Preparation method of polyurethane and SBS (Styrene Butadiene Styrene) composite modified asphalt

A technology of compound modified asphalt and polyurethane, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of easy segregation, poor high temperature storage stability, and large amount of modifiers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: the preparation method of the polyurethane of the present embodiment and SBS composite modified asphalt, carry out according to the following steps:

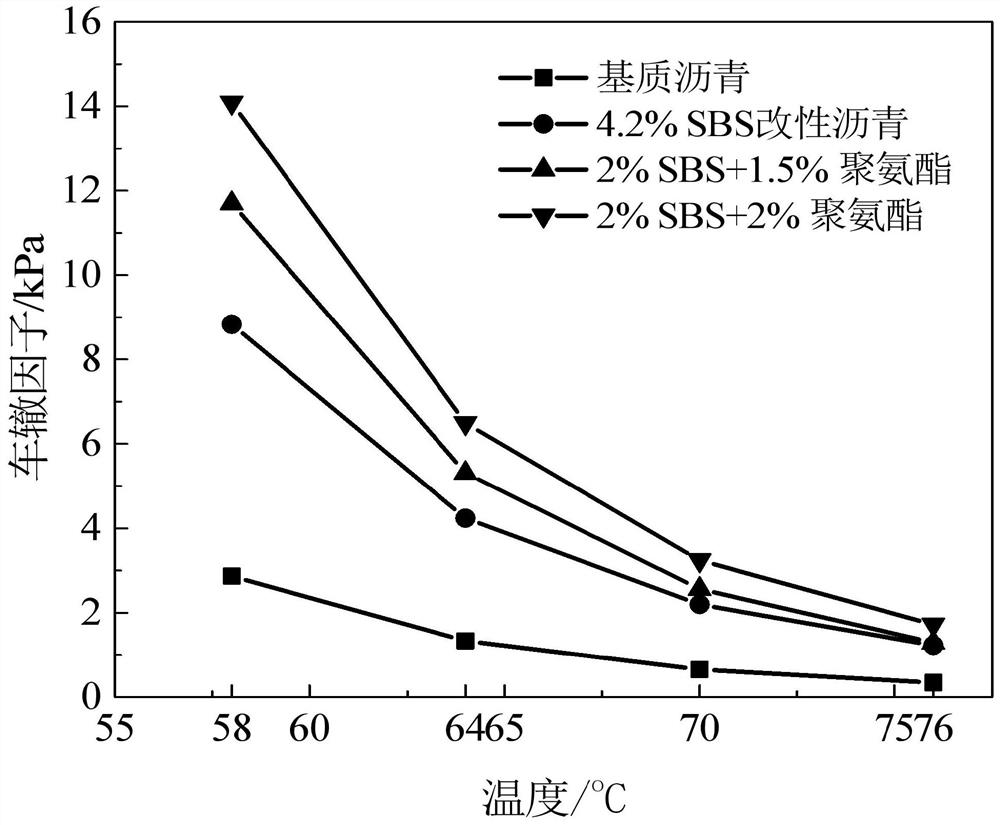

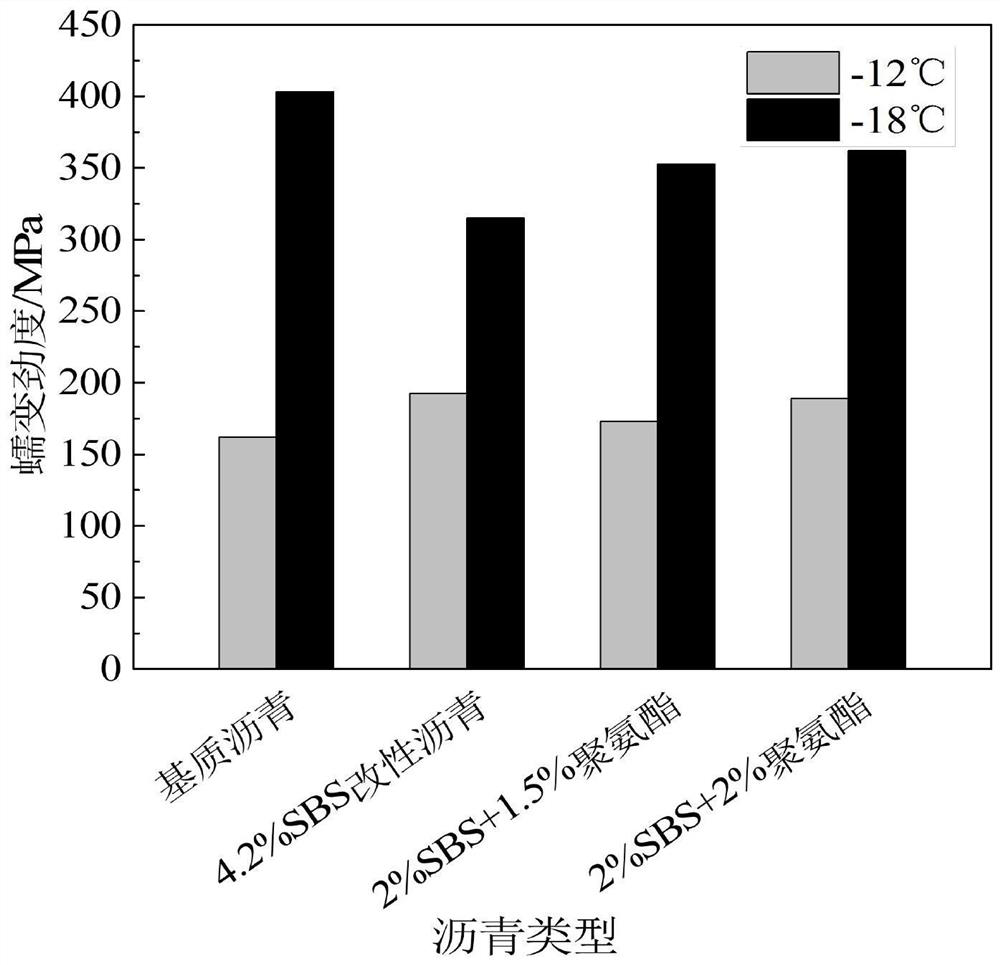

[0023] 1. Weigh 900g base petroleum asphalt, 18g styrene-butadiene-styrene block copolymer (SBS), 18g polyurethane reactive additive; wherein styrene-butadiene-styrene block copolymer is linear SBS, produced by Huizhou Li Changrong Rubber Co., Ltd., the trade name is SBS 3501; the polyurethane reactive additive is liquid, and has isocyanate as the active functional group, produced by BASF;

[0024] 2. Heat the base petroleum asphalt to 170°C, add styrene-butadiene-styrene block copolymer (SBS) to the base petroleum asphalt, and stir for 15min at a speed of 1500rpm; then increase the speed to 4000rpm, continue stirring for 1h to obtain SBS modified asphalt matrix;

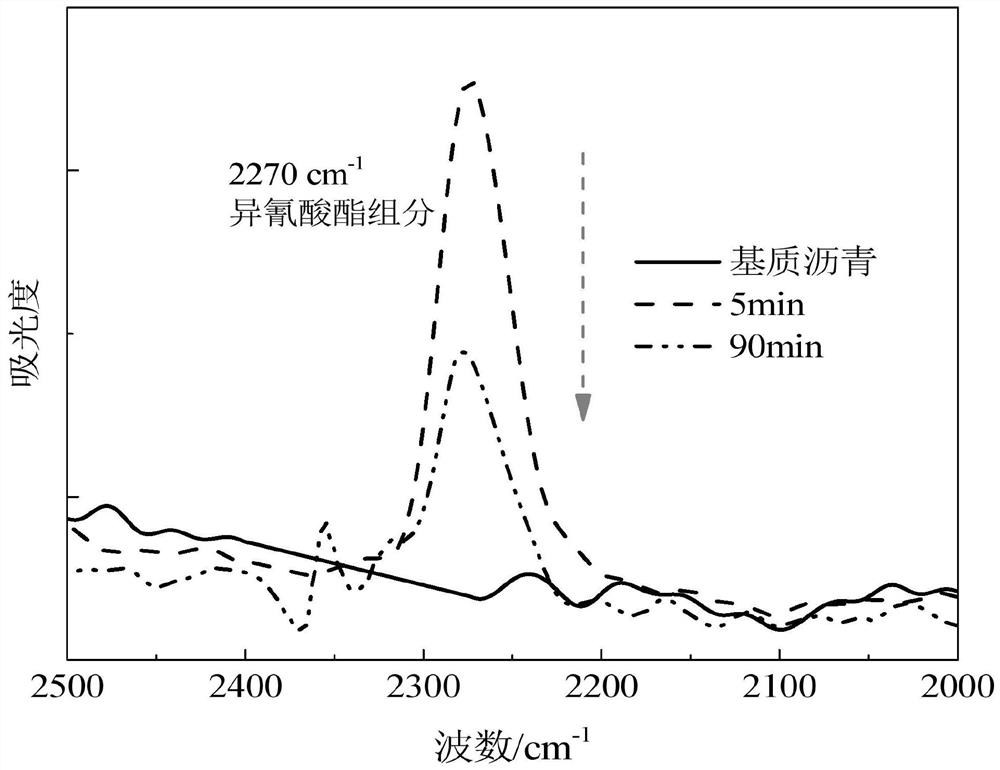

[0025] 3. Reduce the temperature of the SBS modified asphalt matrix to 145°C, add polyurethane reactive additives, and stir at a speed of 3000rp...

Embodiment 2

[0026] Embodiment 2: the preparation method of polyurethane and SBS composite modified asphalt of this embodiment is different from embodiment 1 in step 1, weighs 900g matrix petroleum asphalt, 18g styrene-butadiene-styrene block copolymer (SBS), 13.5g polyurethane reactive additive; Others are identical with embodiment 1, obtain polyurethane and SBS composite modified asphalt, and mark as 2%SBS+1.5% polyurethane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com