Positive type radiation-sensitive composition, cured film, interlayer insulating film, method for forming method interlayer insulating film, display element and siloxane polymer

一种层间绝缘膜、显示元件的技术,应用在电气元件、非线性光学、电固体器件等方向,能够解决低介电性、没有记载硅烷化合物使用量等问题,达到耐干蚀性优良、表面硬度改善、耐热性改善的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

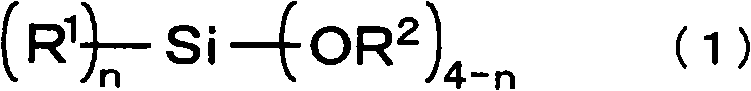

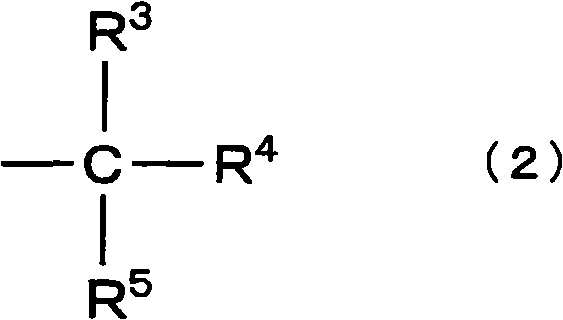

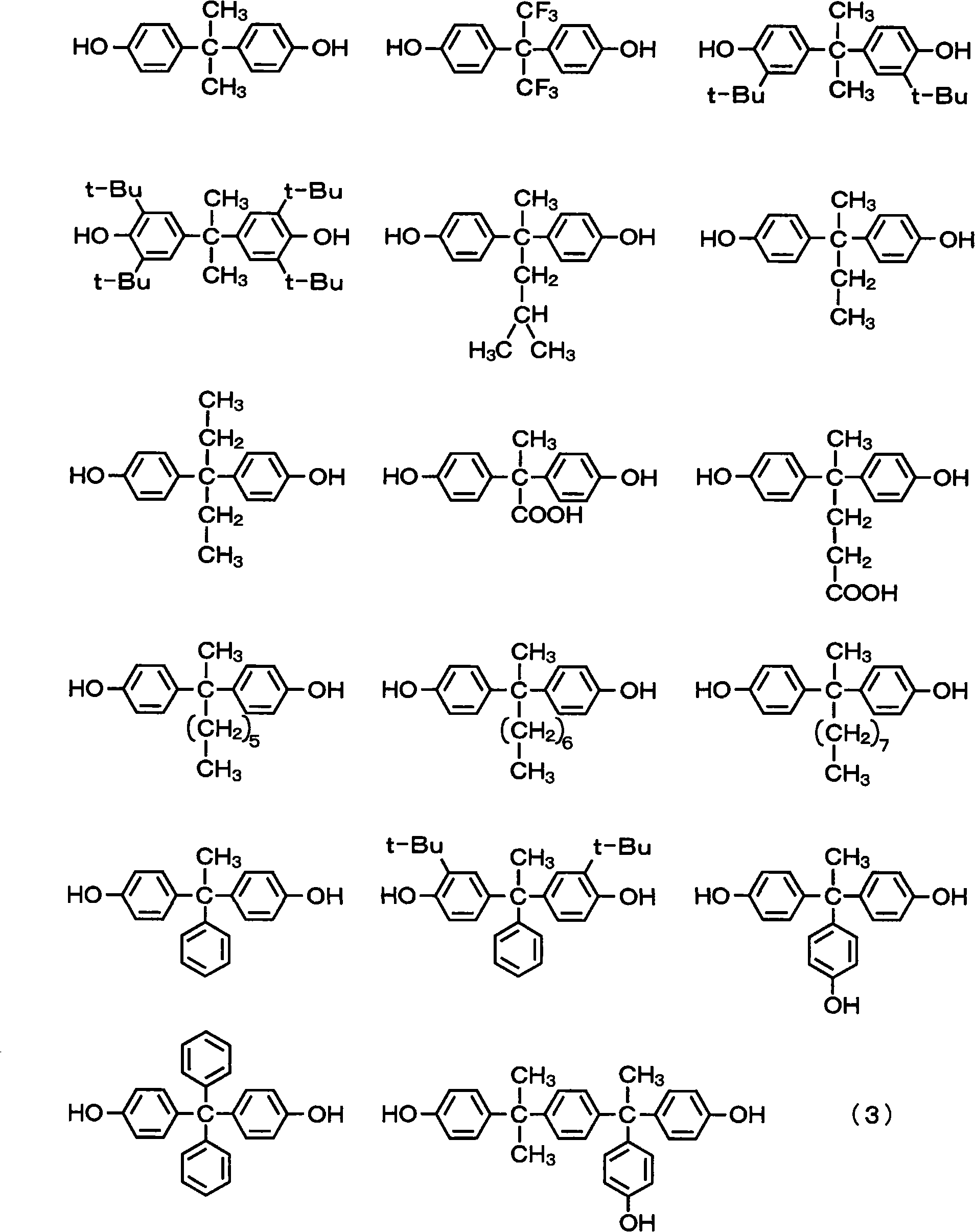

Method used

Image

Examples

Synthetic example 1

[0166] In a vessel with a stirrer, 161.4 g propylene glycol monomethyl ether was added, followed by 128.9 g phenyltrimethoxysilane (0.65 moles), 72.9 g tetraethoxysilane (0.35 moles) and 0.8 g triisopropoxy base aluminum, the solution temperature was heated to 60 °C. After the solution temperature reached 60°C, 54g of ion-exchanged water was added, heated to 75°C, and kept for 3 hours. Next, 159 g of methyl orthoformate was added as a dehydrating agent, and stirred for 1 hour. Furthermore, the temperature of the solution was controlled at 40° C., and the temperature was maintained for evaporation to remove ion-exchanged water and methanol produced by hydrolysis and condensation. The hydrolysis-condensation product (A-1) was obtained as above. The solid content concentration of the hydrolytic condensate (A-1) was 40.3% by mass, the number average molecular weight (Mn) of the obtained hydrolytic condensate was 1500, and the molecular weight distribution (Mw / Mn) was 2. Further...

Synthetic example 2

[0168] In a container with a stirrer, 139.4 g of diacetone alcohol was added, followed by 128.9 g (0.65 mol) of phenyltrimethoxysilane and 47.7 g (0.35 mol) of methyltrimethoxysilane, and stirred at room temperature. Next, an oxalic acid aqueous solution in which 0.18 g of oxalic acid was dissolved in 54 g of ion-exchanged water was added dropwise, and the temperature of the solution was heated to 75°C. After the temperature of the solution reached 75°C, it was kept for 3 hours. Next, 159 g of methyl orthoformate was added as a dehydrating agent, and stirred for 1 hour. Furthermore, the temperature of the solution is controlled at 40° C., and the temperature is maintained for evaporation to remove ion-exchanged water and methanol produced by hydrolysis and condensation. The hydrolysis condensate (A-2) was obtained as above. The solid content concentration of the hydrolytic condensate (A-2) was 40.5% by mass, the number average molecular weight (Mn) of the obtained hydrolytic...

Synthetic example 3

[0170] In a container with a stirrer, 139.4 g of diacetone alcohol was added, followed by 128.9 g (0.65 mol) of phenyltrimethoxysilane and 47.7 g (0.35 mol) of methyltrimethoxysilane, and stirred at room temperature. Next, a phosphoric acid aqueous solution in which 0.18 g of phosphoric acid was dissolved in 54 g of ion-exchanged water was added dropwise, and the temperature of the solution was heated to 75°C. After the temperature of the solution reached 75°C, it was kept for 3 hours. Next, 159 g of methyl orthoformate was added as a dehydrating agent, and stirred for 1 hour. Furthermore, the temperature of the solution was controlled at 40° C., and the solution was evaporated while maintaining the temperature to remove ion-exchanged water and methanol produced by hydrolytic condensation. The hydrolysis-condensation product (A-3) was obtained as above. The solid content concentration of the hydrolytic condensate (A-3) was 40.5% by mass, the number average molecular weight (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| packed density | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com