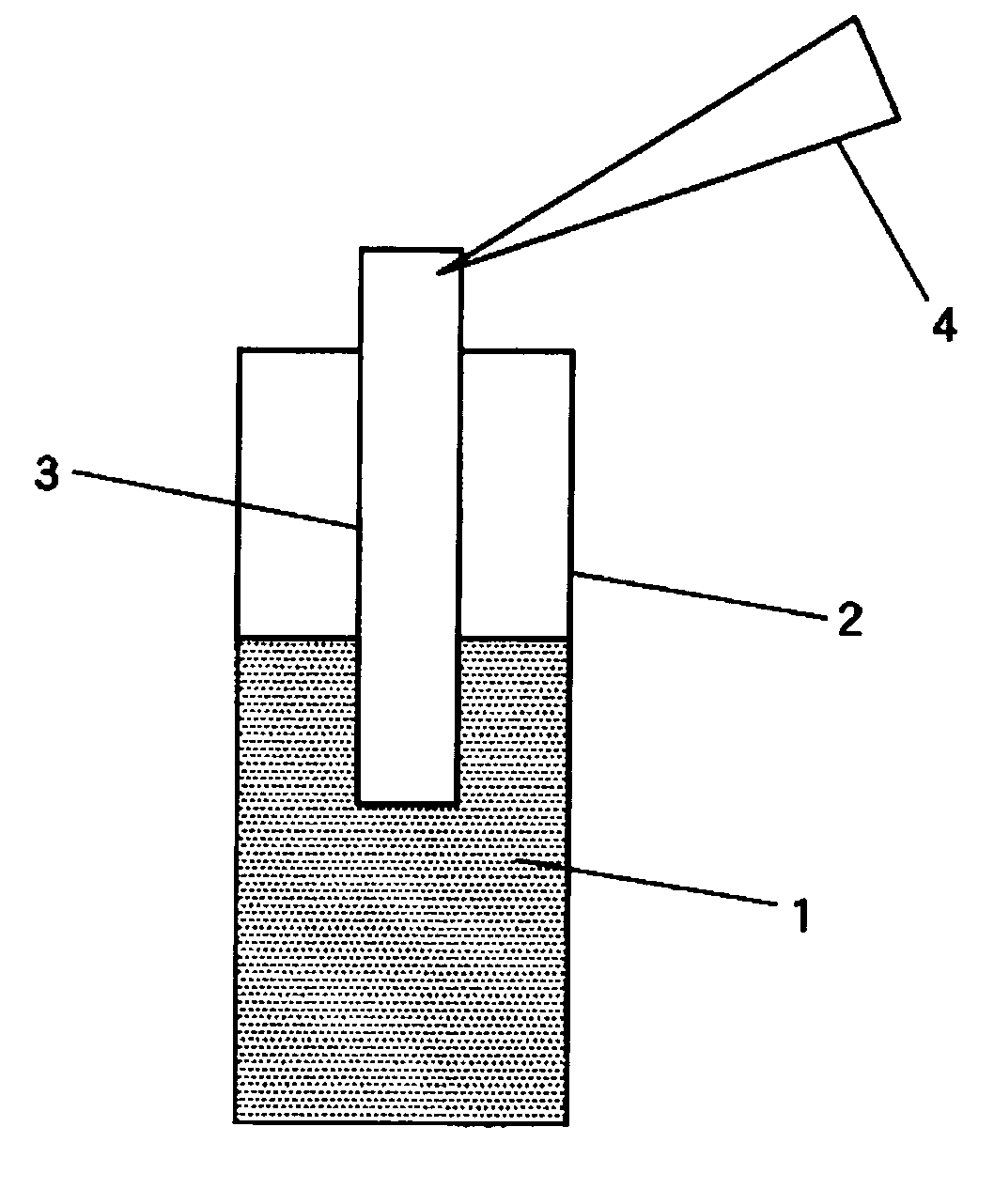

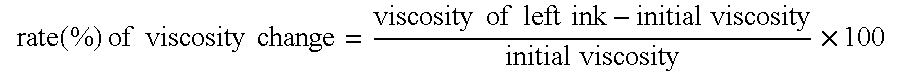

An ink composition for ink jet printing is provided which gives a cured object excellent in adhesion to metallic plates, resistance to etchants, and alkali removability and can be stably ejected with an ink jet apparatus. The ink jet composition for etching resists has a viscosity at 25° C. of 3-50 mPa s and includes monomers comprising: either a polymerizable phosphoric ester compound represented by general formula (I); a polyfunctional monomer having two or more ethylenic double-bond groups per molecule and having no phosphoric ester group, the content of the ethylenic double-bond groups being 4×10−3 to 8×10−3 mol / g; and a monofunctional monomer having one ethylenic double-bond group per molecule and having neither phosphoric ester group nor carboxy group.In the formula, X represents C1-3 alkylene, Y represents C2-3 alkylene, and R represents hydrogen or methyl.

Owner:NISSHIN STEEL CO LTD +1

Recording Ink, Ink/Media Set, Ink Cartridge, Inkjet Recording Method and Inkjet Recording Apparatus

ActiveUS20080233363A1Avoid it happening againHigh image densityDecorative surface effectsLayered productsParticulatesWater dispersible

To provide a recording ink which contains at least a water-dispersible colorant, a water-dispersible resin, a wetting agent, a surfactant and water, wherein the content of the wetting agent in the recording ink is in the range of from 20% by mass to 35% by mass, the total solid content of the water-dispersible colorant and the water-dispersible resin in the recording ink is in the range of from 12% by mass to 40% by mass, the water-dispersible resin contains fluorine resin particulates, and the ratio A:B, where A is the solid content of the water-dispersible resin in the recording ink and B is the solid content of a pigment contained in the water-dispersible colorant in the recording ink, is in the range of 0.5 to 8.

Owner:RICOH KK

Water-based pigment-type ink and ink jet printer

InactiveUS6030440AStably ejectedAvoid cloggingTransportation and packagingDuplicating/marking methodsWater basedPolymer science

A water-based pigment-type ink containing at least water, a pigment and a dispersant, the pigment particles having an average particle diameter of not larger than 0.1 mu m, the weight ratio of the pigment to the dispersant being from 1.2 to 5. The water-based pigment-type ink exhibits more excellent color tone and chroma, by adding the fluorescent pigment in an amount of from 0.1% by weight to 3% by weight with respect to the amount of the ink. Furthermore, the water-based pigment-type ink comprises at least a pigment, a high-molecular dispersant, a surfactant and water, the pigment particles having an average particle diameter of not larger than 80 nm, a maximum particle diameter not being larger than 0.1 mu m, the high-molecular dispersant being added in an amount of from 3% by weight to 20% by weight with respect to the amount of the ink, and the surfactant being added in an amount of from 2% by weight to 4% by weight with respect to the amount of the ink.

Owner:FUJITSU PERIPHERALS

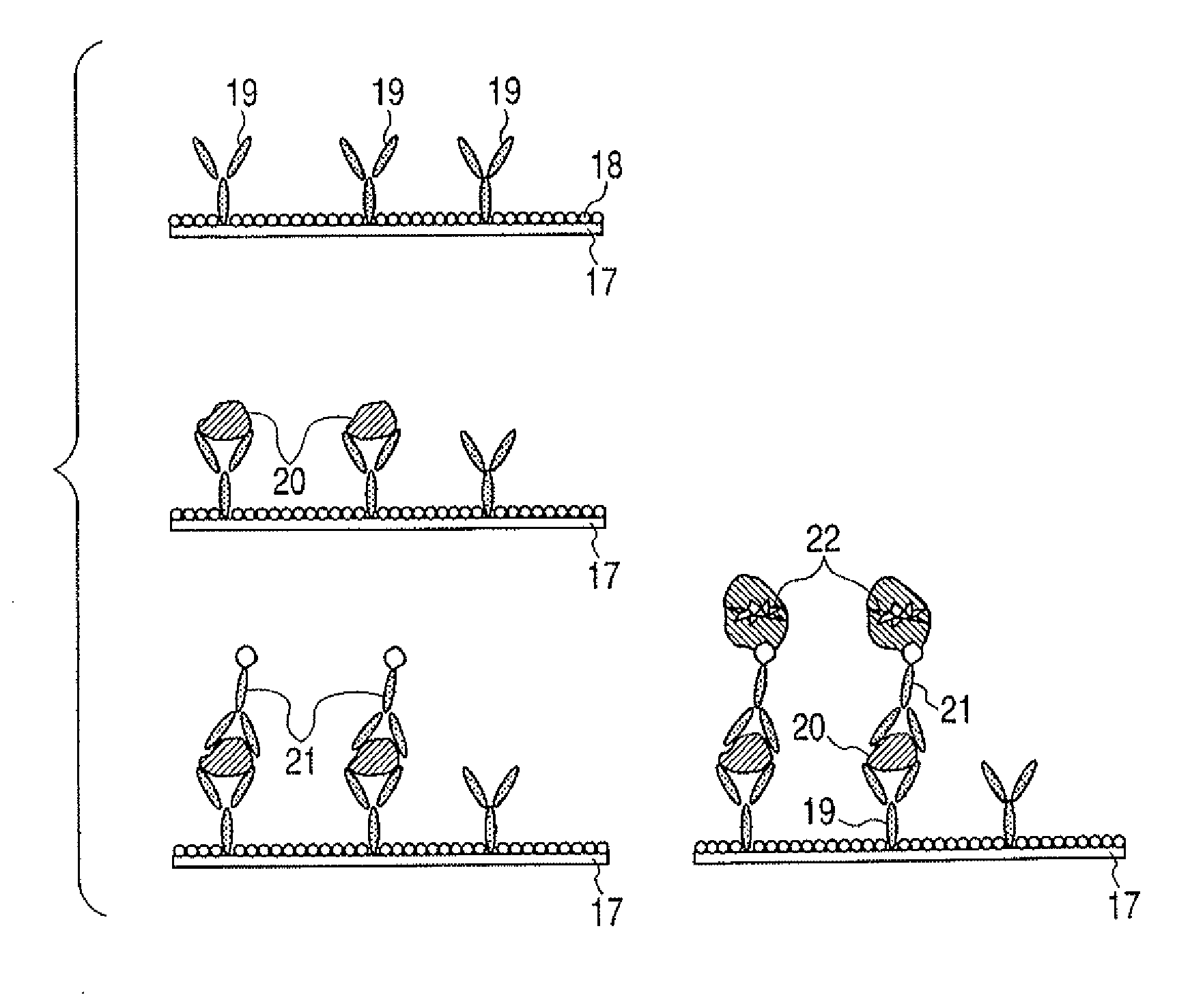

Water-based pigment dispersion, use thereof and process for the production thereof

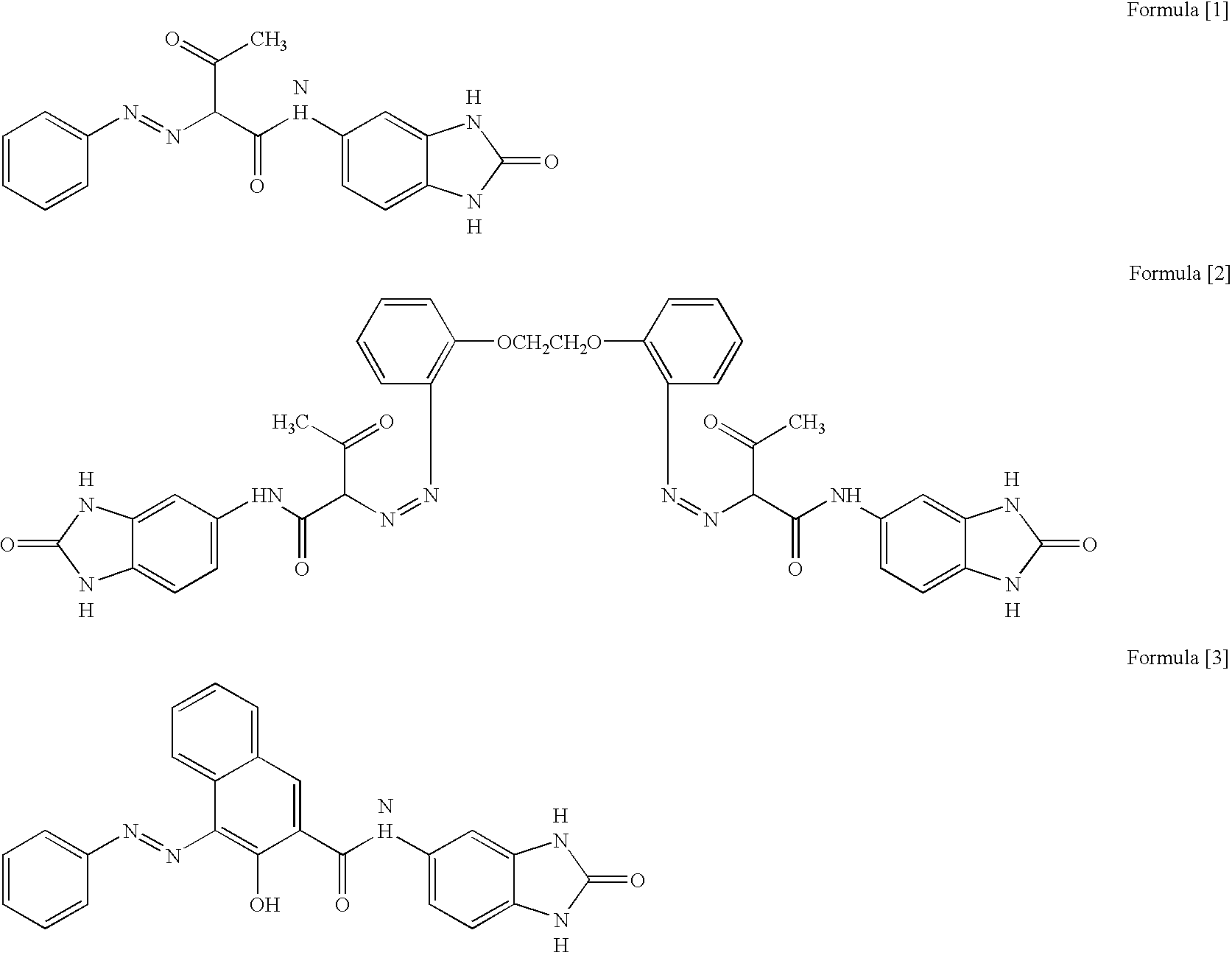

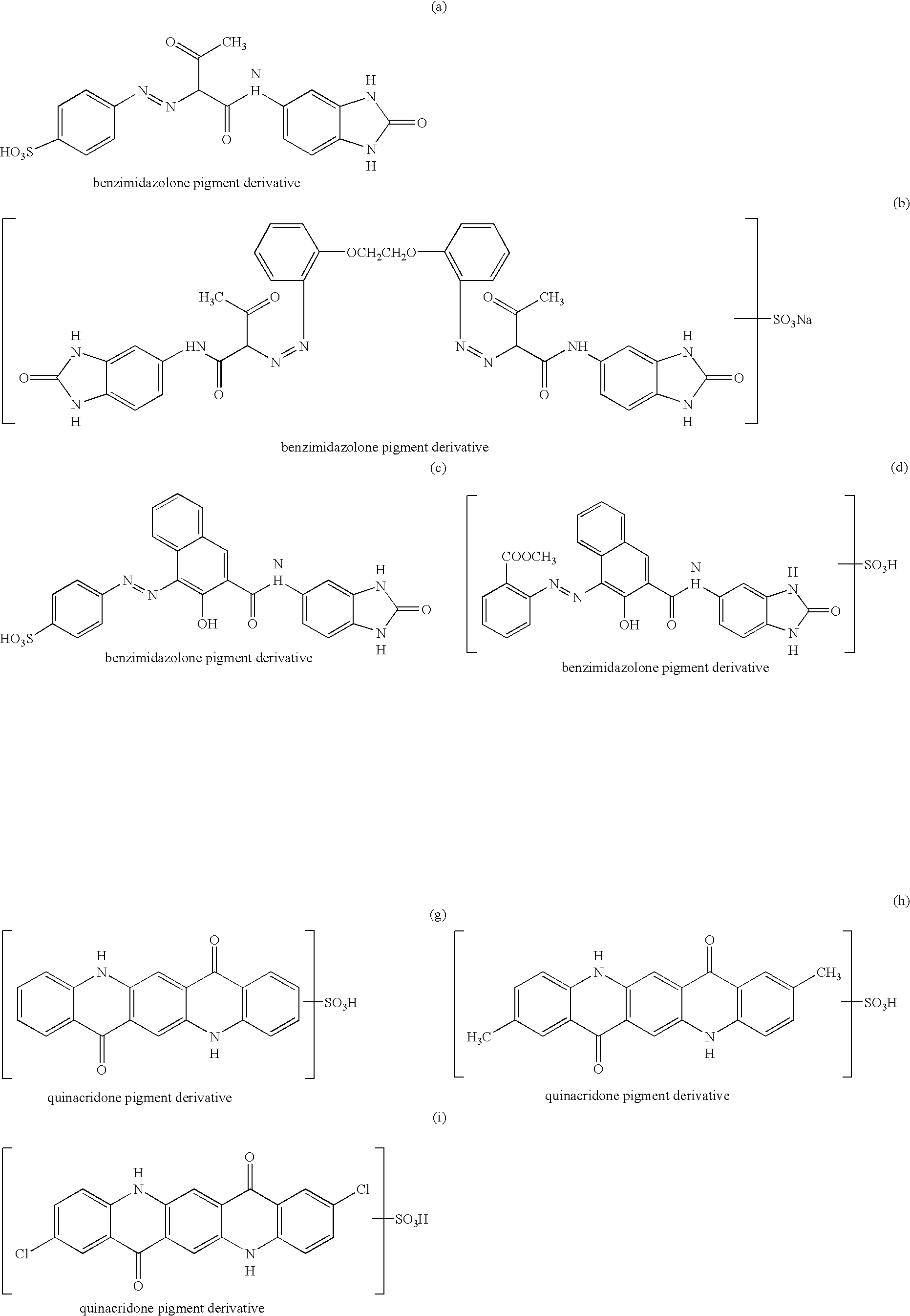

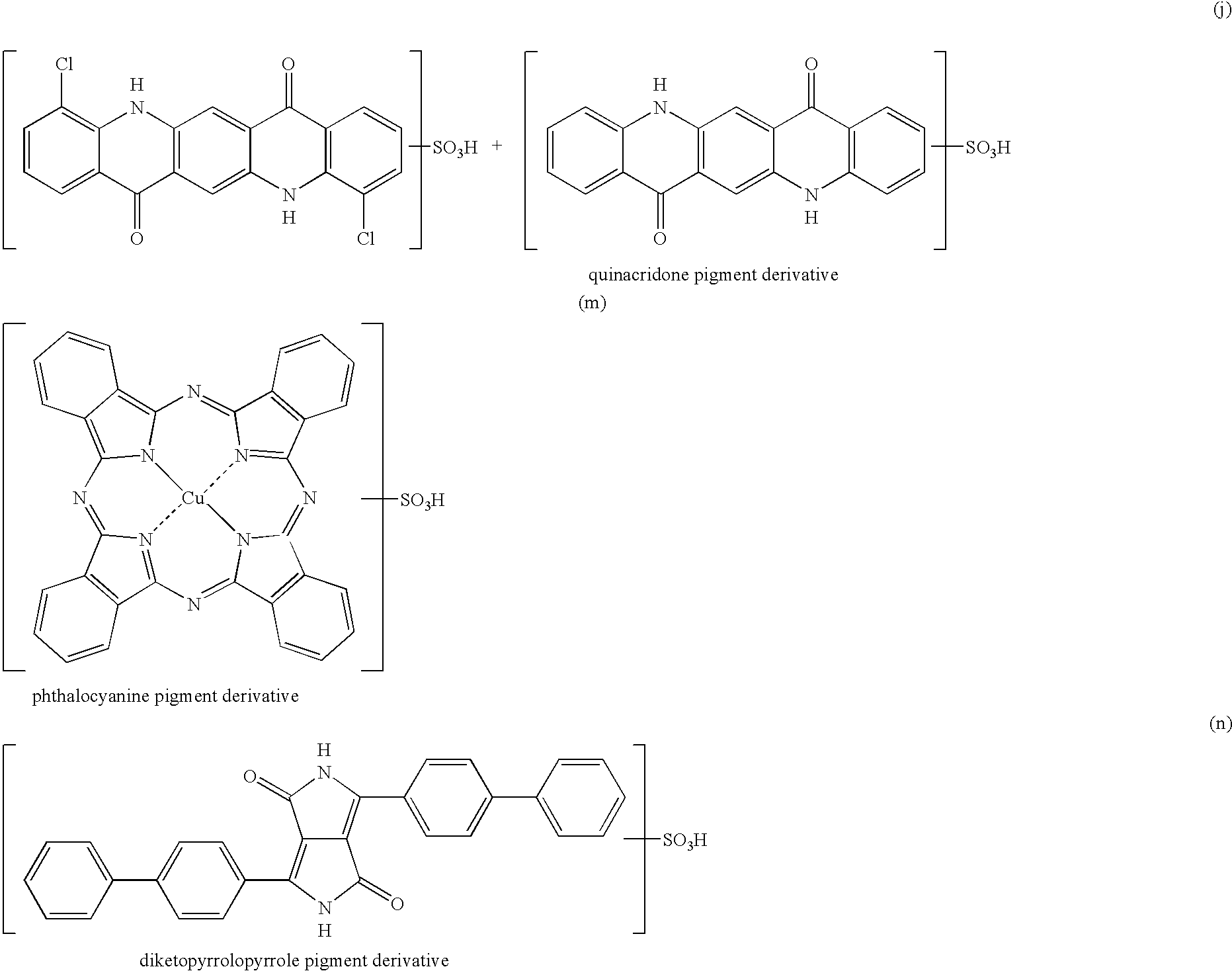

A water-based pigment dispersion comprising 100 parts by weight of a pigment, 3 to 30 parts by weight of a sulfonic acid group-containing pigment derivative and water, wherein the sulfonic acid group-containing pigment derivative has only one sulfonic acid group in a molecule of a pigment of which the type is the same as the type of the pigment to be dispersed, the sulfonic acid group forms at least one salt selected from the group consisting of ammonia salt, an organic amine salt and a salt in which at least 15% of the sulfonic acid group is liberated and the rest is a salt with monovalent metal, the content of metal ion having a valence of at least 2 in a solid matter of the above water-based pigment dispersion is 500 ppm or less, and the above pigment is dispersed in water according to electrostatic repulsion due to the sulfonic acid group-containing pigment derivative adsorbed on the particle surface of the pigment, an inkjet recording liquid containing the same and process for the production thereof.

Owner:TOYO INK SC HOLD CO LTD

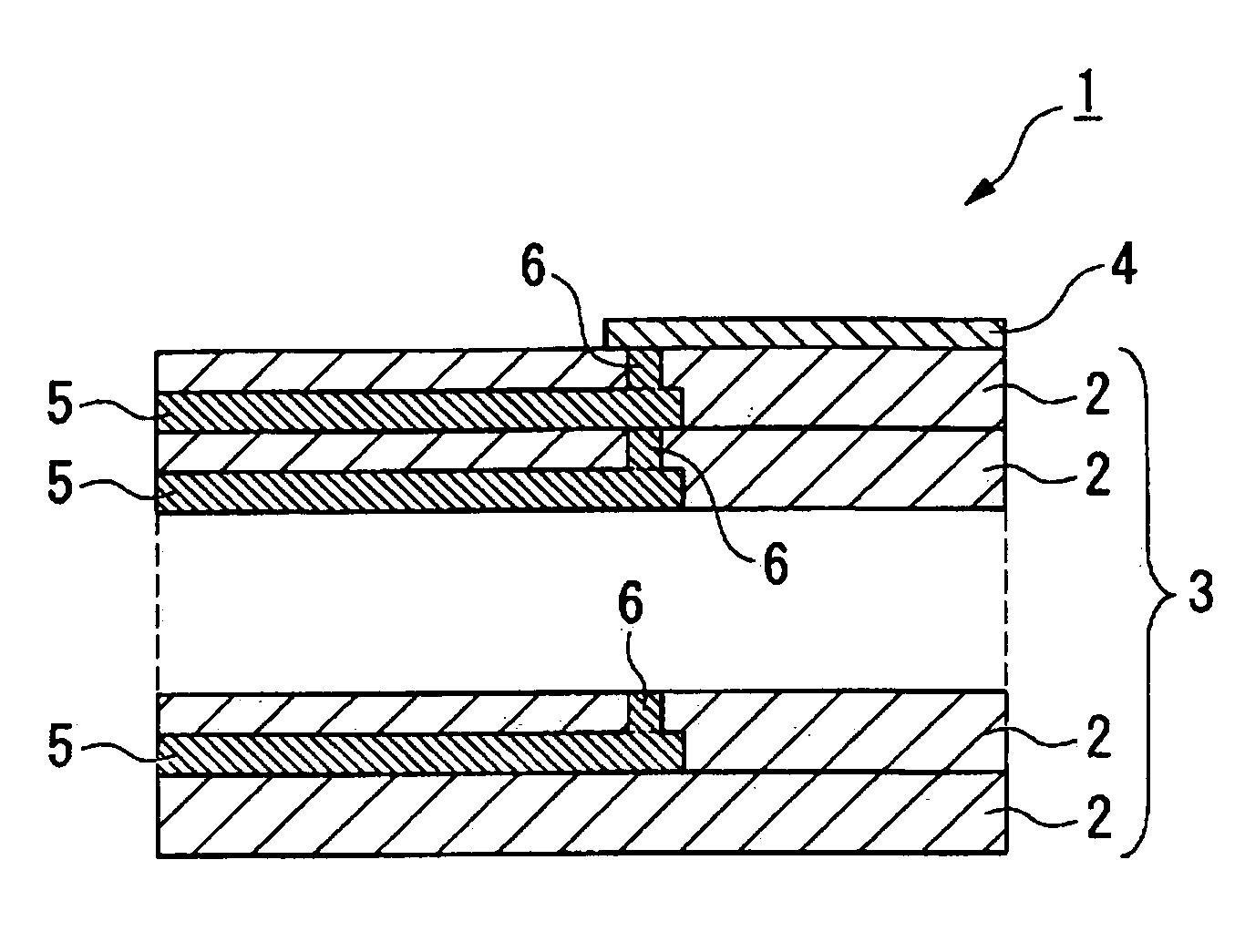

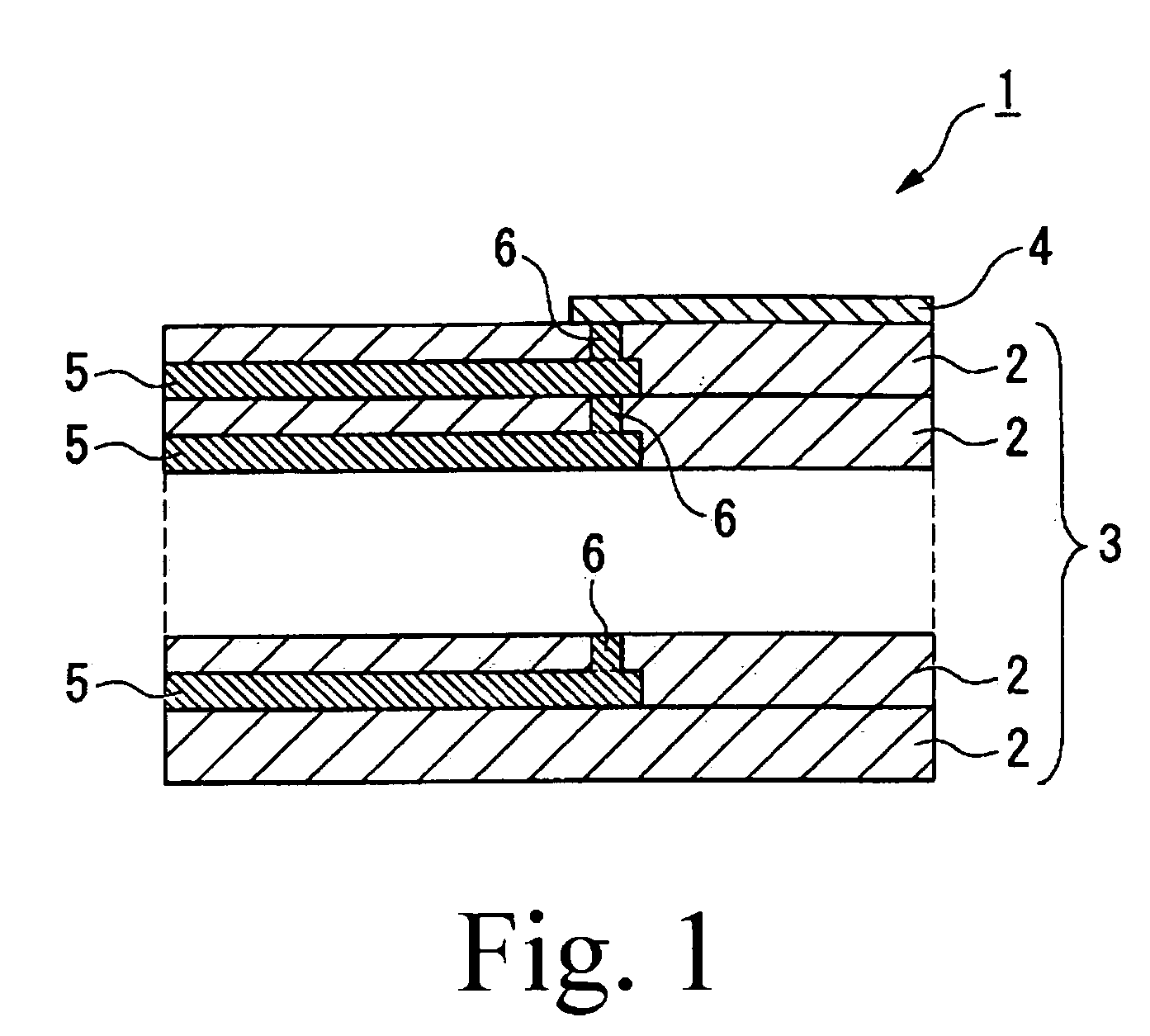

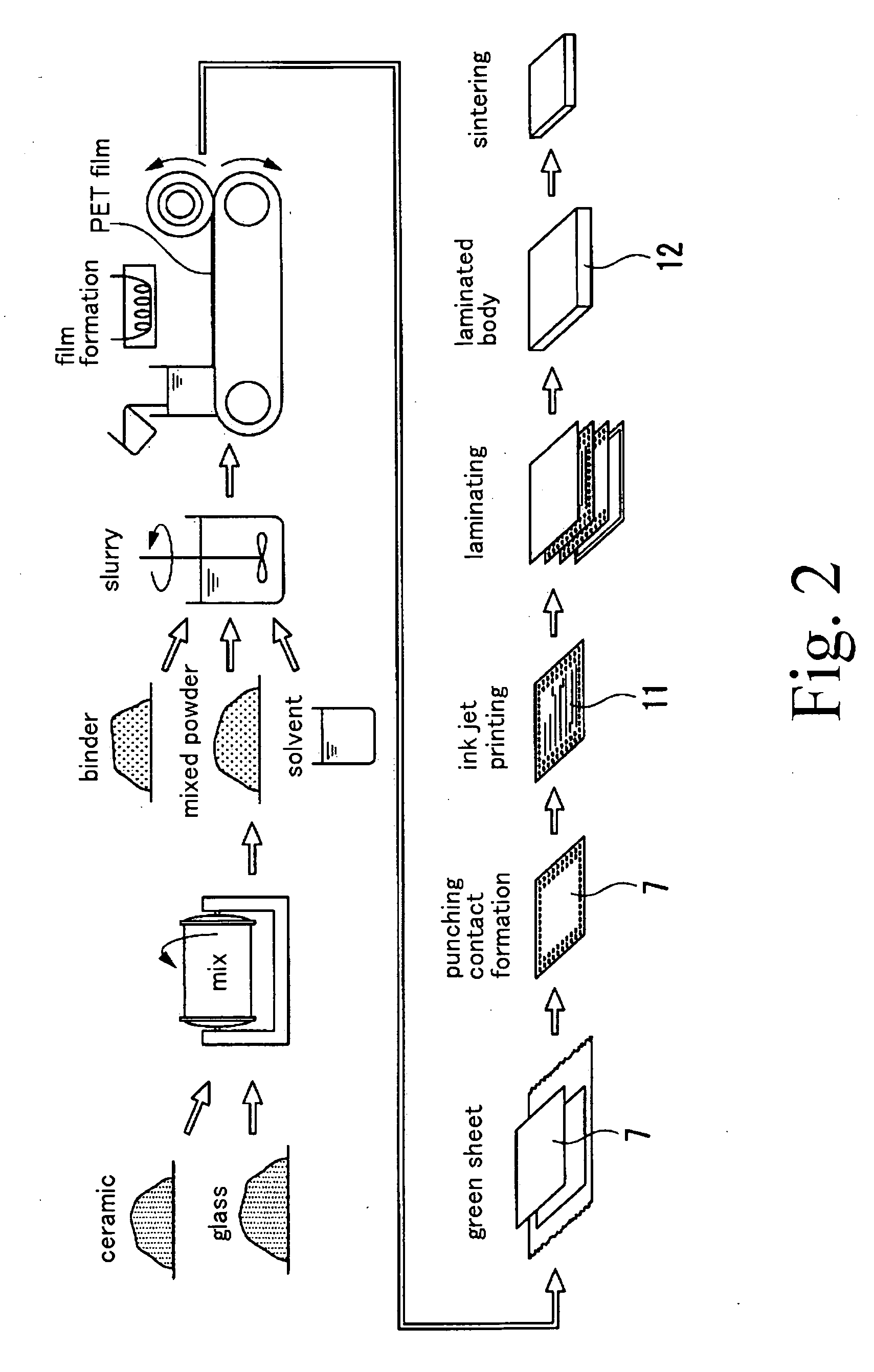

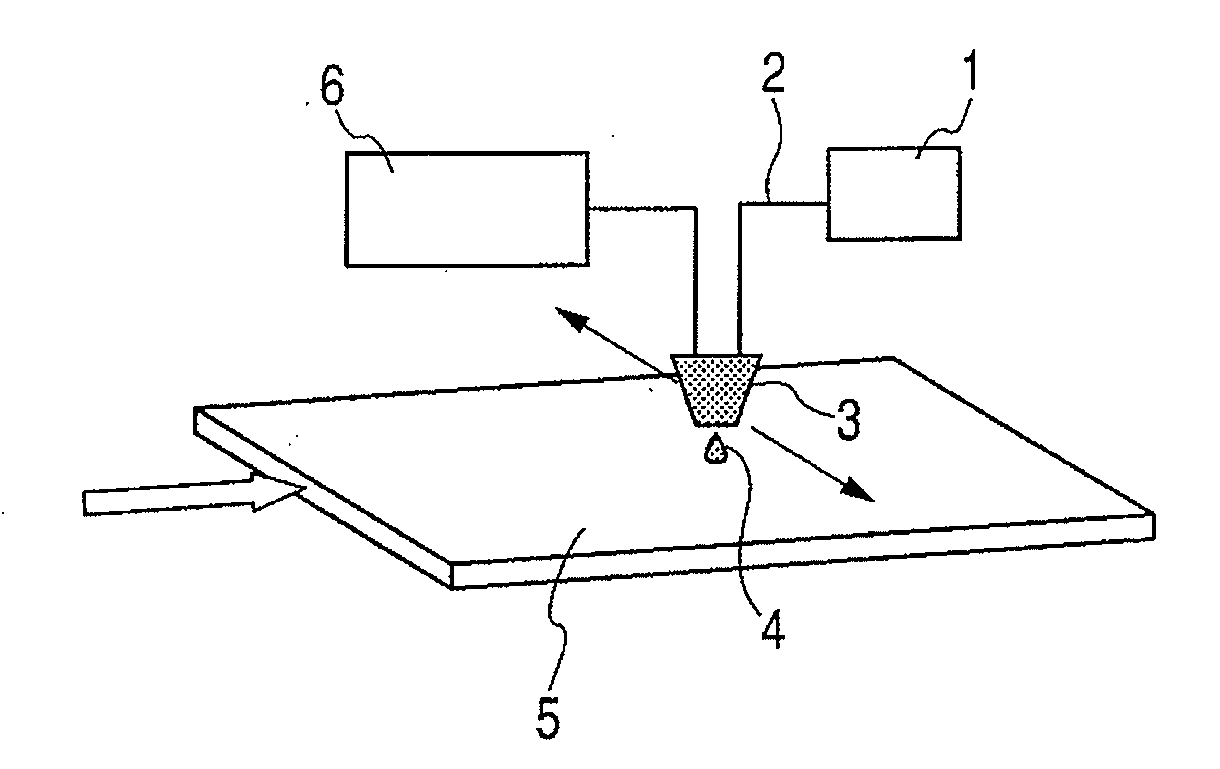

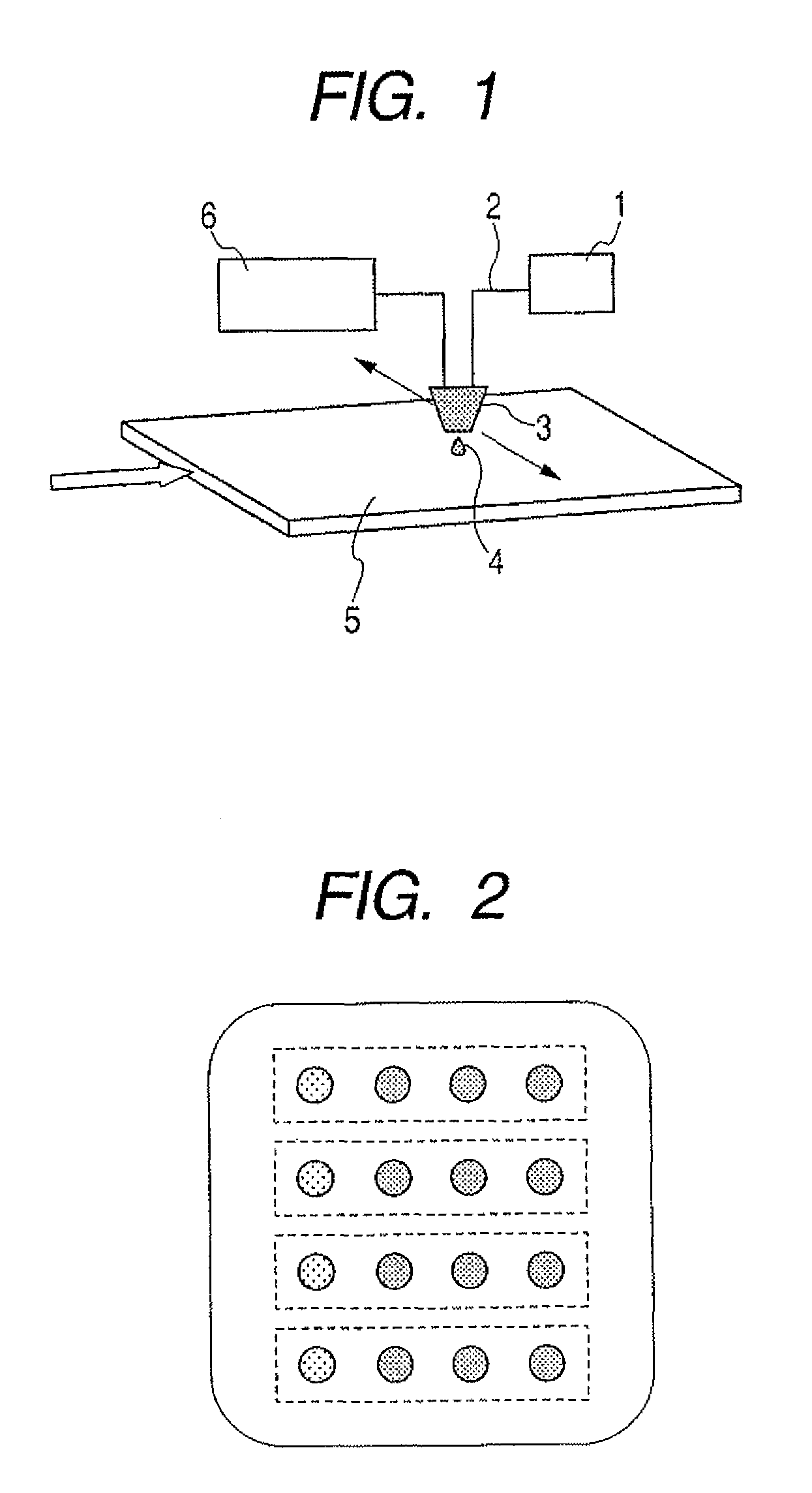

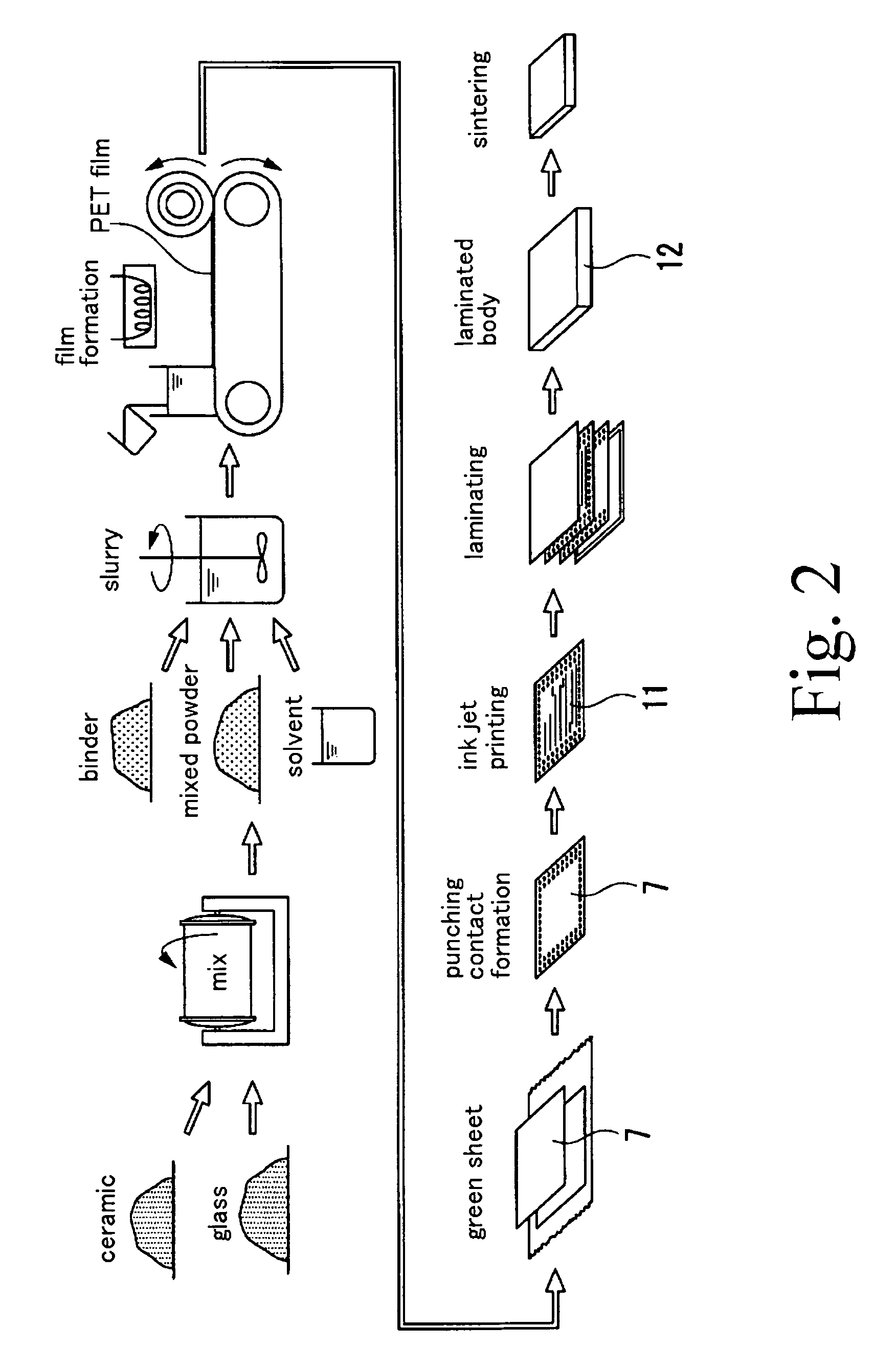

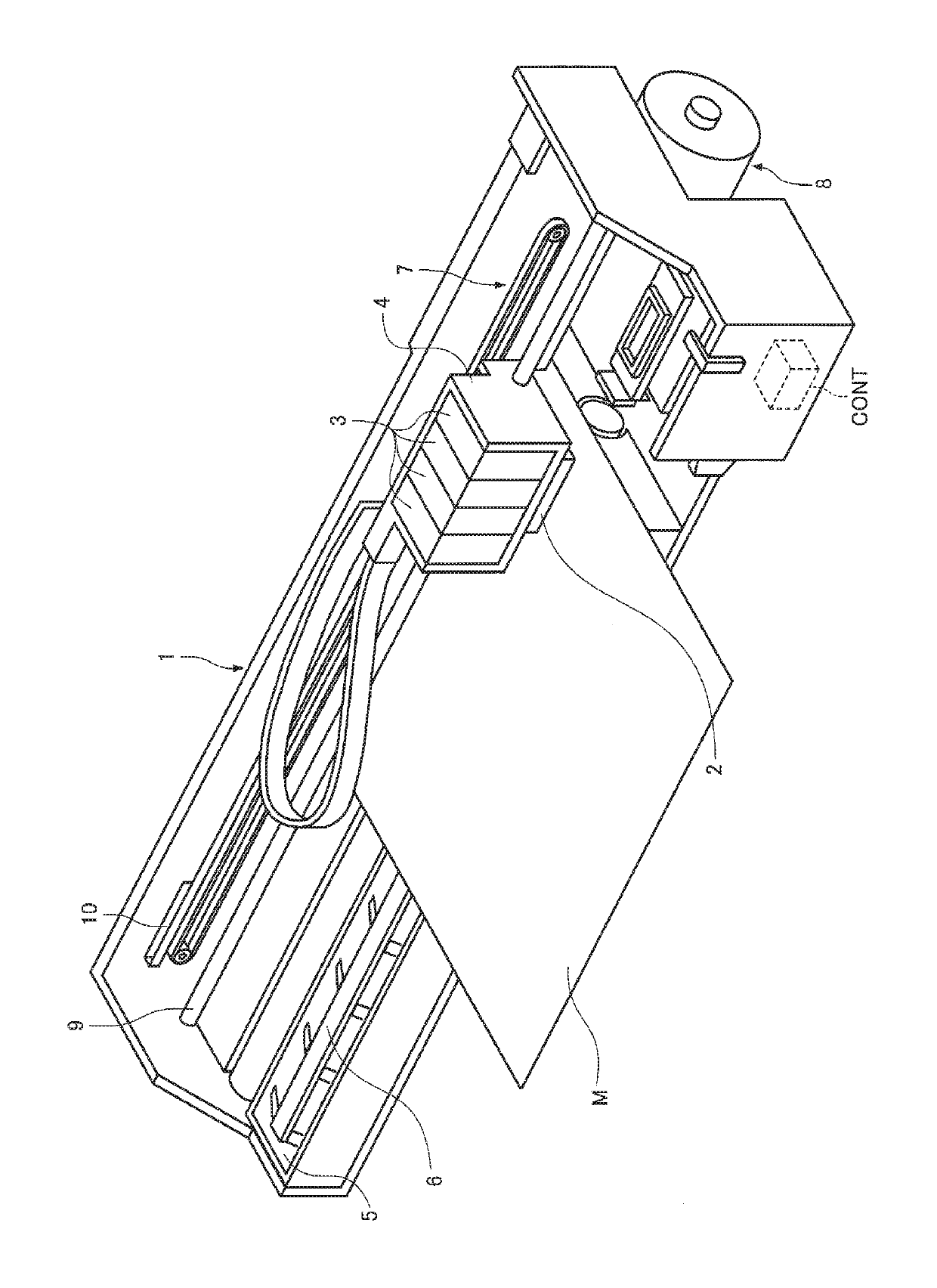

Conductive pattern formation ink, conductive pattern and wiring substrate

InactiveUS20090145638A1Improve reliabilityStably ejectedNanotechConductive layers on insulating-supportsWater basedGas analysis

A conductive pattern formation ink which can be stably ejected in the form of liquid droplets and form a conductive pattern having high reliability, a conductive pattern having high reliability, and a wiring substrate provided with the conductive pattern and having high reliability are provided. The conductive pattern formation ink is used for forming a conductive pattern by ejecting the ink in the form of liquid droplets on a surface of a ceramic molded body using a liquid droplet ejecting method, the ceramic molded body being made of a material containing ceramic particles and a binder. The ink contains a water-based dispersion medium, and metal particles dispersed in the water-based dispersion medium, wherein the water-based dispersion medium contains oxygen molecules and nitrogen molecules, and wherein when the water-based dispersion medium is analyzed using a gas chromatography method, a total amount of the oxygen and nitrogen molecules contained in the water-based dispersion medium is 12 ppm or less.

Owner:SEIKO EPSON CORP

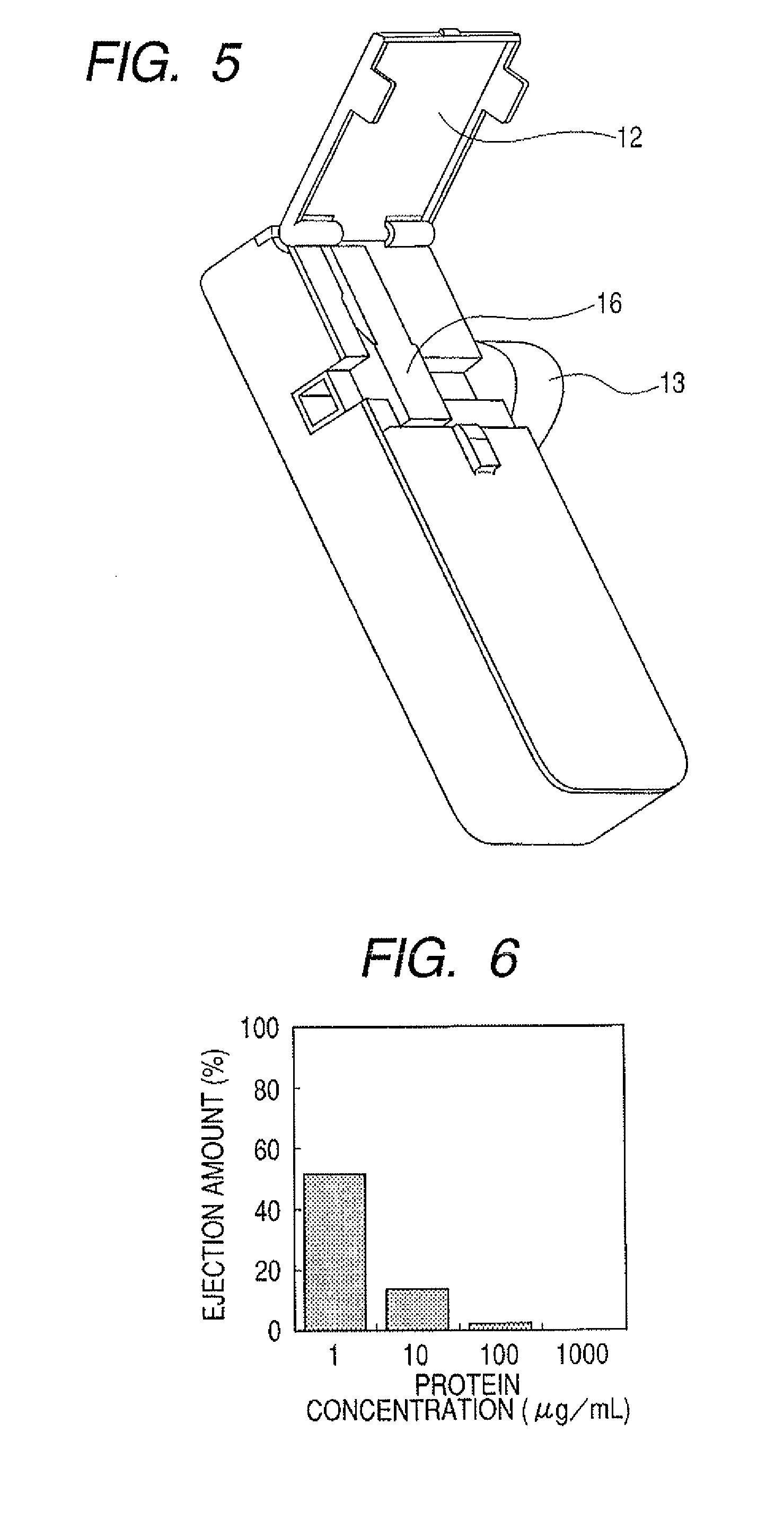

Ejection liquid, ejection method, method of making droplets from liquid, cartridge and ejection device

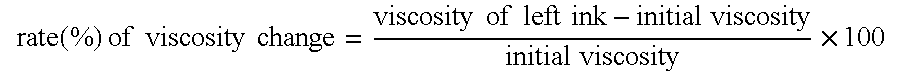

InactiveUS20090060869A1Stably ejectedStabilizing ejectionPowder deliveryPeptide/protein ingredientsThermal energySURFACTANT BLEND

The present invention provides a liquid composition, as an ejection liquid used for stably ejecting liquid droplets, including at least one kind of a protein and a peptide, and a compound having a betaine skeleton by application of thermal energy to the liquid; a method of making droplets form the liquid; and an ejection method and an ejection device suitable for utilizing protein liquid droplets. By adding a compound having a betaine skeleton to an aqueous solution of at least one kind of a protein and a peptide, the liquid composition is improved in stability for ejection by application of thermal energy. Further, a surfactant may be further added to the liquid composition containing the compound having a betaine skeleton, and in this case the effect of stable ejection can be obtained.

Owner:CANON KK

Aqueous ink composition and image forming method

InactiveUS20140313268A1Excellently and uniformly dissolveHigh resolutionInksOrganic dyesOrganic solventPolymer chemistry

The aqueous ink composition contains (A) a polymer that has an SP value of 18.6 to 20 and contains a hydrophilic group-containing repeating unit (a1) of 5% to 45% by mass, (B) a pigment, (C) water, and (D) an organic solvent represented by the following Formula (I).

Owner:FUJIFILM CORP

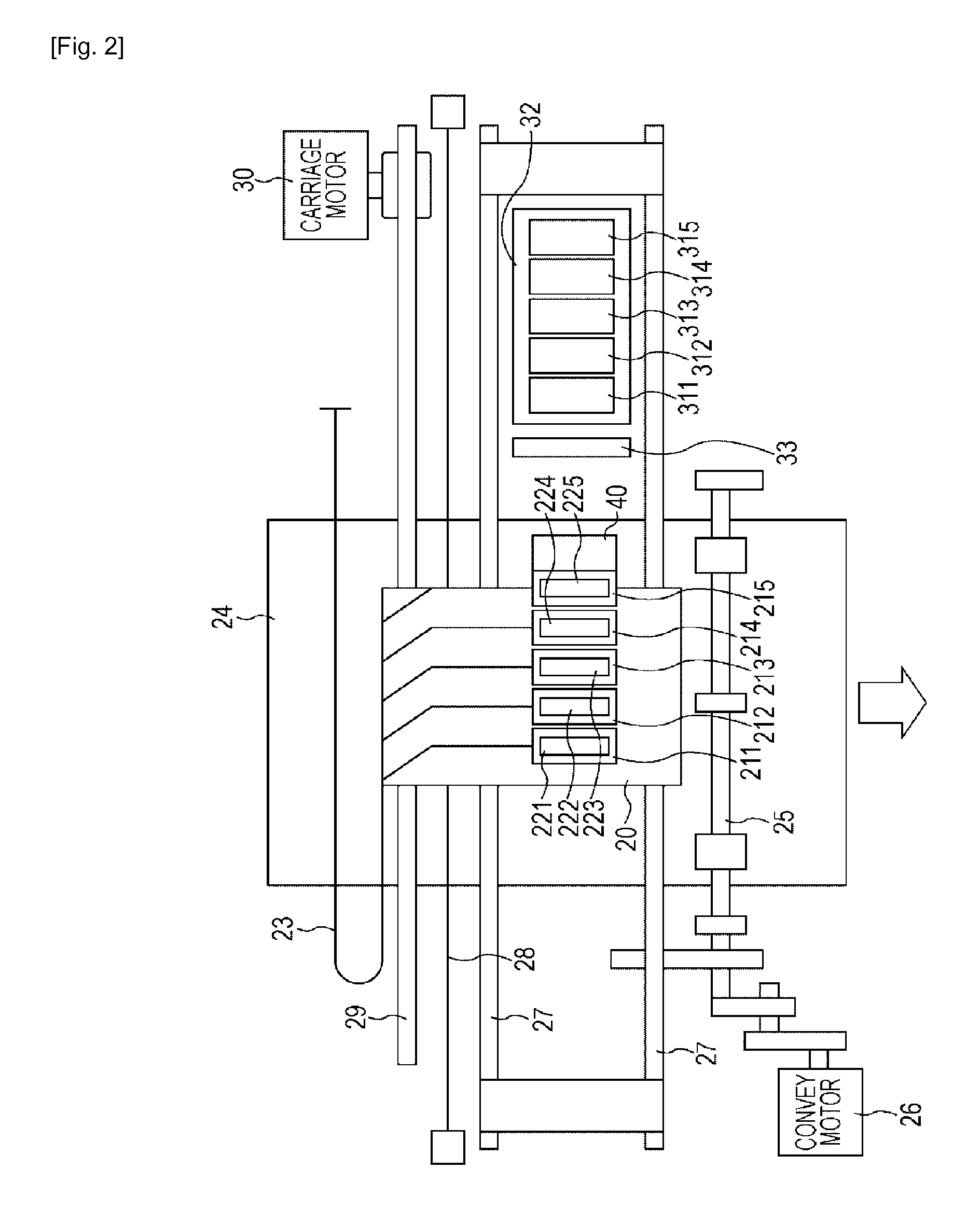

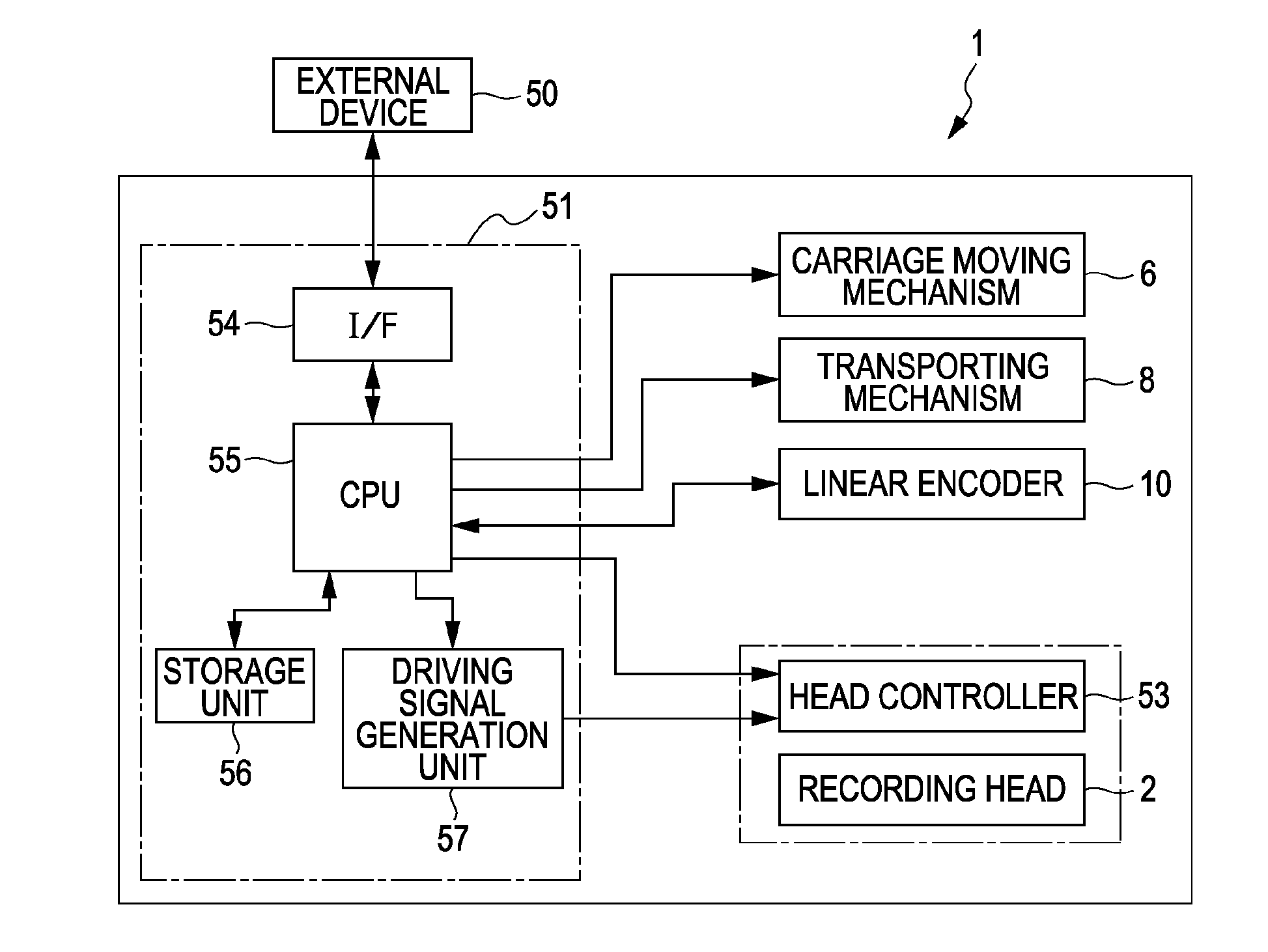

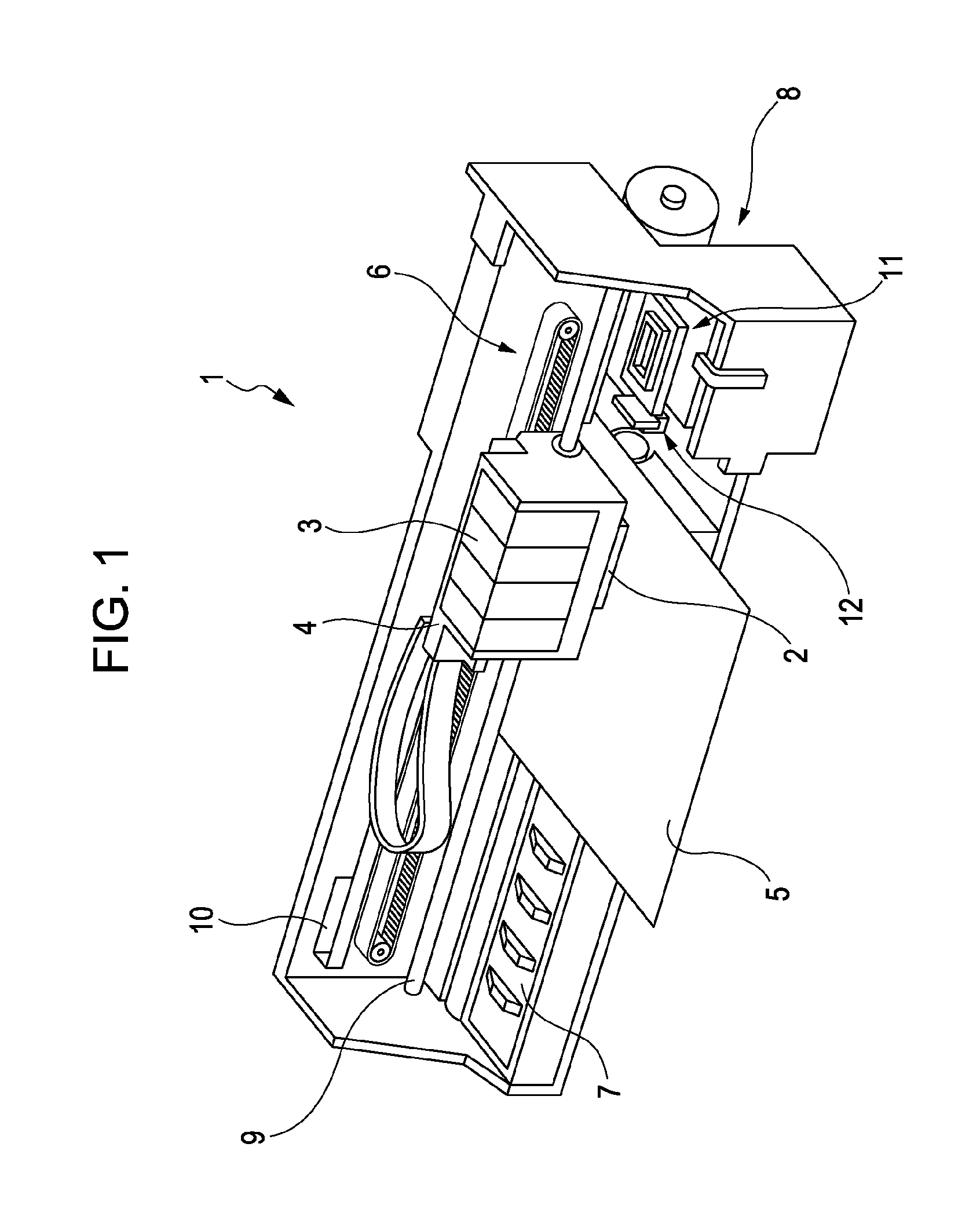

Inkjet recording method, inkjet recording device, and recorded material

ActiveUS8899711B2Enhance the imageStably ejectedMeasurement apparatus componentsInksSignal generatorRecording head

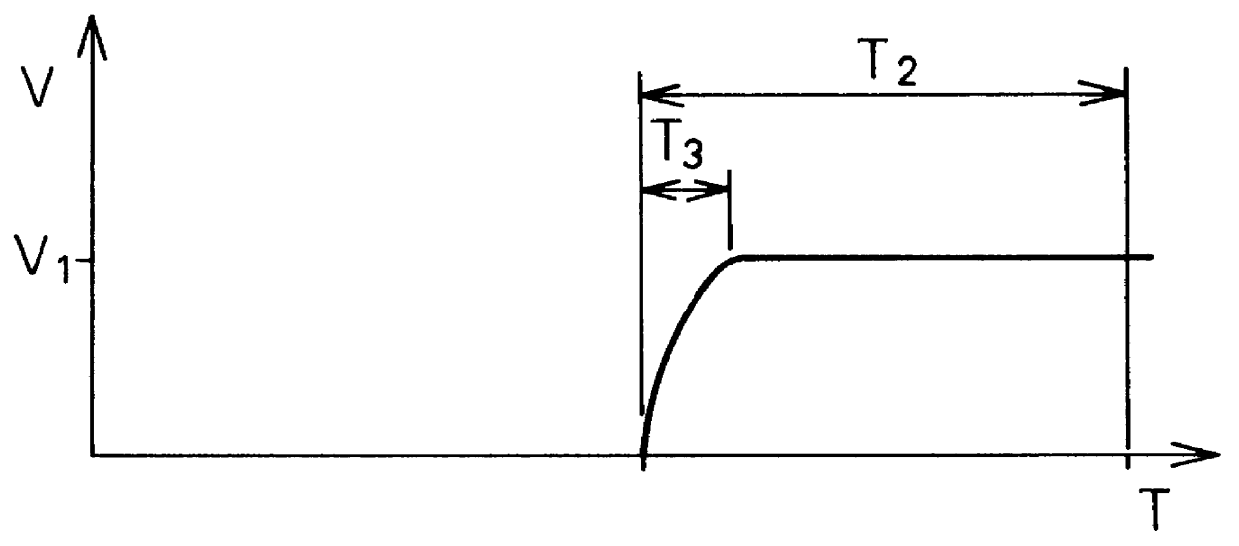

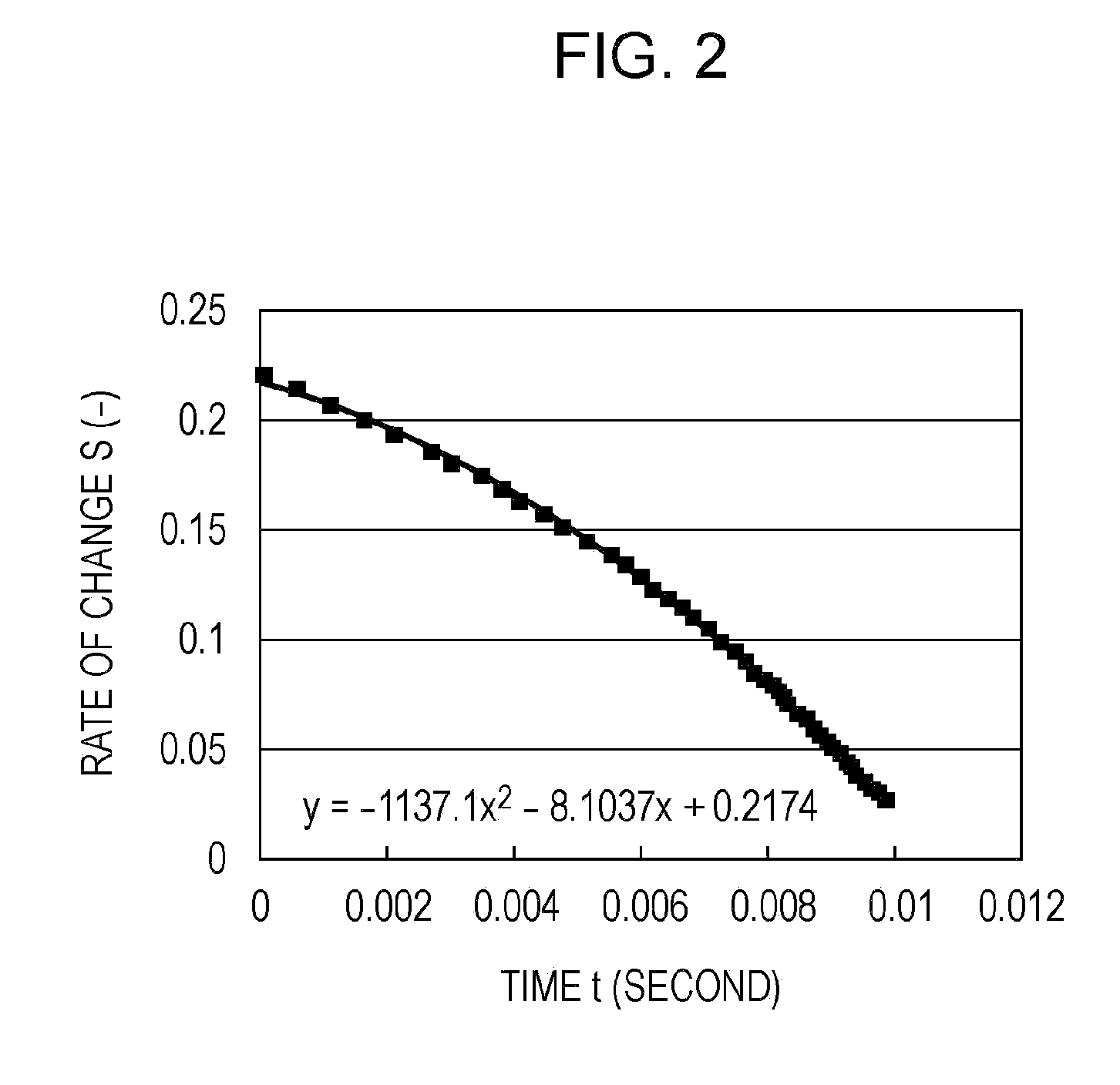

An inkjet recording method is performed using an inkjet recording device including a recording head provided with a nozzle, a pressure chamber, a pressure generator and a driving signal generator, the method satisfying the following requirements (1) and (2): (1) it is required to use aqueous ink having a dynamic surface tension larger by 10 mN / m or more than a static surface tension when the surface life measured at 25° C. by a maximum foaming pressure method is 15 ms and a dynamic surface tension larger by 5 mN / m or more than a static surface tension when the surface life measured by a maximum foaming pressure method is 1500 ms and (2) it is required that the signals have a drawing pulse in one print period and a meniscus of the aqueous ink is drawn into the nozzle in two stages by the drawing pulse.

Owner:RICOH KK

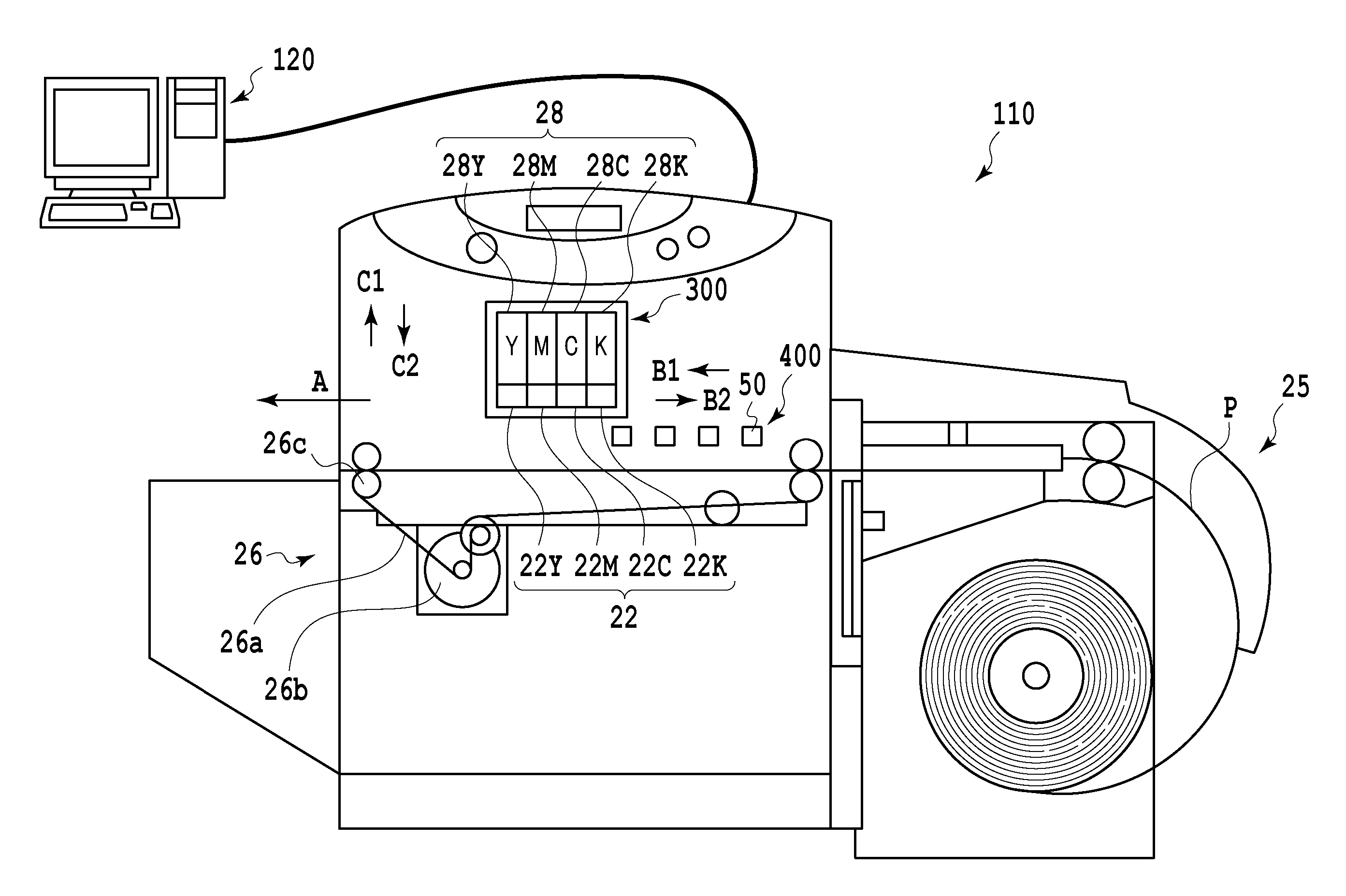

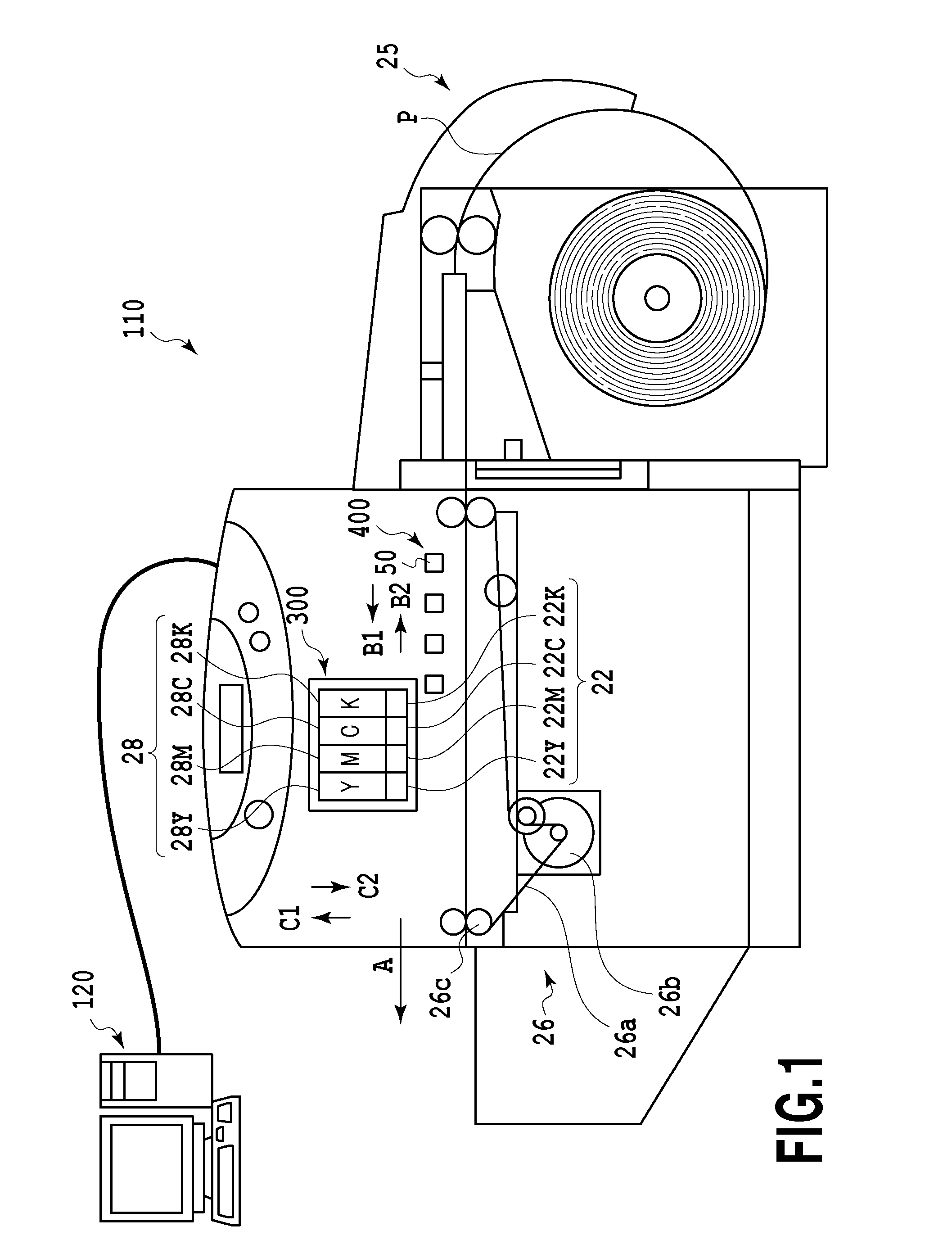

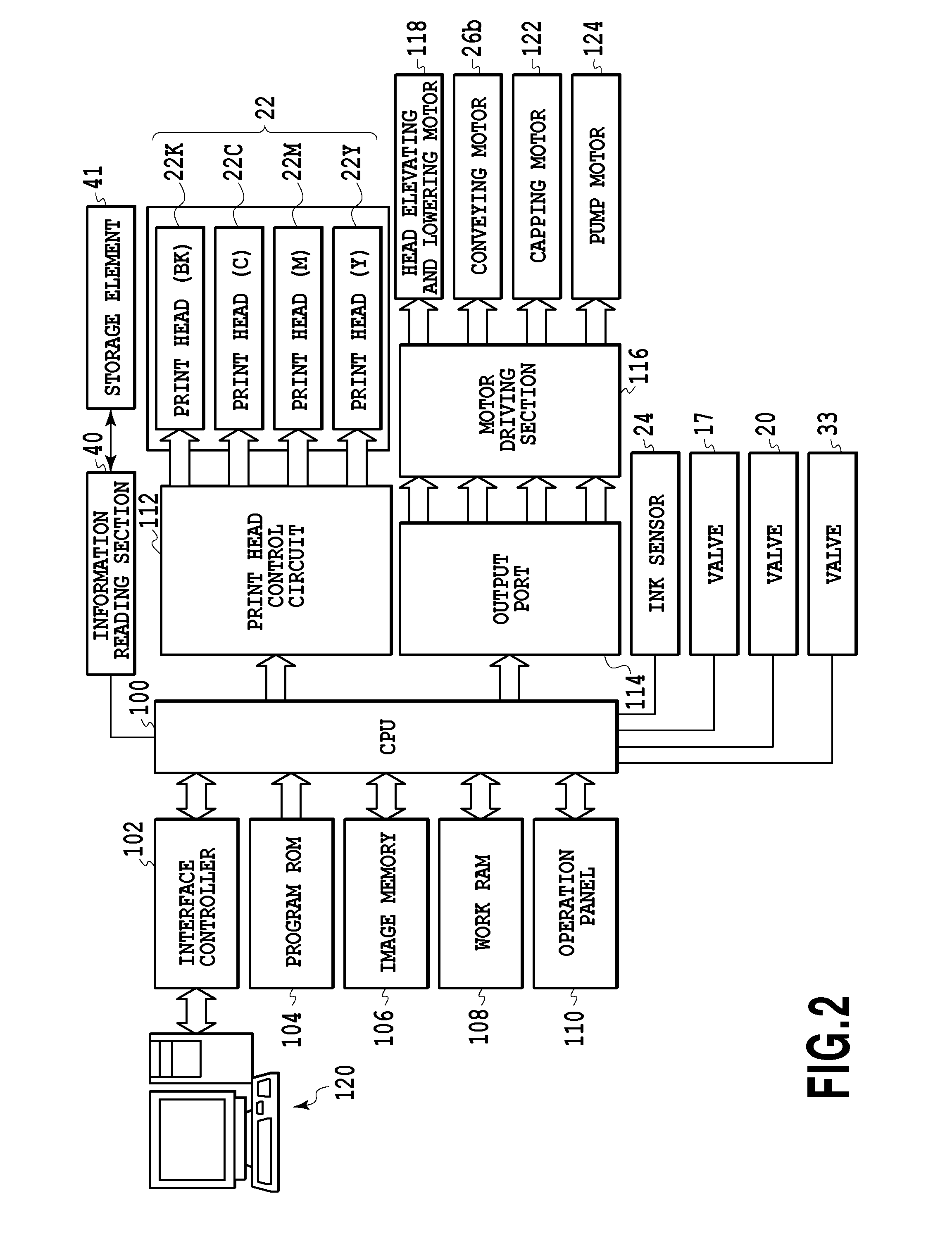

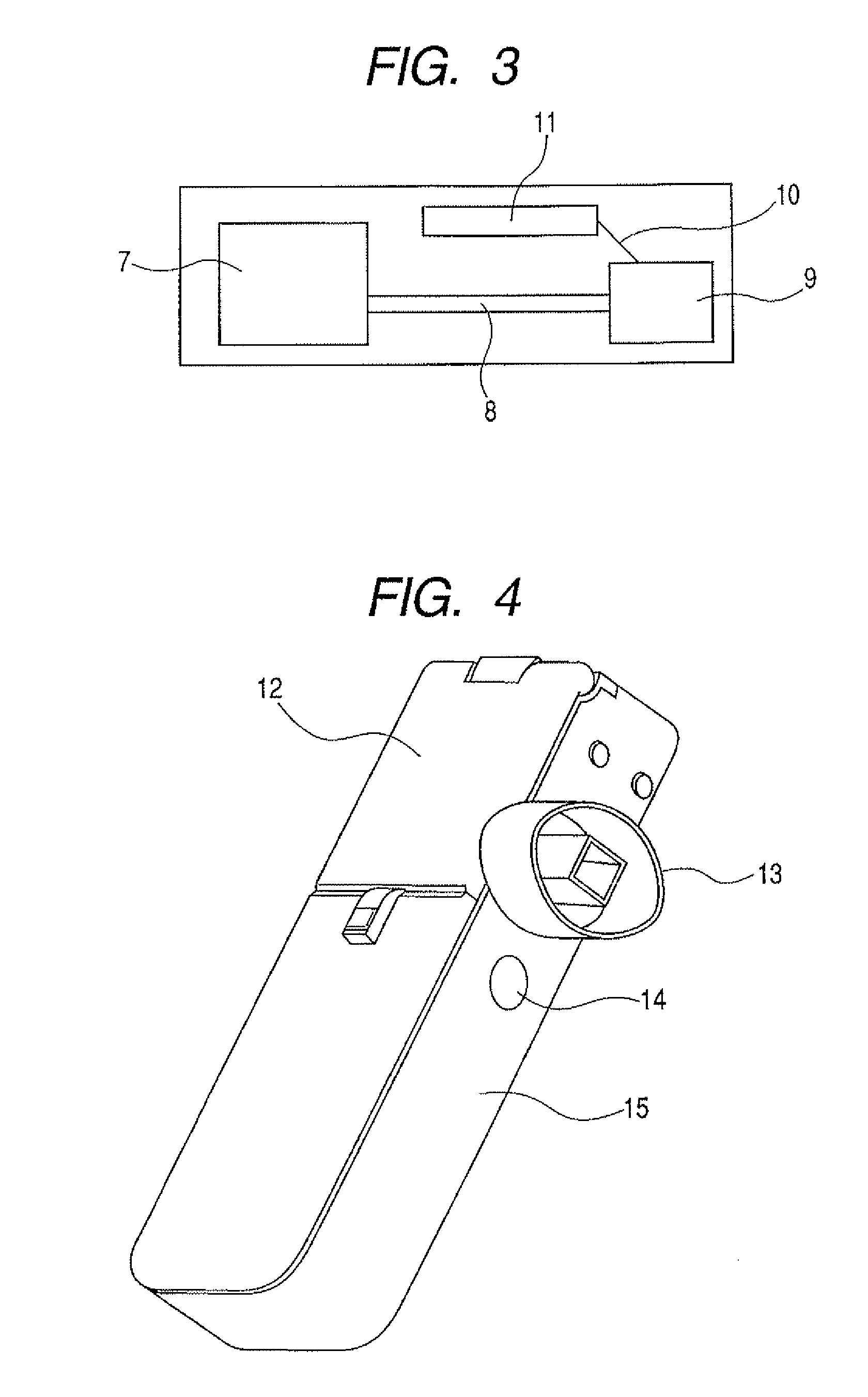

Ink jet printing apparatus and ink jet printing method

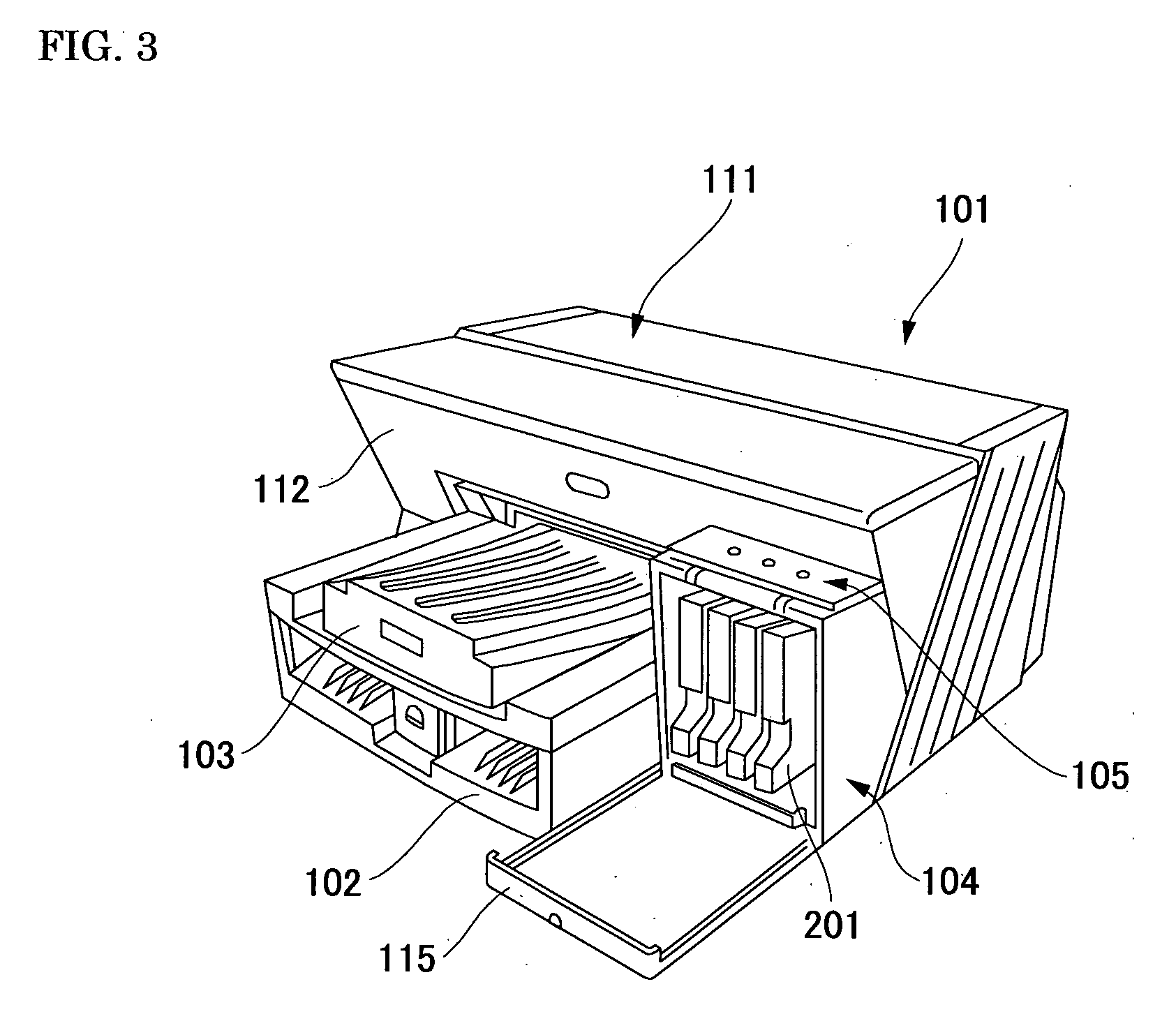

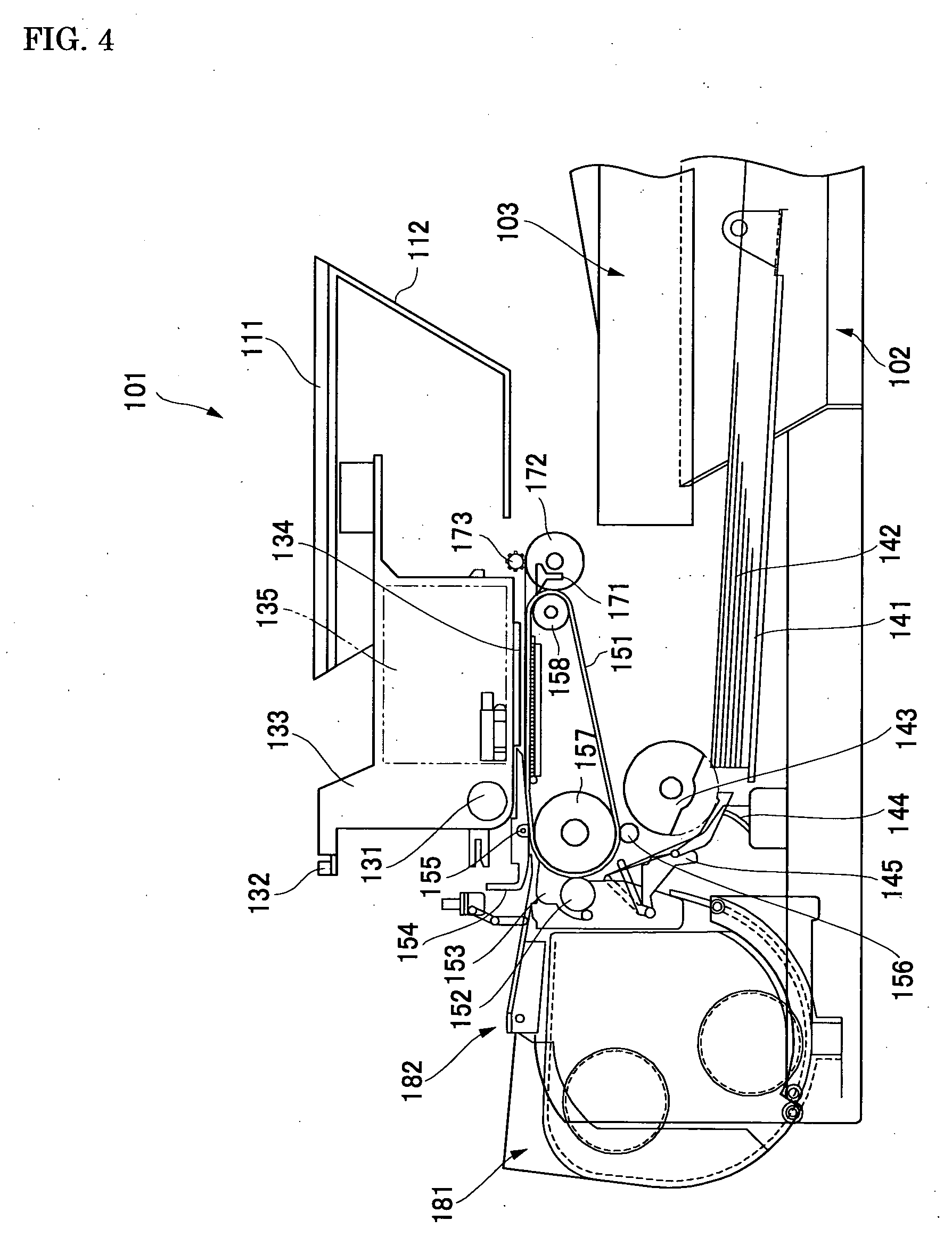

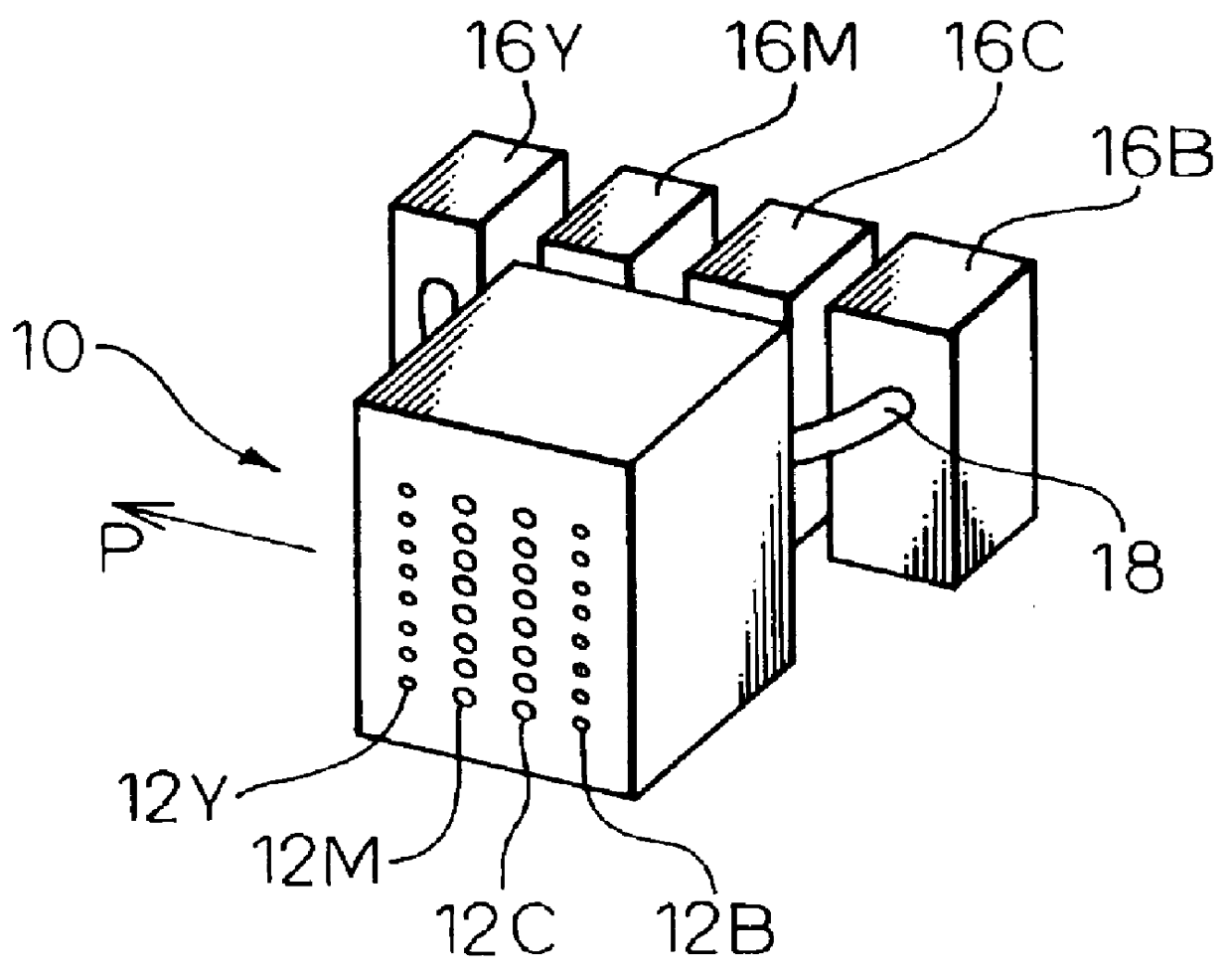

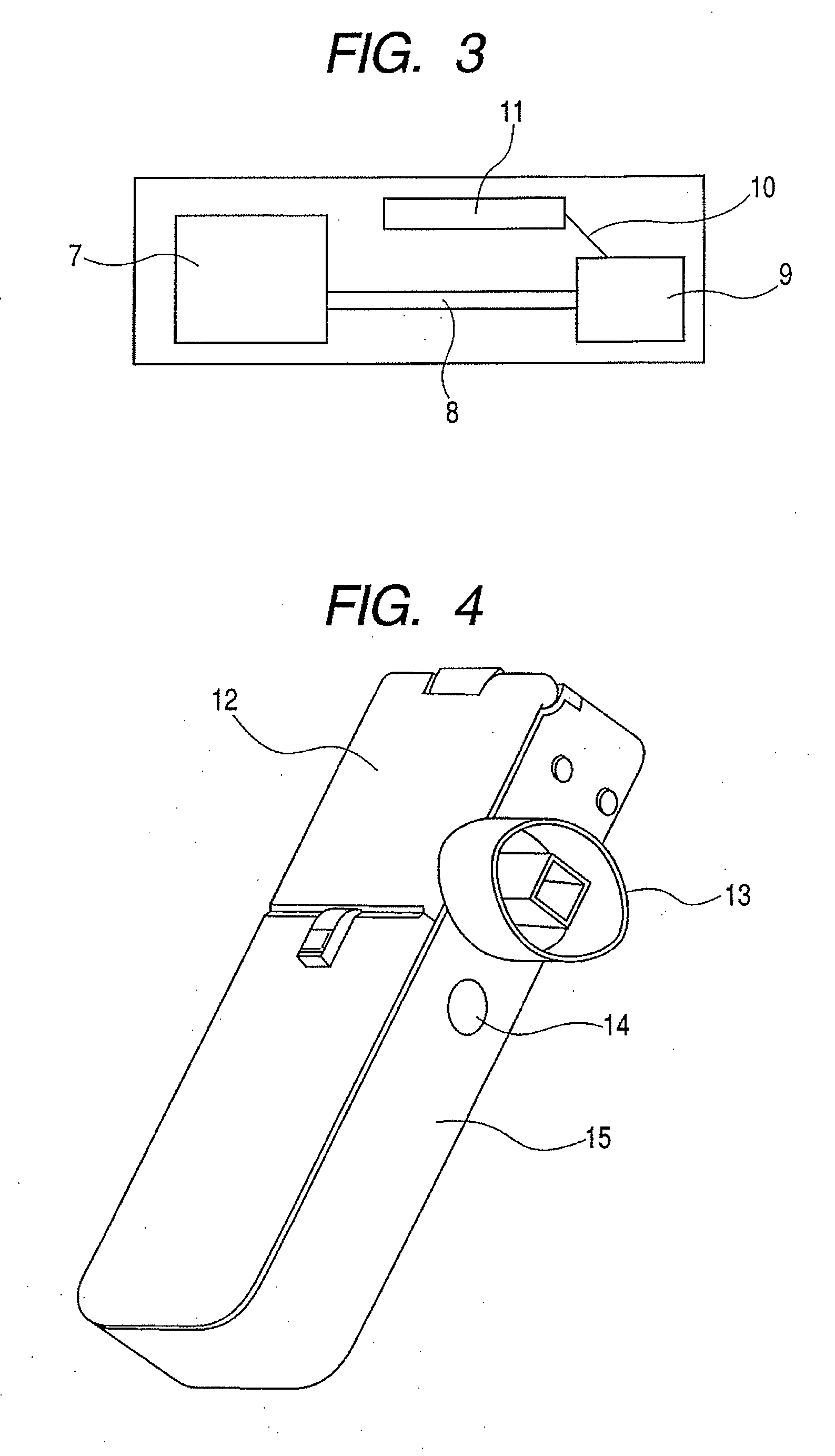

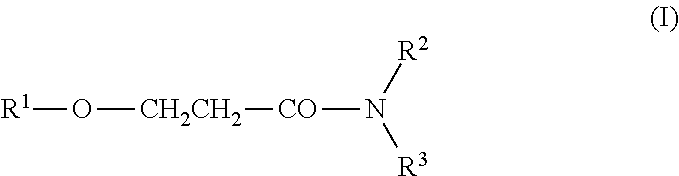

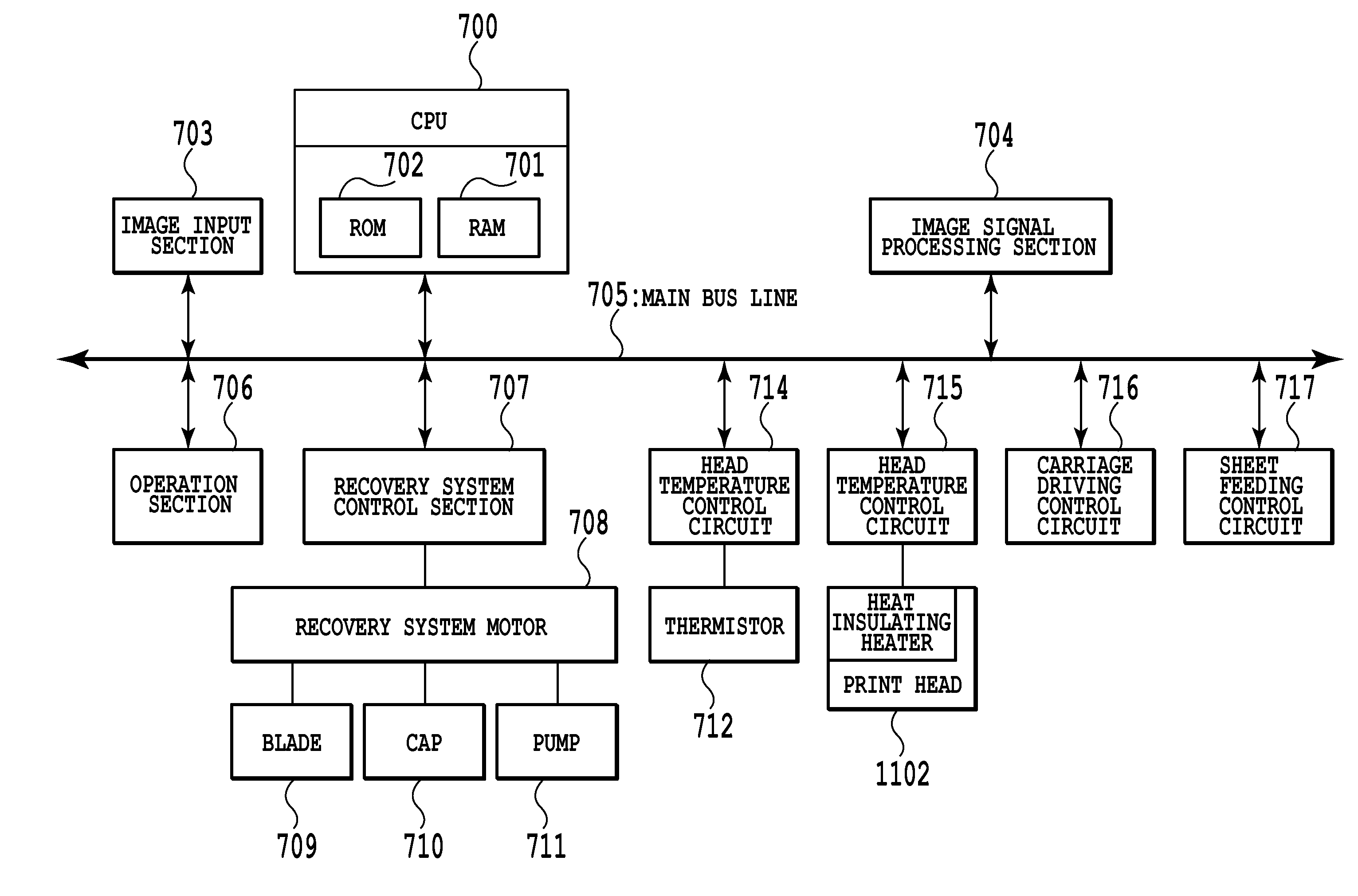

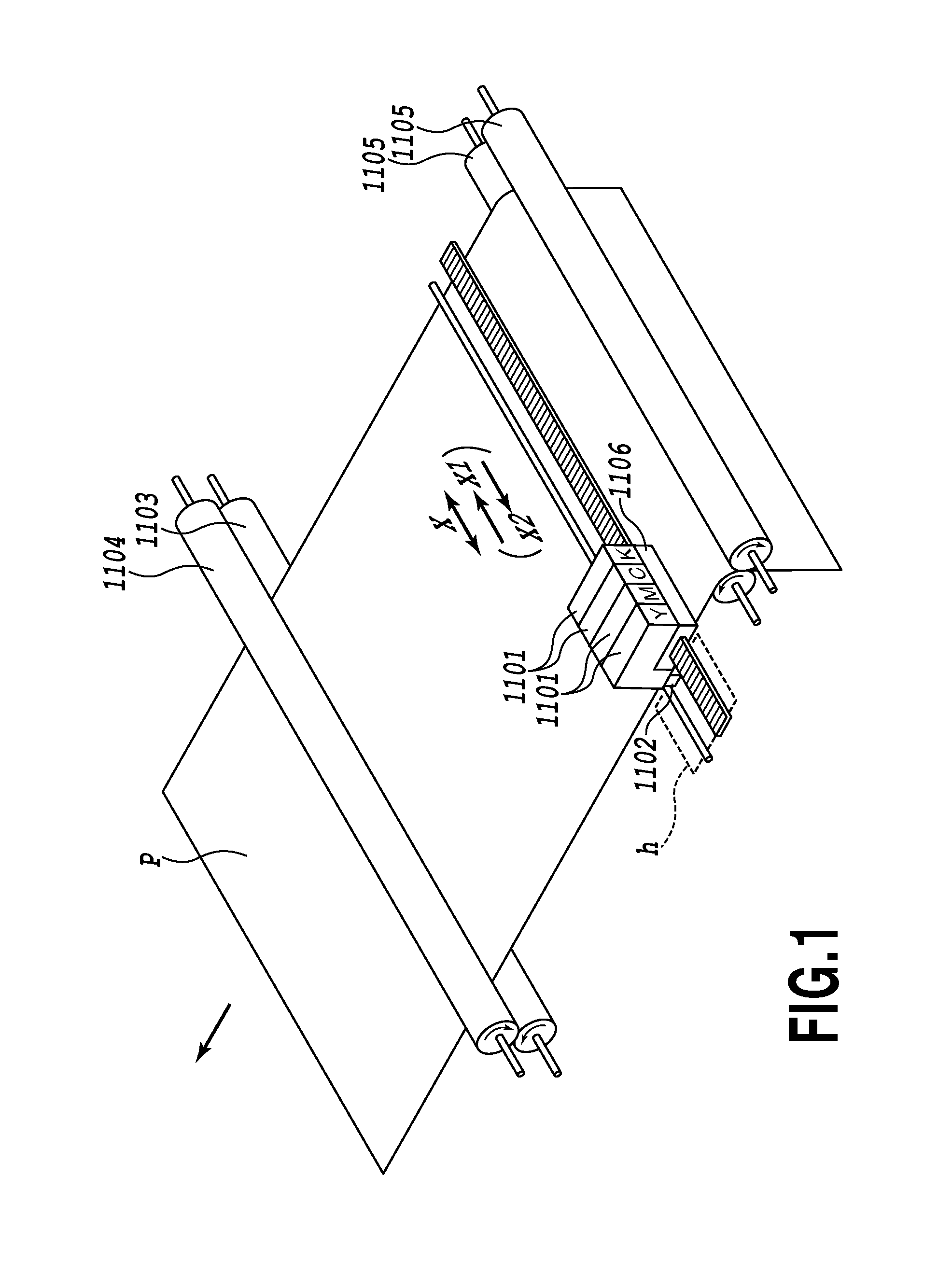

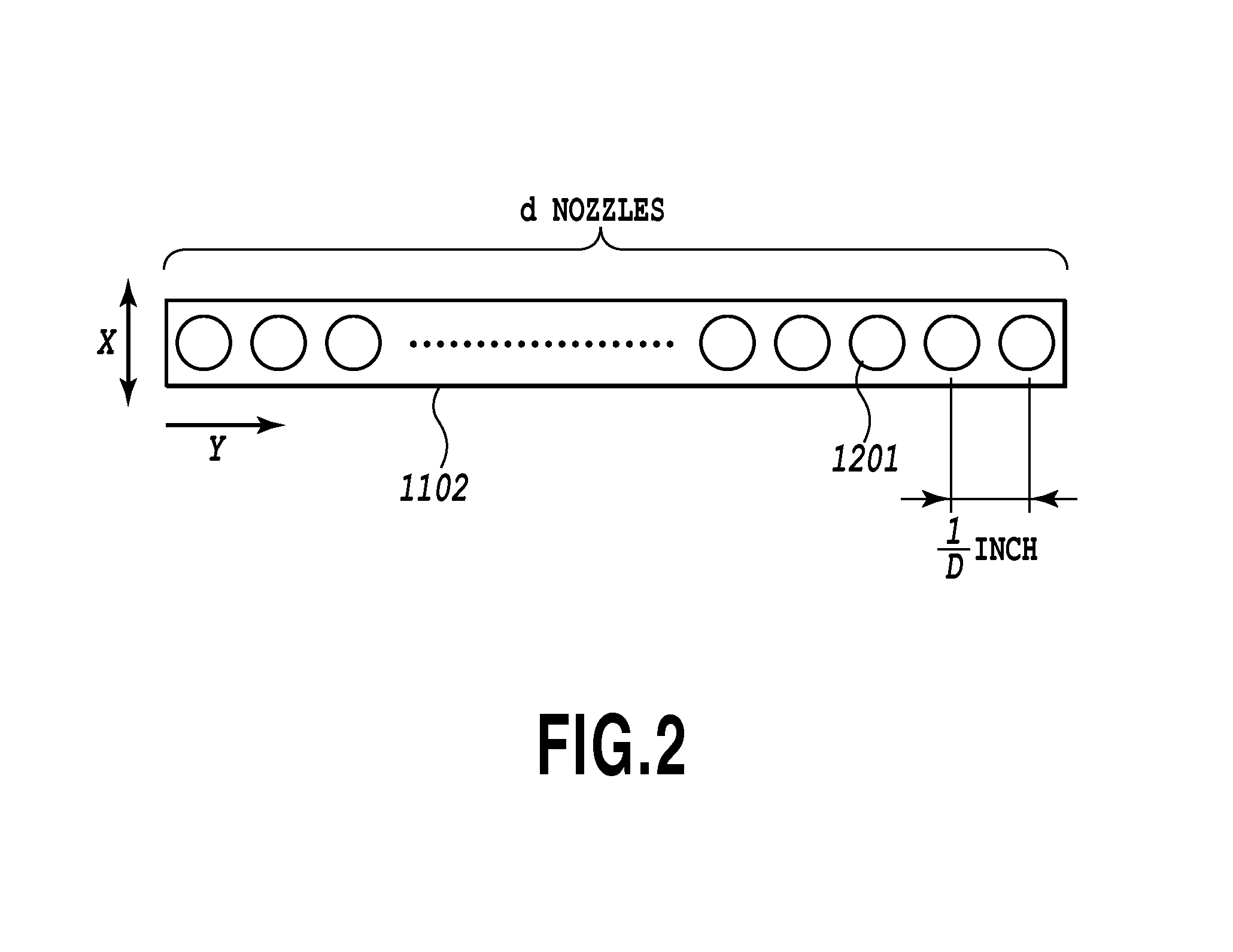

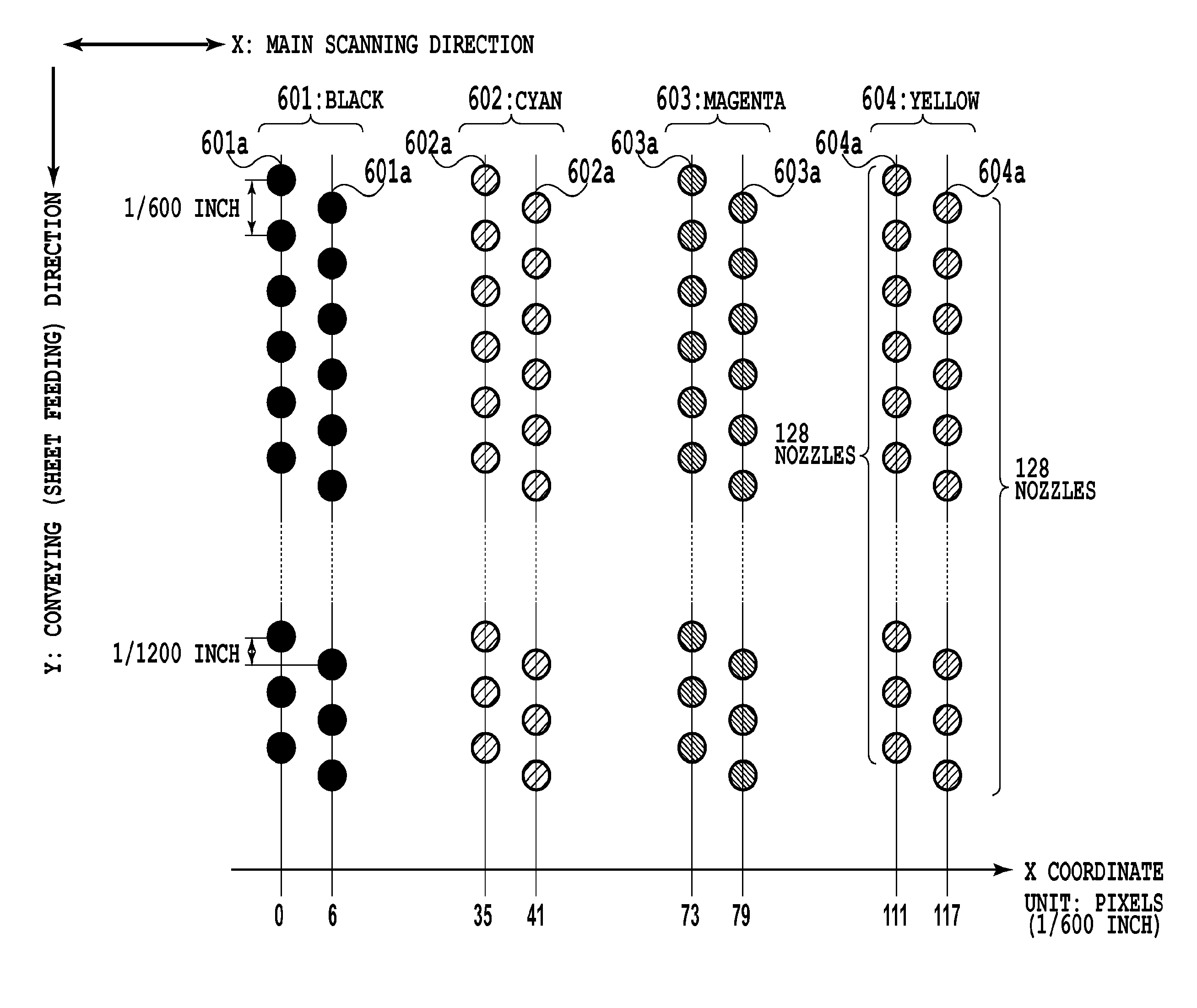

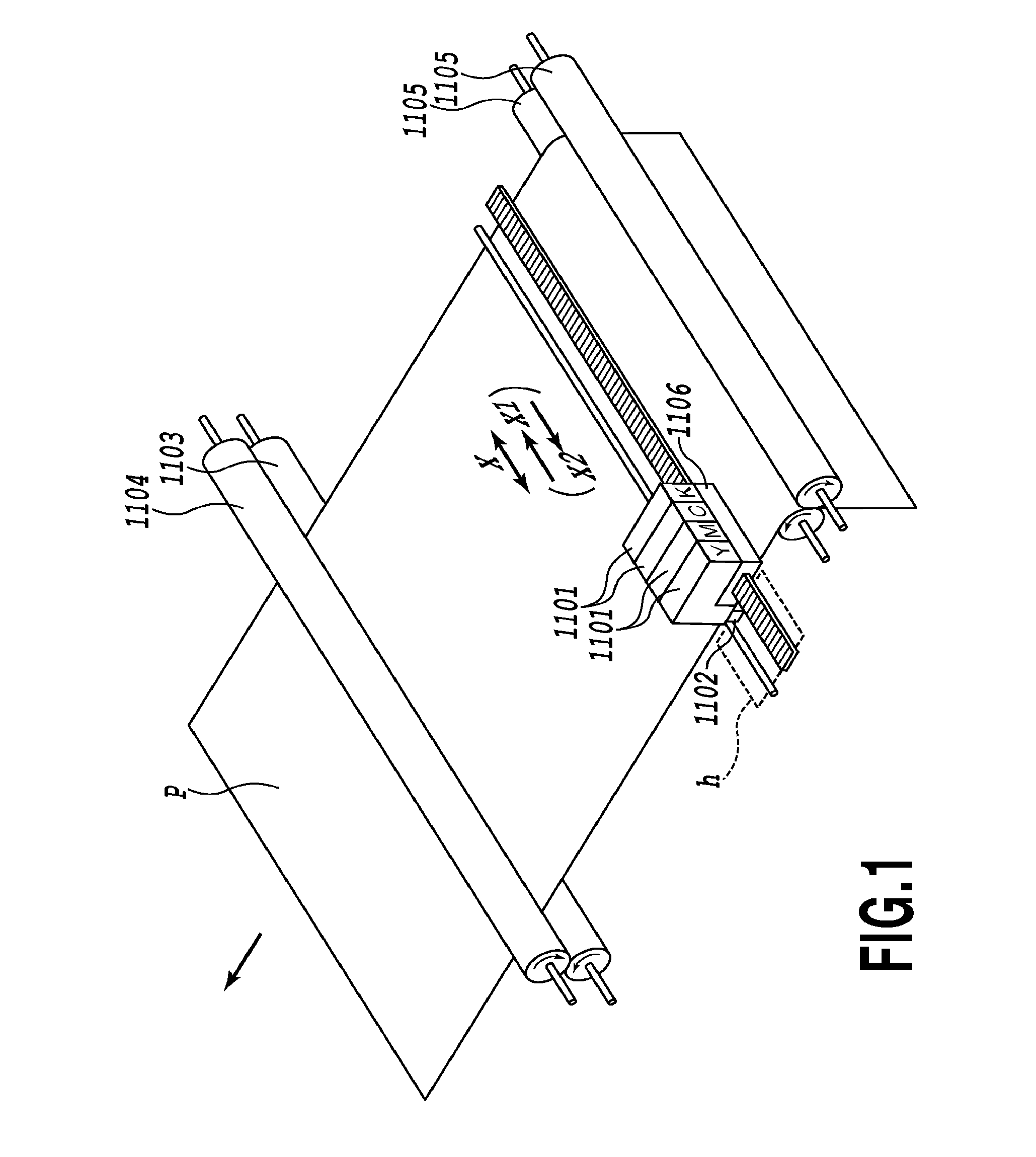

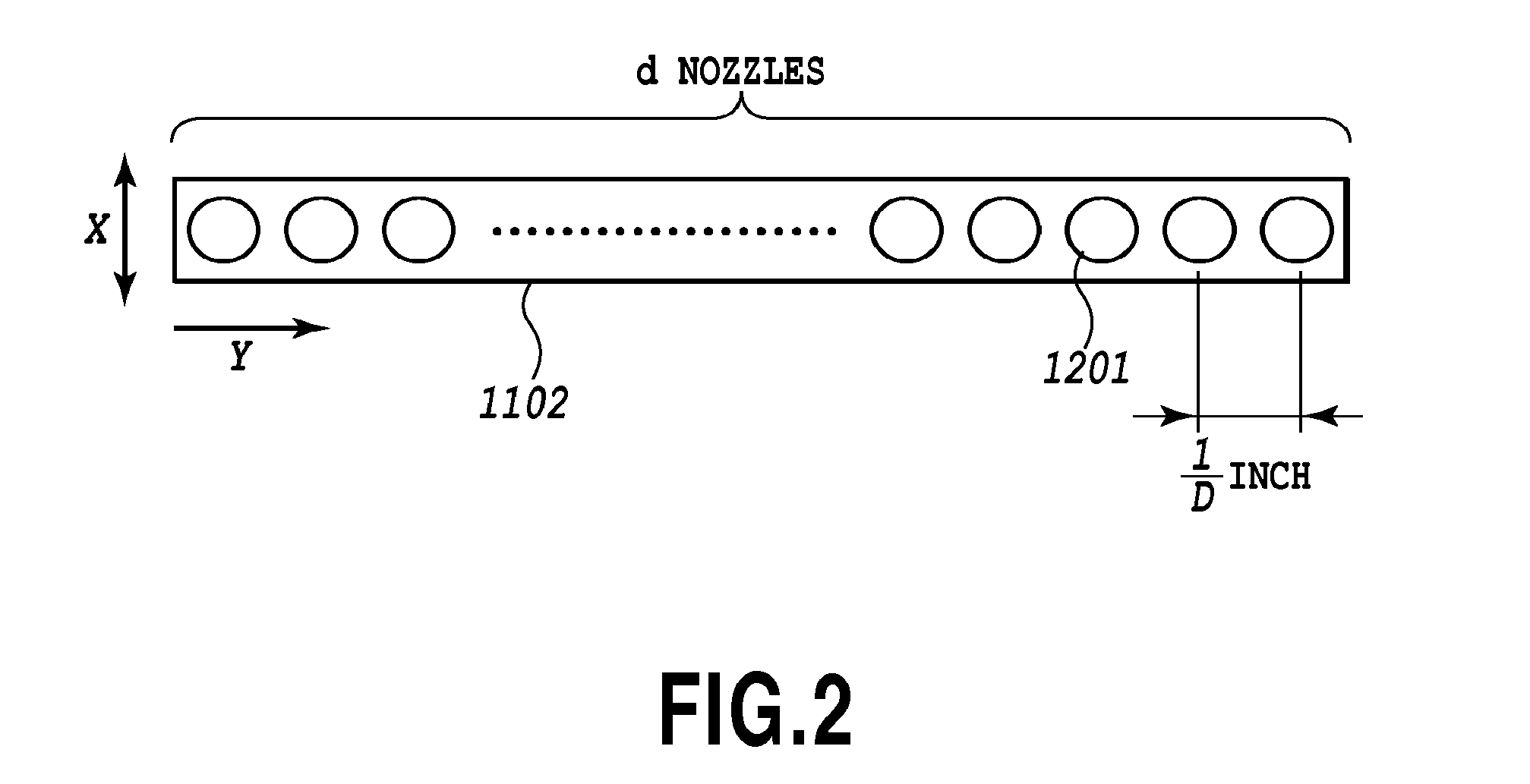

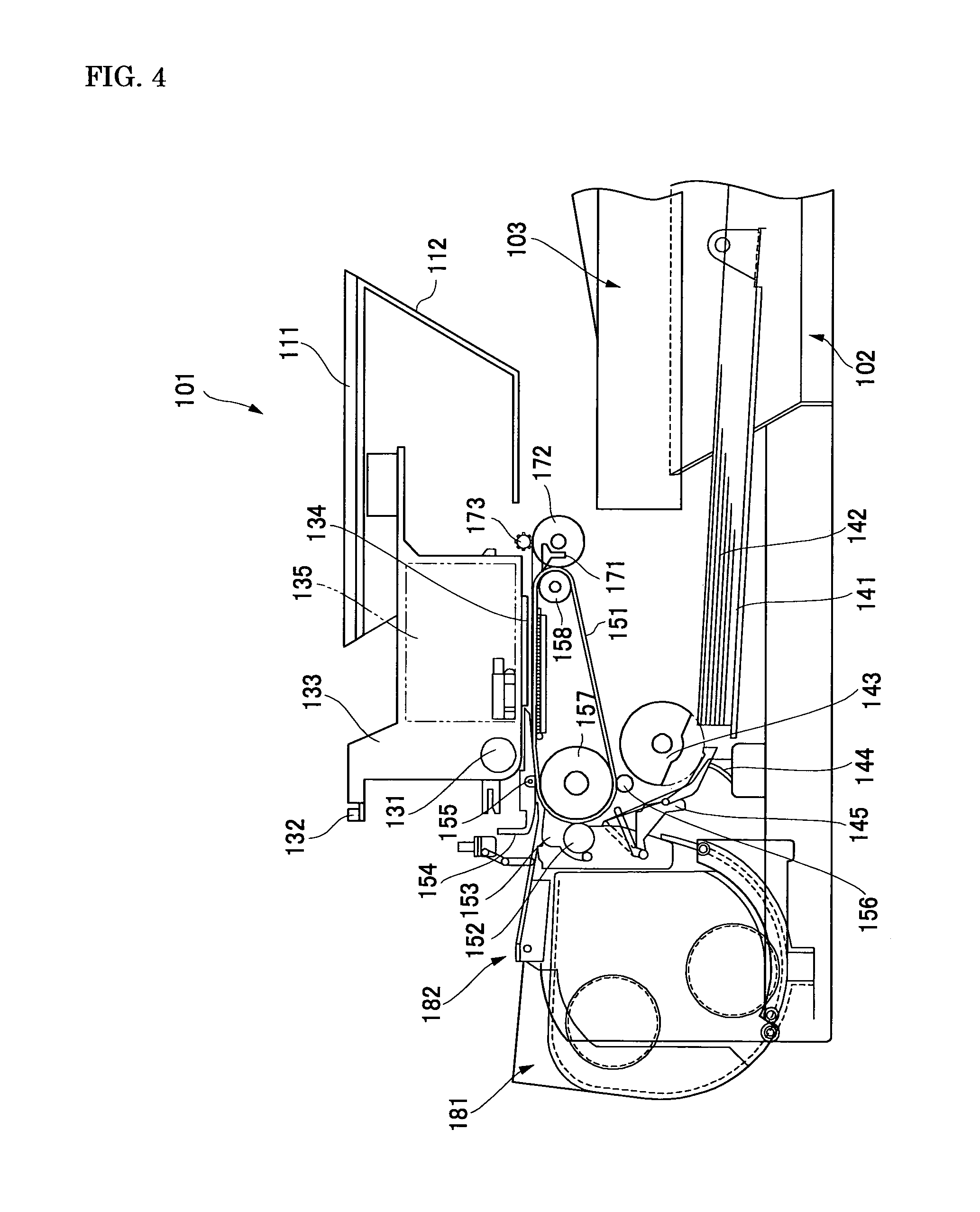

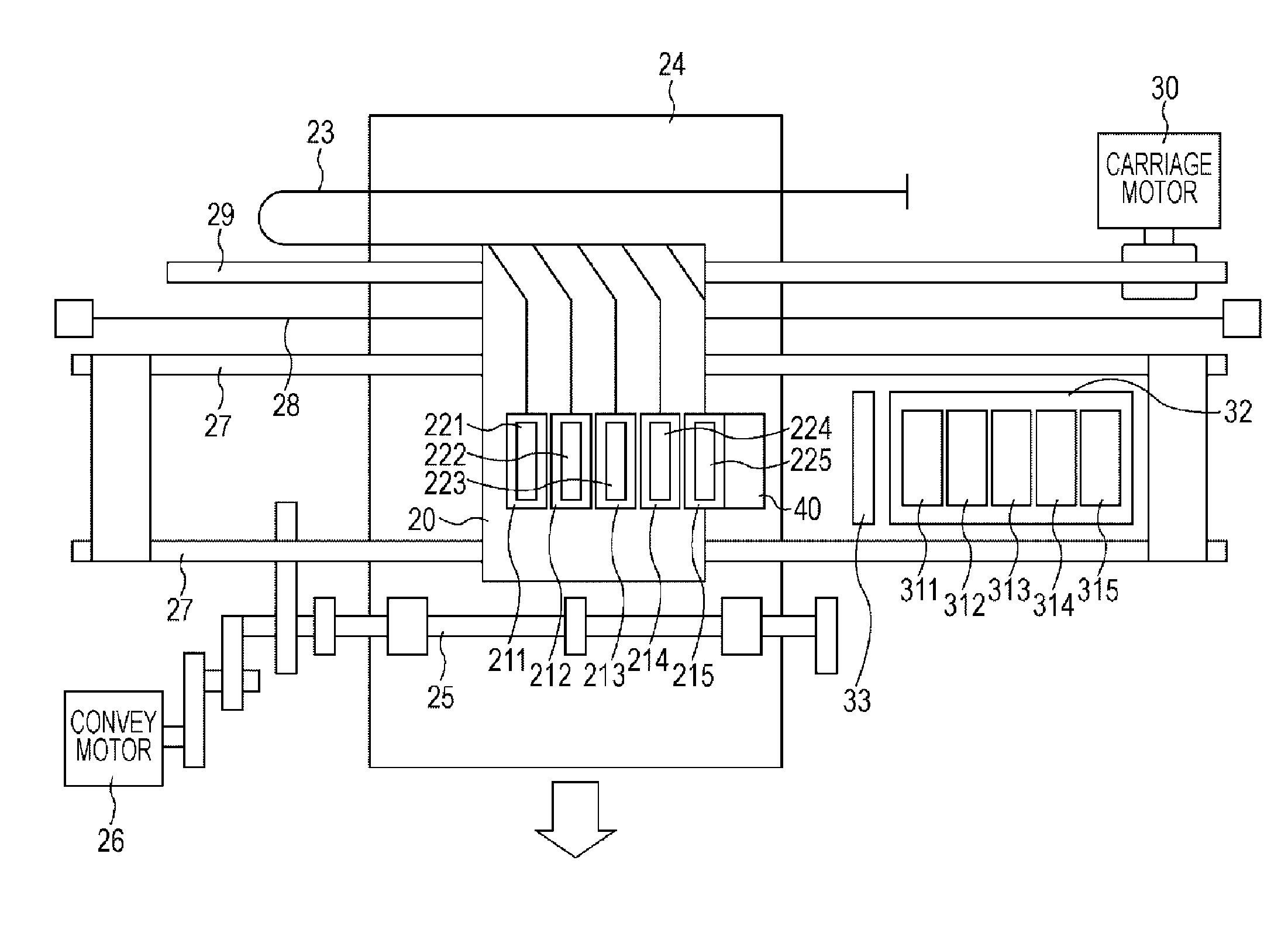

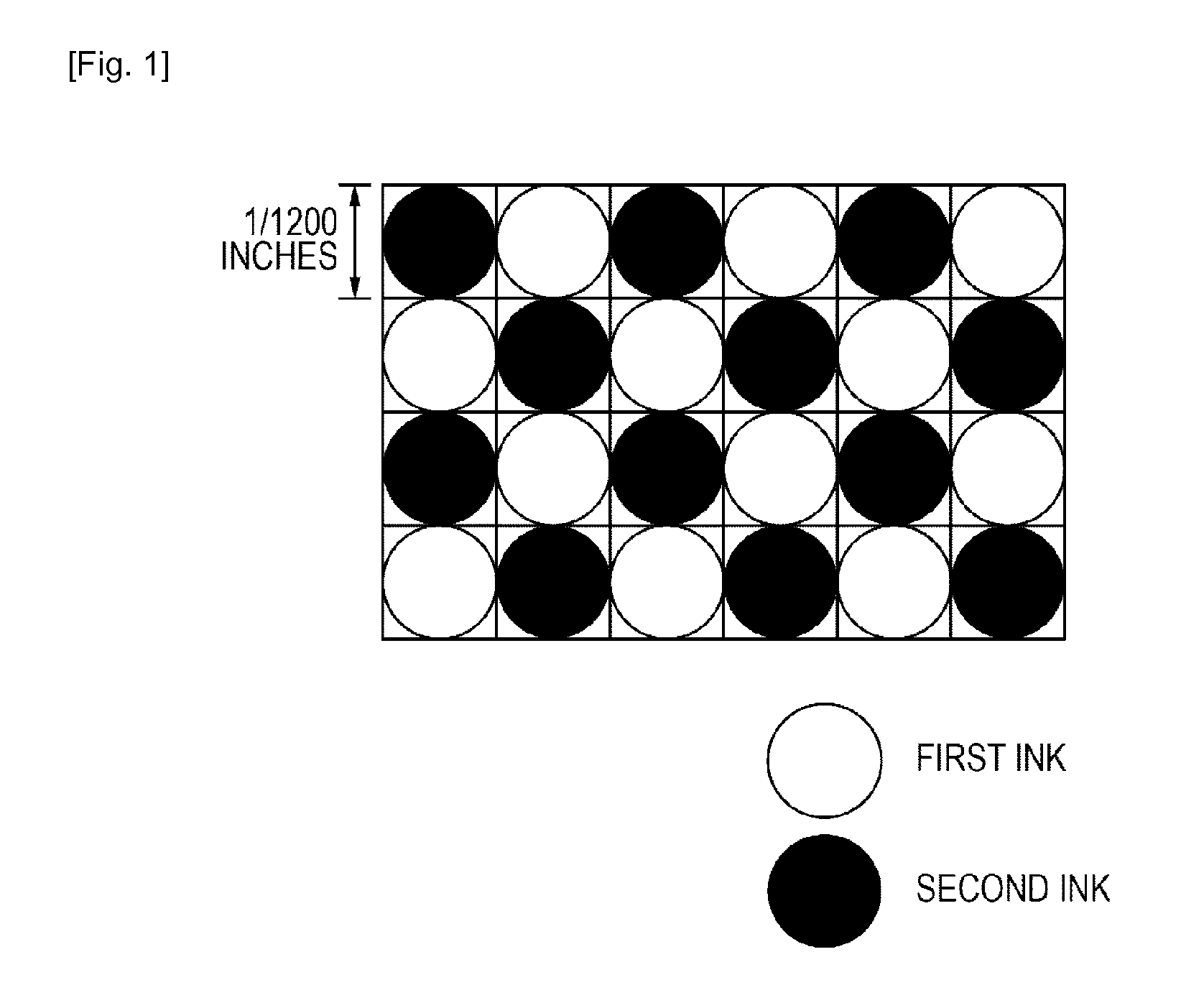

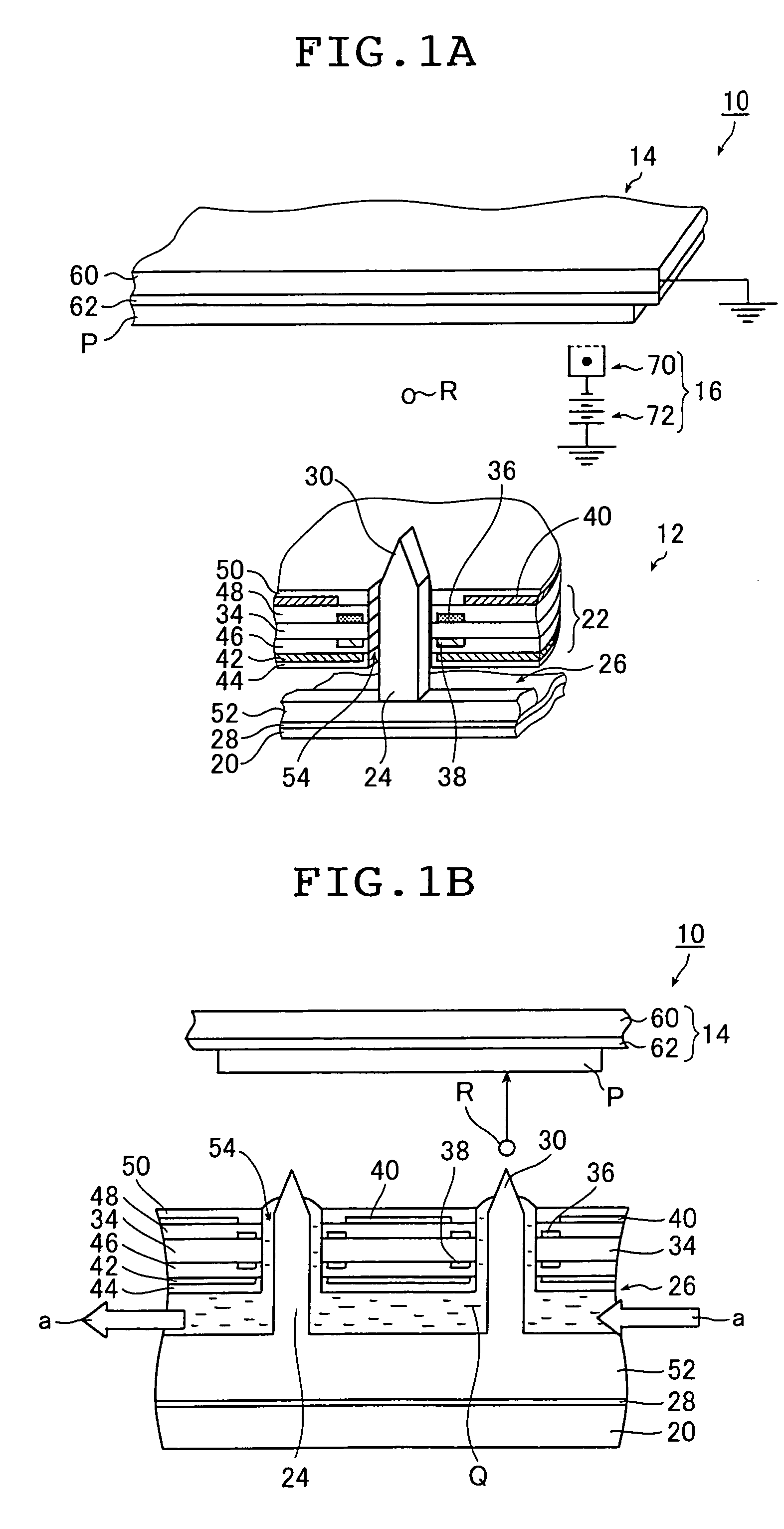

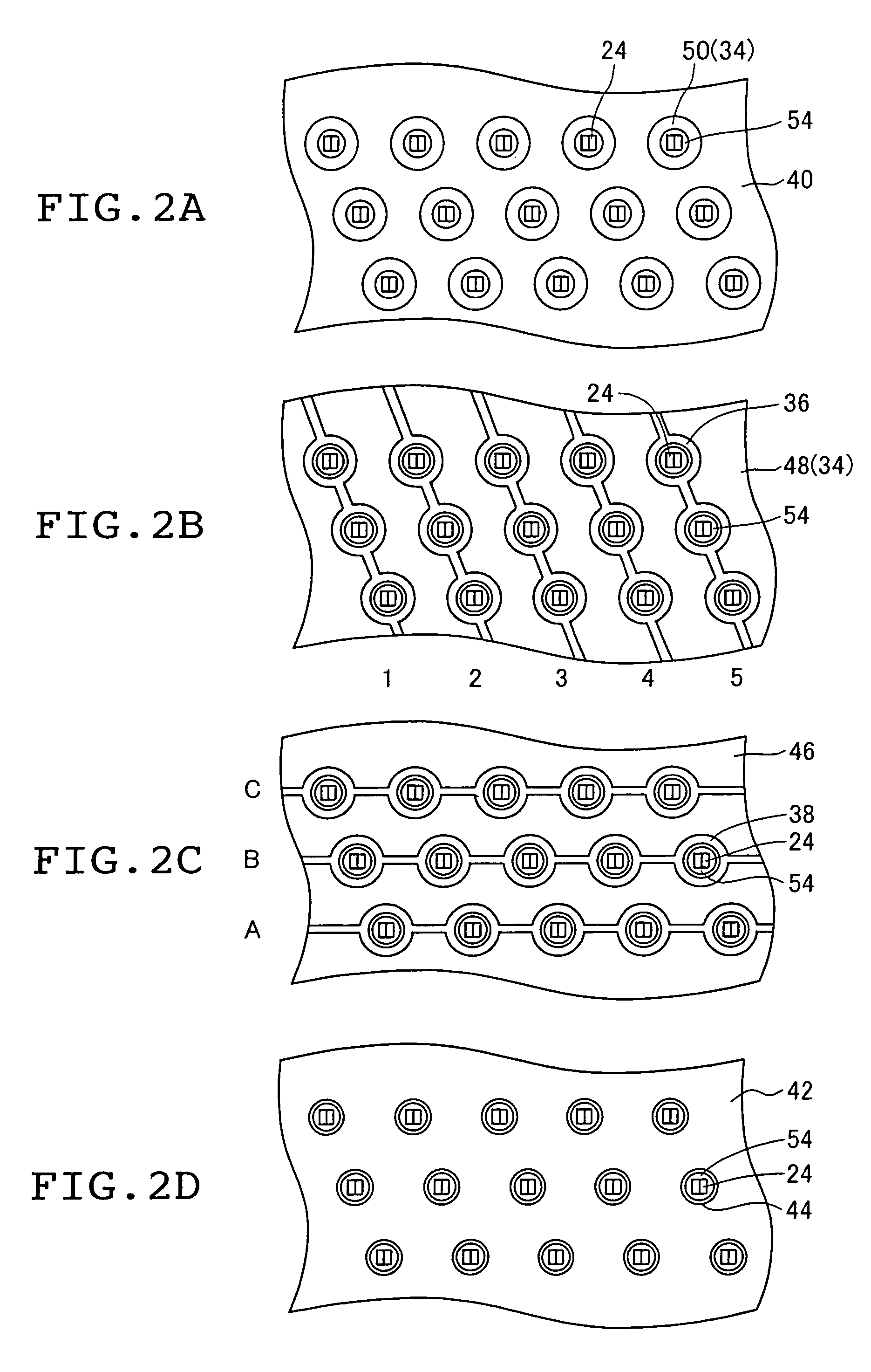

InactiveUS20090015612A1Reduce in quantityStably ejectedElectrographic process apparatusOther printing apparatusEngineeringElectrical and Electronics engineering

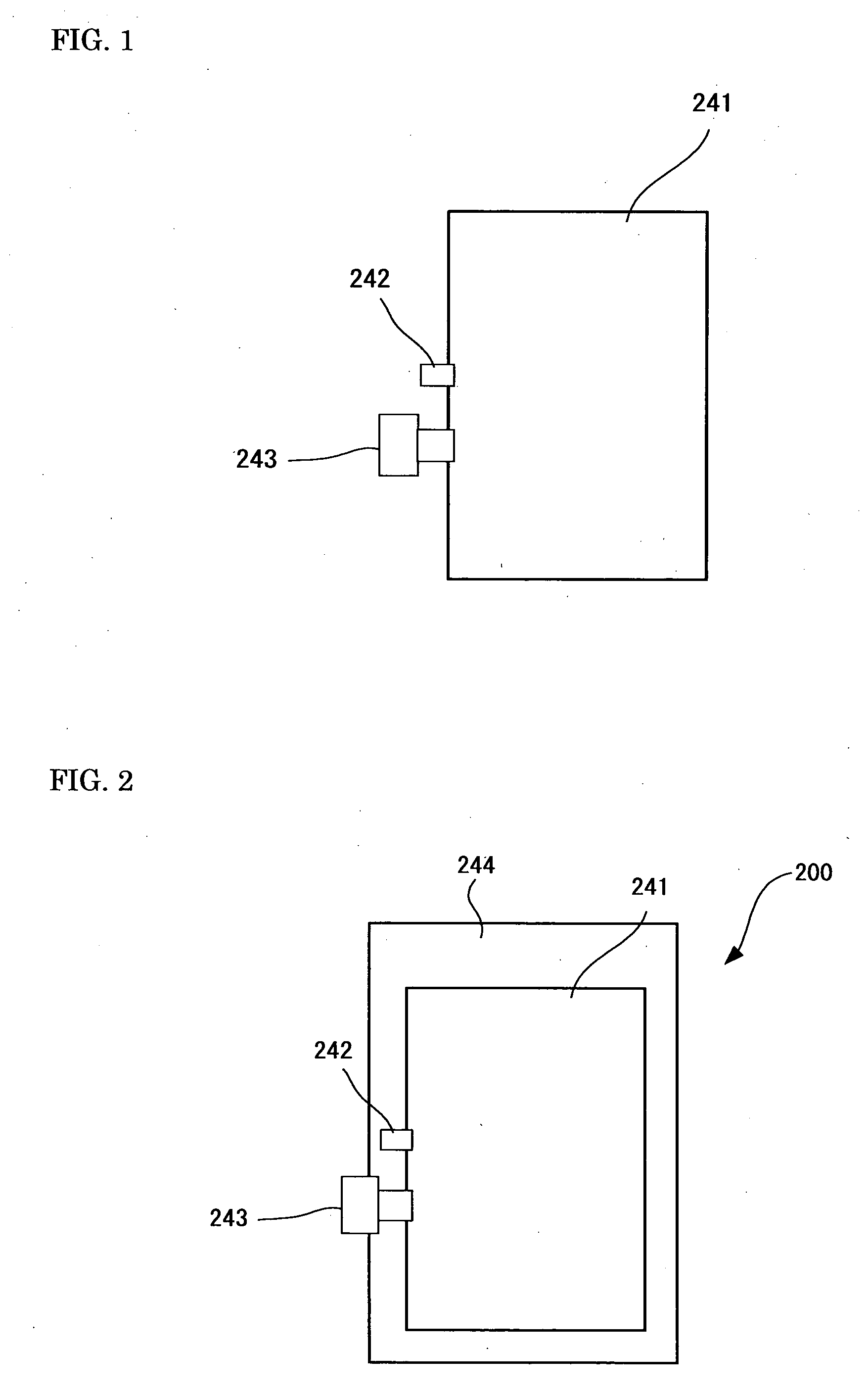

The present invention provides an ink jet printing apparatus and an ink jet printing method which are based on the multi-pass printing method using a print head having a plurality of nozzle rows and which enables a reduction in the number of nozzles to be simultaneously driven, allowing ink to be stably ejected. On the basis of the multi-pass printing method of dividing print data into a plurality of pieces by using mask patterns, the mask patterns are offset according to the positional relationship between the plurality of nozzle rows in the print head.

Owner:CANON KK

Ink jet printing apparatus and ink jet printing method

InactiveUS20130241997A1Reduce in quantityStably ejectedElectrographic process apparatusPrintingElectrical and Electronics engineeringNozzle

The present invention provides an ink jet printing apparatus and an ink jet printing method which are based on the multi-pass printing method using a print head having a plurality of nozzle rows and which enables a reduction in the number of nozzles to be simultaneously driven, allowing ink to be stably ejected. On the basis of the multi-pass printing method of dividing print data into a plurality of pieces by using mask patterns, the mask patterns are offset according to the positional relationship between the plurality of nozzle rows in the print head.

Owner:CANON KK

Inkjet ink

ActiveUS20090198003A1Improve in repellencyStable ejectionDuplicating/marking methodsInksSolventLong chain

An inkjet ink is provided, which is hardly wettable to the surface of nozzle plates, and thus is stably ejected and is prevented from staining images. The inkjet ink is an oil-based inkjet ink which contains at least a pigment, a pigment-dispersing agent and a solvent constituted by at least an ester solvent, a salt of a long-chain polyaminoamide and a polar acidic ester in an amount of 1% by weight or more relative to the total amount of the ink.

Owner:RISO KAGAKU CORP

Ejection liquid, ejection method, method of making droplets from liquid, cartridge and ejection device

InactiveUS20110104113A1Stably ejectedStabilizing ejectionPowder deliveryOrganic active ingredientsThermal energySURFACTANT BLEND

The present invention provides a liquid composition, as an ejection liquid used for stably ejecting liquid droplets, including at least one kind of a protein and a peptide, and a compound having a betaine skeleton by application of thermal energy to the liquid; a method of making droplets form the liquid; and an ejection method and an ejection device suitable for utilizing protein liquid droplets. By adding a compound having a betaine skeleton to an aqueous solution of at least one kind of a protein and a peptide, the liquid composition is improved in stability for ejection by application of thermal energy. Further, a surfactant may be further added to the liquid composition containing the compound having a betaine skeleton, and in this case the effect of stable ejection can be obtained.

Owner:CANON KK

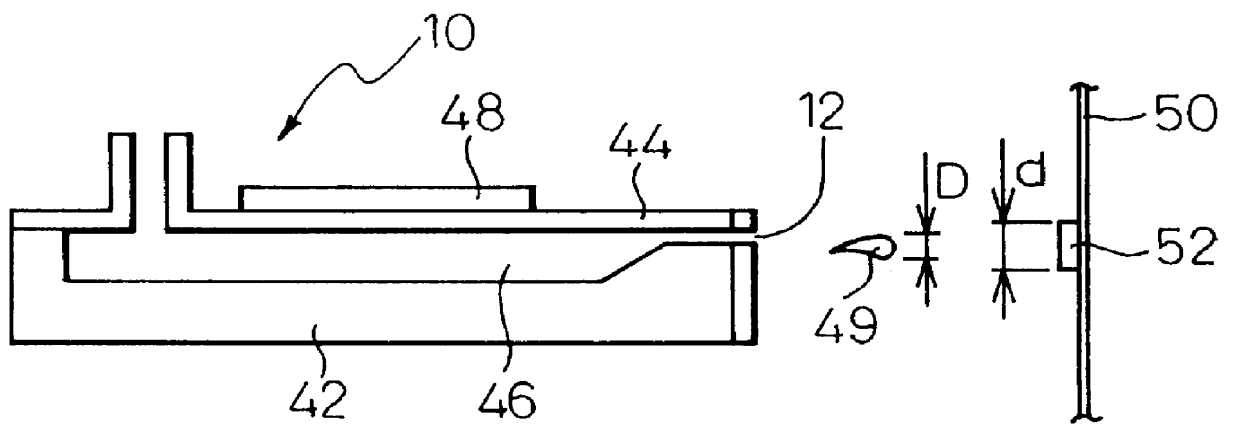

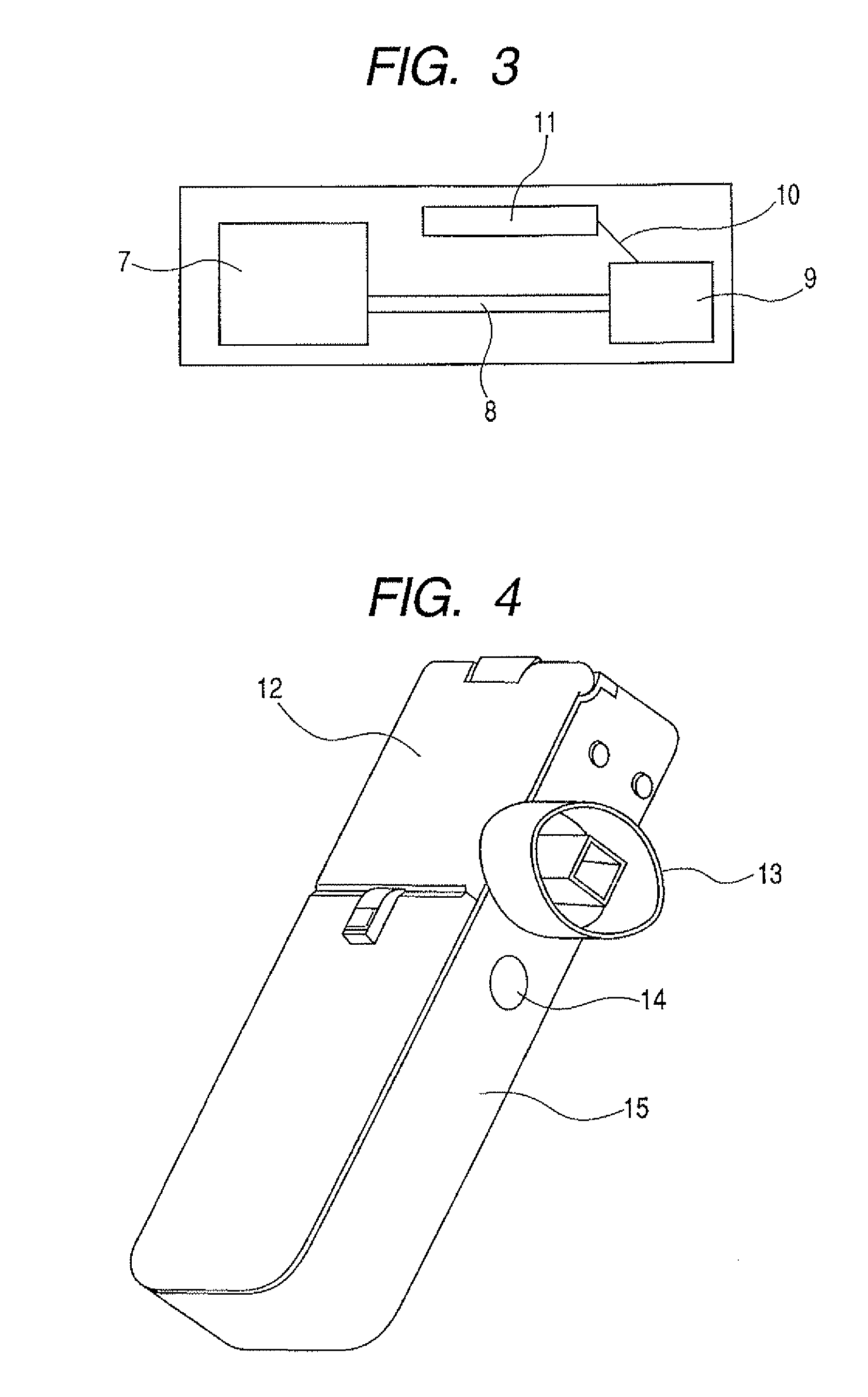

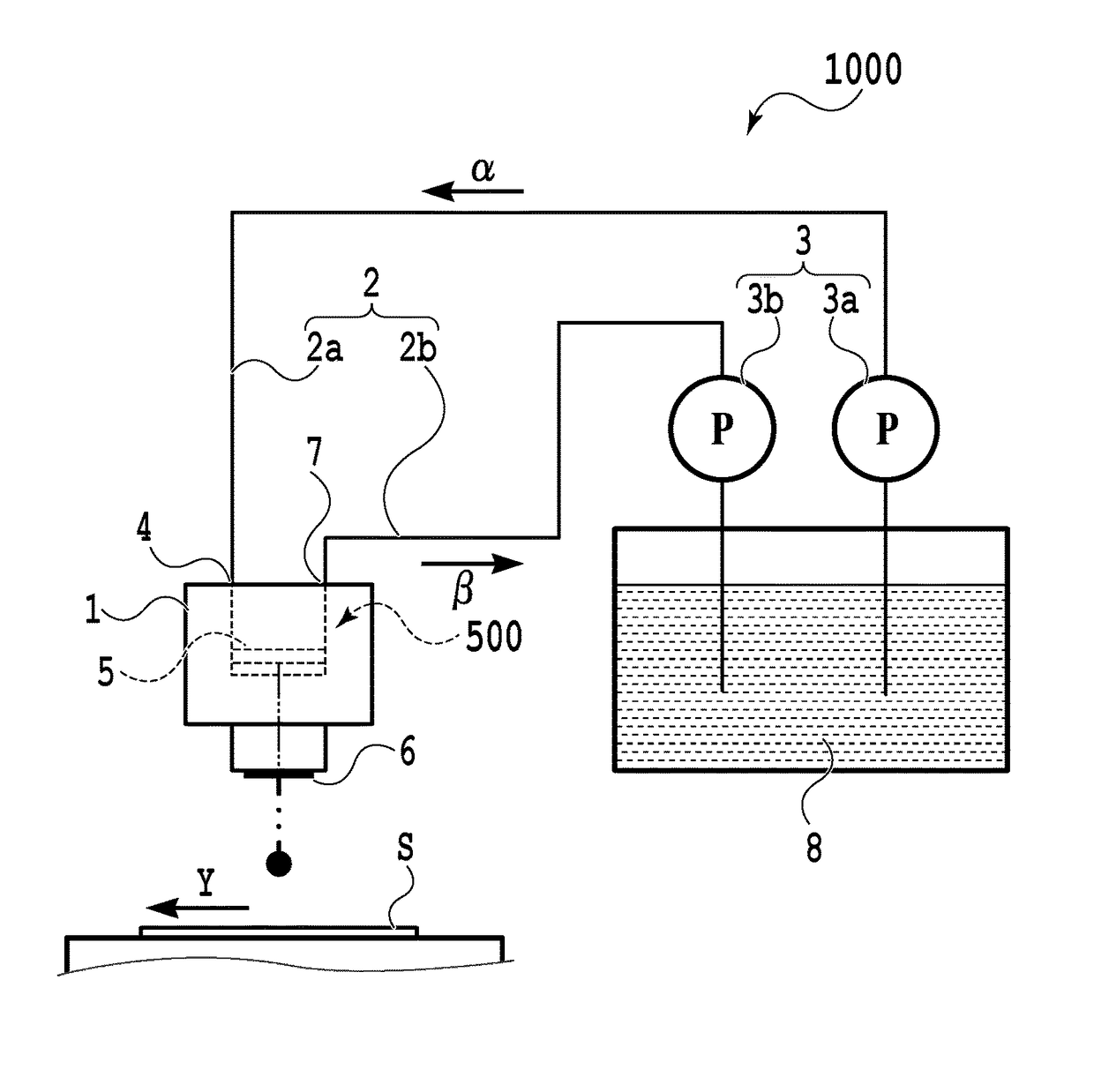

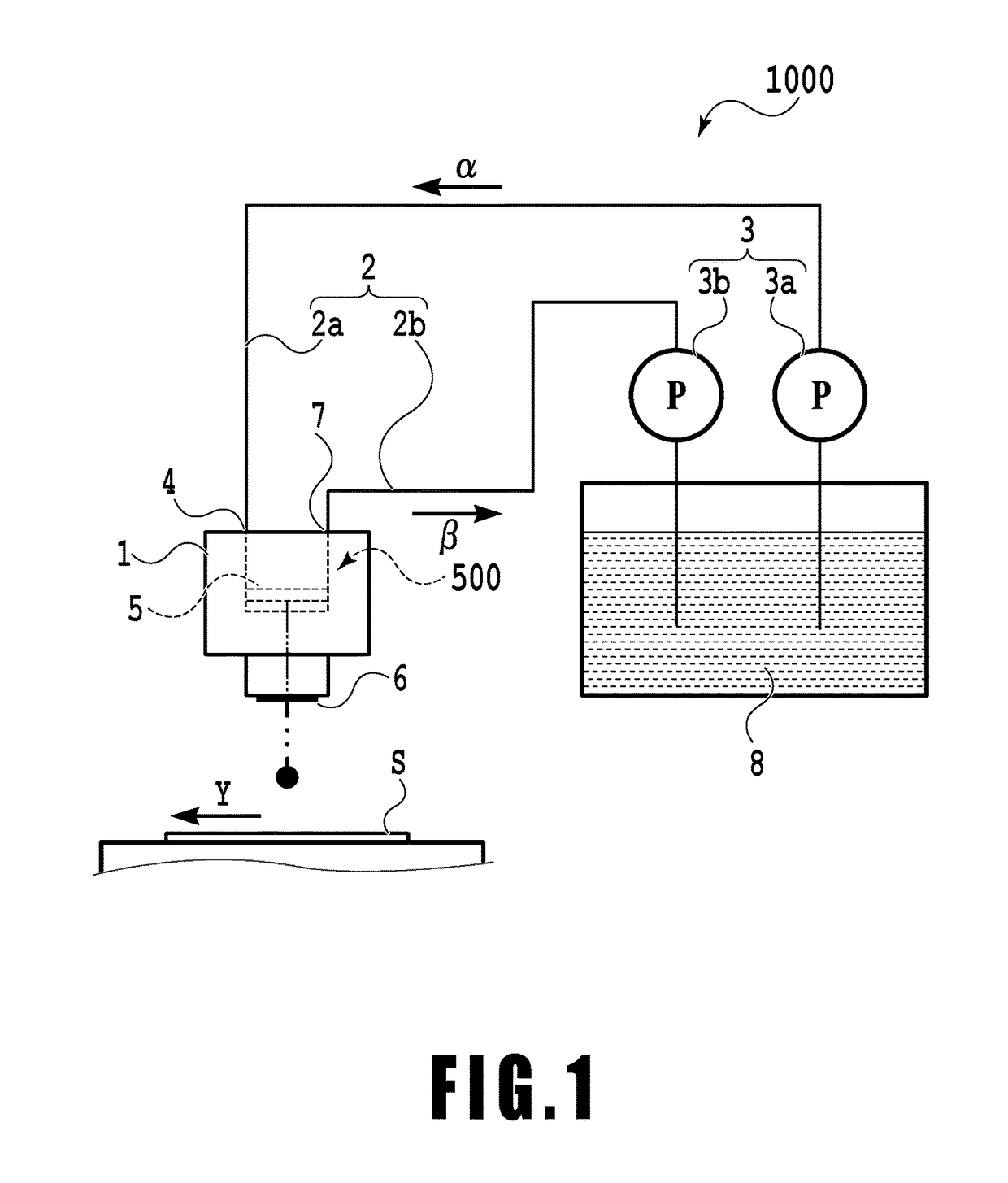

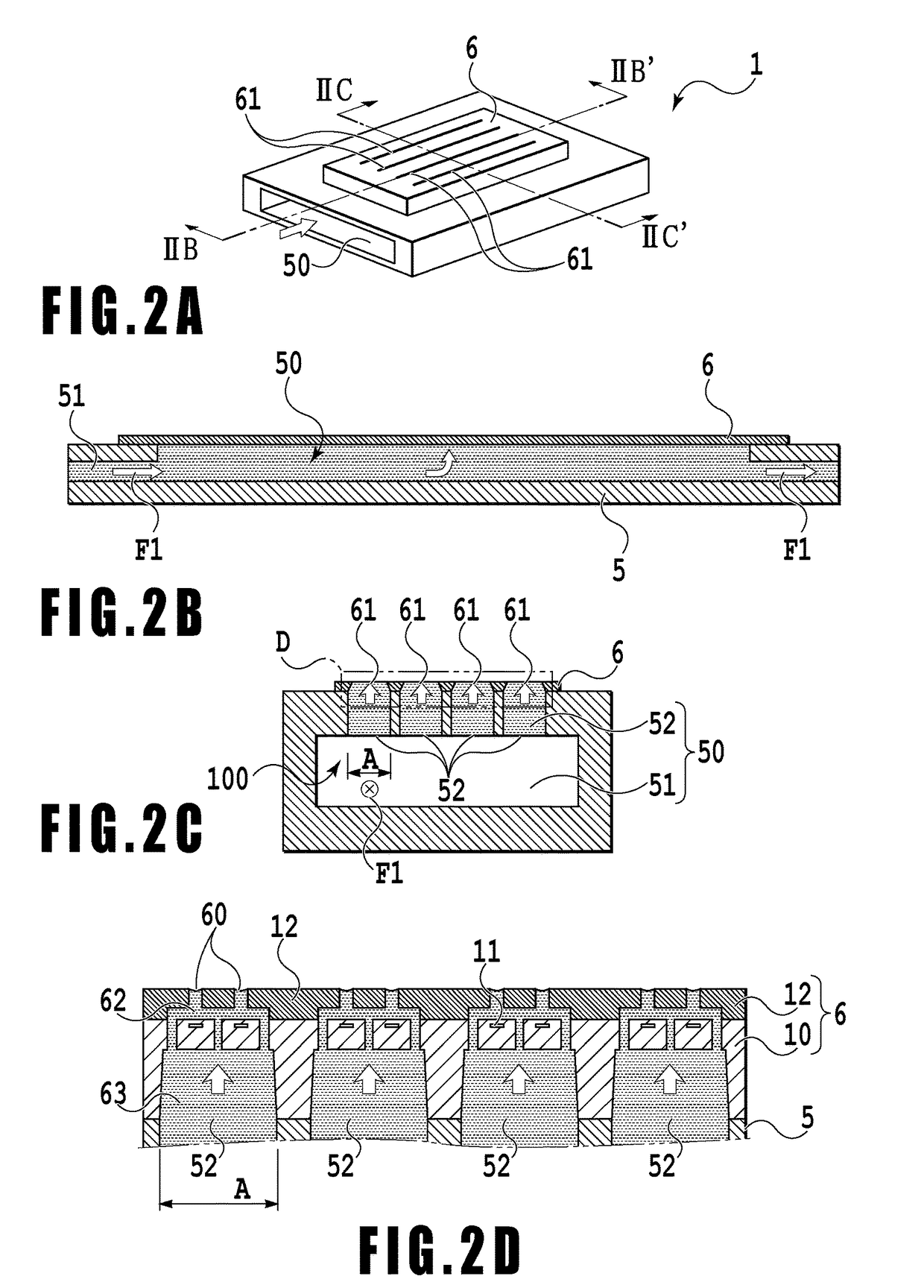

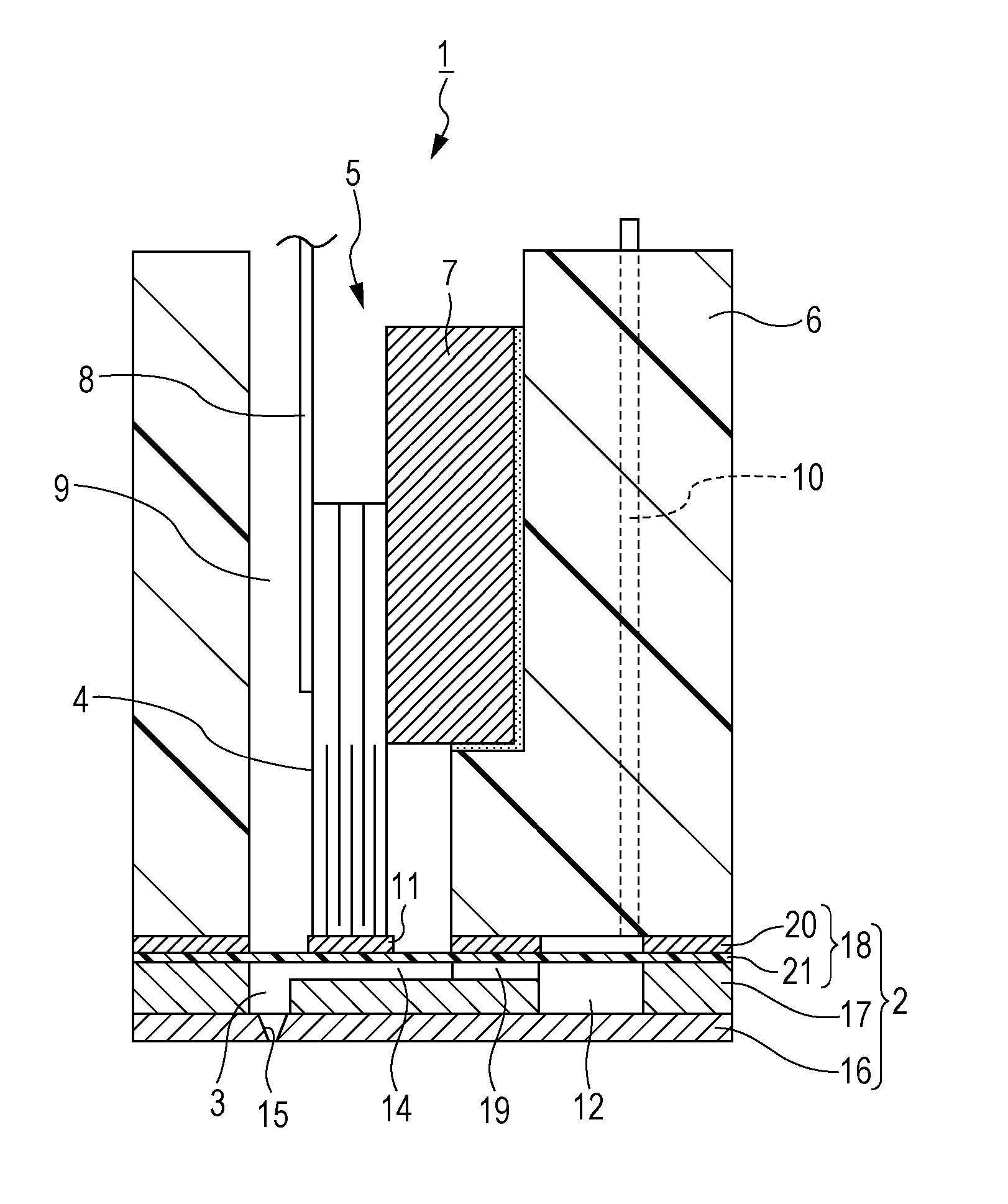

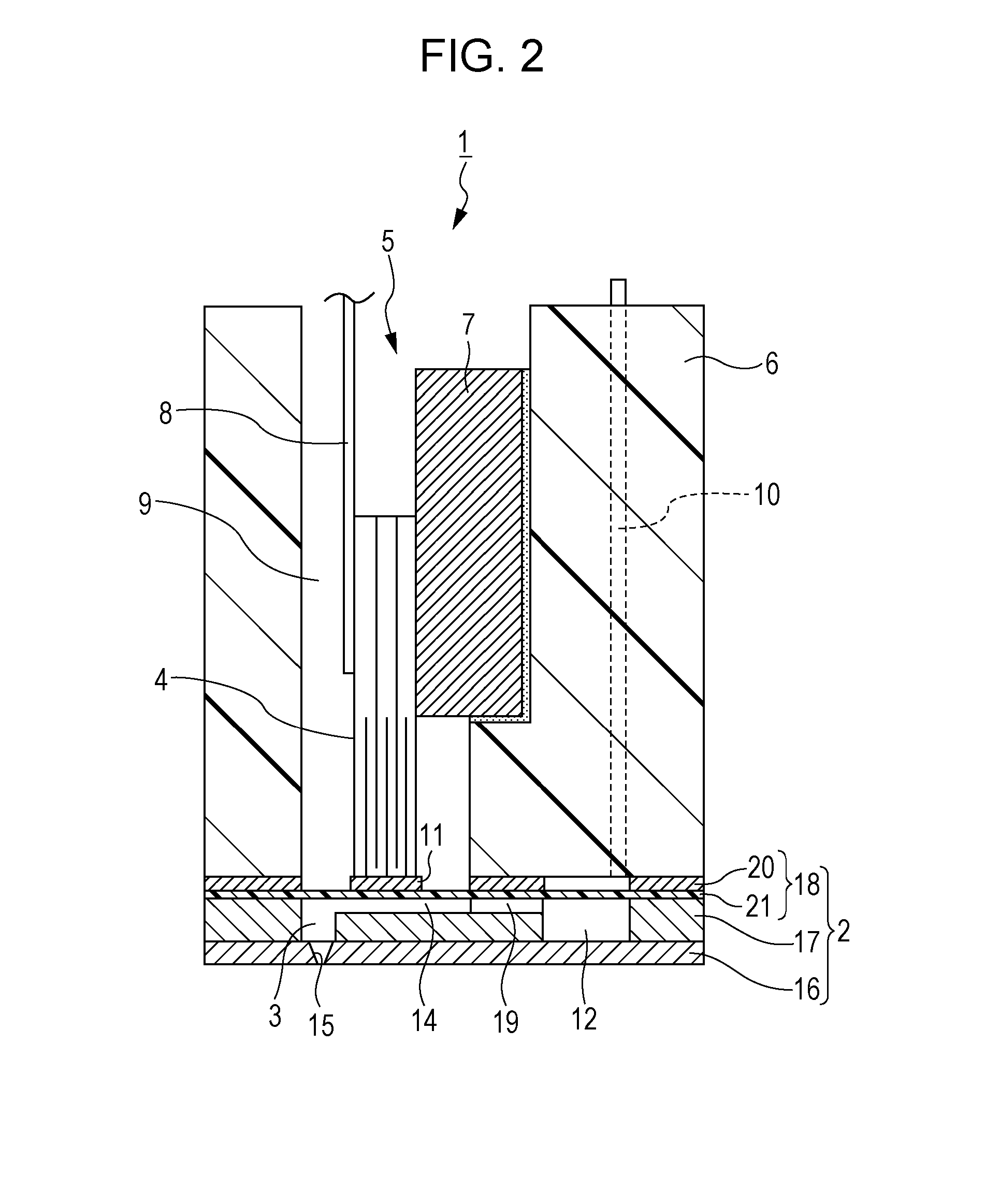

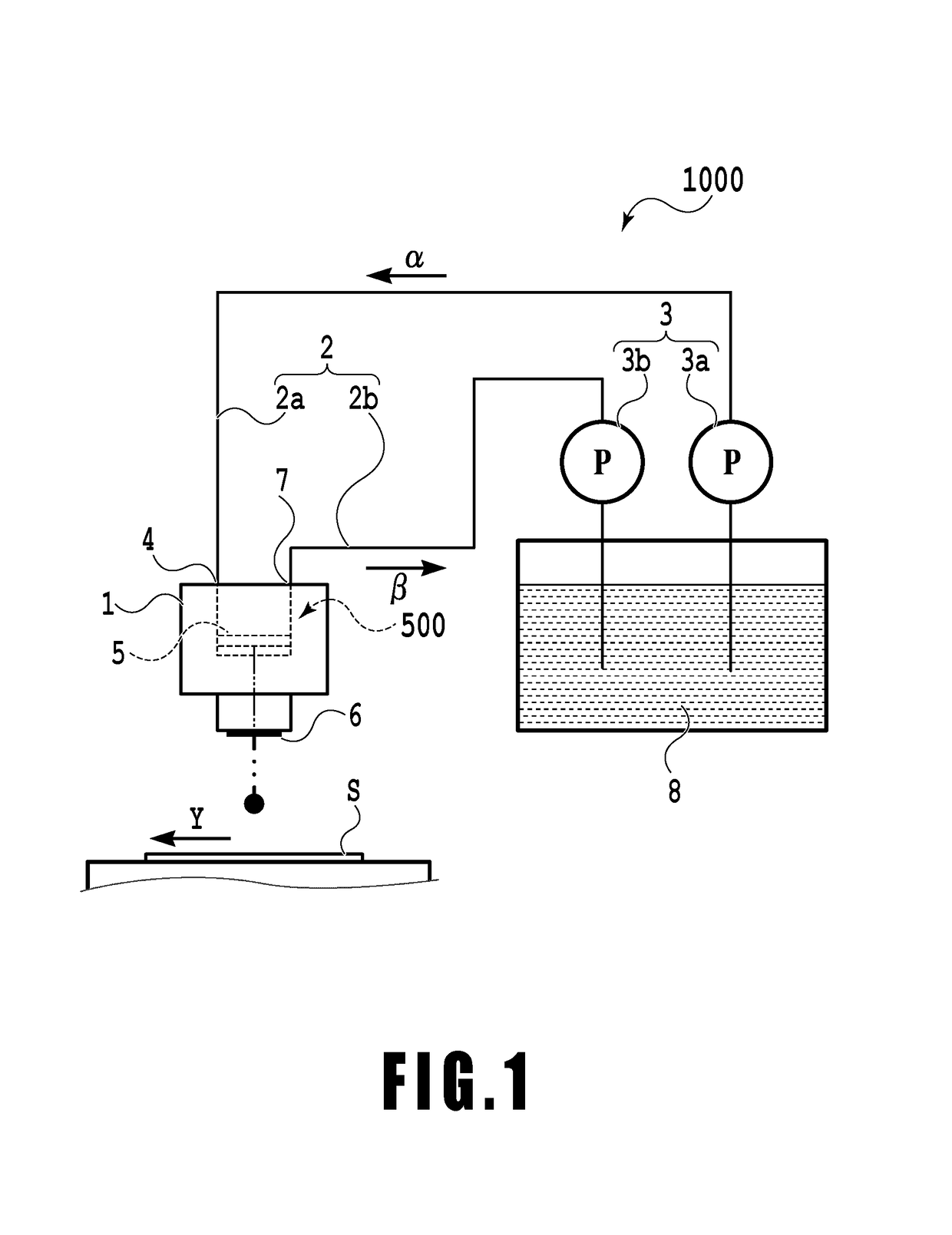

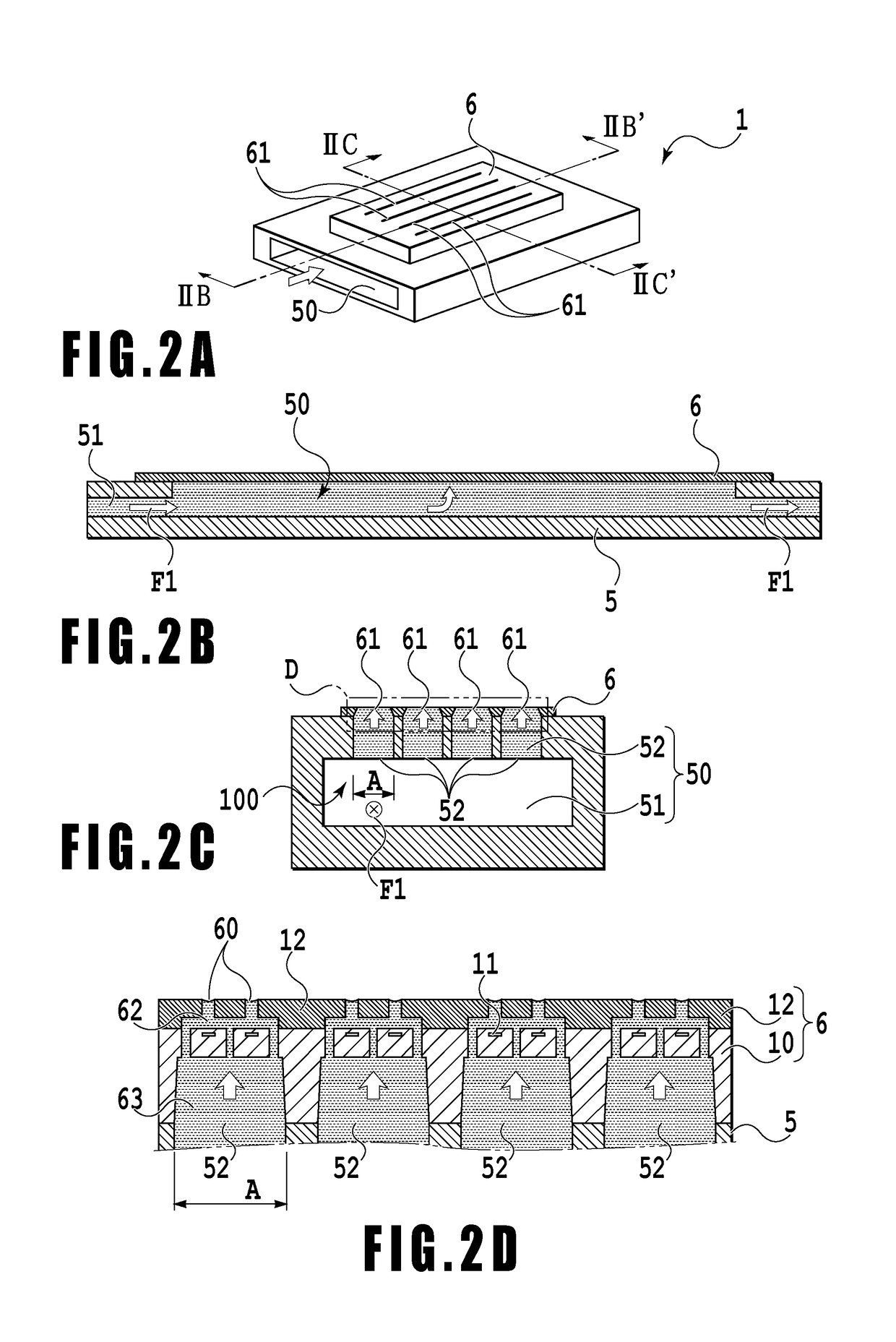

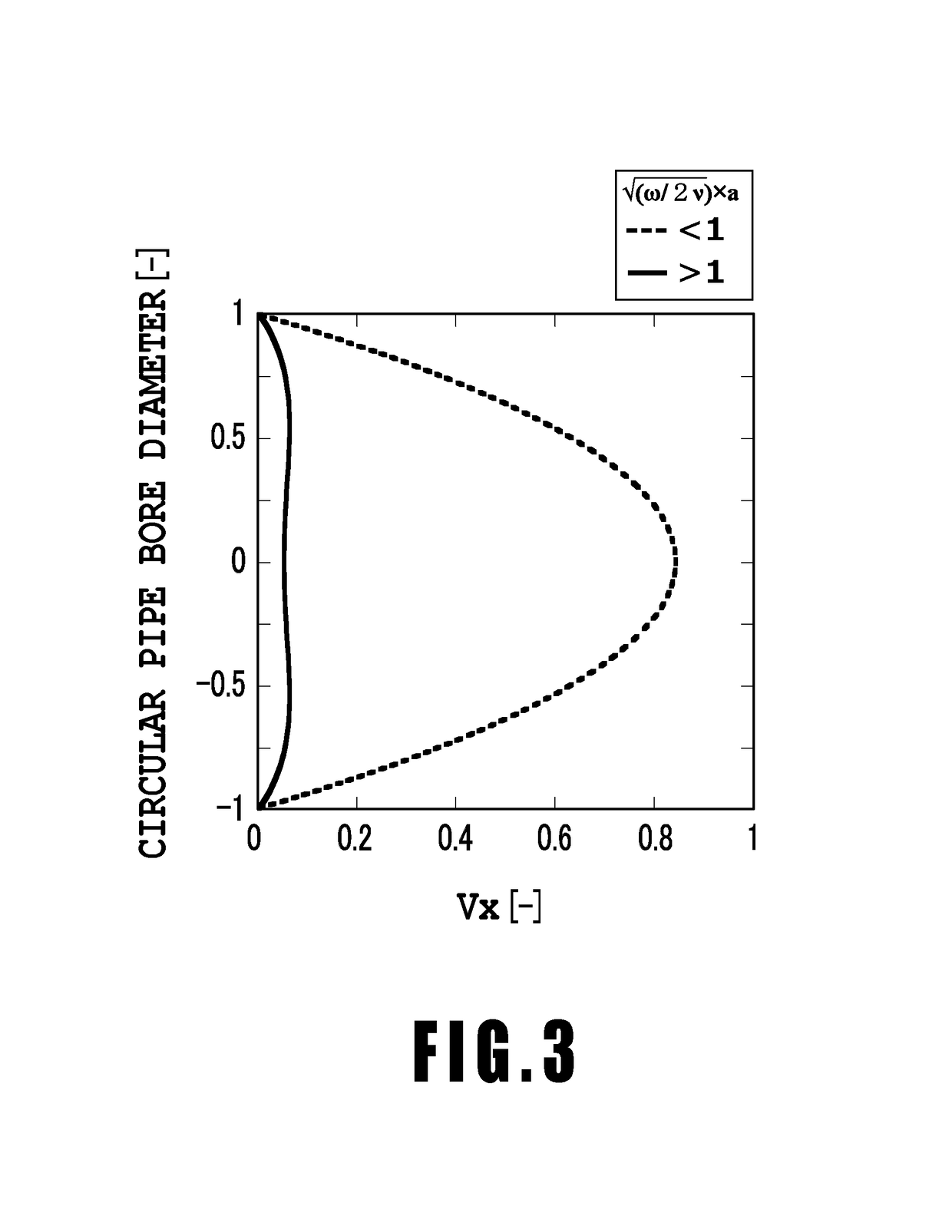

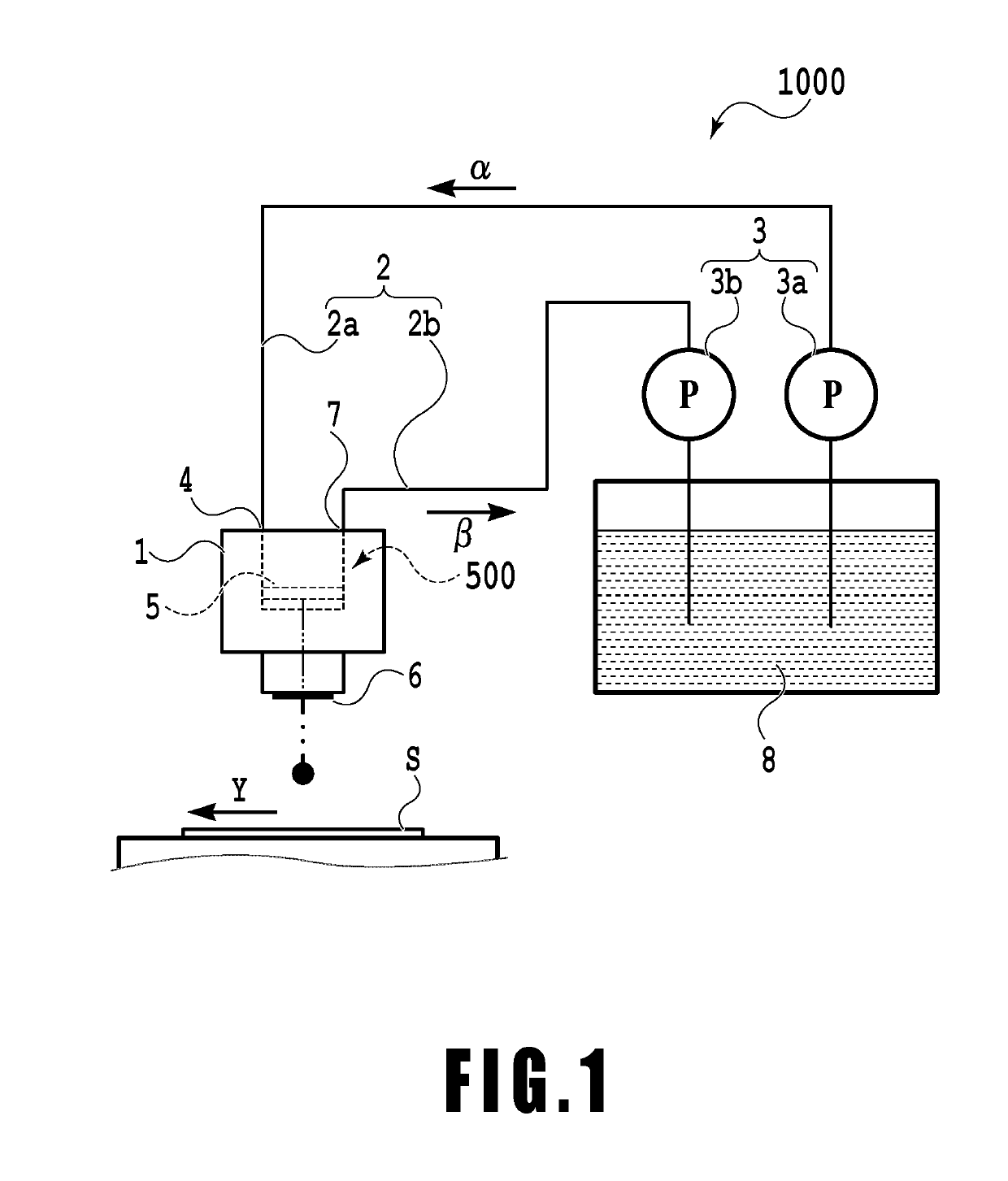

Liquid ejection apparatus and liquid ejection head

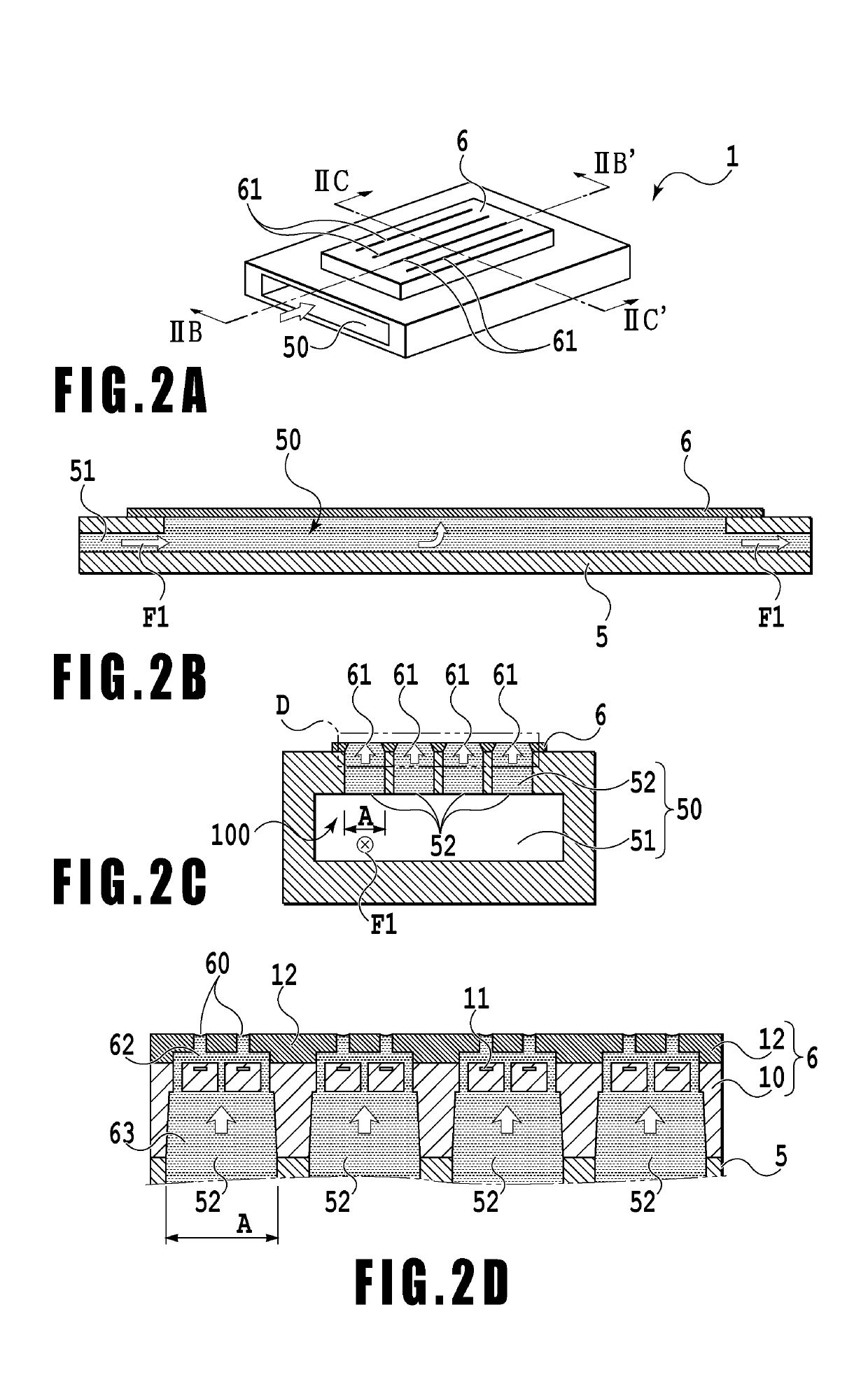

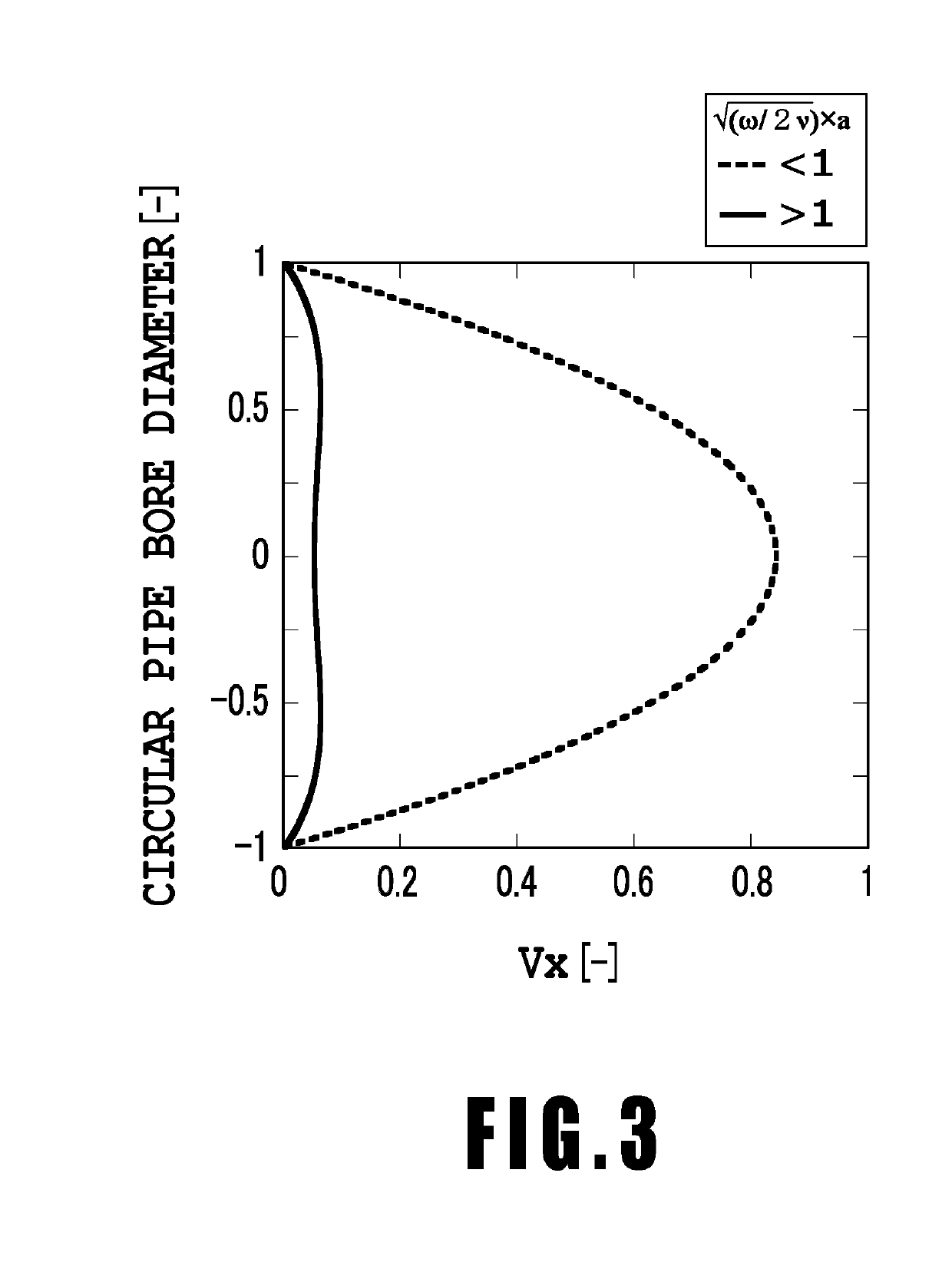

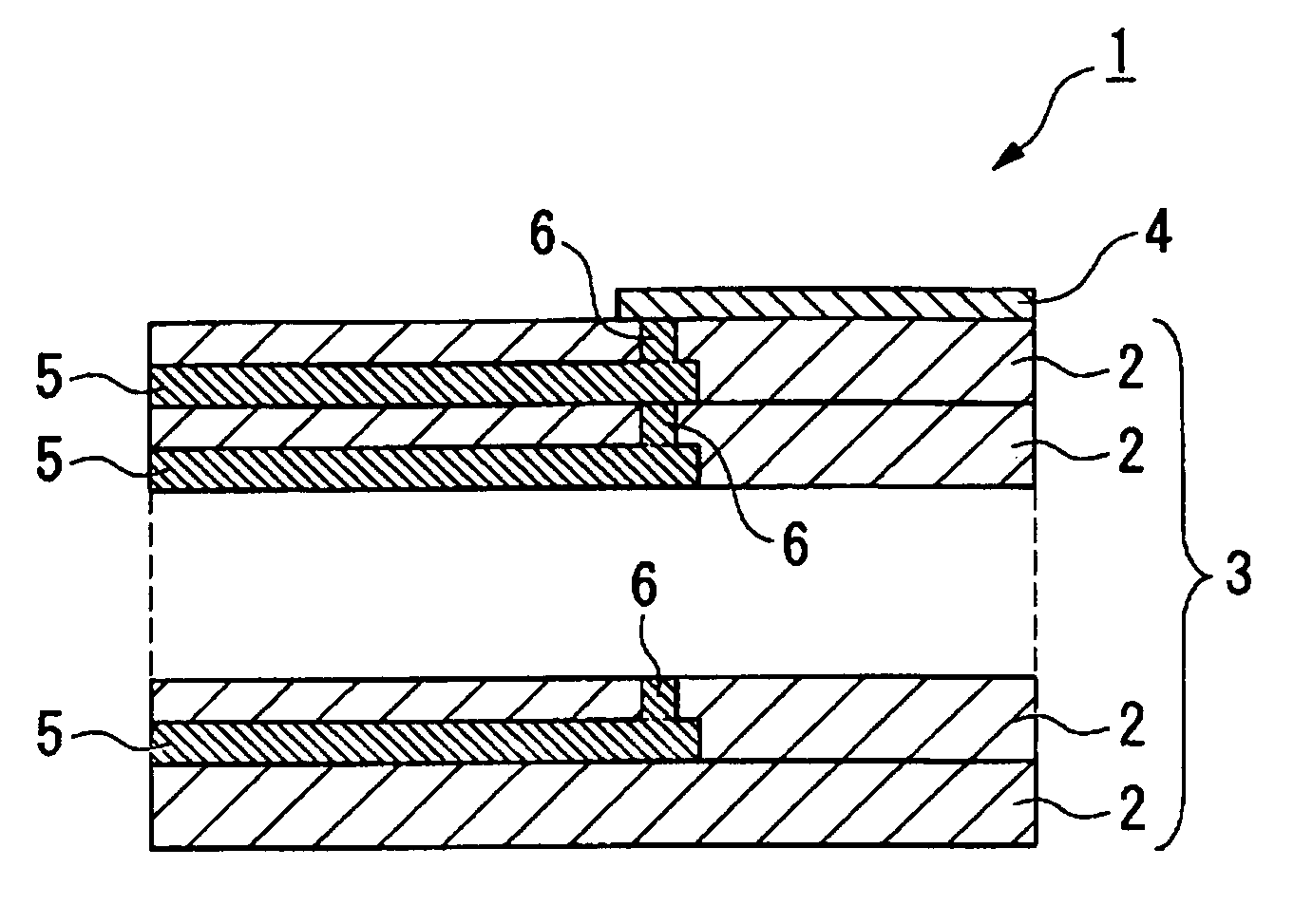

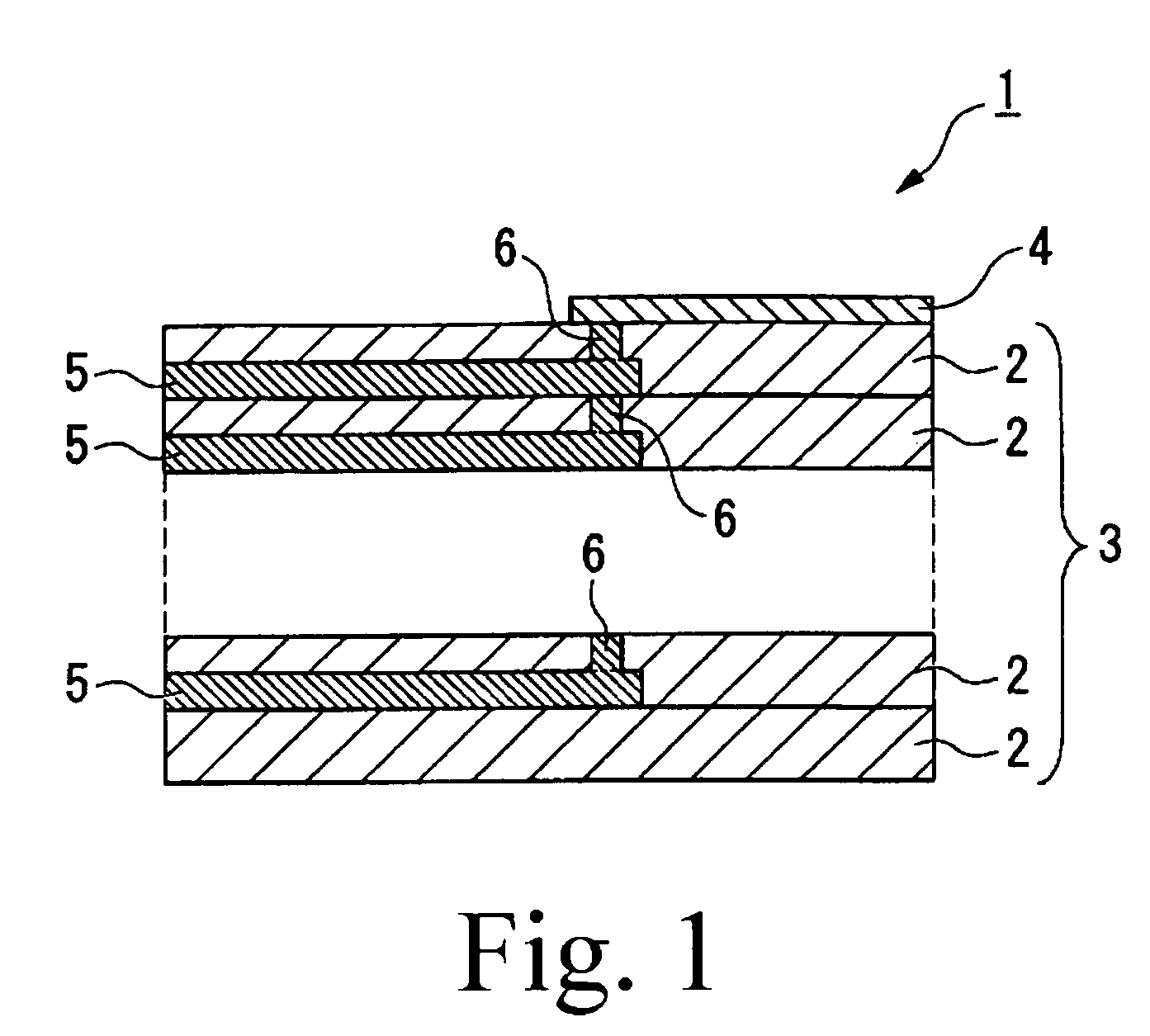

An object is to provide a liquid ejection apparatus that allows suppression of a fluctuation in a pressure of a liquid in a flow path caused by a liquid delivery unit, enabling the liquid to be stably ejected through an ejection port. The liquid ejection apparatus including a liquid ejection head having an ejection port through which a liquid is ejected, a flow path configured to communicate with the ejection port, and a liquid delivery unit configured to feed the liquid to the flow path. A relation between an angular frequency ω of the liquid delivered from the liquid delivery unit, a coefficient of kinematic viscosity ν of the liquid, and an equal diameter a of at least a part of a section of an extra-head flow path in a direction normal to a direction in which ink flows satisfies √(ω / 2ν)×a>1.

Owner:CANON KK

Ink jet printing apparatus and ink jet printing method

ActiveUS20150085004A1Relaxing negative pressureStably ejectedOther printing apparatusEngineeringControl unit

An ink jet printing apparatus includes a print head configured to be able to eject an ink fed from an ink tank that contains the ink in a closed space so as to apply a negative pressure to the ink, a communication path configured to allow a liquid chamber in the print head to communicate with an outside of the liquid chamber, an opening and closing unit configured to open and close the communication path, and a control unit configured to open the communication path in accordance with a pressure in the print head via the opening and closing unit, to bring the liquid chamber and the outside into communication with each other.

Owner:COPYER

Ink-jet ink composition for etching resist

ActiveUS8425790B2Improve adhesionStably ejectedImpression capsDecorative surface effectsPhosphoric Acid EstersResist

An ink composition for ink jet printing is provided which gives a cured object excellent in adhesion to metallic plates, resistance to etchants, and alkali removability and can be stably ejected with an ink jet apparatus. The ink jet composition for etching resists has a viscosity at 25° C. of 3-50 mPa s and includes monomers comprising: either a polymerizable phosphoric ester compound represented by general formula (I); a polyfunctional monomer having two or more ethylenic double-bond groups per molecule and having no phosphoric ester group, the content of the ethylenic double-bond groups being 4×10−3 to 8×10−3 mol / g; and a monofunctional monomer having one ethylenic double-bond group per molecule and having neither phosphoric ester group nor carboxy group.In the formula, X represents C1-3 alkylene, Y represents C2-3 alkylene, and R represents hydrogen or methyl.

Owner:NISSHIN STEEL CO LTD +1

Ink composition and recording method

ActiveUS20110229647A1High quality imagingLess affectedMixing methodsDuplicating/marking methodsEngineeringMechanical engineering

Owner:SEIKO EPSON CORP

Fluid material ejecting apparatus

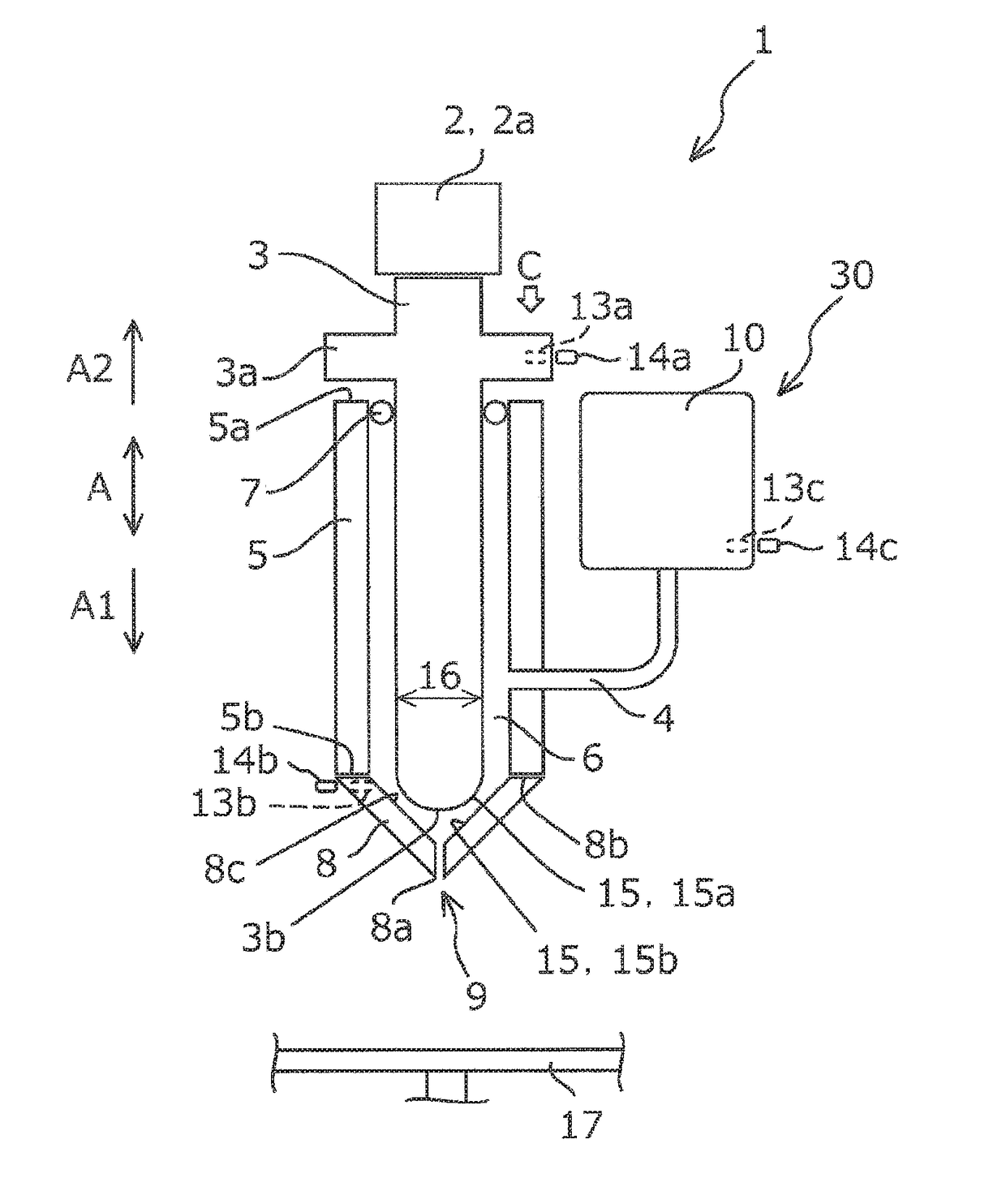

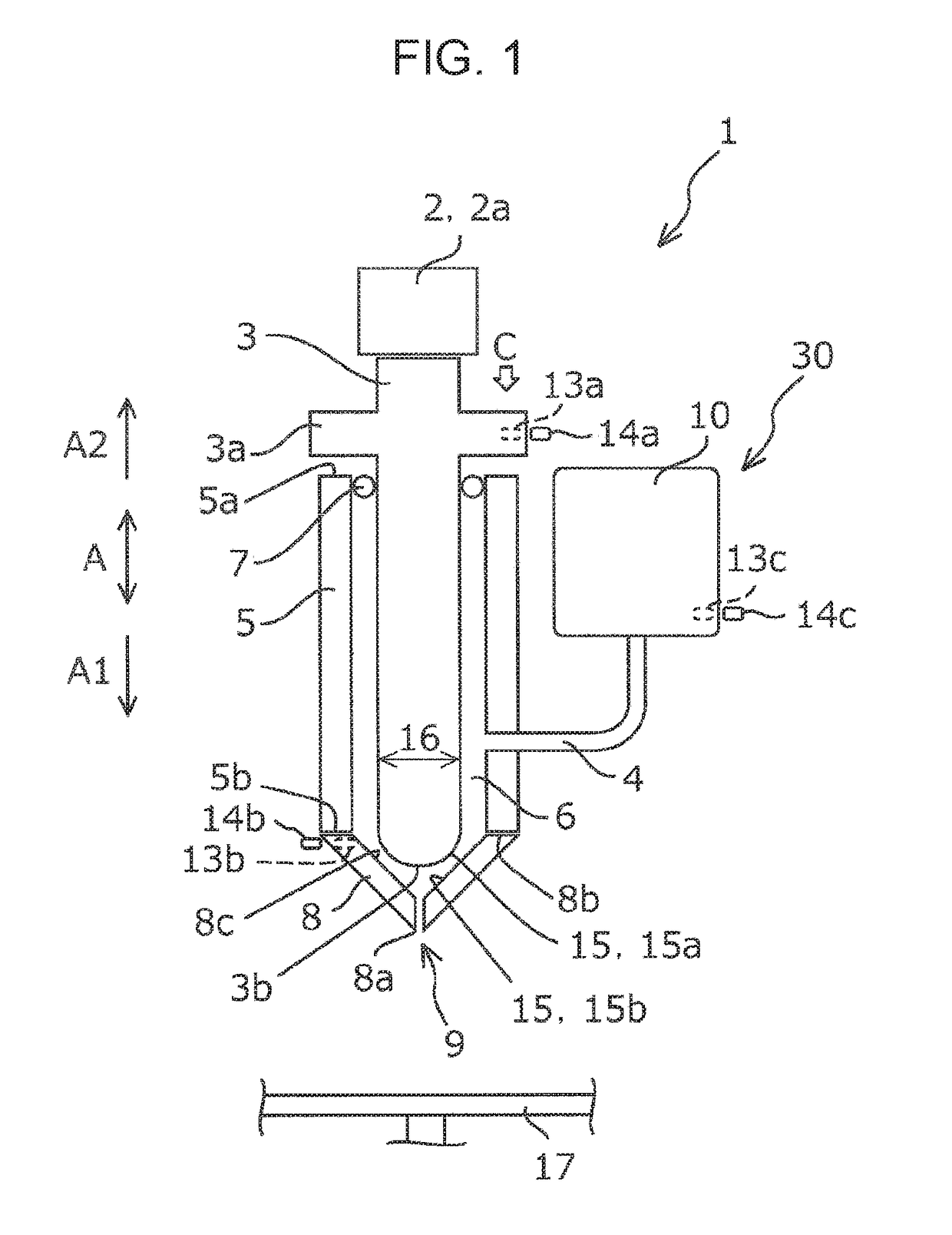

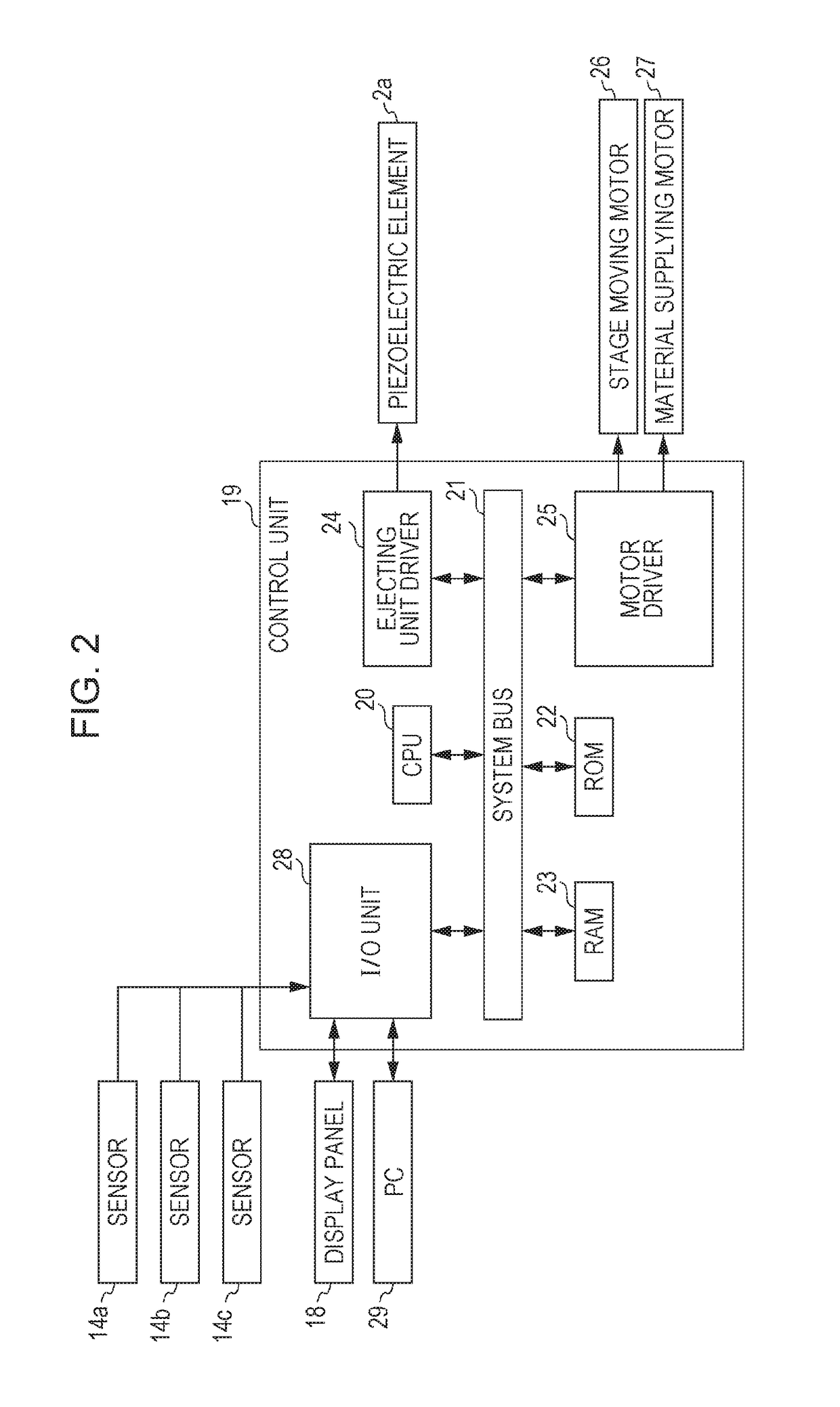

InactiveUS20180085825A1Stably ejectedHigh Vickers hardnessAdditive manufacturing apparatusCeramic shaping apparatusHardnessPiston

A fluid material ejecting apparatus includes a material chamber to which a fluid material containing at least one of metal particles and ceramic particles is supplied, a valve seat constituting a part of the material chamber and including an ejection port, a piston movable in the material chamber in directions toward and away from the ejection port, and a driver of the piston. The driver is configured to cause the piston to contact the valve seat from a position away from the valve seat and move in the direction toward the ejection port so as to slide along the valve seat, to thereby eject the fluid material through the ejection port. Sliding surfaces of the piston and the valve seat via which the piston and the valve seat contact each other have a higher Vickers hardness than the particles contained in the fluid material.

Owner:SEIKO EPSON CORP

Recording ink, ink/media set, ink cartridge, inkjet recording method and inkjet recording apparatus

ActiveUS8927623B2Avoid it happening againExcellent image density and saturation and image durability characteristicMeasurement apparatus componentsDecorative surface effectsParticulatesWater dispersible

To provide a recording ink which contains at least a water-dispersible colorant, a water-dispersible resin, a wetting agent, a surfactant and water, wherein the content of the wetting agent in the recording ink is in the range of from 20% by mass to 35% by mass, the total solid content of the water-dispersible colorant and the water-dispersible resin in the recording ink is in the range of from 12% by mass to 40% by mass, the water-dispersible resin contains fluorine resin particulates, and the ratio A:B, where A is the solid content of the water-dispersible resin in the recording ink and B is the solid content of a pigment contained in the water-dispersible colorant in the recording ink, is in the range of 0.5 to 8.

Owner:RICOH KK

Ink jet printing ink

InactiveUS20120236078A1High fastnessStably ejectedDuplicating/marking methodsInksVitrificationThermal energy

An ink jet printing ink for use in an ink jet printing method. The ink is ejected from a print head by the action of thermal energy and includes water, a self-dispersing pigment, and at least two types of resin particles. One of the at least two types of resin particles (resin particle A) and another of the at least two types of resin particles (resin particle B) have an average particle size of 80 nm or more but 220 nm or less and an acid value of 25 mgKOH / g or more but 150 mgKOH / g or less. The resin particle A has a glass transition temperature of 25 degrees Celsius or less. The resin particle B has a glass transition temperature of 25 degrees Celsius or more. A difference in glass transition temperature between the resin particle A and the resin particle B is 10 degrees Celsius or more.

Owner:CANON KK

Liquid ejecting apparatus and controlling method thereof

InactiveUS20130286068A1Stably ejectingStably ejectedOther printing apparatusEngineeringSolid content

A liquid ejecting apparatus that includes a liquid ejecting head capable of ejecting a liquid containing solid contents from a nozzle, by driving pressure generating unit for changing a capacity of a pressure chamber communicating with the nozzle; and control unit for controlling the drive of the pressure generating unit, wherein the control unit drives the pressure generating unit so that a volume of the liquid ejected from the nozzle per a unit time is equal to or less than 60 nl / s, and an initial speed of the liquid ejected from the nozzle is equal to or less than 8 m / s.

Owner:SEIKO EPSON CORP

Ink jet recording method

InactiveUS7270400B2Stable ink dropletsHigh resolutionDuplicating/marking methodsInksEngineeringExtremity Part

Owner:FUJIFILM CORP +1

Ink jet textile printing ink composition, ink set, and printing method

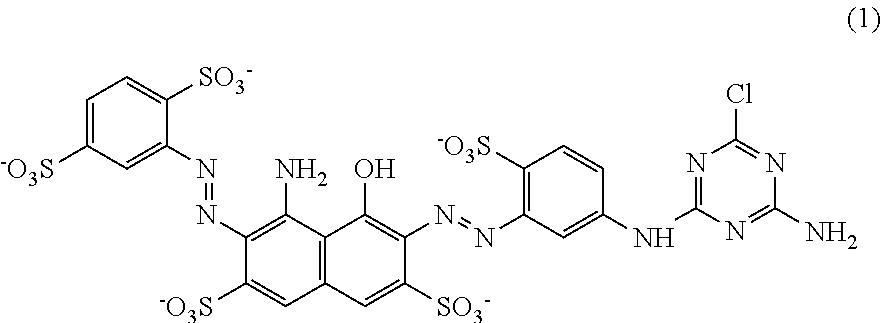

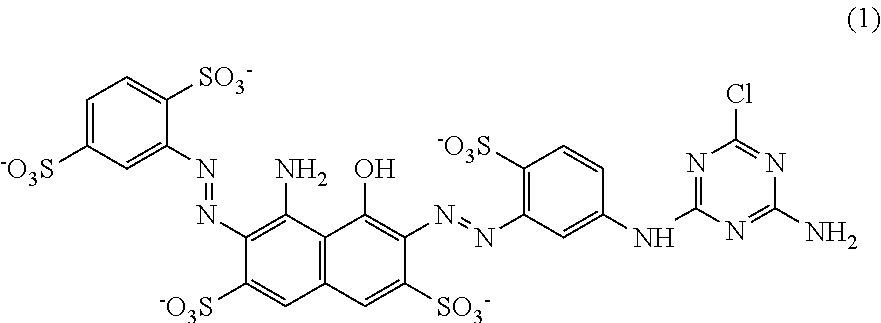

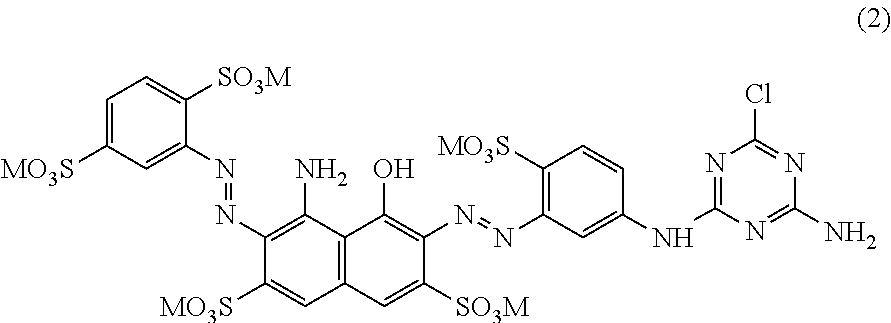

An ink jet textile printing ink composition according to the invention contains Li+, Na+, and a compound represented by the following formula (1):

Owner:SEIKO EPSON CORP

Ink composition, ink jet recording apparatus, and ink jet recording system

Owner:SEIKO EPSON CORP

Ejection liquid, ejection method, method of making droplets from liquid, cartridge and ejection device

InactiveUS8530412B2Stably ejectedStabilizing ejectionOrganic active ingredientsPowder deliveryThermal energySURFACTANT BLEND

The present invention provides a liquid composition, as an ejection liquid used for stably ejecting liquid droplets, including at least one kind of a protein and a peptide, and a compound having a betaine skeleton by application of thermal energy to the liquid; a method of making droplets form the liquid; and an ejection method and an ejection device suitable for utilizing protein liquid droplets. By adding a compound having a betaine skeleton to an aqueous solution of at least one kind of a protein and a peptide, the liquid composition is improved in stability for ejection by application of thermal energy. Further, a surfactant may be further added to the liquid composition containing the compound having a betaine skeleton, and in this case the effect of stable ejection can be obtained.

Owner:CANON KK

Liquid ejection apparatus and liquid ejection head

An object is to provide a liquid ejection apparatus that allows suppression of a fluctuation in a pressure of a liquid in a flow path caused by a liquid delivery unit, enabling the liquid to be stably ejected through an ejection port. The liquid ejection apparatus including a liquid ejection head having an ejection port through which a liquid is ejected, a flow path configured to communicate with the ejection port, and a liquid delivery unit configured to feed the liquid to the flow path. A relation between an angular frequency ω of the liquid delivered from the liquid delivery unit, a coefficient of kinematic viscosity ν of the liquid, and an equal diameter a of at least a part of a section of an extra-head flow path in a direction normal to a direction in which ink flows satisfies √(ω / 2ν)×a>1.

Owner:CANON KK

Inkjet ink

ActiveUS8137449B2Increase repulsionWithout impairing storage stability of inkDuplicating/marking methodsInksSolventPigment

An inkjet ink is provided, which is hardly wettable to the surface of nozzle plates, and thus is stably ejected and is prevented from staining images. The inkjet ink is an oil-based inkjet ink which contains at least a pigment, a pigment-dispersing agent and a solvent constituted by at least an ester solvent, a salt of a long-chain polyaminoamide and a polar acidic ester in an amount of 1% by weight or more relative to the total amount of the ink.

Owner:RISO KAGAKU CORP

Ink composition

An ink composition for ink jet recording includes: a first phase containing a pigment, a cellulose derivative, and water; and a second phase containing an organic solvent having a 50% distillation point of 280° C. or lower, in which the content of the cellulose derivative in the first phase is 3 mass % to 15 mass % with respect to the total mass of the first phase.

Owner:SEIKO EPSON CORP

Liquid ejection apparatus and liquid ejection head

An object is to provide a liquid ejection apparatus that allows suppression of a fluctuation in a pressure of a liquid in a flow path caused by a liquid delivery unit, enabling the liquid to be stably ejected through an ejection port. The liquid ejection apparatus including a liquid ejection head having an ejection port through which a liquid is ejected, a flow path configured to communicate with the ejection port, and a liquid delivery unit configured to feed the liquid to the flow path. A relation between an angular frequency ω of the liquid delivered from the liquid delivery unit, a coefficient of kinematic viscosity ν of the liquid, and an equal diameter a of at least a part of a section of an extra-head flow path in a direction normal to a direction in which ink flows satisfies √ / (ω / 2ν)×a>1.

Owner:CANON KK

Conductive pattern formation ink, conductive pattern and wiring substrate

InactiveUS8173050B2Improve reliabilityStably ejectedNanotechConductive layers on insulating-supportsWater basedGas analysis

A conductive pattern formation ink which can be stably ejected in the form of liquid droplets and form a conductive pattern having high reliability, a conductive pattern having high reliability, and a wiring substrate provided with the conductive pattern and having high reliability are provided. The conductive pattern formation ink is used for forming a conductive pattern by ejecting the ink in the form of liquid droplets on a surface of a ceramic molded body using a liquid droplet ejecting method, the ceramic molded body being made of a material containing ceramic particles and a binder. The ink contains a water-based dispersion medium, and metal particles dispersed in the water-based dispersion medium, wherein the water-based dispersion medium contains oxygen molecules and nitrogen molecules, and wherein when the water-based dispersion medium is analyzed using a gas chromatography method, a total amount of the oxygen and nitrogen molecules contained in the water-based dispersion medium is 12 ppm or less.

Owner:SEIKO EPSON CORP

Textile printing method

ActiveUS10337142B2High fastnessImprove the level ofTypewritersDyeing processTextile printerEngineering

A textile printing method includes heating a cloth, and applying an ink composition onto the heated cloth by ejecting the ink composition from an ink jet head. The ink composition contains resin fine particles and has a viscosity of 4.5 mPa·s or less at 40° C. and a surface tension of 28 mN / m or less at 40° C.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com